heat-timer Multi-MOD Platinum User manual

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

STAGEHELP NEXT

PRESS TO

SELECT

BACK

SYS= 125oF OD= 31oF

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

4-20 mA

SYSTEM

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

TGT= 126oF

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Multi-MOD

Platinum

HT# 059299-00 A

HT# 059299-00 A

Content 2

Multi-MoD PlatinuM overview 3

Standard Features 3

Optional Features 4

MoDulation ConCePt 4

unDerstanDing oPeration ConCePt 5

Reset Ratio/Outdoor Reset 5

Space Feedback Concept 6

initial Pilot PrograM 7

Make Sure You Have the Right Control 7

Multi-MoD PlatinuM FunCtion Chart 8

Multi-MoD PlatinuM BaCk Chart 9

extension FunCtion Chart 10

extension BaCk Chart 11

installation 12

Mounting the Enclosure 12

Activate the Battery 12

Remote Communication Wiring 12

BACnet MSTP or Modbus RS485 Wiring 12

Internet or BACnet IP Ethernet Wiring 13

Input Wiring 17

Outdoor sensor 17

System Sensor 17

4-20mA Temperature Sensor Wiring 18

Setback Wiring 20

Interfacing to MPC 20

Interfacing to HWR 20

Connecting Multi-MOD Platinum to Extensions 21

External Set Point Wiring 22

Connecting Internet communication 22

Connecting BACnet Communication 22

Connecting MODBUS Communication 22

Network Sensors Wiring 22

Modulating Output Card Installation 23

DisPlay 23

Button FunCtions 23

DisPlay stage MoDulation status 24

Display Messages 24

systeM startuP Menu 25

systeM startuP 26

Sensor Type 26

Sensor Type Table 26

System Temperature Sensor Type 26

EMS Input Mode 27

Stage Interface 27

DHW Set Point 29

Sensor Fault 29

Fast Cool Down 30

Day Light Saving 30

systeM settings Menu 31

systeM settings 32

Season 32

Set Point 32

Outdoor Cutoff Temperature 32

Outdoor Reset Settings 32

Reset Ratio 33

Target Offset 33

Minimum Target 33

Maximum Target 34

System Run-On 34

stage MoDulation 36

Gain 36

Purge Delay 36

Lag Delay 37

Standby Time 37

Last-Stage-Hold 37

Soft-off Delay 37

Modulation Speed 38

Lead Stage Rotation 38

Lead Stage 38

Lead Auto Rotate 38

stage settings 39

Stage Menu 39

Moving Around the Stages Menus 39

Mode 39

Ignition % 40

Modulation Start 40

Copy Settings (Stage A Only) 41

sCheDules Menu 42

Schedules 42

Shift 42

Day/Night Schedule 43

Copy Schedule 44

Set Date and Time 44

Vacation Schedule Setting 44

CoMMuniCation Menu 45

Internet Communication 45

Space Lockout 45

Day and Night Target 46

Space Feedback Gain 46

BACnet Communication 46

Modbus Communication 46

MaintenanCe Menu 47

System and Outdoor Sensor Trim 47

Stage Output Trim 47

seCurity 48

Password Enabled 48

Password Change 48

reset Control to FaCtory DeFaults 48

trouBleshooting 49

sPeCiFiCations 51

Multi-MOD Platinum Specications 51

Extension Module Specications 51

wiring DiagraMs 52

warranty 58

HT# 059299-00 A

The Multi-MOD Platinum is a multi-boiler modulating control It uses PID logic in addition to overlapping

the lead and lag boiler modulation, its patent logic, to achieve a smooth modulation and efcient system

performance It is capable of modulating 4 on board boilers When used with extensions panels it can

connect to a total of 20 modulating boilers Up to two external extensions can be used, each connecting to

8 modulating boilers The Multi-MOD Platinum is used in a variety of applications including building heating

and process applications

The Multi-MOD Platinum can operate in heating or cooling applications

When connected to a temperature sensor and an outdoor sensor, the Multi-MOD Platinum

can change the target based on the outdoor temperature (Outdoor Reset) or it can

modulate the boilers to maintain a xed set point See "Sensor Type" on page 26

The Multi-MOD Platinum can operate in a temperature or pressure environment to

maintain a set point For high temperature applications it can connect to 4-20mA

temperature sensors See "Sensor Type" on page 26

It accurately modulate motors using any of the 0-5V, 0-10V, 1-5V, 2-10V, 4-20 mA, or

0-135Ω modulating signals It can also modulate a combination of boilers with different

modulating signals See "Output Type" on page 27

The Multi-MOD Platinum now has a built-in 7-day schedule Each day has 4 day and 4

night time settings See "Schedules" on page 42

The Multi-MOD Platinum can accept setback input from external controls to lower the

target Set Point See "Setback Wiring" on page 20 and "Setback" on page 35

The Boost raises the building space temperature to day levels quicker It does that by

raising the target water temperature before the rst day schedule See "Boost and Early

Shutdown" on page 34

This feature allows the user to temporarily switch the control from Night Time settings to

Day Time settings or visa versa See "Shift" on page 42

The outdoor sensor is used to turn all the outputs off whenever the outdoor temperature

rises above the outdoor Cutoff value See "Outdoor Cutoff Temperature" on page 32

The Multi-MOD Platinum operation can be turned off during off-season using the Season

setting See "Season" on page 32

The control has three modes of rotation: Manual, Last-On, or Automatic The Automatic

option rotates the stages based on time See "Lead Stage Rotation" on page 38

Use Normal (PID) logic for slow responding systems as in heating systems Use Process

in fast responding systems See "Modulating Mode" on page 28

Any stage can be set to be a standby boiler (backup boiler) A Standby boiler will only run

after the rest of the boilers reach full re and remain at it for the Standby Delay period

See "Standby Time" on page 37

This input checks for component status before activating any stage It can be used to

check the combustion air damper or ow switch status See "Prove Wiring" on page 19

This input turns off the heating from a remote location See "Shutdown Wiring" on page 18

This output can be used to activate a system pump, combustion air damper, or perform

any other function that is required before any stage is activated

The control offers multiple DHW Priority options See "Prove/DHW Mode" on page 28

The Multi-MOD Platinum can accept a remote 4-20 mA set point signal See "External

Set Point Wiring" on page 22

The Gain adjusts the aggressiveness of the modulation See "Gain" on page 36

This feature is used primarily to reduce boiler short cycling The Last Stage Hold

maintains the system on longer and off longer See "Last-Stage-Hold" on page 37

The Multi-MOD Platinum is equipped with a password that is used to stop unauthorized

user from changing any of the control settings See "Security" on page 48

HT# 059299-00 A

The Internet communication option gives remote access to the control from

any computer with a web browser The access is through Heat-Timer ICMS

web site Internet ready controls have the capability to connect to a large

number of network sensors These sensors can be space, temperature,

pressure, oil tank levels, and many more Furthermore, the Internet option

adds history graphing, export reports to e-mail, and alarming that is delivered

by e-mail, web, and text messaging See "Internet Communication" on page

45

The Multi-MOD Platinum can be upgraded to communicate over BACnet IP

or MSTP networks All Multi-MOD Platinum functions can be monitored from

a remote location See BACnet Communication Upgrade Manual

The Multi-MOD Platinum can be upgraded to communicate over Modbus

RTU networks All Multi-MOD Platinum functions can be monitored from a

remote location See Modbus Communication Upgrade Manual

When the Multi-MOD Platinum is equipped with Internet communication,

it can connect to a large number of wireless and wired space sensors It

uses the space average temperature to regulate the building heat for better

comfort control and fuel savings See "Space Feedback Concept" on page 6

The Multi-MOD Platinum modulates the boilers to achieve the smoothest operation and highest system

efciency It does that by overlapping the lead and lag boiler operation The concept depends on the

Ignition % and the Modulation Start %

20%

20%

Purge

60%

100%

20%

20%

100%

Boiler A Modulating

Boiler B Modulating

Purge

Boiler B

MODULATING CONCEPT

SETTINGS:

Ignition % = 20%

Modulation Start % = 60%

Lag boiler drop= 40% x 60% = 24%

Modulation Increasing

Boiler A

20% 100%

20%

20%

24%

20%

Lead Boiler A remain

at 20% until System

Sensor exceeds Target

Lag Boiler B remains

at Ignition % while Lead

Boiler A modulates down Decrease Modulation

Boiler A

Boiler B

When the control needs to start heating, it activates the System output In most cases, this output operates

a system pump or a combustion air damper Then, the control checks the safety components operation

status by checking the Prove input for closure If the Prove signal was shorted, the control starts the

lead boiler Purge Whenever a boiler is activated, it must rst go through the Purge period See "Purge

Delay" on page 36 During Purge the control sets the boiler modulation to the lowest ring rate set by the

Ignition % See "Ignition %" on page 40 After the Purge ends, the control starts to modulate the lead boiler

gradually Whenever, the lead boiler reaches its Modulation Start %, the control starts the lag boiler Purge

See "Modulation Start" on page 40 After the lead boiler reaches its full capacity, the lag boiler may start its

upward modulation This process repeats for each additional lag boiler or until the system is satised

HT# 059299-00 A

20%

20%

Purge

60%

100%

20%

20%

100%

Boiler A Modulating

Boiler B Modulating

Purge

Boiler B

MODULATING CONCEPT

SETTINGS:

Ignition % = 20%

Modulation Start % = 60%

Lag boiler drop= 40% x 60% = 24%

Modulation Increasing

Boiler A

20% 100%

20%

20%

24%

20%

Lead Boiler A remain

at 20% until System

Sensor exceeds Target

Lag Boiler B remains

at Ignition % while Lead

Boiler A modulates down Decrease Modulation

Boiler A

Boiler B

When the load is reduced, the control will gradually decrease the lag boiler's modulation until it reaches its

lowest ring % The lag boiler will remain at the Ignition % while the control is reducing the lead boiler's

modulation When the lead boiler reaches 40% of the Modulation Start %, the control turns off the lag

boiler

The Multi-MOD Platinum has multiple operating modes that

satisfy most hydronic or steam systems When used to control

a hydronic system, it can change the target Set Point based

on outdoor temperature (Outdoor Reset) or it can modulate its

stages to achieve a xed Set Point

In Outdoor Reset, the Multi-MOD Platinum controls a hot water

heating system to provide a building with comfortable and even

heat levels It varies the temperature of the circulating heating

water in response to changes in the outdoor temperature The

heating water temperature is controlled through the modulation of

the stages

The Multi-MOD Platinum also controls the system-circulating

pump with an adjustable Outdoor Cutoff When the outdoor

temperature is above Outdoor Cutoff, the pump is off and no

heating water is circulated through the system When the outdoor

temperature drops below the Outdoor Cutoff, the system pump

output is activated and the heating water circulates through the

system The temperature of the heating water is controlled by the

Reset Ratio, Offset, Minimum Target, Maximum Target, and the

outdoor temperature

Reset Ratio (Outdoor : Water)

70 60 50 40 2030 0 -1010 -20

100

120

110

130

140

150

160

180

170

190

200

210

220

Water Temperature (in °F)

Reset Ratio Curves

Outdoor Temperature (in °F)

1:1.25

1:1

1.25:1

1.5:1

2:1

3:1

4:1

1:4 1:3 1:2 1:1.5

When a building is being heated, heat escapes through the walls,

doors, and windows to the colder outside air The colder the

outside temperature, the more heat escapes If you can input

heat into the building at the same rate that it is lost out of the

building, then the building temperature will remain constant The

Reset Ratio is an adjustment that lets the building achieve this

equilibrium between heat input and heat loss Outdoor reset is

the most efcient way a building can be heated

HT# 059299-00 A

The starting reset ratio for most systems is the 100 (OD):100

(SYS) (Outdoor Temperature : Heating Water Temperature) ratio

This means that for every degree the outdoor temperature drops,

the temperature of the heating water will increase one degree

The starting point of the ratio is adjustable, but comes factory

set to 70°F Outdoor Temperature and 100°F Water Temperature

For example with a 100 (OD):100 (SYS) ratio, if the outdoor

temperature is 50°F, this means that the outdoor temperature has

fallen 20° from the starting point of 70°F Therefore, the heating

water temperature will increase 20° to 120°F (100°F + 20°F)

When controlling a none-condensing

boiler directly without the use of a

mixing valve, minimum boiler water

temperature must be set to boiler

manufacturer specifications In that

case, system temperature must not go

below such temperature

Each building has different heat loss characteristics A very well

insulated building will not lose much heat to the outside air, and

may need a Reset Ratio of 200 (OD):100 (SYS) (Outdoor :

Water) This means that the outdoor temperature would have

to drop 2° to increase the water temperature 1 degree On the

other hand, a poorly insulated building with insufcient radiation

may need a Reset Ratio of 100 (OD):200 (SYS) This means

that for each degree the outdoor temperature drops the water

temperature will increase 2° The Multi-MOD Platinum has

a full range of Reset Ratios to match any buildings heat loss

characteristics

A heating curve that relies not only on Outdoor temperature but

also on type of radiation will improve the comfort See the Building

Suggested Settings table for different types of radiation based on

an average building insulation and heat loss The contractor can

ne-tune these settings to the specic building need

Radiators (Steel & Cast

Iron) 100 : 100 0˚F

Baseboard (Finned copper

tube& Cast Iron) 100 : 100 0˚F

Radiant (High Mass/

Concrete) 400 : 100 -10˚F

Radiant (Low Mass/Joists) 200 : 100 -10˚F

Fan Coils & Air Handlers 100 : 100 20˚F

A Multi-MOD Platinum control that is equipped with Internet

communication is capable of using Heat-Timer space sensors to

ne-tune its outdoor reset operation while providing signicant

savings The Multi-MOD Platinum adjusts the target water

temperature based on the Space Feedback Gain and the

difference between the current Space Average and the Space

target Example: Using a Space Feedback Gain of 4, if the

Space Average is 70°F and the day target is set to 72°F, the

control will add 4° to the System Target temperature for every 1°

(ambient temperature) the Space Average is below the Space

Target In this example, it would add 8° to the target water

temperature to compensate for the 2° reduction in the Space

Average See "Space Feedback Gain" on page 47

If the Space temperature exceeded the Space Target by 2°

while the target water temperature is at the Minimum Target

temperature for an hour, the control will turn the boilers off until

the Space Average drops below the Space Target

HT# 059299-00 A

Setting an Initial Pilot Program eases the installation and conguration of the Multi-MOD Platinum and gives

the opportunity to use many of the energy saving features while providing comfort

The program should consist of the following:

• Select the features that your system can utilize,

• Making sure you are ordering the right control and accessories (Multi-MOD Platinums do not come with

sensors or stage relays, these items must be ordered separately,

• Install and wire the Control,

• Set the System Startup menu,

• Set the System Settings,

• Set the Stages and their rotation,

• Set the Schedules

• Adjust the Reset Ratio and Water Offset (In Reset Mode Only) or set the Set Point,

The following are for communication equipped controls only:

• If the control had communication, connect and install the communication,

• If the control had Internet communication, install and wire the sensors

If you need the Multi-MOD Platinum to do additional tasks that either is not listed or do not know

how to congure them, contact Heat-Timer Corp Sales Department either by Phone (973)575-4004,

E-mail to: support@heat-timercom, or using the web contact form http://wwwheat-timercom

HT# 059299-00 A

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

STAGEHELP NEXT

PRESS TO

SELECT

BACK

SYS= 125oF OD= 31oF

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

4-20 mA

SYSTEM

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

TGT= 126oF

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

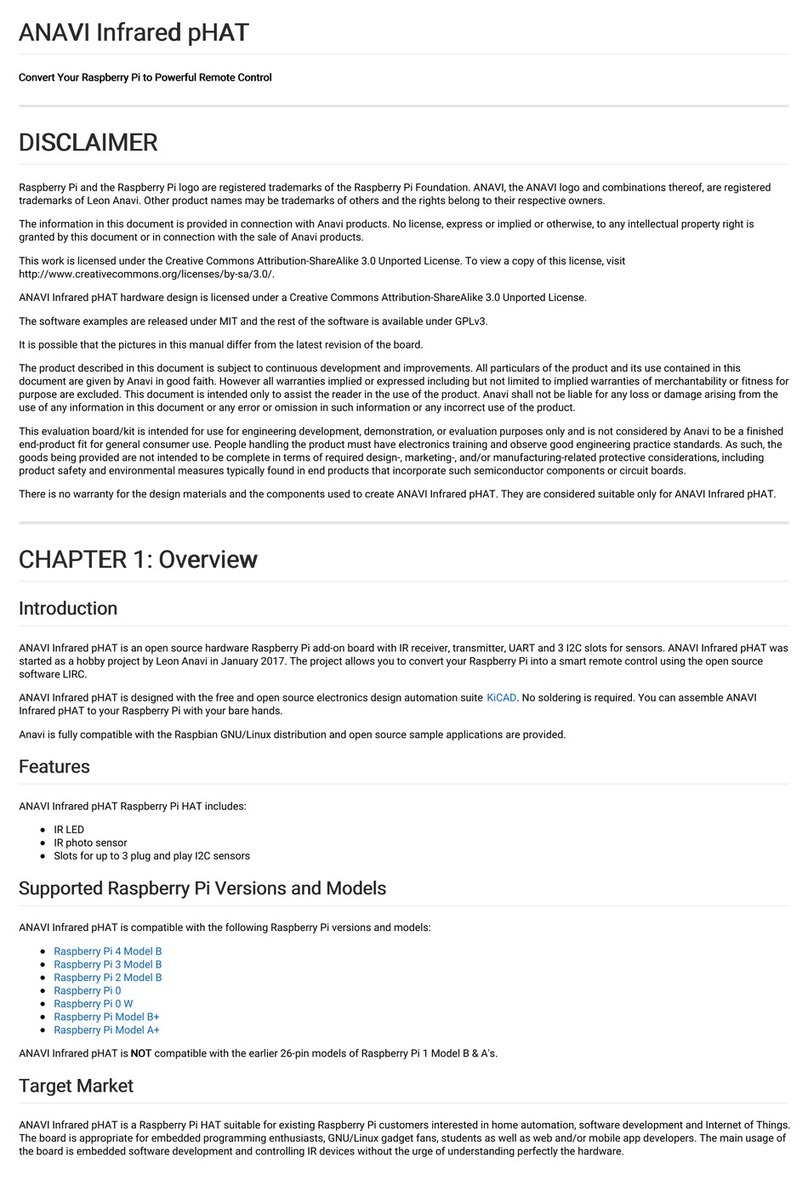

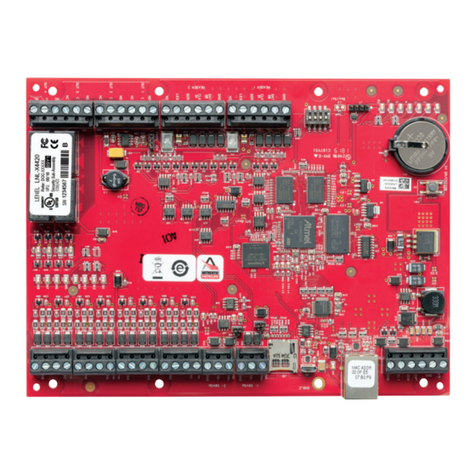

Green Ground screw

must be connected

to Earth Ground

120VAC

Power

System Output controls

pumps, dampers, valves or

other system components.

Each output is wired in series

with each unit’s limit circuit.

The modulation outputs can be

voltage (0-5V, 0-10V, 1-5V, 2-10V,

4-20ma, or 135Ω). Different output boards

mount on the back of the Multi-MOD

to determine the output type.

If a unit is in Lockout,

the MultiMOD will not

consider it an active

To System Temp sensor

mounted in common header

4-20mA power sourcing

input for pressure and

temperature sensors

When closed, all heat

outputs are turned off*

To Heat-Timer network

sensors (Not MSI)**

* DRY CONTACTS ONLY

** Only available with the Remote Communications package

Checks status of system

components or DHW Call*

Depress the knob to go to menu and

accept changes. Rotate the knob to

scroll and change settings.

Depress the button to view the date and

time or to go back through the menus

The digital display shows the system status,

set point, lead stage <in brackets>, and

status of each stage.

To Outdoor sensor

Provides remote set

point adjustment with

a 4-20mA signal or

provides a setback

function

LEDs indiate each

output relay status

Button functions vary

Each active stage must

have a relay installed.

Relays must be

ordered separately

(HT# 500054-00)

HT# 059299-00 A

N

5V

8V

CPU Board

Battery

Ethernet

RS485

Main Board

Control Stages

A & B

Control Stages

C & D

A1

G1

B1

A2

G2

B2

RS485

Communication Board

(HT# 900234-20-XXX)

Fuse

Battery

HT#020002-00

Ethernet (RJ45) connects to:

• Internet

• BACnet IP Green RS485 connects to:

• MSI HUB interface

RS485 connects to

Extensions only.

Cables are provided with

Extension

Modulating Output Cards:

• 135Ω Output Card (HT# 900203-135)

• Current and Volt Output Cards

(HT# 900203-C/V)

Black RS485 connects to:

• BACnet MSTP

• Modbus RTU

• Network Manager

HT# 059299-00 A

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

LOCKOUT

INPUTS

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

E F G H I J K L

MODUALTION OUTPUTS MODUALTION OUTPUTS

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12 C13 C14 C15 C16 C17 C18 C19 C20 C21 C22 C23 C24

- + +

- + +

- + +

- + +

MADE IN U.S.A.

SAFETY

GROUND

MUST BE

CONNECTED

EXTENSION

MODULE

C O R P O R A T I O N

R

POWER COMMUNICATION

STAGE

ACTIVE

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

Lockout

Lockout

E

F

G

H

I

J

K

L

E

F

G

H

I

J

K

L

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

LINE

NEUTRAL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Serial No.:

OPERATING

LIMIT OUTPUTS

E

F

G

H

I

J

K

L

Relay

Outputs*

* DRY CONTACT ONLY

Communication LED

Blinks on good

communication

Power LED

will be ON

Green Earth

Ground screw

120VAC

Power

Burner Modulating

Outputs. Not used

with the HWRQ

Lockout

Inputs *

Stage LED is O

when relay is

energized

HT# 059299-00 A

1 2 3 4 5 6 7 8

On

Control Stages

1 & 2

Control Stages

3 & 4

Control Stages

5 & 6

Control Stages

7 & 8

Modulating Output Cards:

• 135Ω Output Card (HT# 900203-135)

• Current and Volt Output Cards

(HT# 900203-C/V)

Fuse

RS485 connects to

(MMOD, HWRQ, or

MPCQ Platinum)

Dip Switches

determine Extension

number

EXT1 Dip1=ON, DIP2=ON

EXT2 Dip1=OFF, DIP2=ON

HT# 059299-00 A

• Select a location near the equipment to be

controlled

• The surface should be at, sufciently wide, and

strong enough to hold the Multi-MOD

• Installation location should be away from extreme

heat, cold, or humidity

• Remove the control from its enclosure by removing

the top center screw and loosening the two bottom

screws

• Screw the enclosure to the surface through the

mounting holes in the back of the enclosure

• Return the panel to the enclosure Replace the top

screw and tighten the bottom two screws

Use existing the Enclosure Knockouts

DRILLING HOLES THROUGH THE CONTROL

ENCLOSURE VOIDS CONTROL WARRANTY

Mounting Holes

Communication

Knockout

Wiring

Knockouts

Enclosure

Lock

• Turn the Multi-MOD Platinum panel over to reveal the

piggyback circuit board (CPU board)

• Remove the plastic strap the covers the battery The contacts

should be touching the battery

Do not install the battery unless you plan to power the control at once

If the control is not powered, the battery will lose its charge in 100 days

N

5V

8V

CPU Board

Battery

Ethernet

RS485

Main Board

Control Stages

A & B

Control Stages

C & D

A1

G1

B1

A2

G2

B2

RS485

Communication Board

(HT# 900234-20-XXX)

• If a control is ordered as a standard control, it can be eld

upgraded to have communication by adding the appropriate

upgrade kit A new CPU board and a communication board will

be included in any of the Upgrade Kits

Multi-MOD Internet Upgrade Kit 900204-20-RINet

Multi-MOD BACnet IP or MSTP Upgrade Kit 900204-20-BAC

Multi-MOD Modbus Upgrade Kit 900204-20-BUS

• All Communication to Modbus RTU or BACnet MSTP must use

the RS485 on the control's Communication Board

N

5V

8V

CPU Board

Battery

Ethernet

RS485

Main Board

Control Stages

A & B

Control Stages

C & D

A1

G1

B1

A2

G2

B2

RS485

Communication Board

(HT# 900234-20-XXX)

Connect to BACnet MSTP Network

or MODBUS RTU Network

RS485 Cable

HT# 059299-00 A

• The RS485 cable length must not exceed 3500 feet

• The RS485 cable must use one of the Platinum control’s

enclosure side knockouts Do not use bottom knockouts for

communication cabling

• Connect the RS485 cable coming from the BACnet MSTP or

Modbus network to the Black RS485 communication socket on

the back of the control’s Communication Board The terminals

are labeled ‘A1 (+)’, G1 (Ground), and ‘B1 (-)’

The RS485 Ground terminal (G) MUST be

connected to the BMS RS485 Ground

• The Ethernet cable must use one of the Platinum control’s

enclosure side knockouts Do not use bottom knockouts for

communication cabling

• For reliable communication, the maximum Ethernet cable run

must not exceed 200'

• Use only CAT-5E Ethernet cable or better when connecting

from the Internet Modem, router or the IP network to the

Ethernet RJ45 communication socket on the back of the

control’s Communication Board

Class 1 voltage wiring (low voltage) must use a different knockout

and conduit from any Class 2 voltage wiring (high voltage)

N

5V

8V

CPU Board

Battery

Ethernet

RS485

Main Board

Control Stages

A & B

Control Stages

C & D

A1

G1

B1

A2

G2

B2

RS485

Communication Board

(HT# 900234-20-XXX)

Connect to BACnet IP Network

or the Internet

CAT5-E Cable

• Bring the 120VAC power wires through the enclosure's bottom knockouts

• Connect the hot line to the Line terminal (1) and connect the neutral line to

the Neutral terminal (2) Connect the green screw to Earth Ground

• Heat-Timer recommends the installation of a surge suppressor and a

power switch before the power line connection

• Use a separate circuit breaker for the control Do not share the control power

with other major equipment, pumps and motors

• Output relays do not source any power A separate power source must be

used Use the output relay to enable or disable the equipment

• Output relays do not source any power If the equipment connected to an

output relay requires power, an external power source must be used

• To use an output, you must install a relay Relays must be ordered

separately (HT# 500054-00)

• Each output relay on the Multi-MOD is rated for 1 Amp (1/8 HP) at 120

VAC 60 Hz If higher relay rating is required, connect the equipment to an

external relay Use the Multi-MOD output relay to control the external relay

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2

3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

L

N

Earth

Ground

120VAC

HT# 059299-00 A

• The System output can be used to activate a pump, a pump starter, a

combustion air damper, or other equipment

• The Multi-MOD Platinum activates the System output whenever there is a

call for any of the stages The System output remains energized whenever

a stage is active

• The System output does not source any power A separate power source

is required for the equipment

• The System relay comes pre-installed

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM

B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3 4 5

6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

System Pump

L

N

120VAC

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

System Pump

L

N

120VAC

• If an outdoor sensor was used, the System output will remain active after

all the stages are turned off for as long as the outdoor temperature is below

the outdoor Cutoff See "Outdoor Cutoff Temperature" on page 32 If the

outdoor temperature rises 2° above the outdoor Cutoff, the System output

de-activates after it runs for the full Run-On period See "System Run-On"

on page 34

• If no outdoor sensor was used and after the last stage turns off, the System

output runs for the Run-On period before turning off

• The System output activated whenever the outdoor temperature drops

below the outdoor Cutoff

• When the outdoor temperature rises 2°F above the Outdoor Cutoff, the

System output will remain active for the Run-On, then turn off

• The Multi-MOD Platinum is designed to operate up to four boilers without

the addition of Extensions modules The Multi-MOD Platinum can connect

to a maximum of two Extension modules maximizing the number of stages

controlled to 20 Each Extension module can connect to a maximum of

eight stages

• Each of the Multi-MOD Platinum or extension stages has an activation

output in addition to the modulation output Each of the stage outputs has

an LED to show its status

• Some modulating boilers may require an activation signal The stage

activation output is used to provide this signal To use the stage activation

output, you must install a relay in the stage relay socket Relays must be

ordered separately (HT# 500054-00)

• Each output relay on the Multi-MOD is rated for 1 Amp at 120 VAC 60 Hz

• Wire the stage activation signal in series with the boiler limits

For proper operation set the Mode of any

unused stage to Off See "Mode" on page 39

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM

B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3 4

5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Boiler1

Ativation Boiler3

Ativation

Boiler2

Ativation Boiler4

Ativation

Boiler

Activation

HT# 059299-00 A

• To have the Multi-MOD Platinum operate the boilers and their pumps, use

SPDT relays (Single-Pole Double-Throw) and TDR relays (Time-Delay

relay)

• The SPDT relay sends the activation signal from the Multi-MOD Platinum

stage activation output to the boiler Interlock (TT) and its pump

• The TDR relay receives the SPDT pump activation signal and send it to the

pump When the SPDT relay signal ends, the TDR keeps the pump running

for an additional period This additional delay acts as the Run-On delay

available for the System output See "System Run-On" on page 34

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3

45 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

SPDT

Relay 1

Boiler

Activation

Boiler1 Pump1

TDR

Relay 1

L N

120VAC

SPDT

Relay 2

Boiler2 Pump2

TDR

Relay 2

L N

120VAC

• The Multi-MOD Platinum can operate up to four 135 Ω modulating motors

(Multi-MOD ordered with 135-Ohm Output cards) Each 135 Ohm Output

card operates two stages See "Modulating Output Card Installation" on

page 23

• Terminals C1, C4, C7, and C10 on the Multi-MOD Platinum connects to the

modulation decreasing terminals on the burners (Blue/Black modulating

wires)

• Terminals C3, C6, C9, and C12 on the Multi-MOD Platinum connects to the

modulation increasing on the burners (White modulating wires)

• Terminals C2, C5, C8, and C11 on the Multi-MOD Platinum connects to the

modulation common terminals on the burners (Red modulating wires)

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Boiler1

135Ω

Signal

B R W

Boiler2

135Ω

Signal

B R W

Boiler4

135Ω

Signal

B R W

Boiler3

135Ω

Signal

B R W

Boiler 135Ω

Modulation Signal

B R W R W R W R WB B B

• The Multi-MOD Platinum can operate up to four 4-20 mA modulating

motors (Multi-MOD ordered with C/V (Current/Voltage) output cards) See

"Modulating Output Card Installation" on page 23

• To program the control for 4-20 mA output, See "Output Type" on page 27

• Apply the supplied label marked Current/Voltage below the modulating

terminals

• The Multi-MOD sources 24VDC excitation voltage for the 4-20mA signal

HT# 059299-00 A

• Terminals C2, C5, C8, and C11 on the Multi-MOD Platinum must be

connected to the modulation Signal (+) terminals on the burners

• Terminals C1, C4, C7, and C10 on the Multi-MOD Platinum must be

connected to the modulation Common terminals on the burners

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Boiler1

4-20mA

Signal

+-

Boiler3

4-20mA

Signal

+-

Boiler2

4-20mA

Signal

+-

Boiler4

4-20mA

Signal

+-

Boiler 4-20mA

Modulation Signal

mA

Com mA

Com

mA

Com mA

Com

• The Multi-MOD Platinum can operate up to four voltage-modulating

motors (Multi-MOD ordered with C/V (Current Voltage) output cards) See

"Modulating Output Card Installation" on page 23

• The Multi-MOD Platinum can modulate any of the following voltage motors:

0-10V, 0-5V, 2-10BV, 1-5V See "Output Type" on page 27

• Apply the supplied label marked Current/Voltage below the modulating

terminals

• Terminals C1, C4, C7, and C10 on the Multi-MOD Platinum must be

connected to the modulation Ground terminals on the burners

• Terminals C3, C6, C9, and C12 on the Multi-MOD Platinum must be

connected to the modulation Voltage (V+) terminals on the burners

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Boiler1

Voltage

Signal

+-

Boiler Voltage

Modulation Signal

Boiler3

Voltage

Signal

+-

Boiler2

Voltage

Signal

+-

Boiler4

Voltage

Signal

+-

V+

GND V+

GND V+

GND V+

GND

• The Multi-MOD Platinum can communicate to and modulate burners

equipped with the Siemens® LMV The LMV communicates over Modbus

networks See "Stage Interface" on page 27

• The LMV Interface communicates the boiler modulation from

the Multi-MOD Platinum to the Siemens® LMV burner control In

addition, it sends the boiler lockout information from the LMV to the

Multi-MOD Platinum Each burner must be connected to a LMV Interface

The LMV Interface must be purchased separately (HT #926621-00) In

addition, an Interface Power Supply (HT #926622-00) must be purchased

for every 10 LMV Interfaces

• See LMV Interface Manual for information on conguring and wiring to the

Siemens® LMV equipped burners

HT# 059299-00 A

• An outdoor sensor must be used when selecting Reset °F or

Reset °C The sensor is used to calculate the system target In

addition it is used in the outdoor Cutoff See "Sensor Type" on

page 26 and "Outdoor Cutoff Temperature" on page 32

• If an outdoor sensor is installed in any of the set point options,

it will only be used in the outdoor Cutoff This feature will

automatically be activated when an outdoor sensor is connected

• Use only the Outdoor Sensor included with the unit

(HT# 904220-00)

• Locate the sensor on the north side of the building at least 10'

above the ground The sensor MUST never be in direct sunlight

• Be sure the location is away from doors, windows, exhaust fans,

vents, or other possible heat or cool sources

• Adhere the Outdoor Label to the back of the sensor base

• Use the Enclosure Base bottom knockout for the conduit Use

the locknut to hold the conduit and enclosure base together

Install and screw the cover to the base

• If screws are used to afx the enclosure to the wall, make sure to

seal around the sensor and wall except from the bottom

Class 1 voltage wiring (low voltage)

must use a different knockout and

conduit from any Class 2 voltage

wiring (high voltage)

To avoid damage to the Multi-MOD,

NO VOLTAGE can be applied to the

Multi-MOD Platinum input terminals

Outdoor Sensor

snap-in location

Shield

not connected

Conduit

Outdoor Label

on back of Sensor

Outdoor Sensor

Mounting

screws

location

Seal around

sensor and wall

Outdoor

drip-hole

Conduit

Well

Sensor

in well

• Connect the sensor wires to the Out Temp terminals

Temperature sensors have no polarity

• Connect the shield to terminal A12 with one of the other sensor

wires Do not connect the shield at the sensor end

• The sensor wires can be extended up to 500’ using 18 AWG

2-conductor shielded cable (HT# 703001-01)

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Shield Outdoor

Sensor

The Multi-MOD must be connected to a temperature or pressure

sensor The sensor connected must match the Sensor Type

selected in the Startup menu Sensors must be ordered separately

Outdoor Sensor

snap-in location

Shield

not connected

Conduit

Outdoor Label

on back of Sensor

Outdoor Sensor

Mounting

screws

location

Seal around

sensor and wall

Outdoor

drip-hole

Conduit

Well

Sensor

in well

• The Multi-MOD Platinum is designed to connect to a Heat-Timer

temperature sensor (HT# 904250-00) The sensor must be

inserted into a 3/8ID well (HT# 904011-00)

• Locate the sensor in the common header where it will register the

output before any takeoffs If the sensor cannot read the output

of all the stages, it will not be able to control the system properly

HT# 059299-00 A

• Attach the sensor wires to the Out Temp terminals (A11 and A12)

Temperature sensors have no polarity

• Connect the shield to terminal A12 with one of the other sensor

wires Do not connect the shield at the sensor end

• The sensor wires can be extended up to 500’ using shielded

2-conductor cable (#18/2)

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Shield System

Temperature

Sensor

TGT= 126oF

SYS= 125oF OD= 31oF

• The Multi-MOD Platinum can connect to a 4-20mA temperature

sensor (HT# 904160-00) See "Sensor Type" on page 26

• Locate the temperature sensor on the main supply header where

it will register the output of all the stages If the sensor cannot

read the output of all the stages, the Multi-MOD Platinum will not

be able to control the stages properly

• 4-20mA Temperature Sensor wires can be extended up to 500' by

splicing with 18 gauge twisted pair wire

• Connect the sensor's Blue wire to terminal PRESS - A5 (S)

• Connect the sensor's Brown wire to terminal PRESS - A6 (+)

• Cut the rest of the transducer wires and tubes

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

TGT= 5 PSI

SYS= 4 PSI OD= 31oF

Brown (+)

Blue (-)

• The Multi-MOD Platinum is designed to connect to a pressure

transducer See "Sensor Type" on page 26

• Locate the transducer on the main supply header where it will

register the output of all the stages If the transducer cannot read

the output of all the stages, the Multi-MOD Platinum will not be

able to control the stages properly

• Attach the transducer to the steam header using a ¼" isolation

tube (pigtail) (HT# 135020-00)

• Pressure transducer wires can be extended up to 500' by splicing

with 18 gauge twisted pair wire

• Connect the Black wire from the pressure transducer to terminal

PRESS - A5 (S)

• Connect the Red wire from the pressure transducer to terminal

PRESS - A6 (+)

• Cut the rest of the transducer wires and tubes

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Cut the rest of

wires and tubes

Connect to

1/4" pigtail

Black (-)

Red (+)

Transducer

4-20mA

TGT= 5 PSI

SYS= 4 PSI OD= 31oF

• The Shutdown is used to turn off the control remotely It can be

congured for Normally Open (Shutdown) or Normally Closed

(TSTAT)

• If boilers are running and he shutdown termnal is closed remotely

all active stages will modulate down to low re (Ignition %) They

will remain there until the adjustable Soft-Off period has nished

See page 37 for Soft-Off

• The System output will remain active until the Run-On Delay

ends, then it will also turn off See "System Run-On" on page 34

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Shutdown

Dry Contact

To avoid damage to the Multi-MOD,

NO VOLTAGE can be applied to the

Multi-MOD Platinum input terminals

HT# 059299-00 A

• The System Prove feature is provided to check the system

component operation status before activating any stages Prove

must be selected from the Prove/DHW Startup option See

"Prove/DHW Mode" on page 28

• A typical use of this feature is to check for water ow before ring

any boiler stages When there is a call for heat, the System

Output relay activates the system pump When the pump

establishes ow, a ow switch closes the Prove input terminals

Only then, can the Multi-MOD Platinum activate and modulate the

boilers as required to hold the set point

• If the Prove input is open on a call for a stage, the Multi-MOD

Platinum will enable only the System output All stage outputs

will be off when the Prove input is open

• A factory installed jumper provides the System Prove signal Do

not remove the jumper unless it is replaced by a Prove signal

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Prove Input

Dry Contact

Do not remove the factory installed

Prove jumper unless it is replaced

by a prove signal If the Prove input

is not closed/shorted, the Multi-MOD

Platinum will NOT activate the stages

The Prove input cannot be used as

a safety limit All equipment must

have its own certified limit and safety

controls as required by code

• The DHW Call feature is used to raise the system Target to the

DHW Set Point In addition, it regulates the operation of the

System output The System output operation varies based on

the DHW Priority setting selected from the Startup menu See

"Prove/DHW Mode" on page 28

• Wire a DHW aquastat to the DHW Call terminals The call must

be dry-contact

• Remove the jumper on the DHW terminals for proper operation

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

DHW Call

Dry Contact

• The Multi-MOD Platinum will not activate or modulate any Stage

in Lockout A Lockout signal tells the Multi-MOD Platinum that

the related stage is encountering a problem and cannot be

started The Stage display status will show (L/O)

• However, using the Lockout will drastically improve the control's

set point management

• There is a Lockout input for each stage on the Multi-MOD

Platinum and Extension Module

• The Lockout signal must be a dry-contact closure from the boiler

No voltage can be placed across the terminals If the source of

the signal has voltage, use a relay

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS B C DA

1 2 3 4 5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

ABCD

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Boiler 1

Lockout

Boiler 2

Lockout

Boiler 3

Lockout

Boiler 4

Lockout

Do not use the Lockout inputs as a

safety check All equipment must

have their certified limit and safety

controls installed as required by code

HT# 059299-00 A

• The Setback is used to reduce the system target when less load

is required during the night or on the weekends when a building is

unoccupied, but a minimum level of heat is still required

• To use the Setback, the EMS Input mode must be set to Setback

See "EMS Input Mode" on page 27 Also, the Setback value must

be greater than 0 See "Setback" on page 35

• The Setback can be activated based on the Night Schedule

settings or an external dry-contact Setback input

• When using an external Setback, wire the dry-contact Setback

signal to the EMS terminals (+) and (SIGNAL)

• When the Setback terminals are shorted, the Setback is enabled

and the Multi-MOD Platinum will hold the lower Set Point The

main display will show "Setback to: 150F" to indicate this

condition

• When the setback signal ends, the Multi-MOD Platinum will revert

to the higher target setting

To avoid damage to the Multi-MOD,

NO VOLTAGE can be applied to the

Multi-MOD Platinum input terminals

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY