1-1

1.0 OVERVIEW

The PORT LF-SD and PORT MFE can be shipped as pop-up buoy system. This allows the unit to float to the

surface upon detaching from a payload.

1.1 Pop-Up Assembly

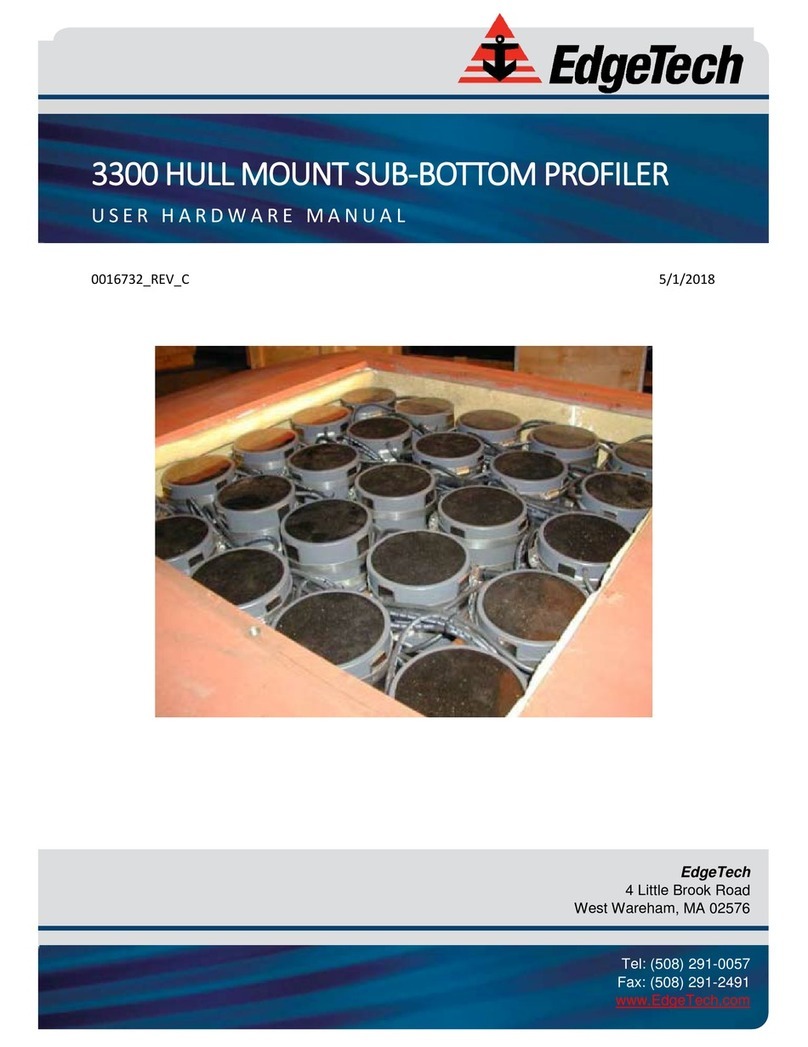

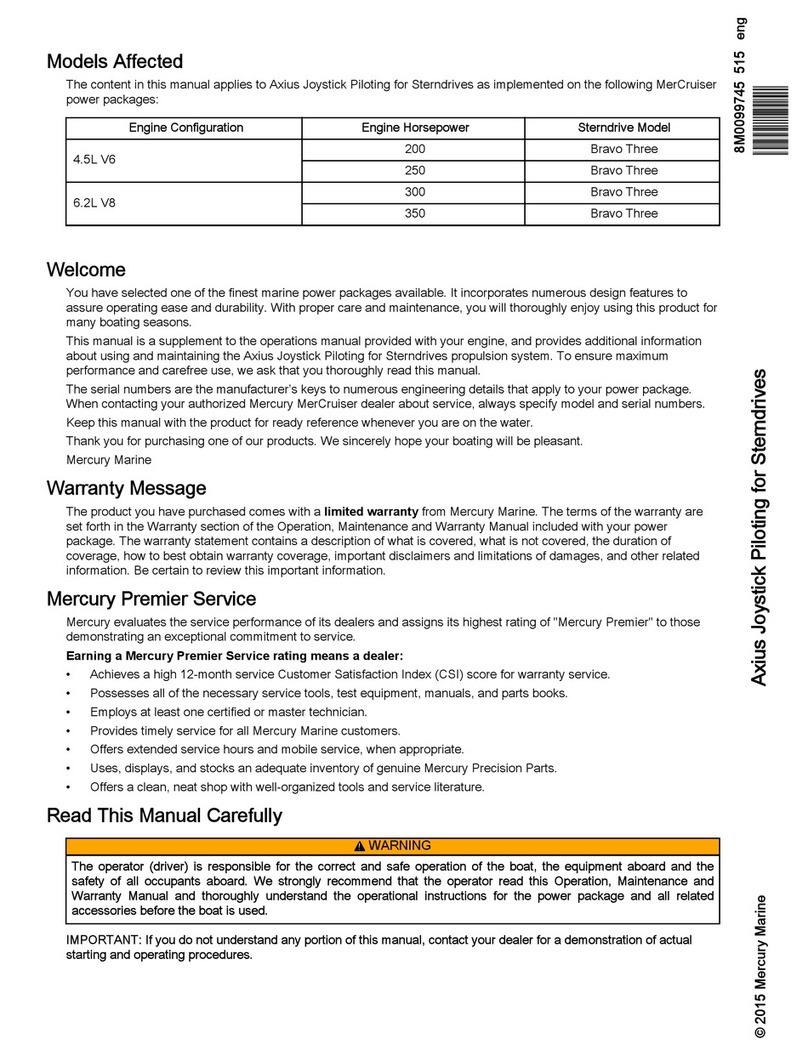

PORT Pop-Up system is shipped assembled. If Pop-Up canister was purchased separately it will consist of:

•(1) Top (Flotation) Cup

•(1) Bottom (Line Holding) bucket

•(1) Sub Flotation Pop-Up Assembly Drawing [PN 0015784]

•(1) Package Containing all Required Assembly Hardware

o(1) Clamp PORT Pop-Up Delrin

o(1) Rubber Strip Neoprene 0.25” thick; 01” wide

o(1) Clamp Hose 0.50 3-1/16 x 4”

o(4) Tie Cable Clamp Head 102mm

o(2) Galvanized Carbon Steel Shackle [1500lb]

Tools needed for assembly

•(1) Flat Head Screwdriver

•(2) 9/16” Wrenches

•(2) 7/16” Wrenches

1.2 Line Packing Considerations

Note: Flaking is the preferred method of line packing. Never wind the

line around the center post, as this can cause line tangling.

The canister’s line capacity is a function of line diameter, line construction, and material. Stiff Lines have

significant ‘memory.’ For example, 3-strand polypropylene does not pack as well as single- or double braid

nylon. The decision of what diameter and type of line to be used needs to be carefully thought out, safe

working loads and shock loading need to be considered.

When packing the canister with line, EdgeTech strongly recommended the line be randomly ‘flaked’ into

the canister. Avoid coiling or laying the line in a pattern, as randomly packing and tamping it down as it

builds up will yield the best results. The end of the line should be attached to the stud, which is inside of

the flotation assembly. Floatation Assembly provides 15lbs. of buoyancy +5lbs. with optional trawl float.