Flint & Walling Commander Pro User manual

Flint & Walling © Copyright 2018. All rights reserved.

1

Commander®Pro Variable

Speed Controller System

Instructions

OWNER INFORMATION

System Model Number

Pump Model / Date Code

Pump Serial Number (Silver Label)

Motor Model / Date Code

Motor Serial Number (Silver Label)

Controller Model / Date Code

Dealer

Address

Install Date

TABLE OF CONTENTS

Safety Instructions................................ 2

System Components .............................. 3

Piping & General Information ....................... 3

Controller Location Selection ....................... 4

Controller Installation / Wiring ....................... 5

Start-up Operation................................ 6

System Troubleshooting ........................... 9

024983 F

DESCRIPTIONS AND FEATURES

The Commander®Pro Variable Speed Controller is a

dependable water system Variable Frequency Drive (VFD)

that uses custom programming to enhance the performance

of submersible pumps. When applied correctly to three phase

motor driven pumps, the drive eliminates pressure cycling

associated with conventional pressure switch controlled water

pumping systems and provides a constant output pressure.

Key features of the drive controller include:

• Can use either a pressure switch (no snap action) or

a 4-20mA transducer as the pressure control. At initial

power up, the controller detects whether a switch or

transducer is connected and automatically sets the

control choice.

• Constant water pressure with a wide range of settings

(30-80 psi) (Note: The maximum obtainable system

pressure is limited by the performance of the pump

installed)

• Smaller pressure tank can be used

• Fits the pump to the application – pump speed is

controlled to provide the optimum performance without

overloading the motor

• No in-rush (power-on transient) current

• Low motor start-up current (soft-starting)

• Active Power Factor Correction minimizes input RMS

current

• Protection features

– Dry run conditions – using intelligent load monitoring

(see Page 7)

– Bound pump – with auto-reversing torque

– High voltage / lightning surge

– Low line voltage

– Short circuit

INCLUDED ITEMS:

A. Controller Unit

B. Pressure switch or Transducer

C. Switch or Transducer Cable

D. Installation Manual

E. Small Screwdriver

F. Warranty Card

G. Switch Adjustment Tool (VS Systems only)

HELP LINE: 800-742-5044

Flint & Walling © Copyright 2018. All rights reserved.

2

Follow all local electrical and safety codes as well

as the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSHA).

The power supply should be a separate circuit,

independent of all other circuits. Be sure it is equipped

with a fuse and disconnect box of ample capacity.

For fire protection, the power supply should be

free of any building, preferably on a direct line

from the transformer. In the event of fire, the

wires will not be destroyed and the water supply

not cut-off.

Always disconnect power source before

performing any work on or near the motor or its

connected load. If the power disconnect point is

out-of-sight, lock it in the open position and tag it

to prevent unexpected application of power. Failure to do

so could result in fatal electrical shock.

DO NOT handle pump with wet hands or when

standing in water as fatal electrical shock could

occur. Disconnect main power supply before

handling pump for any reason.

Shut off power source when voltage drops below 210 on

230 volt installations.

Protect the power cable from coming in contact with

sharp objects, oil, grease, hot surfaces or chemicals.

DO NOT kink the power cable. If damaged replace

immediately.

NEVER leave the control box, fused disconnect switch,

or covers open (either partially or completely) when not

being worked on by a competent electrician or repairman.

Always use caution when operating electrical

controls in damp areas. If possible, avoid all

contact with electrical equipment during

thunderstorms or extreme damp conditions.

Install all electrical equipment in protected area to

prevent mechanical damage which could produce serious

electrical shock and/or equipment failure.

Pump is designed to pump cold ground water that is

free of air or gases. Decreased pump performance and

life expectancy can occur if the ground water is not cold

(86ºF/30ºC) or contains air or gases.

Pump and controls must be securely and

adequately grounded as specified in section 250-

43 item (A) of the U.S.A. National Electric Code

(NEC) and Section 26-954 Canadian Electrical

Code. Failure to do so could result in a fatal injury.

DO NOT use this pump to pump flammable liquids such

as gasoline, fuel oil, kerosene, etc. Failure to follow the

above warning could result in property damage and/or

personal injury.

The pump is intended for use in a well. Motor

frame must be connected to power supply ground

or fatal electrical shock may result. Do not use

this pump in swimming pools.

Capacitors inside the drive controller can still hold

a lethal voltage even after power has been

removed. Allow 10 minutes for dangerous internal

voltage to discharge before making changes to

input power or motor connections.

Do not use motor or system in swimming areas.

IMPORTANT SAFETY INSTRUCTIONS

Rules for safe installation and operation.

Read these warnings and instructions carefully. Failure to follow them could cause serious bodily injury and/or property

damage.

Do not use power factor correction capacitors with the

drive controller. Damage will result to both motor and

drive.

This equipment should be installed by technically

qualified personnel. Failure to install it in compliance

with national and local electrical codes and within stated

recommendations may result in electrical shock hazard,

fire hazard, unsatisfactory performance, or equipment

failure.

NOTE: Units with the "ETL/CUS" mark are tested to UL

standard UL508C & CSA standard C22.2 No. 274.

Flint & Walling © Copyright 2018. All rights reserved.

3

SYSTEM COMPONENTS

Please be sure that you have all major system components

necessary to properly install the submersible pump system.

Other components may also be necessary depending on the

application requirements.

1. Submersible pump end

2. Submersible motor

3. Variable speed controller

4. Pressure tank

5. Pressure switch or transducer (packaged with controller)

6. Pressure relief valve (purchased separately)

7. Pressure gauge (purchased separately)

PIPING

General Information

The system is capable of flows up to 40 GPM. Discharge

piping is recommended to be 1.25” for installations in which

flows will exceed 12 GPM. The use of smaller pipe will

increase friction losses and can severely limit the maximum

capacity of the system.

This pump may be capable of pressures exceeding 325 PSI

under maximum conditions, select pipe accordingly. Consult

your pipe supplier to determine the best pipe material for the

installation

Pump Inspection

Prior to installation check the pump, motor, controller and tank

for shipment damage.

Pressure Tank

The Air-E-Tainer® tank supplied with your system has a

factory set pre-charge of 35 PSI. Installer must recheck to

make sure tank is still 35 PSI. This is 70% of the factory

preset operating pressure of 50 PSI. Any change in operating

system pressure will require that the pre charge in the tank

be modified to 70% of that pressure. See Tank Table for

minimum pressure tank size.

MINIMUM PRESSURE TANK SIZE (TOTAL

CAPACITY)

Controller

Pump Flow

Rating less

than 12 GPM

Pump Flow

Rating 12 GPM or

higher

VS15/TVS15 4.6 Gal (132477) 4.6 Gal (132477)

VS20/TVS20 4.6 Gal (132477) 14 Gal (132661)

VS30/TVS30 14 Gal (132661) 14 Gal (132661)

TVS50 14 Gal (132661) 20 Gal (132662)

Many pumps can develop excessive

pressure, resulting in equipment and property damage

as well as possible injury. Always install a pressure relief

valve capable of passing full pump flow at 100 PSI. Install

the pressure relief valve between the pump and pressure

tank.

PRESSURE SETTING GUIDE

System Pressure

(at Pressure Sensor)

Pressure Tank Setting

(PSI) (+/- 2 psi)

25 18

30 21

35 25

40 28

45 32

50 (factory set) 35

55 39

60 42

65 46

70 49

75 53

80 56

Pressure Relief Valve

The pressure relief valve and the discharge outlet need a

flow rating which exceeds the flow capacity of the installation

at the relief pressure. When located in an area where a water

leak or relief valve blow-off may damage property connect

an adequate drain line to the pressure relief valve. Run the

line to a suitable drain or to an area where the water will not

damage property.

Not providing an adequate relief valve

can cause extreme overpressure which could result in

personal and/or property damage. It is recommended

that you manually activate the valve monthly to keep it in

good working order.

Discharge Pipe

When discharge piping requires an adapter it is

recommended that a stainless steel adapter be used.

Galvanized fittings or pipe should not be connected directly

to the stainless steel discharge head of the pump as galvanic

corrosion may occur. Barb type connectors should always

be double clamped. Torque arrestors are not required on this

installation due to the soft starting characteristics of the motor

and controller

Check Valve

A check valve is factory installed in the discharge head of the

submersible pump. This maintains water within the pipe when

the pump is not operating. For well depths exceeding 100

feet, an additional check valve should be installed every 100

feet.

Safety Rope

A safety rope eyelet is provided at the discharge of the pump.

It is recommended to attach a nylon safety rope. This will

assist in the removal of the pump and also prevent loss of

the unit in the bottom of the well due to a loose fitting or pipe

deterioration.

Flint & Walling © Copyright 2018. All rights reserved.

4

CONTROLLER LOCATION SELECTION

The NEMA 3R controller is intended for indoor and outdoor

use and for operation in ambient temperatures up to 125°

F (50° C). It should be mounted in a location that provides

protection from water sprays greater than 30° from vertical.

The drive should only be accessed by trained and authorized

personnel. To ensure maximum weather protection, the

unit must be mounted vertically with the cover properly

aligned and secured with all lid screws. The following

recommendations will help in selection of the proper location

of the unit:

1. A tank tee is recommended for mounting the tank,

pressure switch/transducer, pressure gauge, and

pressure relief valve at one junction. If a tank tee is not

used, the pressure switch/transducer should be located

within 6 ft. (1.8 meters) of the pressure tank to minimize

pressure fluctuations. There should be no elbows

between the tank and pressure switch/transducer.

2. The unit should be mounted on a sturdy supporting

structure such as a wall or supporting post - please

account for the fact that the unit weighs approximately 20

lbs.

3. The electronics inside the controller are air-cooled. As a

result, there should be at least 6 inches of clearance on

each side and below the unit to allow room for air flow.

IL1721

Commander®Pro

VariableSpeed

Controller

®

FW1629A

COMMANDER® PRO

Variable Frequency Drive

www.getcommanderpro.com

FW1629B

6.8366

2.7963

Notesdo not print

Pressure

Tank Pressure

Switch or

Transducer

Pump

Motor

Pressure

Relief Valve

Figure 2 Location Diagram

There should be at least 6 inches of

clearance on each side and below the unit to allow room

for proper air flow. There are to be no elbows between

the tank and pressure switch.

4. The controller should only be mounted with the wiring

end oriented downward. If possible for best cooling,

the controller should not be placed in direct sunlight

or other locations subject to extreme temperatures or

humidity (mounting location should not be subjected to

condensation).

5. The mounting location should have access to 230V

electrical supply and to the submersible motor wiring.

6. Do not expose the drive to water spray greater than 30°

from vertical.

Note: Installations that require larger than 6 AWG wire will

require an external junction box. Run 6 AWG from the drive

to the junction box and make external connections to the

appropriately sized wire with wire nuts.

WIRING SIZING CHART

Maximum Wire Lengths Connecting the Controller

to The Main Circuit Box

(Based On 3% Voltage Drop At 230V)

Motor

HP

Copper

Wire

Size

(AWG) 14 12 10 8 6 4 3 2

Circuit

Breaker

1.5/2 Max.

Length.

(Ft.)

85* 140* 220 345 550 680 895 20 AMP

3 115* 180 285 455 560 740 25 AMP

5115 185 290 360 470 40 AMP

* Wire with 90°C Insulation only

PUMP WIRING

If submersible pump type is chosen, the output of the drive is

3-phase. (If the option is available, 3-wire may be available

for submersible pumps).

The power output terminals (for motor wire connections) are

located on the lower right-hand side of the controller and are

labeled RED, BLK, YEL and (W). To select the wire size refer

to the pump owner’s manual, NEC and local codes for proper

wire size.

NOTICE: Regardless of owner’s manual, wire length should

not exceed 1000 ft.

If the Commander Pro Controller is used with above ground

motors the output is limited to 3-phase. To maximize motor

life the cable length between the controller and the motor

should be limited to a maximum length of 25 ft. Refer to the

pump owner’s manual, NEC and local codes for proper wire

size. Caution: Correct motor rotating needs to be verified to

avoid pump and motor damage.

Due to the inherent voltage changing

characteristics of variable frequency drives (VFD), there

is additional stress placed on the insulation of the wire

between the controller and the motor compared to a

standard pump system. Extra care must be taken when

using Un-jacketed Flat Parallel Pump Cable to ensure that

the insulation on each of the separated wires is the same

thickness. Care must also be taken to ensure a proper

seal with shrink tubing on any splices. Failure to take

these precautions can lead to “wire burn through” that

will shut down the system. Under these circumstances,

no permanent damage usually occurs to the controller or

motor. For further details call Technical Support at

800-742-5044.

SEPARATED WIRE

Flint & Walling © Copyright 2018. All rights reserved.

5

Figure 3 Wire Illustration

NOTE: DO NOT USE ALUMINUM WIRE.

Attention: To meet full compliance with FCC Part 15

Subpart B and CENELEC EN 55011, shielded motor

cable should be used between the drive motor output and

the motor. Using shielded cable provides the maximum

filtering to reduce radiated & conductive emissions which

can cause interference with other devices.

CONTROLLER INSTALLATION PROCEDURE

1. Disconnect electrical power at the main breaker

2. Drain the system (if applicable)

3. Install pressure switch or transducer - the pressure switch

or transducer has a 1/4 - 18 National Pipe Thread (NPT)

connection.

4. Remove the controller cover by removing the lid screws.

Attach the unit to the wall using mounting screws (not

included).

Wiring Connections

1. Verify that the power has been shut off at the main

breaker.

2. Verify that the dedicated branch circuit for the controller is

equipped with the correct rating of circuit breaker.

3. Remove the controller lid.

L1 L2

IN OUT + - S1 S2

ALARMS FAN SENSOR

IL1791

RED

BLK

YEL

Feed motor and ground leads

through appropriate knockout

and connect to RED, BLK, YEL

and Won right hand terminal

block.

Figure 4

4. Feed the motor and ground leads thought the appropriate

knockout on the bottom right side of the unit and connect

them to the terminal block positions. Submersible

3-Phase or 3-Wire 1-Ph motors: follow colors as marked:

Red (RED), Black (BLK), Yellow (YEL) and (W).

Submersible 3-Phase or 3-Wire 1-Ph motors: follow

colors as marked: Red to RED, Black to BLK, Yellow

(YEL) and Green Ground wire (W). Submersible 2-Wire

1-Ph motors: Connect motor leads to BLK, YEL and

Green Ground wire (W).

Above Ground Motor (3-Phase Only): L1 to RED,

L2 to BLK, L3 to YEL and Green Ground wire (W)

Verify motor rotation to avoid damage

to pump & motor.

L1 L2 RED BLK YEL

IN OUT + - S1 S2

ALARMS FAN SENSOR

IL1790

Feed 230V power and ground

leads through appropriate

knockout and connect to

L1, L2 and Won left hand

terminal block

Figure 5

5. Feed the 230V power and ground leads through the

appropriate opening on the bottom left side of the

controller and connect them to the terminals marked L1,

L2 and W.

S2

IL1792

S1

Feed the pressure

switch/transducer

wire through the strain

relief (bottom right) and

route cable through

grommeted hole above

the motor power terminal

block.

Connect to S1 and S2

terminals on display board

terminal strip.

For transducer,

Brown wire connects to S1

Blue wire connects to S2

Grommeted hole

IN OUT + -

ALARMS FAN SENSOR

Figure 6

6. Install provided strain relief in the smaller hole on the

bottom right hand side of the controller unit. Feed the

pressure switch or transducer leads through the strain

relief and route the leads through the grommetted hole

above the motor terminals.

- For Switch (VS Drive Kit): Connect the red and black

lead wires to the terminals marked "S1" and "S2"

(interchangeable) on the display board terminal strip with

a small screwdriver (provided).

- For Transducer (TVS Drive Kit): Connect the Brown wire

to the terminal marked "S1" the Blue Wire to terminal

Flint & Walling © Copyright 2018. All rights reserved.

6

"S2" on the display board terminal strip with a small

screwdriver (provided).

Tighten the strain relief on the pressure switch/transducer

lead.

IL0026

Remove rubber end cap

to adjust pressure. Use

7/32” allen wrench

Pressure switch

boot

Figure 7 Pressure Switch

IL1875

Figure 8 Pressure Transducer

A 10 foot section of cable is provided with the system

to connect to the pressure switch / transducer. Lengths

of up to 100 feet can be used, provided the appropriate

shielded cabling is used. Consult the factory for proper

cable specification.

7. Use the appropriate strain relief or conduit connectors

(not included).

8. Replace the cover. Do not over-tighten the screws.

9. Set the pressure tank pre-charge to 70% of the desired

water pressure setting. To check the tank’s pre-charge,

de-pressurize the water system by opening a tap.

Measure the tank pre-charge with a pressure gauge at its

inflation valve and make the necessary adjustments.

NOTE: For pressure switch installation (VS systems) only,

Follow steps 10, 11 & 12. (Figure 7)

For pressure transducer installations, skip to Step 13.

10. Connect the other end of the pressure switch cable with

the two spade terminals to the pressure switch. The

connections are interchangeable.

11. The pressure switch communicates the system pressure

to the controller. The switch is preset at the factory to

50 psi, but can be adjusted by the installer using the

following procedure:

a. Remove the rubber end-cap.

b. Using a 7/32” Allen wrench (provided), turn the

adjusting screw clockwise to increase pressure

and counter-clockwise to decrease pressure. The

adjustment range is between 30 and 80 psi (1/4 turn =

approximately 3 psi).

c. Replace the rubber end cap.

d. Reset the pressure tank pre-charge to the appropriate

pressure

12. Cover the pressure switch terminals with the rubber boot

provided.

For pressure transducer installation (TVS systems) only,

Follow Step 13. (Figure 8):

13. Connect the free end of the transducer cable to the

transducer by lining up the keyway on the connector

to the transducer, pressing the cable into place & then

tightening the thumbscrew finger tight.

START-UP OPERATION

Apply power to the controller. The display should briefly show

“Please Wait Initializing” and then read “Press Enter to Begin

Set-Up”. Pressing ENTER button will begin taking you through

the quick set-up menu where you can select Pump type

(Submersible or Above Ground); Motor type (Three Phase,

3W Single Phase - if option is available); Maximum Motor

Current; Maximum Frequency; Control (Switch, Transducer)

by using the UP & DOWN buttons to change the setting

and then pressing the ENTER button to save the choice.

Once all the choices have been selected, press the STOP/

START button to save the setting to the controller’s memory.

The drive will then spin the motor in a reverse direction for

a couple of seconds and then begin to run the motor in the

correct direction and begin regulating the pressure. While the

drive is running the motor, for VS drive kits (pressure switch)

the display will show the current that the motor is drawing and

the frequency that is being supplied. When there is no water

use, the controller will shut off the output to the motor and the

display will show “Motor is in Standby Mode”. For TVS drive

kits (transducer) the display will show the transducer pressure

reading, current that the motor is drawing and the frequency

that is being supplied.

NOTE: Conventional private water systems intermittently fill a

pressure tank as commanded by a standard pressure switch

(e.g. 30 - 50 psi). The constant pressure controller maintains

a constant pressure at the pressure switch/transducer up to

the maximum capability of the motor and pump. Although the

pressure is constant at the pressure switch or transducer,

pressure drops may be noticeable in other areas of the home

when additional taps are opened. This is due to limitations in

the plumbing and will be more pronounced the further the taps

are from the pressure switch/transducer. This would be true of

any system, and if observed, should not be interpreted as a

failure in the performance of the constant pressure controller.

Serious or fatal electrical shock may

result from contact with internal electrical components.

DO NOT, under any circumstances, attempt to modify

connections to the drive until power has been removed

and 10 minutes have passed for internal voltages to

discharge!

Flint & Walling © Copyright 2018. All rights reserved.

7

Underload Sensitivity

The controller is configured at the factory to ensure detection

of Underload faults in a wide variety of pumping applications

including dead head and run dry conditions. In very rare

cases (as with certain pumps in shallow wells) this trip level

may result in nuisance faults. If the pump is installed in a

shallow well, activate the controller and observe system

behavior. Once the controller begins to regulate pressure,

check operation at several flow rates to make sure the default

sensitivity does not induce nuisance Underload trips. If it

becomes necessary to desensitize the Underload trip level,

please call of Technical Support at 800-742-5044 for further

details.

UNDERLOAD INTELLIGENT RESET

(Display shows Dry Well Trip)

If a motor Underload fault condition occurs, the most likely

cause is an over-pumped well (dry well) or loss of incoming

feed water to the pump. In a dry well situation to allow

the well to recover, the controller will wait 30 seconds to 5

minutes, determined by the amount of time the motor had

been running before sensing the dry well, before restarting

the motor. For example, the first time the fault occurs and

the pump has been running 6 minutes, the controller stop the

motor and will wait 30 seconds before attempting to restart

the pump. If the system would then run for 2 minutes and an

dry well fault recurs, the controller will wait 3 minutes before

attempting to restart the pump. This schedule allows for the

minimum off-time possible based on the recovery time of the

well.

If there is an obstruction (such as a closed valve) between

the pump and the pressure switch/transducer, the controller

will also sense an underload deadhead condition stopping the

motor to avoid damaging the pump.

0

1

2

3

4

5

6

0 1 2 3 4 5 6 7 8

IL1448

Run T ime (Minut es)

O Time (Minutes)

“Intelligent Reset” Recovery Time

Over Temperature Protection

The controller is designed for full power operation in ambient

temperatures to up to 125°F (50°C) as long as the input

voltage is at 230V. Under severe thermal situations, the

controller will reduce power output by reducing the output

frequency in order to avoid shutting down. Full speed output

is restored when the temperature cools.

External alarm trip terminals

The control is fitted with an Alarm In terminal block on the

display board. Using these terminals, an external control

switch can be wired to the drive. With this connection, an

external control such as an over pressure, under pressure,

timer, low level switch, etc. can be used to trip the drive with

an “External Fault” trip. For this connection to work properly,

the Alarm in Relay contact condition setting in the Advanced

Features Menu must be set to match the switch position

to activate the drive. (Example: An irrigation timer closes a

contact to single the drive to run, the Alarm In Relay setting

should be set to NC (Normal Closed) for the drive to be active

during the irrigation cycle.)

This connection can also be used with the “External Control”

feature in the advanced options menu to put the drive in

standby rather than causing an external fault trip.

Caution: The external control must be a dry contact

(i.e. no voltage applied to the Alarm In terminals of the

controller) to not damage the drive circuit boards. An

external control with voltage can only be used with the

controller if an isolation relay is used in conjunction with

the voltage source. Contact technical support for more

information.

Leaky Systems (Pressure Switch Control)

Leaky water systems might keep the controller running due

to the accurate pressure sensing capability of the pressure

switch. Continuous running or starts and stops do not hurt

the controller, pump or motor. However, to reduce the on-time

of the controller/pump/motor, a “Bump-Mode” has been

programmed into the drive. During very low flow (or leaky)

conditions this feature periodically increases the speed of the

pump several PSI above the set point and shuts off the pump.

This adds some time to bleed off before the system starts

up again. This “Bump-Mode” can be turned off or adjusted if

desired. Please call Technical Support at 800-742-5044 for

further details.

Fill Pipe Mode (Transducer Control)

At initial power up, the drive is automatically in the Fill Pipe

Mode for 3 minutes. This allows a new installed system to

fill the pip and build up pressure without having the pump

trip out because it is sensing low pressure. If additional time

is needed, this mode can be turned back on and the time

increased in Parameter menu #7.

Use of Engine Drive Generators

There are several technical issues that go into correct sizing

of a generator for use with a VFD controller. Since the VFD

is a “non-linear load”, the generator needs to be oversized

considerably for proper operation. Listed below is minimum

recommended sizing of a generator for each drive rating if the

VFD controller is the only load on the generator. Because of

the variation in design of voltage controls used in generators,

the generator manufacture should always be contacted to

verify the correct sizing when used with a VFD controller.

For best results when used with a generator in the Advanced

Features Menu the Powered by Generator option needs to

be set to “Yes”.

Flint & Walling © Copyright 2018. All rights reserved.

8

VFD Minimum Generator rating

VS/TVS15 4.8kW

VS/TVS20 8.0kW

VS/TVS30 10.0kW

TVS50 15.7 KW

Note: If additional loads are being supplied by the generator,

the generator manufacture should be contacted for correct

sizing. When the controller is being supplied power by a

generator the Powered by Generator option should be set

to YES in the advanced features menu to minimize possible

damage to the drive.

Drive Configuration

When sized correctly, the drive controller package systems

are fully programmed and are ready to go right out of the box

without need for additional configuration. There are several

parameters that can be changed:

Figure 9 Display and Keypad

Capacitors inside the drive controller

can still hold a lethal voltage even after power has been

removed. Allow 10 minutes for dangerous internal voltage

to discharge before making changes to input power or

motor connections.

By pressing and holding the EDIT & ENTER buttons down

together for 5 seconds, you enter into the program menu.

Using the UP & DOWN buttons, you can scroll through the

menus and view the current settings. To make a change to

a parameter press the EDIT button followed by the UP and

DOWN buttons to set or choose the new value. Once the

new values is set, press the ENTER button to accept the new

value or the ESCAPE button to discard the change. Once

you are done viewing and changing the parameters press

ESCAPE to return to the home screen.

For further information to change these parameters, please

call Technical Support at 800-742-5044.

KEY:

APPLIES ONLY TO TRANSDUCER

APPLIES ONLY TO PRESSURE SWITCH

APPLIES TO EITHER OPTION

(1) Control Choice Switch or Transducer At initial power-up, the drive will detect what control devise is

attached and will automatically set the control choice. If a switch or

transducer is not hooked up, the drive will default to Switch as it's

control choice.

Set Transducer Range

(Only for Transducer

Control)

50-300 PSI

Default 100 PSI

Programs the drive to the range of the pressure transducer that is

attached. (Drive ships with 100PSI transducer.)

Set Pressure Set Point

(Only for Transducer

Control)

15 - (Max Transducer range - 5)

Default 50

Target system pressure.

Set Draw Down PSI

(Only for Transducer

Control)

2-15 PSI

Default 5 PSI

Sets the amount that the system pressure has to drop below the set

point while the drive is in standby before the drive will restart the

motor.

Access menu options by pressing and holding edit and enter for 3 seconds.

Menu Option Action Notes

Flint & Walling © Copyright 2018. All rights reserved.

9

(2) Maximum motor current Set Max Motor Amps.

Default 1.5Hp Drive = 5.9 A

Default 2.0Hp Drive = 8.1 A

Default 3.0Hp Drive = 10.9 A

Protects the pump motor assembly from operating beyond its

maximum capability.

(3) Maximum frequency Options 60, 70, 80 Hz.

Default 80 Hz.

Setting frequency determines the maximum motor speed. For

matched HP rating of motor & pump end, set to 60 Hz. For pump

end of half the HP rating of the motor (i.e. 3/4HP pump & 1.5 HP

motor), set to 80 Hz.

(4) Pass code enable (Y/N) Sets 5 digit pass code using Up/

Down keys.

Default No.

Pass code restricts parameters being changed by non-authorized

individuals. If pass code lost, Call 1-800-345-9422 for assistance.

(5) Underload protection (On, Off, Prime) Turns underload

protection on, off, or off for 30 minutes.

Default ON.

Recommend that this is left On. Provides pump protection from

deadhead or dry well conditions. May need to be Off/Prime when

priming a centrifugal or if filling irrigation system.

Set Deadhead trip point: Default 1.5Hp Drive = 5.0 A

Default 2.0Hp Drive = 6.4 A

Default 3.0Hp Drive = 8.2 A

If the motor current falls below this set point when drive has ramped

to maximum frequency, the drive will trip on Deadhead Fault. Adjust

down in increments of .2 if experiencing nuisance deadhead trip.

Set Dry well trip point: Default 1.5Hp Drive = 3.9 A

Default 2.0Hp Drive = 5.3 A

Default 3.0Hp Drive = 6.5 A

If the motor current falls below this set point when drive has ramped

to maximum frequency, the drive will trip on Dry Well Fault. Adjust

down in increments of .2 if experiencing nuisance dry well trip.

Set Dry well off time: Off, 15 to 240 Min, 12 Hrs, or 24 Hrs.

Default Off.

If set to "Off", dry well time is variable by Intelligent reset. This can be

set to fixed time off before restarting in a range of 15 to 240 minutes

in increments of 15 minutes, or 12 or 24 hours if desired.

(6) Bump mode

(Switch Control Mode)

(On, Off) Leak detection.

Default On.

Turns On or Off a small pressure boost if the drive detects a very

low load (leak condition). This will reduce the run time of the

pump and drive.

Set bump mode

frequency:

Sets bump mode threshold frequency.

Default 45 Hz.

When the drive is running for 15 seconds below this frequency.

and current is below the BM current, the drive will ramp up

for the BM duration regardless of switch state to create an

overpressure drawdown.

Set bump mode duration: Sets the time duration of the ramp up

for a bump in PSI (.5 to 2.0 sec.)

Default 0.5 sec.

By increasing this duration time, the amount of overpressure

for drawdown can be increased. Caution: Increasing this time

too much has the potential of creating a high over pressure

condition.

Set bump mode current: Sets bump mode threshold detection

current.

Default 1.5Hp Drive = 3.1 A

Default 2.0Hp Drive = 4.7 A

Default 3.0Hp Drive = 6.1 A

When the drive is running for 15 seconds below this current and

the frequency is below the BM frequency, the drive will ramp

up for the BM duration regardless of switch state to create an

overpressure drawdown.

(6) Standby Sensitivity

(Transducer Control Mode)

Parameters for allowing the drive go into

standby mode at no/low flow.

Set Standby frequency: Sets Standby threshold frequency.

Default 45 Hz.

When the drive is running for 15 seconds below this frequency. and

current is below the standby current, the drive will begin ramping the

motor speed down and monitor system pressure to go into standby

mode.

Set Standby Drawdown: Sets the amount the system pressure

can fluctuate after low load is sensed

and still go into standby mode(.5 to 2.0

PSI)

Default 0.5 PSI

By increasing this duration time, the amount of overpressure for

drawdown can be increased. Caution: Increasing this time too much

has the potential of creating a high over pressure condition.

Set Standby current: Sets Standby threshold detection

current.

Default 1.5Hp Drive = 3.1 A

Default 2.0Hp Drive = 4.7 A

Default 3.0Hp Drive = 6.1 A

When the drive is running for 15 seconds below this current and

frequency is below the standby current, the drive will begin ramping

the motor speed down and monitor system pressure to go into

standby mode.

Set Standby rate: Sets Standby deceleration rate (5-35)

Default 15.

This is the rate that the drive begins slowing down the motor to enter

standby mode.

(7) Broken pipe mode (On/Off).

Default ON.

Turn On/Off broken pipe trip. When On, if the drive is running the

PMA continuously for the set time period, the drive will trip out on

"Broken Pipe".

Set broken pipe run time: (1, 8, 16, 24, 48) Hours

Default 24 Hours.

Define the time that the drive can run continuously before tripping on

Broke Pipe.

Access menu options by pressing and holding edit and enter for 3 seconds.

Menu Option Action Notes

Flint & Walling © Copyright 2018. All rights reserved.

10

(8) Advanced features

Drive parameters View the current output Hz, Amps & heat

sink temperature.

Used for diagnostic purposes in troubleshooting overheating drive.

Motor Type (Submersible/Above Ground) Change

setting for the type of pump motor

This option in used to change the setting for the type of pump motor

the control was set to use during the initial set-up menu.

Manual run pump mode (Off/On) Sets pump to run without

pressure switch.

Default OFF

Turn on a manual run condition at a set frequency for a defined

amount of time.

Set manual pump

frequency:

(50, 60, 70, 80 Hz)

Default 60 Hz.

Set the constant frequency (motor speed) of the Pump. (only required

if manual mode ON)

Set manual pump run time: (1/2, 1, 4, 8, 16, 24, 48, Cont.) - Hours)

Default 24 Hours.

Sets the time that the drive will run before shutting itself off. If set

for Cont. (typically not recommended), the drive will run continuously

until it is stopped manually. Broken pipe mode is not active when

manual run is on. (only required if manual mode ON)

External control mode (Off/On).

Default OFF.

Determines if the Alarm In contacts trips out the drive or just puts it in

Standby Mode. If Off and the contacts wired to the Alarm In terminal

blocks are inverse of the Alarm in Rely settings, the drive trips out on

External Trip. (Used for protection like over pressure.) If On and the

contacts wired to the Alarm In terminal blocks close, the drive goes to

Standby Mode. (Used for control like a timer contact for an irrigation

system.)

Alarm In Relay (NO/NC) Sets alarm in contact settings.

Default NO.

If set to normally Open, drive will operate normally when the contacts

are open & trip (or go to standby mode) when contacts close.

(Example: An irrigation timer closes a contact to single the drive to

run, the Alarm In Relay setting should be set to NC (Normal Closed)

for the drive to be active during the irrigation cycle.)

Drive status relay (NO/NC) Sets alarm out relay as

normally open or normally closed.

Default NO.

The state of the relay changes when the drive trips. Typically not for

use in most residential applications.

Powered by Generator (No/Yes)

Default No.

Set the drive circuitry to expect power delivered from a gas driven

generator. Depending upon application a 5-10% pressure drop of can

be experienced when the drive is running the pump & motor at full

speed.

Ramp up sensitivity

(Switch Control Mode)

(1, 2, 3, 4, 5) Sets Ramp Up speeds.

Default 2.

If excessive pressure fluctuations on pressure gage is noticed, the

ramp rates can be adjusted.

Ramp down sensitivity

(Switch Control Mode)

(1, 2, 3, 4, 5) Sets Ramp Down speeds

Default 2.

If excessive pressure fluctuations on pressure gage is noticed, the

ramp rates can be adjusted.

Minimum Start-Up Time

(Switch Control Mode)

0.5-5 Seconds

Default 1.3

The minimum time the drive will ramp up when coming out of standby.

(9) Reset to factory defaults Resets drive to factory defaults Resets the drive to the initial start-up menu for drive set-up.

(10) Control Settings

(Transducer Control Mode)

Advance control settings for use with

Transducer.

Transducer Calibration Used to calibrate transducer reading with

external pressure gage.

Enter Pressure Gauge

Reading

20-80 PSI Adjust value to match the pressure reading of the external pressure

gauge & press enter.

PID Set Points Adjust Transducer feedback control

parameters.

By increasing this duration time, the amount of overpressure for

drawdown can be increased. Caution: Increasing this time too much

has the potential of creating a high over pressure condition.

Set PID Control P 100-5000 Default: 400 Adjustments can change the quickness of the drive reacting to

pressure changes to reduce excessive pressure fluctuations.

Set PID Control D 1000-10000 Default: 5000

Set PID Control D 10-150 Default: 150

Pipe Fill Mode

Set Pipe Fill Time: 1-15 Minutes

Default 3 min.

Sets the time limit that pipe fill mode is active.

Pipe Fill Mode (On, Off) Fill Pipe

Default: Off

Turns On/Off Fill Pipe mode. When Pipe Fill mode is on, the drive will

not trip out on Deadhead/Low PSI fault.

Access menu options by pressing and holding edit and enter for 3 seconds.

Menu Option Action Notes

Flint & Walling © Copyright 2018. All rights reserved.

11

SYSTEM TRIP CODE TROUBLESHOOTING

Should an application or system problem occur, built-in diagnostics will protect the system. The red “FAULT” light on the front

of the controller will flash and a fault condition will be shown on the display. In some cases, the system will shut itself off until

corrective action has been taken. Fault codes and the recommended corrective action for each are listed in the following

table. To view the trip codes in the recent trip log, press and hold the UP & DOWN keys at the same time for 1 second. The

log will show the last 20 trips as well as the time in days, hours & minutes since the trip occurred. (Note: the trip time will only

increment while the drive has power.) If no trips have been recorded, “No Fault” will be displayed in the log.

Fault Possible Causes Corrective Action

KEY:

APPLIES ONLY TO TRANSDUCER

APPLIES ONLY TO PRESSURE SWITCH

APPLIES TO EITHER OPTION

Short circuit

Shorted motor cables Check motor wires and drop cable for shorts or bad connections

Shorted motor Replace motor

Damaged wire insulation Check drop cable for insulation damage

Internal hardware short If motor is disconnected and the fault is present when reset, replace drive.

Locked Rotor Motor/pump misaligned Verify Pump is mounted flush on motor mounting flange.

Bound pump Check for debris n pump

Transducer Found

(Switch Control)

Drive set for Switch control, but a

transducer signal was detected.

Change drive control choice from Switch to Transducer in Control

Choice menu

Shorted Transducer

(Transducer Control)

Drive has detected a short circuit between

S1 & S2 terminals

Internal short of transducer. Replace transducer.

Switch is hooked up between S1 & S2 Replace switch with transducer.

Open Transducer

(Transducer Control)

Transducer lead not connected properly to

transducer (or cut)

Check transducer lead connection and/or replace transducer lead wire.

Loose connection on terminals S1 & S2 Check transducer lead connection at drive terminals S1 & S2

Transducer lead wire backwards at S1 & S2

terminals

Switch transducer leads at S1 & S2

Transducer failed as an open circuit Replace transducer

Deadhead

(Switch control)

Pump running against a closed discharge. Make sure that there is not a valve closed or obstruction

between the pump and pressure switch

Damaged or clogged pressure switch Check continuity across switch contacts without wire connected

and replace and/or clean pressure port.

Deadhead sensitivity incorrect Adjust deadhead sensitivity in Underload Protection menu

Deadhead

(Transducer Control)

Pump running against a closed discharge. Make sure that there is not a valve closed or obstruction

between the pump and pressure transducer

Deadhead sensitivity incorrect Adjust deadhead sensitivity in Underload Protection menu

Clogged pressure transducer Check transducer for pressure port and clean

Damaged or inoperative transducer Replace transducer

Low PSI

(Transducer Control)

Pipe has not filled Reset pipe fill mode in Menu #10 Control Settings and increase fill time if

necessary.

Valve closed between pump & transducer Open valve between pump & transducer.

Clogged Pressure transducer Check transducer for pressure port & clean

Damaged or inoperative transducer Replace transducer

Dry Well

Over pumped/dry well Wait for well to recover and automatic restart timer to time out

Blocked pump screen Clear pump screen

Broken pump shaft Replace pump shaft (or pump)

Worn pump Replace pump

Under Voltage Low line voltage Check line voltage Report low voltage to the power company

Power was removed from Drive Check voltage is present on all input lines & connections secure

(Color) Leg Open

Loose connection Check connections on drive motor terminals for leg specified

Defective splice Check all splice connections on drop cable for leg specified

Defective cable Check continuity of drop cable for leg specified

Open motor winding Replace motor

Overheated

Excessive heating of Drive Check that the ambient temperature is not above 125°F

Check for obstructed or inoperable fan

Check for blocked vents

Broken Pipe

Drive has been running without going into

standby mode for set time

Check for broken or leaking pipe and repair as necessary

Application calls for long run time Increase broken pipe run time in Advanced Feature menu

Turn off Broke Pipe protection in Advanced Feature menu

External Trip Contacts closed on "Alarm In" terminals Check condition of switch wired into "Alarm In" terminals

Flint & Walling © Copyright 2018. All rights reserved.

12

TVS/VS15 TVS/VS20 TVS/VS30 TVS50

Input from

Power

Source

(single

phase)

Voltage 180 -264 AC 180 -264 AC 180 -264 AC 180 -264 AC

Frequency 48 - 62 Hz 48 - 62 Hz 48 - 62 Hz 48 - 62 Hz

Current (max) 14.5 Amps RMS 1ø 19 Amps RMS 1ø 23 Amps RMS 1ø 36 Amps RMS 1ø

Power Factor 1.0 (constant) 1.0 (constant) 1.0 (constant) 1.0 (constant)

Output to

Motor (three-

phase)

Voltage Adjusts with Frequency Adjusts with Frequency Adjusts with Frequency Adjusts with Frequency

Frequency Range 30 - 80 Hz

Current Factory

Programmed

5.9 amps (RMS, each

phase)

8.1 amps (RMS, each

phase)

10.9 amps (RMS, each

phase)

18.0 amps (RMS, each

phase)

Current (max) 6.5 amps (RMS, each

phase)

8.5 amps (RMS, each

phase)

10.9 amps (RMS, each

phase)

18.0 amps (RMS, each

phase)

Pressure

Setting

Factory preset 50 PSI

Adjustment range 30 - 80 PSI switch / 15 - 95 PSI transducer

Operating

Conditions

Temperature (at 230

VAC input) -20° to 50°C (-4° to 125°F)

Relative Humidity Max 95% Non-condensing

Controller

Size

NEMA 3R (Indoor/

Outdoor) 17” H x 9.25” W x 5.25” D 19" H X 9.75" W X 5.25"

D

Weight 19 lbs. 25 lbs.

Minimum generator sizing 4.8kW 8.0kW 10.0kW 15.7kW

SYSTEM TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Water flow rate is not as

high as expected.

Motor/Pump is running backwards. Switch two of the three wires leading from the controller to the

3-phase motor.

Pump capacity cannot supply the demand. Use pump with higher flow rating (if head requirement is still

satisfied).

Temperature in the controller is too high. If the

controller’s heat exchanger becomes too hot,

the controller will reduce the output frequency

to the motor to lower the power consumption.

Make sure there is at least 4 inches of room around the controller for

movement of air. Avoid direct sunlight. Reduce ambient temperature

below 104°F (40°C). Increase input voltage if below 230 VAC.

Pump capacity cannot supply the demand. Use pump with higher flow rating (if head requirement is still

satisfied).

Excessive pressure

fluctuations.

Waterlogged tank. Check tank for bladder damage. Replace if necessary.

Reset the tank pre-charge pressure (should be 70% of pressure

switch/transducer setting).

Pressure tank is too small for flow rating of the

pump.

Use larger tank (4 gal. tank minimum).

Motor runs continuously

with no flow demand.

Leak in the household or outdoor plumbing. Check for leaky faucets, valves and/or pipe fittings and repair.

Leak in the pitless adapter. Re-seat the pitless adapter. Replace seal as needed.

Drive will not come out of

standby mode

Bad pressure switch Check continuity across pressure switch terminals and replace if

necessary

Loose pressure switch wire connection or

broken wire

Check pressure switch wire connections on display board and at

pressure switch. Check wire for continuity.

Drive is in switch control mode and transducer

is hooked up backwards.

Check to ensure transducer brown lead is connected to S1 and blue

lead is connected to S2 terminals. Change control mode from switch

to transducer.

DRIVE SPECIFICATIONS

This manual suits for next models

7

Table of contents

Popular Control System manuals by other brands

Magnetic Autocontrol

Magnetic Autocontrol MAGSTOP MIB 10-C090 operating instructions

HBX

HBX SNO-0600 installation manual

Penn

Penn P77 Series installation guide

Bosch

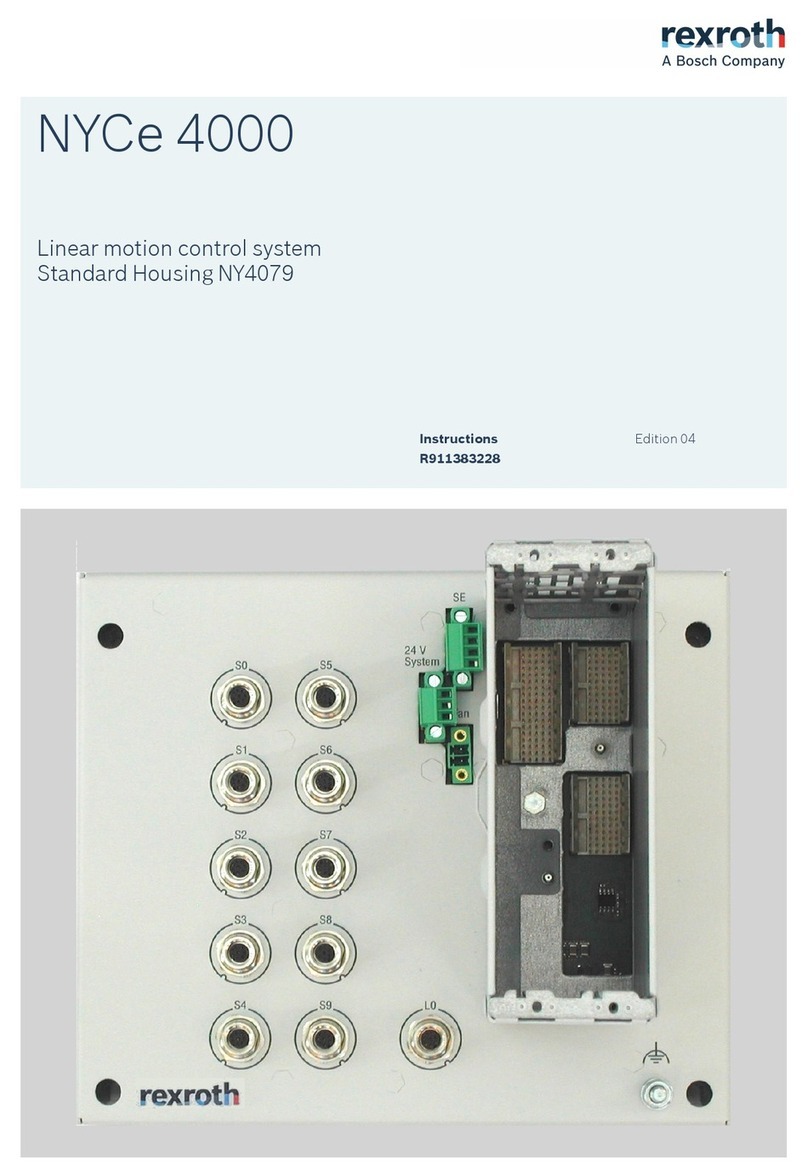

Bosch Rexroth NYCe 4000 manual

Linak

Linak JUMBO Home user manual

Chore-Time

Chore-Time FLEX-IR ST73000 Installation and operating instructions