FAM1500-K v1.0 manual Jun. 2022 — p.3/15 www.ightofharmony.com

Kit Notes (cont.)

your soldering iron tip to the pre-soldered pad to reow the solder. Then you

can solder the other side normally.

• Flux is your friend. Use ux. Water-soluble ux is best for a clean nish, but

you have to make sure to get it all off when done, as it can corrode the joint

and some uxes may also be capacitive. You can also use no-clean ux.

• Smallest rst. Solder the components in increasing order of size.

• Minimize heat exposure. Heat destroys components, and SMD are particularly

sensitive because they have less mass to distribute the heat. Flux helps with

this too.

• Use the face plate to line up the potentiometers,jacks, and LEDs, before

soldering; this is much easier than resoldering them to line them up correctly

afterward. You may have to attach and remove the panel a few times with this

kit because of the component density.

Assembly Order

The easiest build order is as follows:

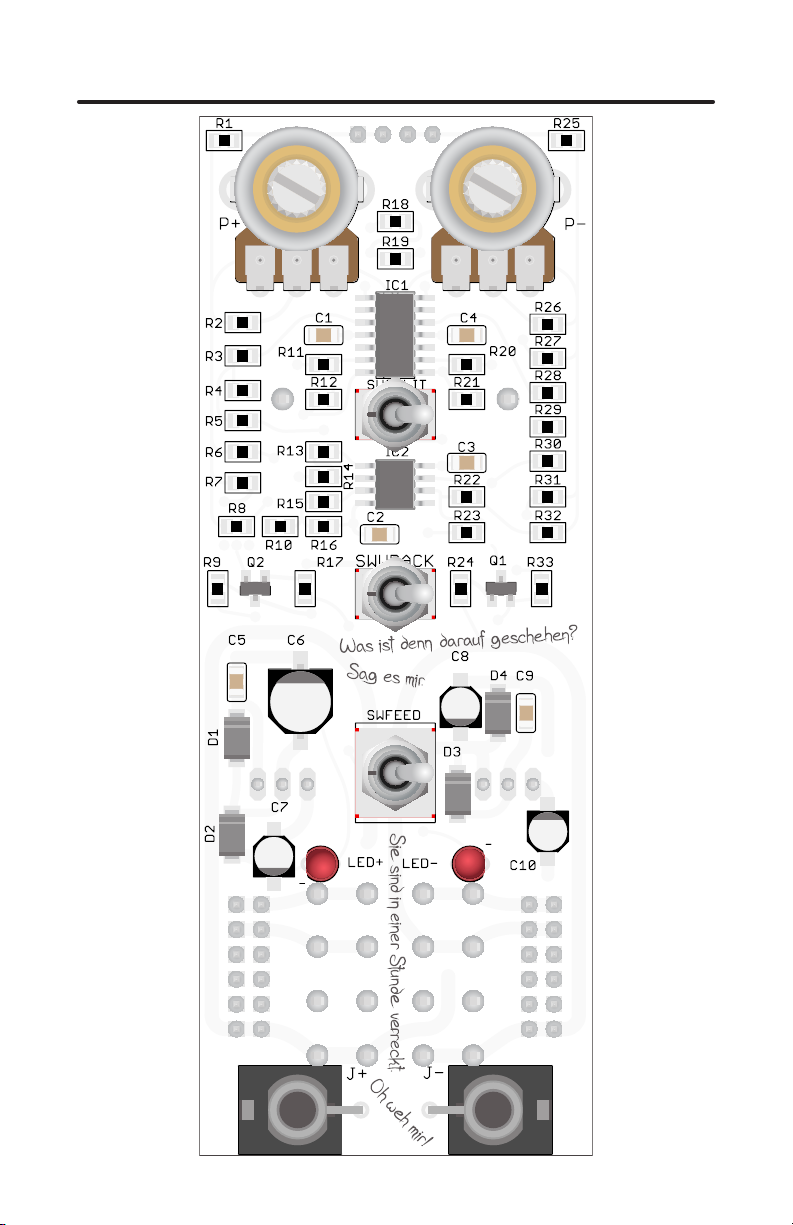

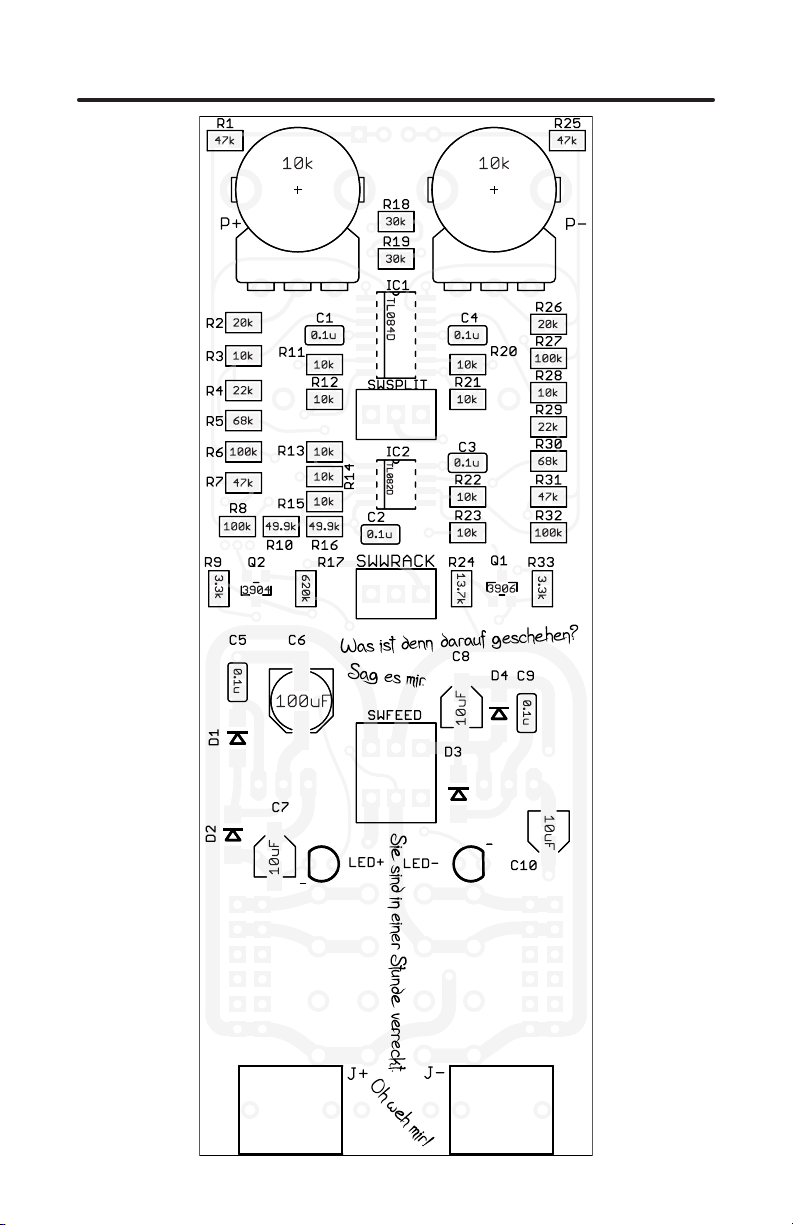

1. All SMD. For the rest, follow the order shown on Page 7:

2. Install & solder the rear chaining header.

3. Install & solder the potentiometers, switches, and LEDs. Trim the LED

leads.

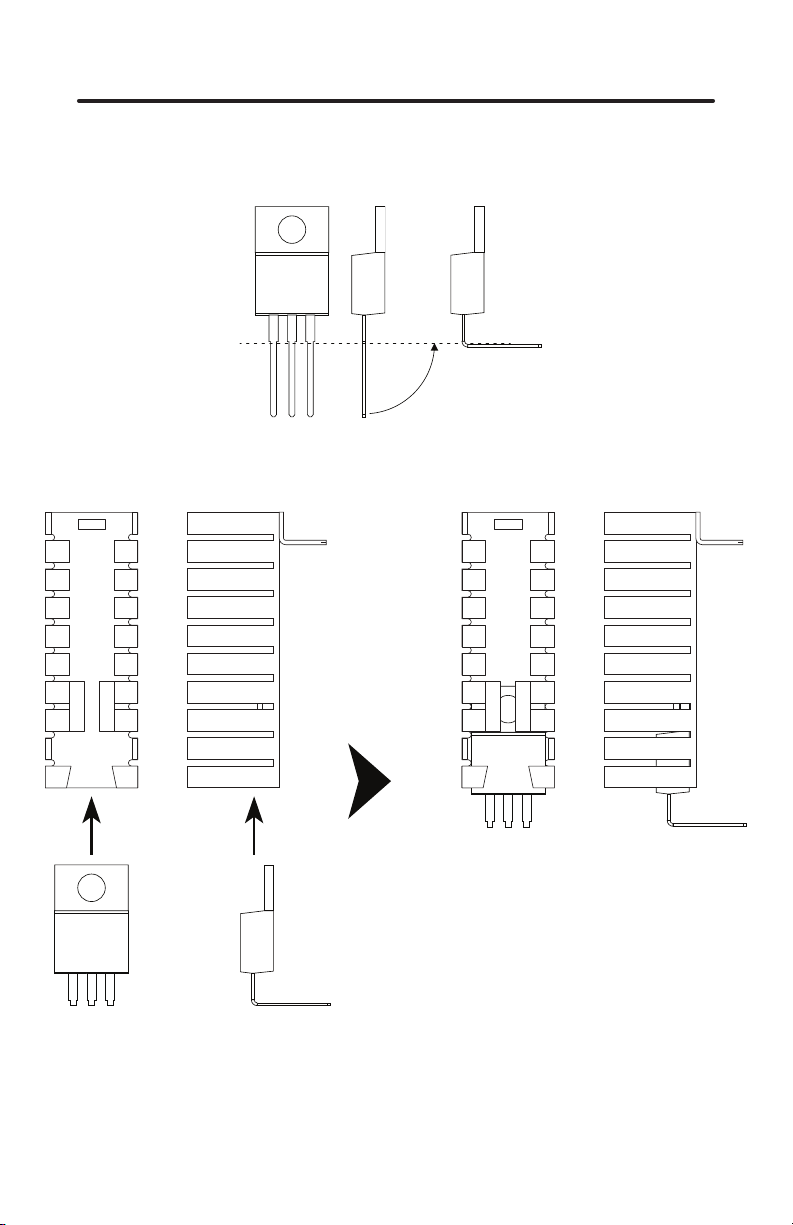

4. Assemble the regulators and heat sinks (see graphic, p.9), then install

them on the PCB. Install & solder the quick-connect tabs.

5. Install & solder the 2x8 shrouded headers. NOTE THE ORIENTATION.

Due to the cramped board layout, there wasn't enough room for the

CV and Gate pins, so they have been removed from the headers (see

graphic p.5).

6. Install & solder the jacks.

7. Attach the panel - see toggle switch jam nut instructions on p.14.

Help

If you're still having problems, email me! I am always happy to help. When

emailing, please include high-resolution pictures of your circuit boards.

Most of the troubleshooting requests I have received were solved by zooming

in and closely examining the pictures. Cold solder joints are sneaky and hard to

spot if you haven't dealt with them before. A cold solder joint is where the solder

doesn't adhere to both the pad and the component lead, and just owed around

one of them without making contact. They happen, and they suck, but they're easy

xes once you nd them.