Cleco DGD mPro400GC Guide

mPro400GC

Global Controller

Hardware Description

P2174HW-EN

2017-01

2 P2174HW-EN 2017-01 en00d451.fm, 12.01.2017

About this Hardware Description

This Hardware Description is the -- original Hardware Description -- and is intended for all persons who are

connecting and installing the mPro400GC controller.

The Hardware Description does the following:

• describes all connections and its set-up.

The following documents provide additional information for the operation and service of the mPro400GC

controller.

• Recovery Installation

• Parts manual, no. PL12-1000EN

• System description, Fastening technology, no. P1730E

Disclaimer:

Apex Tool Group reserves the right to modify, supplement or improve this document or the product without

prior notice. This document may not be reproduced in whole or in part in any way, shape or form, or copied

to another natural or machine-readable language or to a data carrier, whether electronic, mechanical, opti-

cal or otherwise, without the express permission of Apex Tool Group.

DGD and Cleco are trademarks of the Apex Tool Group Division.

Symbols in the text:

italics Identifies menu items such as Diagnosis

> Identifies the selection of a menu item from the menu such as File > Print

<…> Identifies elements such as buttons, push button or external keyboard input, e.g. <F5>

Courier Identifies elements such as input fields, checkboxes, radio buttons or drop-down menus.

Indicates the name of paths and files, e.g. setup.exe

/ Separates the subdirectories of file paths, e.g. file/print

(OS9 operating system)

• Identifies lists

Identifies instructions to be followed

en01d441_bedingt.fm, 12.01.2017 P2174HW-EN 2017-01 3

Workplace safety symbols

Warning notes are identified by a signal word and a pictogram:

• The signal word describes the severity and the probability of the impending danger.

• The pictogram describes the type of danger.

Observe these notes and proceed with special care in the situations described. Pass all safety instructions

on to other operators. In addition to the safety instructions in these programming instructions, all local safety

and accident prevention rules must be observed .

WARNING! Potentially hazardous situation for health and safety.

If this warning is not observed, death or serious injury may occur.

CAUTION! Potentially hazardous situation to health and safety, or risk of material and environmental damage. If this

warning is not observed, injuries or damage to materials or the environmental could occur.

General notes

include application tips and particularly useful information but no hazard warnings.

This pictogram identifies all references to potential electrical shock, alerting of hazards to life

and health of personnel.

This sign warns of a possibly damaging situation.

If the note is not adhered to, the product or parts of it may be damaged.

ATTENTION!

4 P2174HW-EN 2017-01 en01d441_bedingt.fm, 12.01.2017

Set-Up Guide

1

1 Set-Up Guide

1.1 Controller description

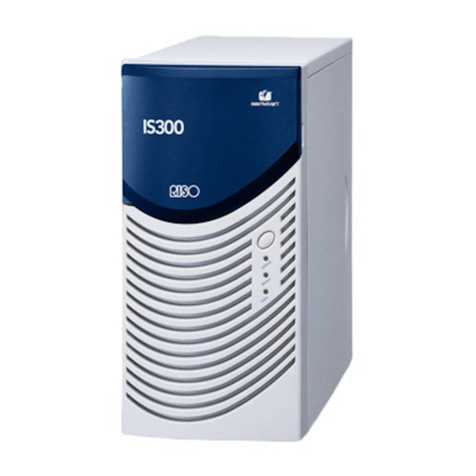

The mPro400GC product line consists of three controllers; Master, Primary and Secondary.

•Primary - Controls up to sixteen (16) tools. This unit includes a servo. One (1) standard corded hand-

held or fixtured tool could directly connect. For further corded tools / fixtured spindles are Secondary

controllers required.

•Master - Controls up to sixteen (16) tools. This controller does not include a servo. For corded tools / fix-

tured spindles are Secondary controllers required.

•Secondary - Controls one (1) corded handheld or fixtured tool. Must be used with a Master or Primary

controller.

Abb. 1-1: Controller Description

Controller Order no. Controls up to

(…) tools Servo

included Tool compatibility

Primary mPro400GC-P 16 1 18–48 AirLB1)

Cordless EC tool

DGD-Intelligent-Spindles (BTS Series)2)

1) Limited to 1 tool

2) Additional Hardware necessary. For programming mark Advanced > Controller Settings > Display Mpro Button.

Master mPro400GC-M 16 – Cordless EC tool

DGD-Intelligent-Spindles (BTS Series)3)

Secondary mPro400GC-S 1 1 18–48 AirLB1)

c01259.png

en01d441_bedingt.fm, 12.01.2017 P2174HW-EN 2017-01 5

Set-Up Guide 1

1.2 General Information

It is mandatory that national, state and local safety and wiring standards be followed during installation.

These standards take precedence over any information presented in this section.

• Do not energize the unit until all connections have been properly made.

• Equipment must be properly grounded before applying power. Units energized by cord and plug must be

connected to an approved and properly grounded receptacle.

• All units must be energized by an isolated line.

• The unit must always be closed and secured prior to energizing the unit.

• Ensure the power switch is in the „off“ position prior to connecting the power cord.

Though it is not mandatory, the following instructions are highly recommended for the protected operation of

your unit.

• Use oversized feeder lines to reduce electrical noise and voltage drop.

1.3 Checking your unit

Take time to ensure you have the required peripheral equipment and cables necessary to set-up and run

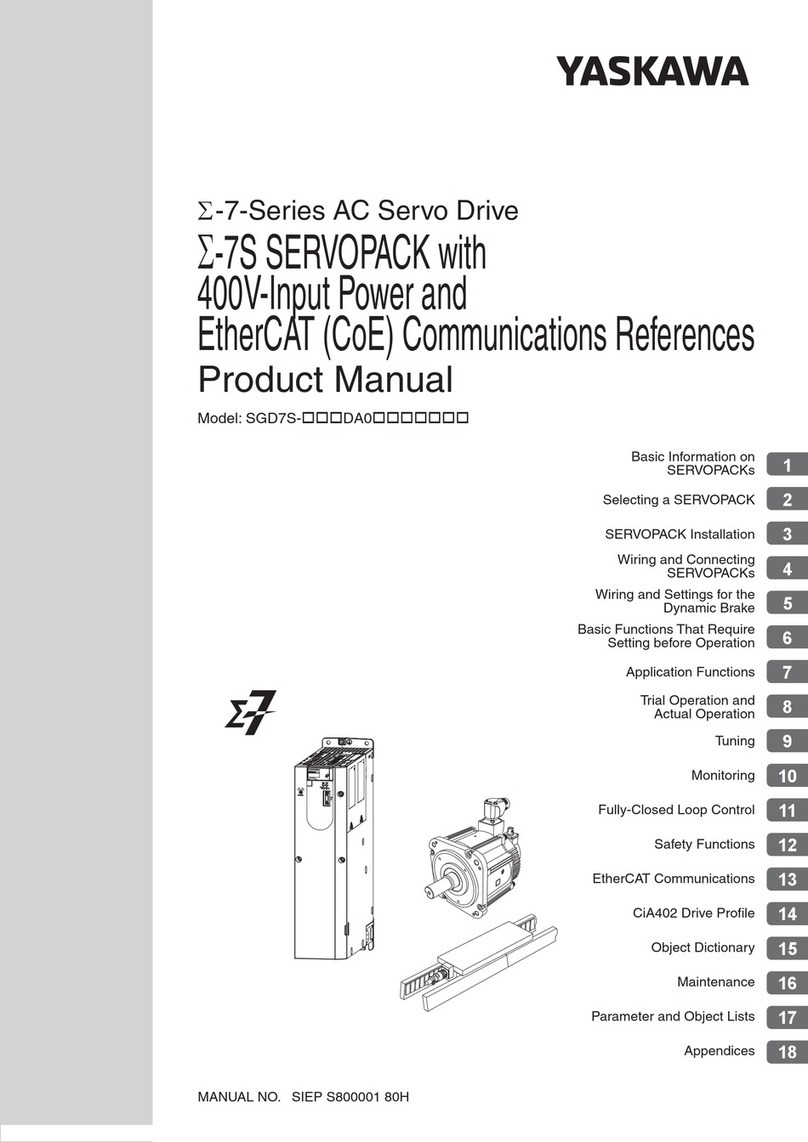

your unit. If you do not have all the necessary items, contact your distributor. Refer to Abb. 1-2: for an illus-

tration of your unit.

1.4 Software

Your unit has been preloaded with software and requires no additional software to begin your fastening pro-

cess. If you are interfacing your unit with an external computer, mPro-Remote interfacing software is

required.

1.5 Installing the Unit

1.5.1 Assembly

Each unit is used primarily as a single or multiple tool process/controller/monitor installed in a work station

or work area. It may be wall mounted, beam mounted, suspended overhead or pedestal mounted. Always

choose a stable location to avoid the possibility of unit damage and/or operator injury through hitting, falling,

vibration or inconvenient mounting. All cables attached to the unit should be located and secured so that

they cannot cause injury to the operator or to passersby. Like all electrical devices, the control system emit

some heat. It should therefore be positioned where air can circulate freely around the housing.

Refer to Abb. 1-3: for mounting hole dimensions.

1.5.2 Location considerations

Your unit should be located to allow access to the front panel and connectors. The unit should be installed

for unrestricted and comfortable viewing of the LCD screen by the operator. The LCD menu screen, key pad

and connectors must be readily accessible for the set-up. Dependent on the peripheral equipment pur-

chased, the unit may be located in a remote position but should still be accessible.

Attachment of accessories and tools should also be considered with the installation locations. Items to be

considered are:

CAUTION! To avoid the hazard of electrical shock or burn, the following instructions must be adhered to. Failure to fol-

low these instructions may also cause damage to your unit and void existing warranties.

6 P2174HW-EN 2017-01 en01d441_bedingt.fm, 12.01.2017

Set-Up Guide

1

• Location of printer

• Attachment of a data collection unit, if desired.

• Attachment of remote annunciators, socket nest, or remote parameter select.

• Attachment of the unit in a network to a computer.

• Operation convenience/safety – keep cables off the floor or dangling in operator areas.

1.5.3 Power source

The controller requires a power supply connection of:

• 104–126 VAC or 207– 253 VAC / 50–60 Hz single phase / 1A Input current (rated), 16A (peak)

1.5.4 Intended use

The mPro400GC may be used only under the following conditions:

• Industrial EMC limit value class A

• Only cables of type authorized by Apex Tool Group may be used.

• Only accessory parts authorized by Apex Tool Group may be used.

• Unauthorized alterations, repairs and modifications are prohibited for reasons of safety and product lia-

bility.

1.5.5 EMC measures

• The filters required to satisfy the EMC regulations are built into the unit.

• The sealed control cabinet and shielded cable provide very good protection against irradiated and radi-

ated interference.

• The tool complies with the following applicable EMC standards:

- EN 61000-6-2:2005

- EN 55011:2007

- EN 61000-4-2:1995 + A1: 1998 + A2: 2001

- EN 61000-4-3:2006 + A1:2008

- EN 61000-4-4:2004

- EN 61000-4-5:2006

- EN 61000-4-6:2009

- EN 61000-4-8:1993 + A1: 2001

- EN 61000-4-11:2004

1.6 Mounting the Controller

1. Loosen the two long mounting screws at the bottom of the controller so the mounting plate can be

separated from the controller. See Abb. 1-2:.

This is a Class A device. The device may cause signal interference; in this case, the operator may be

required to implement suitable EMC measures.

It is prohibited to operate the unit unless the control cabinet is closed. The properties of the shielding

would change and the noise emission would increase.

ATTENTION!

en01d441_bedingt.fm, 12.01.2017 P2174HW-EN 2017-01 7

Set-Up Guide 1

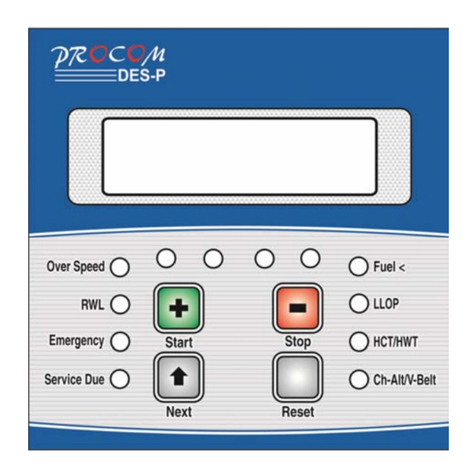

2. Abb. 1-3: illustrates the bolt pattern for hanging the mounting plate on a wall. Note the hole size

dimensions so the correct size bolts are chosen. Size ¼“ or M6 bolts (4) should fit the mounting plate

holes and support the controller.

3. Once the mounting plate is installed in its location the controller can be hung on the bracket utilizing

the four studs protruding from the back of the controller. Once in place, the controller can be secured

at the bottom using the two long screws removed in Step 1.

1.7 Making Connections to the Controller

1. Connect the cable to the tool.

2. Connect the other end of the cable to the controller. The connector at the controller is an Air-LB con-

nector and utilizes a push-pull style connector. Before attempting to attach the cable verify that the

collar on the controller connector is pushed towards the controller. If the collar is pulled away from the

controller the cable will not connect to the controller. Insert the cable connector and pull the collar

away from the controller (towards the cable) to lock the cable in place.

3. Insert the power cord into the controller and into a 115 or 230 VAC power source.

4. Using the ON/OFF power switch at the front of the controller power the controller ON.

8 P2174HW-EN 2017-01 en02d441_bedingt.fm, 12.01.2017

Abb. 1-2: Connector Locations

d01223_1.png

Position Description Position Description

1 System Bus Connector 8 Serial Connector #2

2 Tool Connector 9 Anybus Fieldbus

3 Power Connection 10 Serial Connector #1

4 Mounting Bracket Screw 11 USB ports (2)

5 Mounting Bracket Screw 12 Ethernet Connector #2

6 I/O Connectors 13 Ethernet Connector #1

7 Anybus Fieldbus

1

2

3

13

12

11

10

9

8

7

6

54

en02d441_bedingt.fm, 12.01.2017 P2174HW-EN 2017-01 9

Abb. 1-3: Mounting Information

10.38"

(263 mm)

4× 7.750"

(197 mm)

4× 1.315"

(33.4 mm)

2× 1.250"

(31.8 mm)

2× 12.500"

(318 mm)

14.88"

(378 mm)

1.825"

(46.4 mm)

0.075"

(1.9 mm)

10×.270“ (6.86 mm)

10×.503“ (12.8 mm) 10×.313“

(1.95 mm)

a01224.png

10 P2174HW-EN 2017-01 en02d441_bedingt.fm, 12.01.2017

1.8 Technical Data

1.8.1 Housing

The Global Controller is factory sealed with external access to all connectors. The front of the unit has a

USB and power switch.

On the back of the enclosure is a cover plate that can be removed to access the Compact Flash card which

contains all program data. This secondary level of access requires removing the controller from the mount-

ing plate.

All other connectors are located on the bottom of the enclosure. The mounting bracket has been designed

to also assist with cable management.

1.8.2 Primary/Master Configuration

Note: Pins are numbered exactly as they are on the controller, Pins 1 and 13 at the bottom, Pins 12 and 24

at the top.

Display

• 10.4" TFT Liquid Crystal Display

• Touchscreen

• 800 x 600 resolution

Keyboard

No separate keypad is required. The touchscreen will provide a keyboard image on the screen that can be

used for alphanumeric entry. A USB keyboard can also be connected to the unit and used for typing.

Ports

• Compact Flash – accessed through the back of the enclosure

• Any bus CC

• 2 x RS232 Serial Ports

• 3 x USB 2.0 Ports

• 2 x 10/100MBit RJ45 Ethernet Ports

Discrete I/O

• 8 inputs / 8 Outputs / 2 +24Vdc / 2 GND

• Output Current: 500 mA per output, 2000 mA total

Model Weight* Width Height Depth

lb kg in mm in mm in mm

mPro400GC 31.5 14.5 10.5 267 15 381 11.4 290

en02d441_bedingt.fm, 12.01.2017 P2174HW-EN 2017-01 11

Abb. 1-4: Primary / Master Pin Configuration

The two I/O connectors are populated with both Inputs and Outputs to help reduce cabling when utilizing

four or less Inputs and Outputs. The I/O can be used with the internal 24-volt supply in the controller or an

external 24-volt supply such as a PLC. The following examples 1.8.4 / 1.8.5 utilize Tool Start as an Input

and Cycle OK as an Output.

Pin # I/O Description Pin # I/O Description

12 Out GND2 24 Out GND2

11 In Common GND 23 In Common GND

10 Output O 03 22 Output O 07

9 Output O 02 21 Output O 06

8 Output O 01 20 Output O 05

7 Output O 00 19 Output O 04

6 Input I 03 18 Input I 07

5 Input I 02 17 Input I 06

4 Input I 01 16 Input I 05

3 Input I 00 15 Input I 04

2 In Output Common O0-O3 14 In Output Common O4-O7

1 Out +24 V2 13 Out +24 V2

d01223_1.png

Pin 1 Pin 13

Pin 24

Pin 12

12 P2174HW-EN 2017-01 en02d441_bedingt.fm, 12.01.2017

System Bus Connection

Abb. 1-5: System Bus Connection

Note: The Primary configuration has an output connector only. The Secondary and Master configurations

have both an input and output connector.

AC power supply

• 104–126 VAC or 207–253 VAC

• 50–60 Hz single phase

• 1 A Input current (rated), 16 A (peak)

1.8.3 Secondary Configuration

Note: Pins are numbered exactly as they are on the controller, Pins 1 and 13 at the bottom, Pins 12 and 24

at the top. Some Inputs and Outputs are fixed, not programmable.

Abb. 1-6: Secondary Pin Configuration

Looking at

Controller

1 – PE

2 – DATA-B

3 – GND

4 – +5VDC

5 – DATA-A

6 – N.C.

7 – 0VDC

8 – +24VDC

Input (Pins) Output (Sockets)

d01223_2.png

Pin 1 Pin 13

Pin 24

Pin 12

en02d441_bedingt.fm, 12.01.2017 P2174HW-EN 2017-01 13

Serial Port

• RS232

• System Bus Connectors

- 1 Male

- 1 Female

System Bus Address

Two rotary dials are used to manually set the address for System Bus Devices. Turn the dial until the

desired number appears in the slot. The dial closer to the front of the unit is the most significant digit. The

dial closer to the system bus connectors is the least significant digit. No two system bus devices can have

the same address. After address change is a reboot required.

AC power supply

• 104–126 VAC or 207–253 VAC

• 50–60 Hz single phase

• 1 A Input current (rated), 16 A (peak)

1.8.4 Connections Utilizing the Internal 24-volt Supply

(Primary, Secondary, Master)

INPUTS: Pins 11 and 23 (Common GND) are the Input “returns”

• Controller Internal 24-volt Supply

Pins 11 and 23 must be jumpered to Pins 12 and 24 respectively.

Pin # I/O Description Pin # I/O Description

12 Out Common GND2 24 Out Common GND

11 In Common GND 23 In Common GND

10 Output O 03 22 Output O 07

9 Output O 02 (Yellow LED) 21 Output O 06

8 Output O 01 (Green LED – OK) 20 Output O 05

7 Output O 00 (Red LED – NOK) 19 Output O 04

6 Input I 03 18 Input I 07

5 Input I 02 17 Input I 06

4 Input I 01 (Reverse) 16 Input I 05

3 Input I 00 (Start) 15 Input I 04

2 N. C. 14 N. C.

1 Out +24 VDC 13 Out +24 VDC

14 P2174HW-EN 2017-01 en02d441_bedingt.fm, 12.01.2017

OUTPUTS: Pins 2 and 14 (Output Common) are the voltage source for the Outputs

• Controller Internal 24-volt Supply

Pins 2 and 14 must be connected to Pins 1 and 13 respectively.

1.8.5 Connections Utilizing the External 24-volt Supply

(Primary and Master only)

INPUTS: Pins 11 and 23 (Common GND) are the Input “returns”.

• Controller External 24-volt Supply

Pins 11 and 23 will have to return to the GND of the external 24-volt supply.

OUTPUTS: Pins 2 and 14 (Output Common) are the voltage source for the Outputs.

• Controller Internal 24-volt Supply

Pins 2 and 14 must be connected to the external 24-volt supply.

Connector 1 Connector 2

Pin # I/O Description Pin # I/O Description

12 Out GND2 24 Out GND2

11 In Common GND 23 In Common GND

10 Output O 03 22 Output O 07

9 Output O 02 21 Output O 06

8 Output O 01 20 Output O 05

7 Output O 00 (Linking OK) e. g. 19 Output O 04

6 Input I 03 (Tool Start) e. g. 18 Input I 07

5 Input I 02 17 Input I 06

4 Input I 01 16 Input I 05

3 Input I 00 15 Input I 04

2 In Output Common O0-O3 14 In Output Common O4-O7

1 Out +24 V2 13 Out +24 V2

Connector 1 Connector 2

Pin # I/O Description Pin # I/O Description

12 Out GND2 24 Out GND2

11 In Common GND 23 In Common GND

10 Output O 03 22 Output O 07

9 Output O 02 21 Output O 06

8 Output O 01 20 Output O 05

7 Output O 00 (Linking OK) e. g. 19 Output O 04

6 Input I 03 (Tool Start) e. g. 18 Input I 07

5 Input I 02 17 Input I 06

4 Input I 01 16 Input I 05

3 Input I 00 15 Input I 04

2 In Output Common O0-O3 14 In Output Common O4-O7

1 Out +24 V2 13 Out +24 V2

+-

Please note that all locations may not service all products.

Contact the nearest Apex Tool Group Sales & Service Center for the appropriate facility

to handle your service requirements.

POWER TOOLS SALES & SERVICE CENTERS

Apex Tool Group, LLC

1000 Lufkin Road

Apex, NC 27539

Phone: +1 (919) 387-0099

Fax: +1 (919) 387-2614

www.apexpowertools.com

EUROPE | MIDDLE EAST | AFRICA

Hungary

Apex Tool Group

Hungária Kft.

Platánfa u. 2

9027 Györ

Hungary

Phone: +36 96 66 1383

Fax: +36 96 66 1135

NORTH AMERICA | SOUTH AMERICA

Lexington, South Carolina

Apex Tool Group

670 Industrial Drive

Lexington, SC 29072

Phone: +1 (800) 845-5629

Phone: +1 (919) 387-0099

Fax: +1 (803) 358-7681

Canada

Apex Tool Canada, Ltd.

7631 Bath Road

Mississauga, Ontario L4T 3T1

Canada

Phone: (866) 691-6212

Fax: (905) 673-4400

Mexico

Apex Tool Group

Manufacturing México

S. de R.L. de C.V.

Vialidad El Pueblito #103

Parque Industrial Querétaro

Querétaro, QRO 76220

Mexico

Phone: +52 (442) 211 3800

Fax: +52 (800) 685 5560

Detroit, Michigan

Apex Tool Group

2630 Superior Court

Auburn Hills, MI 48236

Phone: +1 (248) 393-5640

Fax: +1 (248) 391-6295

Brazil

Apex Tool Group

Ind. Com. Ferram, Ltda.

Av. Liberdade, 4055

Zona Industrial Iporanga

Sorocaba, São Paulo

CEP# 18087-170

Brazil

Phone: +55 15 3238 3820

Fax: +55 15 3238 3938

Louisville, Kentucky

Apex Tool Group

1000 Glengarry Drive

Suite 150

Fairdale, KY 40118

Phone: +1 (502) 708-3400

apexpowertools.com/service

ASIA PACIFIC

India

Apex Power Tools India

Private Limited

Gala No. 1, Plot No. 5

S. No. 234, 235 & 245

Indialand Global

Industrial Park

Taluka-Mulsi, Phase I

Hinjawadi, Pune 411057

Maharashtra, India

Phone: +91 020 66761111

Australia

Apex Tool Group

519 Nurigong Street, Albury

NSW 2640

Australia

Phone: +61 2 6058 0300

China

Apex Power Tool Trading

(Shanghai) Co., Ltd

2nd Floor, Area C

177 Bi Bo Road

Pu Dong New Area, Shanghai

China 201203 P.R.C.

Phone: +86 21 60880320

Fax: +86 21 60880298

Japan

Apex Tool Group Japan

Korin-Kaikan 5F,

3-6-23 Shibakoen, Minato-Ku,

Tokyo 105-0011, JAPAN

Phone: +81-3-6450-1840

Fax: +81-3-6450-1841

Korea

Apex Tool Group Korea

#1503, Hibrand Living Bldg.,

215 Yangjae-dong,

Seocho-gu, Seoul 137-924,

Korea

Phone: +82-2-2155-0250

Fax: +82-2-2155-0252

|0816 |

England

Apex Tool Group GmbH

C/O Spline Gauges

Piccadilly, Tamworth

Staffordshire B78 2ER

United Kingdom

Phone: +44 1827 8727 71

Fax: +44 1827 8741 28

France

Apex Tool Group S.A.S.

25 rue Maurice Chevalier

B.P. 28

77831 Ozoir-La-Ferrière

Cedex, France

Phone: +33 1 64 43 22 00

Fax: +33 1 64 43 17 17

Germany

Apex Tool Group GmbH

Industriestraße 1

73463 Westhausen

Germany

Phone: +49 (0) 73 63 81 0

Fax: +49 (0) 73 63 81 222

Sales Center

Service Center

Other manuals for DGD mPro400GC

3

Table of contents

Other Cleco Controllers manuals

Cleco

Cleco CellCore 200 Series Guide

Cleco

Cleco DGD mPro400GC User manual

Cleco

Cleco mPro400GCD-S User manual

Cleco

Cleco DGD mPro400GC User manual

Cleco

Cleco mPro400GCD-M User manual

Cleco

Cleco DGD mPro400GC Owner's manual

Cleco

Cleco mPro400GCD-P Guide

Cleco

Cleco TME-100 Owner's manual

Cleco

Cleco mPro400GCD-P Guide

Cleco

Cleco mPro300GCD-STO User manual