3

INSTALLATION

FLUSH PANEL MOUNTING

1. Select location which is reasonably clean and dry, with adequate

access. Ambient limits 0 to 40°C.

2. Remove fascia cover (Fig.4) using the key supplied (Fig.2).

3. Rotate locking screws through a quarter turn and separate

controller sections (Fig.5).

4. Unplug ribbon cable by pressing outwards the side locking wings

(Fig.6). (If flush mounted, omit steps 5 to 8 and proceed to 9).

WALL MOUNTING (or Rear Panel Mounting)

5. Remove conduit cut-outs as required with a sharp knife. Screw

back section to wall (Fig.7). When trunking is used the controller

must be mounted using 32mm spacer bushes.

6. Connect wiring in accordance with appropriate scheme diagram.

Observe wiring precautions given in table on Page 8.

7. Move slide switch 'S' to correct position for the application (see

Commissioning, Fig.16).

8. Reassemble controller by plugging ribbon cable back into socket

on rear power board. Take care to align plug and socket the right

way round - DO NOT FORCE. Push controller case onto base

section, locating the two guide rods into the bushes and turn

screws to relock (Fig.8).

FLUSH PANEL MOUNTING

9. Move slide switch 'S' to correct position for the application (see

Commissioning, Fig.16).

10. Remove power board from the base section by undoing two front

screws 'A' (discard) and two rear screws 'B' which mount the

bushes (Fig.9).

11. Refit the two bushes into base section with screws 'B' (Fig.10).

12. Place the two hexagonal space bushes 'C' (supplied) over the

locking rods in front part of controller (Fig.11).

13. Carefully fold the ribbon cable as shown (Fig.12). Reposition the

power board over the ribbon cable (board points to rear when

assembled) using the two screws/washers 'D' supplied (Fig.13).

14. Fit controller into panel cut-out (138 x 138mm) and secure using

brackets/screws provided (Fig.14).

15. Wire up as step 6 and remove conduit cut-outs from base section,

see step 5.

16. Plug ribbon cable back into socket. Observe right way round - DO

NOT FORCE. Refit back of controller, locating the two bushes on

the guide rods and turn screws to relock (Fig.15).

Caution

Do not switch on mains power until commissioning checks 1 to 8

have been carried out.

COMMISSIONING

SYSTEM CHECK

1. Check that all equipment is correctly located and fitted.

2. Remove controller from back section (see Installation 2, 3 and 4).

3. Check all control circuit wiring.

a. Ensure there is no mains on low voltage (upper) terminals.

b. Check all wires are in accordance with scheme diagram or

diagrams on this leaflet.

c. Ensure all necessary links and resistors have been connected

or removed as instructed.

4. Check slide switch 'S' is in correct position for application.

5. Temporarily remove sensor wires and substitute a simulator. If not

available, connect a variable resistor, or switchable fixed resistors

of values approximately 2200 Ohms, 1800 Ohms and 1500 Ohms.

6. Rotate D.P.H. selector switch to fast run position 'T'.

7. Reassemble case, plugging in (ribbon cable) if unplugged.

8. Set Td to 20°C, Tn to 10°C, and override switch to Auto . If a

simulator is used, set this to 16°C. Otherwise select the 1800 Ohm

resistance to simulate this value.

9. Switch on power supply and set the clock as detailed in 'SETTING

THE CLOCK'.

10. Override time switch ON then OFF. See dialogue or digital clock

setting instructions for details.

11. Plant and R2 relays should now be 'Off'. (Neither LED illuminated).

12. Override time switch 'On'. After approximately 15 seconds the

'Plant' relay should energise and after a further 15 seconds relay

R2, when slide switch 'S' is in position 'A'. (Both LEDs illuminated).

13. This test simulates a 'Fast Run' optimum start period of 2 hours

speeded up to 30 seconds with a plant switch-on half way through

this period because the simulated inside temperature of 16°C is

half way between 12°C (max. preheat) and 20°C (zero preheat).

Boost is terminated when the relay R2 is energised at the end of

this period.

14. Override time switch to 'Off' position. Both plant and R2 relays

should de-energise. (Both LEDs off).

15. Set simulator above 20°C or select the 1500 Ohms resistance.

Relay R2 should energise ( LED illuminated).

16. Set simulator below 10°C or select the 2200 Ohm resistance. The

'Plant' relay should energise ( LED illuminated). This test is to

check frost protection.

17. Switch off power supply. Open case. Remove simulator or

resistances. Reconnect room sensor wires. Reassemble case.

Switch on power supply.

18. Set time switch and parameters as following section.

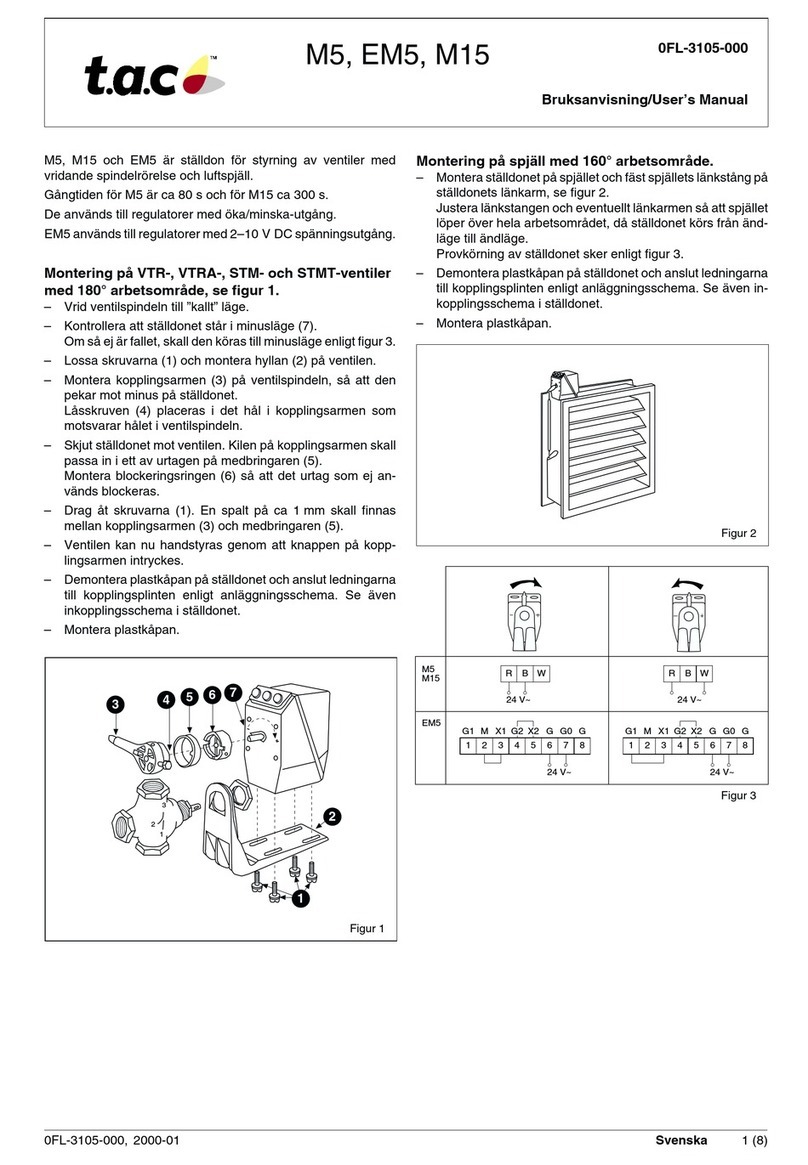

WALL MOUNTING

Position 'A' gives termination of boost on relay R2,

for use on applications involving day control from a

compensator or other Satchwell controllers (see

connection diagrams Fig.4 and Fig.5).

Position 'B' gives a single pole change-over output

from relay R2 for day control of pump/boiler and/or

motorised valve (see connection diagrams Fig.6,

Fig.7 and Fig.8).

Slide

switch 'S'

Fig.16

Slide switch 'S' on circuit

board inside front portion

of controller