FLEXPRIN APOLLO-6 User manual

APOLLO-6

USER MANUAL

Revision D Issued on: May 2020

User Manual APOLLO-6

2

Summary

1OBJECTIVE .....................................................................................................................................3

2INTRODUCTIONS ...........................................................................................................................3

3SECURITY REQUIREMENTS.............................................................................................................5

4TECHNICAL SPECIFICATION ............................................................................................................6

4.1 SPECIFICATIONS SUMMARY.............................................................................................. 6

4.2 PROJECT......................................................................................................................... 7

4.3 CERTIFICATIONS AND DOCUMENTATION............................................................................7

5BEFORE OPERATION........................................................................................................................8

5.1 VISIBILITY AND SEA CONDITIONS......................................................................................8

5.2 MAINTENANCE CONDITIONS .............................................................................................8

6OPERATION WITH PASSENGERS ....................................................................................................8

6.1 CRANE OPERATOR...........................................................................................................8

6.2 BOARDING ......................................................................................................................8

6.3 LANDING .........................................................................................................................9

6.4 COMMUNICATION.............................................................................................................9

7OPERATION WITH STRETCHER.......................................................................................................9

7.1 PREPARATION FOR TRANSPORT WITH STRETCHER............................................................. 9

7.2 CRANE OPERATOR.........................................................................................................10

7.2 LANDING .......................................................................................................................11

7.3 COMMUNICATION...........................................................................................................11

8INSPECTION AND MAINTENANCE ................................................................................................11

8.1 INSPECTION BEFORE EACH OPERATION...........................................................................11

8.2 DETAILED INSPECTION EVERY 3MONTHS ........................................................................11

8.3 ANNUAL INSPECTION AND PERIODIC REVIEW. ..................................................................12

9SPARE PARTS ................................................................................................................13

User Manual APOLLO-6

3

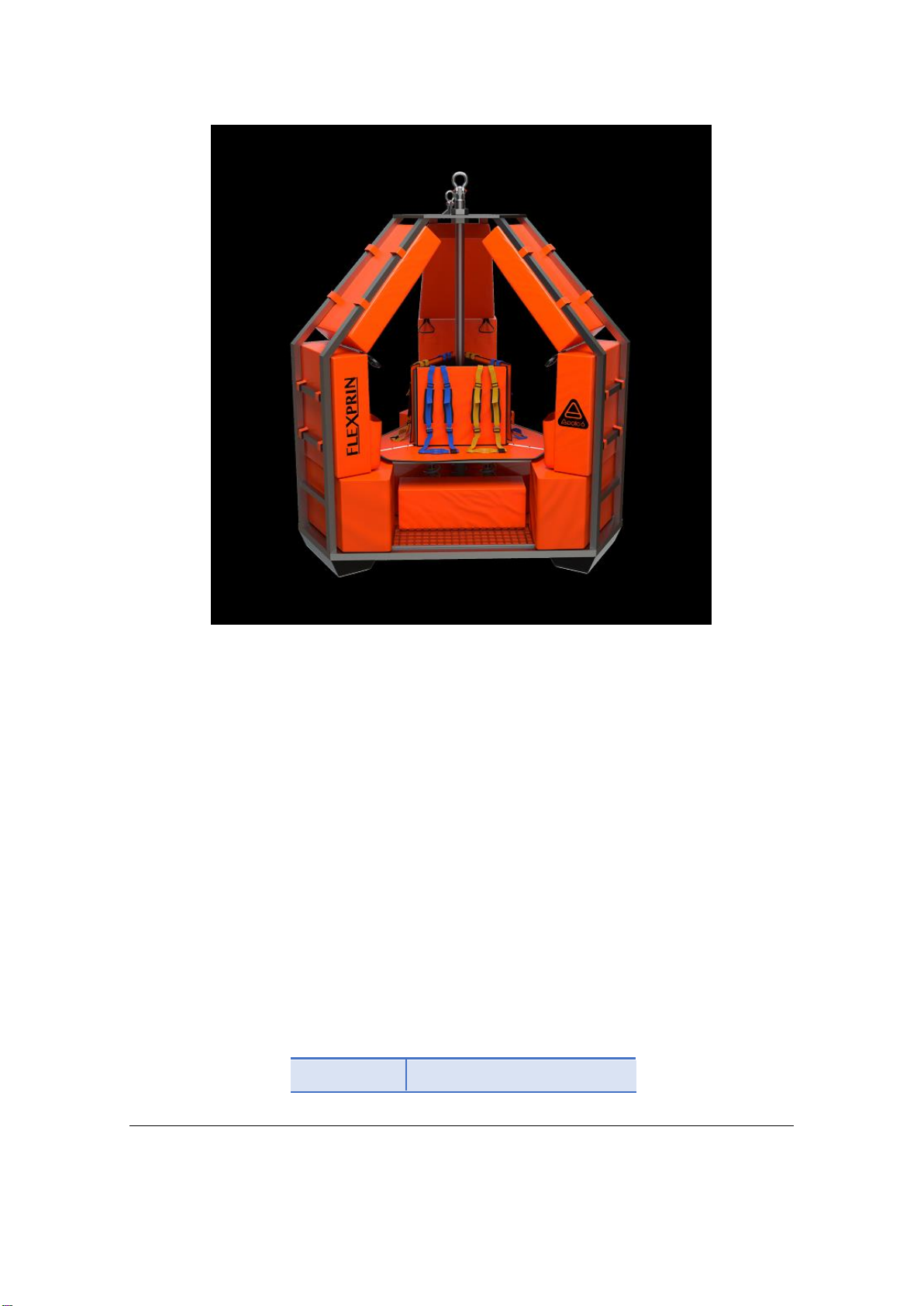

1 OBJECTIVE

This manual contains operating and maintenance instructions of the personnel transfer

basket APOLLO 6, with capacity for 6 passengers.

The user is responsible for the safe use of the equipment after becoming aware of the

relevant information contained in this manual.

The user must ensure to use all safety measures provided under the applicable

legislation provided and in operational practices when using of APOLLO-6.

Extra copies of the latest revision of this manual can be downloaded from the website:

http://www.flexprin.com.br/produto/cesta-de-transbordo-offshore-apollo6/

2 INTRODUCTIONS

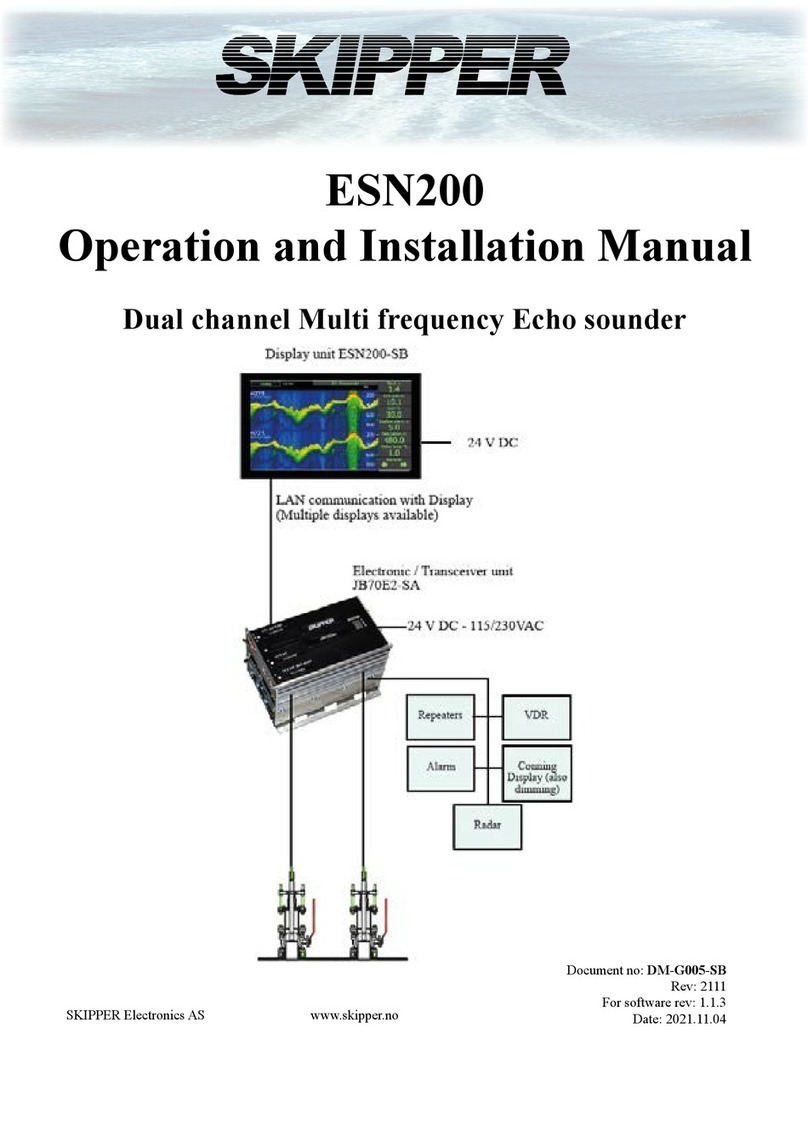

The personnel transfer basket is a device capable of transferring people safely between

the sea unit and a vessel and vice versa, and must be operated by a crane.

The equipment is capable of ensuring safety and comfort to the passengers, providing

protection against vertical and transverse impacts in case the basket collides with the

side of the vessel, fall on deck or at sea. It has the ability to float and hold the vertical

position steadily, even if initially positioned at an angle of 35 degrees. In case of falling

into the sea in overhanging position, it has capacity of getting out of the overhang and

float keeping the escape routes above sea level.

APOLLO-6 basically consists of:

1) Stainless steel external structure with low-density closed cell foam covered with

orange rubberized fabric floats;

2) A set of seats with flexible springs located in the central part;

3) A stainless steel floor at the bottom of the basket with floaters attached and three

impact absorbers that guarantees the stability of APOLLO-6 even on unstable

surfaces. The three free spans allows the rapid evacuation of passengers.

User Manual APOLLO-6

4

The accesses for the passengers are large and easy to use. In transport, passengers

must remain seated with the seat belt buckled, and the carry-on luggage in the correct

place.

The use of this equipment for transportation of equipments and large luggage is

inappropriate. For such purpose, it must be used basket or work netting.

User Manual APOLLO-6

5

3 Security Requirements

I. Before any operation with the transfer basket, clear instructions must be given

to all personnel involved.

II. People who suffer from nausea or acute vertigo should not be transported by the

PERSONNEL TRANSPORTATION BASKET.

III. If transfer is necessary, the affected person must be placed on the stretcher and

attached to the seat belt inside the unit. (This person must be accompanied by

another person during the transfer).

IV. Anyone has the right to refuse transfer by a PERSONNEL TRANSPORT

BASKET.

V. Every person positioned within the PERSONNEL TRANSPORTATION BASKET

must wear approved life jackets.

VI. An approvedSOLAS lifejacket with light maybe requiredfor useat night. Several

offshore companies also use SOLAS lifejacket for transfer during rough sea

condition / bad weather.

VII. Every person in the PERSONNEL TRANSFER BASKET must stay inside the

unit and hold the safety handle.

VIII. If the crane operator's view is obstructed, the PERSONNEL TRANSFER

BASKET should not be moved untilalternative communication devices or signals

are put into service.

IX. When transferring people, the PERSONNEL TRANSFER BASKET should be

raised just high enough to carry out the transfer. Then, gently lowered to the

deck for landing.

X. The crane operator may refuse to lift anyone who does not comply with his

instructions.

User Manual APOLLO-6

6

4 TECHNICAL SPECIFICATION

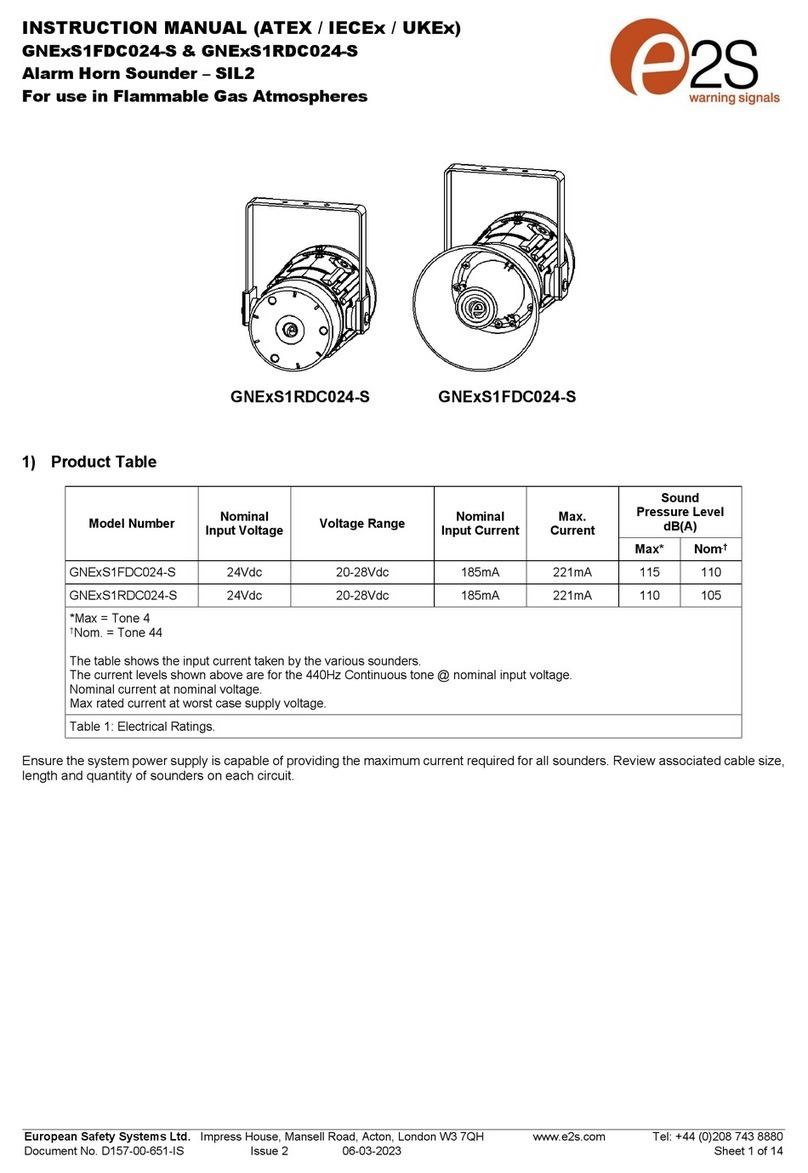

4.5 Specifications Summary

EQUIPMENT:

PERSONNEL TRANFER BASCKET

MODEL

APOLLO 6

MAXIMUM PASSENGER CAPACITY

6 PEOPLE and 540Kg

MAXIMUM LUGGAGE CAPACITY

60 Kg

LIGHTWEIGHT

576 Kg

MAXIMUM OPERATIONAL LOAD

600 Kg

TOTAL OPERATIONAL DISPLACEMENT

1.176 Kg

PROOF DISPLACEMENT (for cable calculation

purposes)

2.587 Kg

PASSENGER CAPACITY WITH STRETCHER

1 stretcher e 2 companions

NUMBER OF ACCESSES TO PASSENGERS

3

HIGHT

2800 mm

LENGTH

2350 mm

WIDTH

2720 mm

SUPPORT CABLE

9.000 mm

SECURITY CABLE

9.100 mm

LEAD CABLE

2.000 mm

MANUFACTURING

In compliance with NBR ISO 9001: 2015 and

NORMAN 05 / DPC standards

MATERIALS

Shackle for cable and safety clamping

Steel

Lifting and secondary cable

Steel cable, 5/8 inch diameter

Structural elements

Stainless steel sheet, rods or tube

Floor

Non-slip stainless steel platform

Screws, nuts, washers and other fasteners

Stainless steel

Fixing of structural elements

Welding

Floaters

Fire retardant Rubberized fabric, and closed

cell.

Seats

marine plywood

Seat shock absorbers

Stainless steel springs

Main shock absorbers

Rubber compound

User Manual APOLLO-6

7

4.5 Project

Verification

Manufactured by ISO 9001: 2015

Approved by the Directorate of Ports and

Coasts (DPC) Brazil

Impact Behavior

Personnel transfer baskets are designed to

protect passengers from vertical (3.25 m / s)

and horizontal (2.00 m / s) impacts. For this,

its structure was designed with a safety factor

greater than 10. The structure acts as a safety

cocoon against impacts.

Shock Absorbers

Shock absorbers below the seats and impact

absorbers at the base, guarantee passengers

greater comfort in case of vertical impact.

Lifting cables

Two lifting cables are mounted on this

equipment. The first one with 9.0 meters is

capable of suspending 2.2 times the

maximum load with a large safety margin.

And the 9.1-meter emergency cable that goes

into operation in the event of failure of the

main cable.

Other features

Full-height seatsSeat belts with quick release

buckles

Stretcher capacity

Stability angle - 35 °

4.5 Certifications and Documentation

Certifications

Homologation Certificate (DPC)

Nº: 211.012/2018 Rev.1

Manufacturer's certificate ISO 9001:2015

Quality Certificate Lifting and Safety Cable

Assembly

Ring Quality Certificate

Quality Certificate Stainless Steel Tubes

User Manual

1 User Manual for the Client

Additional

FLEXPRIN will keep copies of the certificates

mentioned above and additional

documentation as mentioned below.

Material certification for critical and non-

critical components. Inspection and

maintenance history.

User Manual APOLLO-6

8

5BEFORE OPERATION

5.5 Visibility and Sea Conditions

The person in charge of the operation and the crane operator must check visibility

and sea conditions.

Visibility of the entire operating area should be good.

Wind with force less than 30 knots

-Wave height less than 4 meters.

5.5 Maintenance Conditions

The person in charge of the operation must observe visual inspection and

maintenance conditions.

Visual inspection of cables, eyelets, shackles and clips.

Visual inspection of seat belts.

Visual inspection of the floats, regarding fixation and integrity.

Documents Verification. The Apollo’s maintenance certificate must be

present in the documentation and tools compartment. The validity of the

certificate must be checked. The use of equipment with the

maintenance certificate expired is not recommended.

6 OPERATION WITH PASSENGERS

6.5 Crane operator

The crane operator must position the equipment at the boarding point so that passengers

can safely board.

6.5 Boarding

Passengers equipped with lifejackets, must embark in order and position determined by

the person in charge of the operation. Seat belts fastened and Carry-on luggage goes in

the compartment next to the seat.

User Manual APOLLO-6

9

The person in charge of the operation must determine the sequence and embarkation

position of each passenger, towards a better load distribution. Such procedure

maximizes comfort during transportation.

The person in charge of the operation must authorize the start of the operation after all

passengers are safe and accommodated.

6.5 Landing

The transfer baskets are equipped with guide cables, so that the personnelat the landing

point can assist the crane operator to land at the specified location.

Passengersmust disembark, together with their carry-on baggage, atthe timethe person

in charge of the maneuver determines.

6.5 Communication

All parties involved in the operation must have continuous radio communication in a

range released for other uses. Provide at least one extra radio frequency range for use

in case of emergency.

7 OPERATION WITH STRETCHER

7.5 Preparation for transport with stretcher

The APOLLO-6 personnel transfer basket was designed for patients’ transfer on a

stretcher and their companions. To such, before operation, remove two contiguous

lateral floaters from their inner position and reposition in the outer of the equipment.

Depending on the training of the on-board crew, this operation is relatively simple and

quick, loosen 2 screws of the locking catch, reposition the floating and tighten back the

2 fastening screws

User Manual APOLLO-6

10

Platforms with 2 or more transfer baskets are recommendedto be able tokeep a transfer

basket in stretcher mode so that emergencies will be met in the shortest possible time.

7.5 Crane operator

The crane operator must position the equipment at the point of embarkation so

that passengers can safely board.

7.3 Boarding

Place the stretcher that will transport the patient on the seat that had its space increased

by the repositioning of the Floaters. 3-point seat belts should make attachment of the

stretcher to the seat.

The front passenger should preferably use the diametrically opposite seat.

The person responsible shall authorize the start of operation after all passengers have

been safely accommodated.

User Manual APOLLO-6

11

7.4 Landing

The Personal transfer baskets are equipped with guide cables, so that the personnel at

the landing point can assist the crane operator at the landing at the specified location.

The stretcher and the passenger must disembark as soon as the person in charge of the

maneuver determines.

7.5Communication

All parties involved in the operation must have continuous radio communication in a

range released for other uses. Provide at least one extra radio frequency range for use

in case of emergency.

8 INSPECTION AND MAINTENANCE

The transfer baskets must undergo the following preventive maintenance:

8.1Inspection before each operation.

Before each operation, the transfer personnel baskets must undergo a visual inspection,

by the person in charge of its operation.

In this inspection, the operator must check the following points:

The 6 seat belts are securely fastened.

The lifting cables are properly connected.

If there are loose or damaged parts.

- After this inspection the equipment can be operated.

If any of these items fails, it must be fixed or the equipment removed from use and

corrective maintenance scheduled.

8.2Detailed inspection every 3 months

The personneltransfer basketsmust undergo a visual inspection by theperson in charge

of its operation every 3 (three) months.

User Manual APOLLO-6

12

In this inspection, the operator must check the following points:

The 6 seat belts are securely fastened.

The lifting cables are properly connected.

If the lifting cables serial numbers correspond the numbers on your warranty

certificates and if they are within the term of use.

The fixing screws are tightened and gripped.

Remove equipment from use and scheduled corrective maintenance if any of

these items fails.

8.3Annual inspection and periodic maintenance.

Personnel transfer baskets must undergo an annual detailed inspection by

manufacturer's specialized team or authorized by the manufacturer.

For this maintenance, equipment will be completely disassembled. All its removable and

fixed parts inspected.

After this maintenance, the equipment will receive the revision certificate issued by the

manufacturer.

The first annual maintenance must be performed at the manufacturer's premises. The

second, third and fourth annual reviews can be carried out on board by a specialized

team, trained and accredited by the manufacturer. This cycle must be repeated every 5

years, that is, in the 5th year the basket tests and revision must be done at the

manufacturer's premises. Next four years on board. On the 10th year at the factory, and

so on.

User Manual APOLLO-6

13

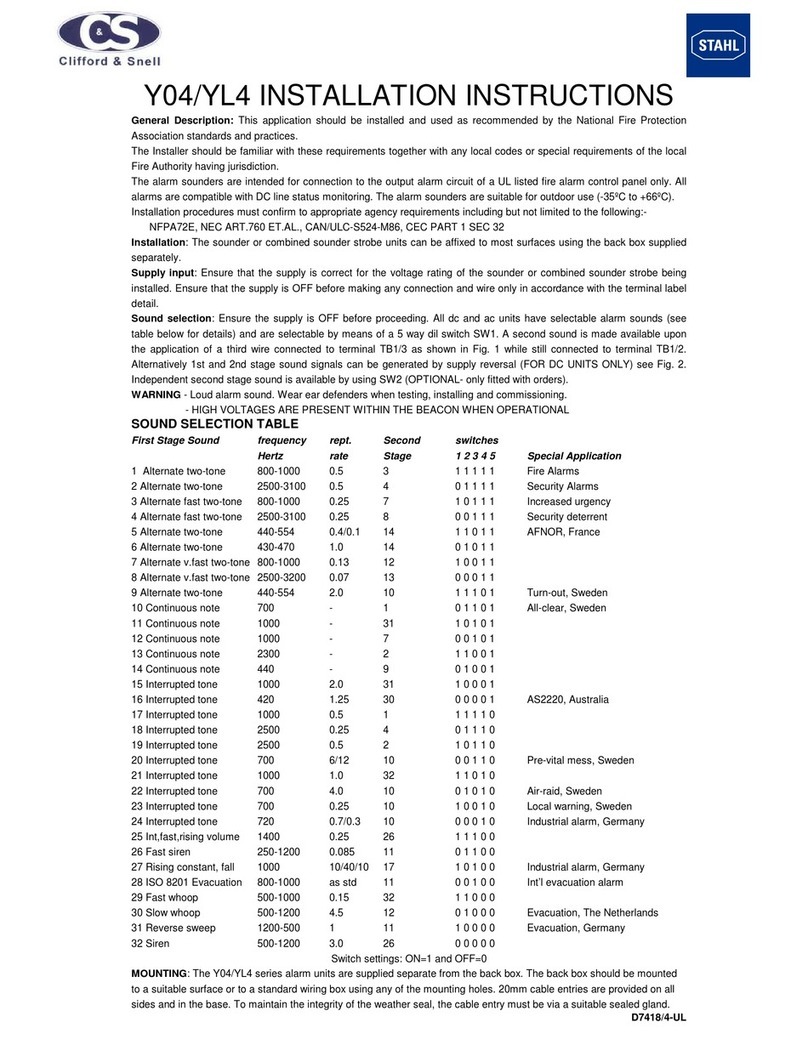

9 SPARE PARTS

Materials

Frequency

1) Lower side float

If there are malfunctions

2) Upper side float

If there are malfunctions

3) Floor float

If there are malfunctions

4) Lower center float

If there are malfunctions

5) Central mast

Every 5 years or If there are

malfunctions

6) Stainless steel lifting eye

Every 5 years or If there are

malfunctions

7) Complete seat

If there are malfunctions

8) Seat belt

If there are malfunctions

9) handles

If there are malfunctions

10) M48 nut

Every 5 years or If there are

malfunctions

11) Lifting eye fixing screws

Anual

12) Spring

If there are malfunctions

13) Shock absorbers

If there are malfunctions

14) Cable for complete lifting

Every 5 years or If there are

malfunctions

15) Impact absorbers

Every 5 years or If there are

malfunctions

16) Cover

recommended for the best

preservation of the basket

17) Set of stickers

If there are malfunctions

18) Nameplate

If there are malfunctions

19) Guide cable

If there are malfunctions

20) Tools

If there are malfunctions or missing

21) Stretcher

If there are malfunctions or missing

22) Stretcher attachment cables

-

23) Fastening elements for the bottom plate

Anual

Table of contents