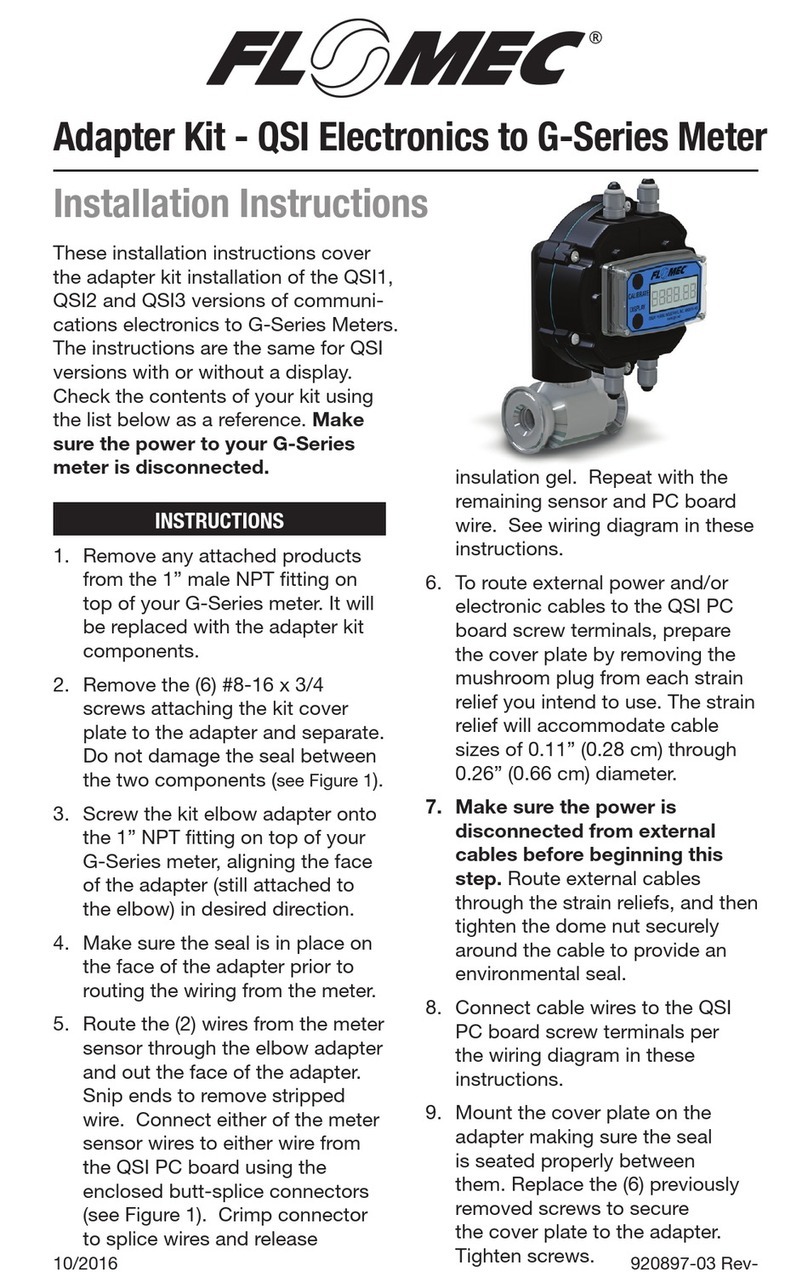

Flomec QSI Series User manual

920897-01 Rev-10/2016

Adapter Kit - QSI Electronics to OM Meter

Installation Instructions

INSTRUCTIONS

1. Remove the circular plate (or

other product) from the top

of your OM meter. It will be

replaced with the adapter kit

components.

2. Remove the (6) #8-16 x 3/4

screws attaching the kit cover

plate to the adapter and separate.

Do not damage the seal between

the two components (see Figure

2).

3. Install the O-ring received with

the kit in the O-ring gland on the

bottom of the adapter; mount

the adapter to the OM meter and

secure with (4) metric screws

provided with the kit. Tighten

screws.

4. Make sure the seal is in place on

top of the adapter prior to routing

the wiring from the meter.

5. Route the wiring from the meter

up through the adapter and

connect the wires to the QSI

PC board screw connectors,

per the wiring diagram in these

instructions.

6. To route external power and/or

electronic cables to the QSI PC

board screw connectors, prepare

the cover plate by removing the

mushroom plug from each strain

relief you intend to use. The strain

relief will accommodate cable

sizes of 0.11” (0.28 cm) through

0.26” (0.66 cm) diameter.

7. Make sure the power is

disconnected from external

cables before beginning this step.

Route external cables through the

strain relief(s), and then tighten

the dome nut securely around the

cable to provide an environmental

seal.

8. Connect cable wires to the QSI

PC board screw connectors

per the wiring diagram in these

instructions.

9. Mount the cover plate on the

adapter making sure the seal

is seated properly between

them. Replace the (6) previously

removed screws to secure the

cover plate to the adapter.

Tighten screws.

These installation instructions

cover the adapter kit installation of

the QSI1, QSI2 and QSI3 versions

of communications electronics to

OM Meters. The instructions are

the same for QSI versions with

or without a display. Check the

contents of your kit using the list

below as a reference. Make sure

the power to your OM meter is

disconnected.

2

O-RING

ADAPTER

SEAL

COVER PLATE

Q09 DISPLAY (SHOWN)

(OR)

NO DISIPLAY

(4) M5-0.8 X 12 SCREW

(6) SCREWS, #8-16 X 3/4

(4) MUSHROOM PLUGS

O-RING GLAND

Figure 1

KIT CONTENTS

• (1) Completely assembled QSI

module (with or without a display).

• (4) M5-0.8 x 12 metric screws.

• (1) O-ring.

• (1) Instruction sheet.

• (1) QSI Owner’s manual.

• (1) Q09 Owner’s manual (if kit

includes Q09 display).

3

TEMP SENSOR

PT100-Red Sensor VCC Output

PT100-White Input High Side

PT100-Blue Input Return

RS-485 (Galvanically Isolated)

RS485 (+) Positive Signal

RS485 (-) Negative Signal

RS485 GND Circuit Ground*

PULSE INPUT

+5V 5VDC output to pow-

er external sensor

(+)

Digital Pulse Fre-

quency Input, up to

3kHz

(-) Digital Pulse Return

4-20mA (Galvanically Isolated)

(+)

4 to 20mA current

loop - current in to

transmitter

(-)

4 to 20mA current

loop - current out of

transmitter*

Coil A Low level sine wave

input

Coil B Low level sine wave

input

GPI SENSOR

Ribbon cable connection to GPI

custom sensor designs

PULSE OUTPUT

(Galvanically Isolated)

(-) Pulse Output return

current*

(+)

Pulse Output fre-

quency output. This

is a “current sinking

open collector” out-

put.***

POWER INPUT

(-) 12-36V AC or DC

Input A**

(+) 12-36V AC or DC

Input B**

*NOTE: It is not recommended to

connect isolated ground connections

together or to board common.

**NOTE: Polarity of voltage for AC/

DC is not important. However an

earth ground isolated power supply is

required to prevent earth ground loop

currents and ground fault conditions.

***NOTE: This output may require an

external pull up resistor if interfacing

equipment does not include one.

PT100-Red

Coil A

GPI Sensor

Coil B

-

+

-

+

PT100-White Sensor #1

PT100-Blue

PT100-Red

PT100-White

PT100-Blue

RS-485 +

RS-485 -

RS-485 GND

+5v

+

-

+

-

Sensor #2

RS-485

Pulse Input

4-20mA

Pulse Output

Power

Figure 2

TERMINAL CONNECTIONS CHART

4

WIRING DIAGRAMS

QSI VERSION 1 PC BOARD

WIRING DIAGRAM

QSI Version 1

RS-485

BTU

Pulse Out

RTDs

RS-485

Pulse

Input Power In

Inputs: Temp Sensors, Pulse Input

Outputs: RS-485, Pulse Output

(+) (-)

Power (-)

Power (+)

ISOLATED

POWER

SUPPLY

12-36V AC/DC

Pulse Out (+)

Pulse Out (-)

Open Collector

Pulse Input

RS485 (-)

RS485 (GND)

R2 may be

required in some

installations.

Recommended

value=120Ω

Shield recommended. If used, connect

to Customer Equipment only.

*Shield

Customer

Equipment

Customer

Equipment

RS485 (+)

RS485 (-)

RS485 (GND)

RS485 (+)

PT100 (White)

PT100 (Blue)

PT100 (Red)

PT100 (White)

PT100 (Blue)

PT100 (Red)

R2

Pulse In (+)

Pulse In (-)

+5V

OM Meter

Electronics

Hall Effect, or

Reed Switch

R1

*NOTE: Regarding resistor “R1”: R1not generally required for distance up to 25 ft.

Use R1= 10k (10000 ohms) for distance up to 50 ft.

Use R1= 5.1k (5100 ohms) for distance up to 100 ft.

Use R1= 2.7k (2700 ohms) for distance up to 250 ft.

Do not use R1less than 2.4k (2400 ohms)

Figure 3

QSI VERSION 1 PC BOARD

WIRING DIAGRAM

QSI Version 1

RS-485

BTU

Pulse Out

RTDs

RS-485

Pulse

Input Power In

Inputs: Temp Sensors, Pulse Input

Outputs: RS-485, Pulse Output

(+) (-)

Power (-)

Power (+)

ISOLATED

POWER

SUPPLY

12-36V AC/DC

Pulse Out (+)

Pulse Out (-)

Open Collector

Pulse Input

RS485 (-)

RS485 (GND)

R2 may be

required in some

installations.

Recommended

value=120Ω

Shield recommended. If used, connect

to Customer Equipment only.

*Shield

Customer

Equipment

Customer

Equipment

RS485 (+)

RS485 (-)

RS485 (GND)

RS485 (+)

PT100 (White)

PT100 (Blue)

PT100 (Red)

PT100 (White)

PT100 (Blue)

PT100 (Red)

R2

Pulse In (+)

Pulse In (-)

+5V

OM Meter

Electronics

Hall Effect, or

Reed Switch

R1

*NOTE: Regarding resistor “R1”: R1not generally required for distance up to 25 ft.

Use R1= 10k (10000 ohms) for distance up to 50 ft.

Use R1= 5.1k (5100 ohms) for distance up to 100 ft.

Use R1= 2.7k (2700 ohms) for distance up to 250 ft.

Do not use R1less than 2.4k (2400 ohms)

Figure 4

See Figure 5

or Figure 6

5

WIRING DIAGRAMS

Figure 5

Connection / Wiring Diagram

Standard Pulse Output Board

+5V

OR

Pulse In -

QSI

Pulse

Input

Pull Up

Resistor

R1

Not Both

Pulse In +

Pulse In +

Pulse In -

Figure 6

Connection / Wiring Diagram

Reed Only Pulse Output Board

X

Pulse In +

Pulse In -

(Recommended, but not required)

6

QSI VERSION 2 PC BOARD

WIRING DIAGRAM

QSI Version 2

Pulse In

BTU

Pulse Out

RTDs

Pulse

Input Power In

Inputs: Temp Sensors, Pulse Input

Outputs: Pulse Output

(+) (-)

Power (-)

Power (+)

ISOLATED

POWER

SUPPLY

12-36V AC/DC

Pulse Out (+)

Pulse Out (-)

Open Collector

Pulse Input

Customer

Equipment

PT100 (White)

PT100 (Blue)

PT100 (Red)

PT100 (White)

PT100 (Blue)

PT100 (Red)

Pulse In (+)

Pulse In (-)

+5V

OM Meter

Electronics

Hall Effect, or

Reed Switch

R1

*NOTE: Regarding resistor “R1”: R1not generally required for distance up to 25 ft.

Use R1= 10k (10000 ohms) for distance up to 50 ft.

Use R1= 5.1k (5100 ohms) for distance up to 100 ft.

Use R1= 2.7k (2700 ohms) for distance up to 250 ft.

Do not use R1less than 2.4k (2400 ohms)

Figure 7

WIRING DIAGRAMS

QSI VERSION 2 PC BOARD

WIRING DIAGRAM

QSI Version 2

Pulse In

BTU

Pulse Out

RTDs

Pulse

Input Power In

Inputs: Temp Sensors, Pulse Input

Outputs: Pulse Output

(+) (-)

Power (-)

Power (+)

ISOLATED

POWER

SUPPLY

12-36V AC/DC

Pulse Out (+)

Pulse Out (-)

Open Collector

Pulse Input

Customer

Equipment

PT100 (White)

PT100 (Blue)

PT100 (Red)

PT100 (White)

PT100 (Blue)

PT100 (Red)

Pulse In (+)

Pulse In (-)

+5V

OM Meter

Electronics

Hall Effect, or

Reed Switch

R1

*NOTE: Regarding resistor “R1”: R1not generally required for distance up to 25 ft.

Use R1= 10k (10000 ohms) for distance up to 50 ft.

Use R1= 5.1k (5100 ohms) for distance up to 100 ft.

Use R1= 2.7k (2700 ohms) for distance up to 250 ft.

Do not use R1less than 2.4k (2400 ohms)

Figure 8

See Figure 5

or Figure 6

7

WIRING DIAGRAMS

QSI VERSION 3 PC BOARD

WIRING DIAGRAM

QSI Version 3

WIRING DIAGRAM

QSI Version 3

4-20mA

Pulse Out

4-20mA

Pulse

Input Power In

Inputs: OM or Conditioned Signal Sensor (Open Collector)

Outputs: Customer Equipment, 4-20mA Sensing, Built-in Loop Power Supply

(+) (-)

Power (-)

Power (+)

ISOLATED

POWER

SUPPLY

12-36V AC/DC Pulse Out (+)

Isolated Outputs

Customer Equipment with Built-in Power Supply

Inputs

Pulse Out (-)

Customer

Equipment

Open

Collector

4-20mA (+)

Min. V = 8.5

Max. V = 36

4-20mA (-)

Customer

Equipment

Customer Equipment without Built-in Power Supply

- 4-20mA Output with Separate Power Supply

(+) (-)

Power (-)

Power (+)

ISOLATED

POWER

SUPPLY

12-36V AC/DC

4-20mA (+)

4-20mA (-) (Current)

(Current)

(Current)

Loop (+)

Loop (-)

Customer

Equipment

Pulse In (+)

Pulse In (-)

+5V

Hall Effect, or

Reed Switch

OM Meter

Electronics

R1

- Digital Pulse Input

- 4-20mA and Pulse Outputs

*NOTE: Regarding resistor “R1”: R1not generally required for distance up to 25 ft.

Use R1= 10k (10000 ohms) for distance up to 50 ft.

Use R1= 5.1k (5100 ohms) for distance up to 100 ft.

Use R1= 2.7k (2700 ohms) for distance up to 250 ft.

Do not use R1less than 2.4k (2400 ohms)

Caution: When reassembling the

cover plate, make sure the

enclosure seal is not crimped or

twisted. Do not over-tighten

screws (hand-tighten only).

(+) (-)

Min. V = 8.5

Max. V = 36

Isolated

Power Supply

Figure 9

QSI VERSION 3 PC BOARD

WIRING DIAGRAM

QSI Version 3

WIRING DIAGRAM

QSI Version 3

4-20mA

Pulse Out

4-20mA

Pulse

Input Power In

Inputs: OM or Conditioned Signal Sensor (Open Collector)

Outputs: Customer Equipment, 4-20mA Sensing, Built-in Loop Power Supply

(+) (-)

Power (-)

Power (+)

ISOLATED

POWER

SUPPLY

12-36V AC/DC Pulse Out (+)

Isolated Outputs

Customer Equipment with Built-in Power Supply

Inputs

Pulse Out (-)

Customer

Equipment

Open

Collector

4-20mA (+)

Min. V = 8.5

Max. V = 36

4-20mA (-)

Customer

Equipment

Customer Equipment without Built-in Power Supply

- 4-20mA Output with Separate Power Supply

(+) (-)

Power (-)

Power (+)

ISOLATED

POWER

SUPPLY

12-36V AC/DC

4-20mA (+)

4-20mA (-) (Current)

(Current)

(Current)

Loop (+)

Loop (-)

Customer

Equipment

Pulse In (+)

Pulse In (-)

+5V

Hall Effect, or

Reed Switch

OM Meter

Electronics

R1

- Digital Pulse Input

- 4-20mA and Pulse Outputs

*NOTE: Regarding resistor “R1”: R1not generally required for distance up to 25 ft.

Use R1= 10k (10000 ohms) for distance up to 50 ft.

Use R1= 5.1k (5100 ohms) for distance up to 100 ft.

Use R1= 2.7k (2700 ohms) for distance up to 250 ft.

Do not use R1less than 2.4k (2400 ohms)

Caution: When reassembling the

cover plate, make sure the

enclosure seal is not crimped or

twisted. Do not over-tighten

screws (hand-tighten only).

(+) (-)

Min. V = 8.5

Max. V = 36

Isolated

Power Supply

Figure 10

See Figure 5

or Figure 6

920897-01 Rev-10/2016

QSI VERSION 3 PC BOARD

WIRING DIAGRAM

QSI Version 3

WIRING DIAGRAM

QSI Version 3

4-20mA

Pulse Out

4-20mA

Pulse

Input Power In

Inputs: OM or Conditioned Signal Sensor (Open Collector)

Outputs: Customer Equipment, 4-20mA Sensing, Built-in Loop Power Supply

(+) (-)

Power (-)

Power (+)

ISOLATED

POWER

SUPPLY

12-36V AC/DC Pulse Out (+)

Isolated Outputs

Customer Equipment with Built-in Power Supply

Inputs

Pulse Out (-)

Customer

Equipment

Open

Collector

4-20mA (+)

Min. V = 8.5

Max. V = 36

4-20mA (-)

Customer

Equipment

Customer Equipment without Built-in Power Supply

- 4-20mA Output with Separate Power Supply

(+) (-)

Power (-)

Power (+)

ISOLATED

POWER

SUPPLY

12-36V AC/DC

4-20mA (+)

4-20mA (-) (Current)

(Current)

(Current)

Loop (+)

Loop (-)

Customer

Equipment

Pulse In (+)

Pulse In (-)

+5V

Hall Effect, or

Reed Switch

OM Meter

Electronics

R1

- Digital Pulse Input

- 4-20mA and Pulse Outputs

*NOTE: Regarding resistor “R1”: R1not generally required for distance up to 25 ft.

Use R1= 10k (10000 ohms) for distance up to 50 ft.

Use R1= 5.1k (5100 ohms) for distance up to 100 ft.

Use R1= 2.7k (2700 ohms) for distance up to 250 ft.

Do not use R1less than 2.4k (2400 ohms)

Caution: When reassembling the

cover plate, make sure the

enclosure seal is not crimped or

twisted. Do not over-tighten

screws (hand-tighten only).

(+) (-)

Min. V = 8.5

Max. V = 36

Isolated

Power Supply

Figure 11

WIRING DIAGRAMS

© 2016 Great Plains Industries, Inc., All Rights Reserved.

Great Plains Industries, Inc. / 888-996-3837 / GPI.net

Other manuals for QSI Series

2

This manual suits for next models

3

Table of contents

Other Flomec Adapter manuals

Popular Adapter manuals by other brands

Sony

Sony MSACEX1 - Adaptateur Memory Stick Duo Express... operating instructions

NETGEAR

NETGEAR XAV1301v1/XAVB1301v1 asennusopas

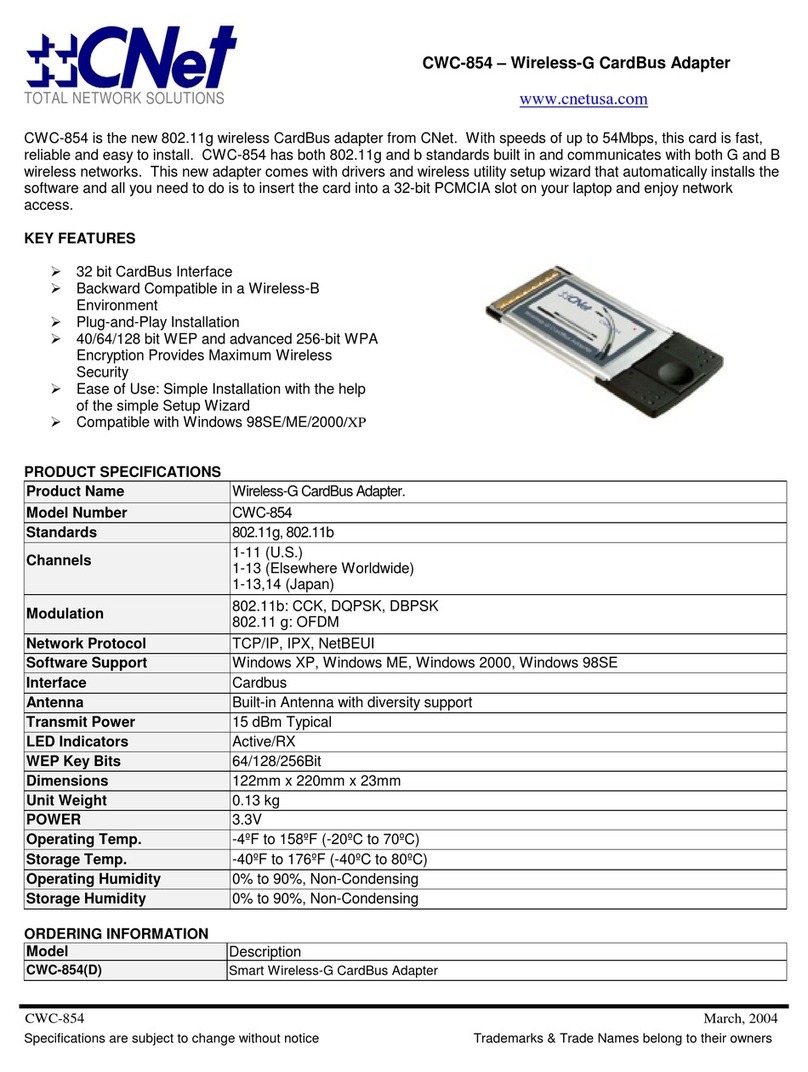

CNET

CNET CWC-854 Product specifications

Cisco

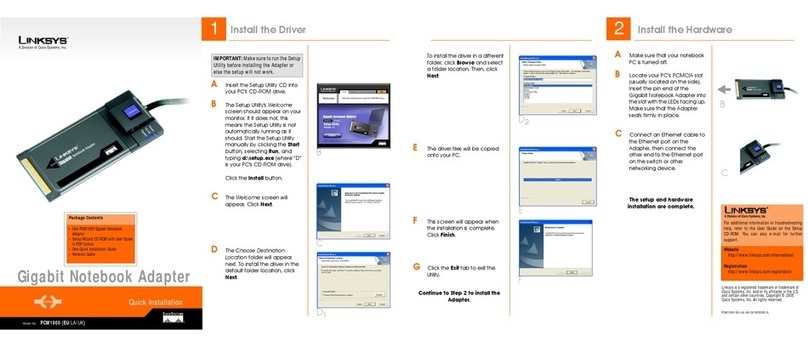

Cisco Linksys PCM1000 Quick installation

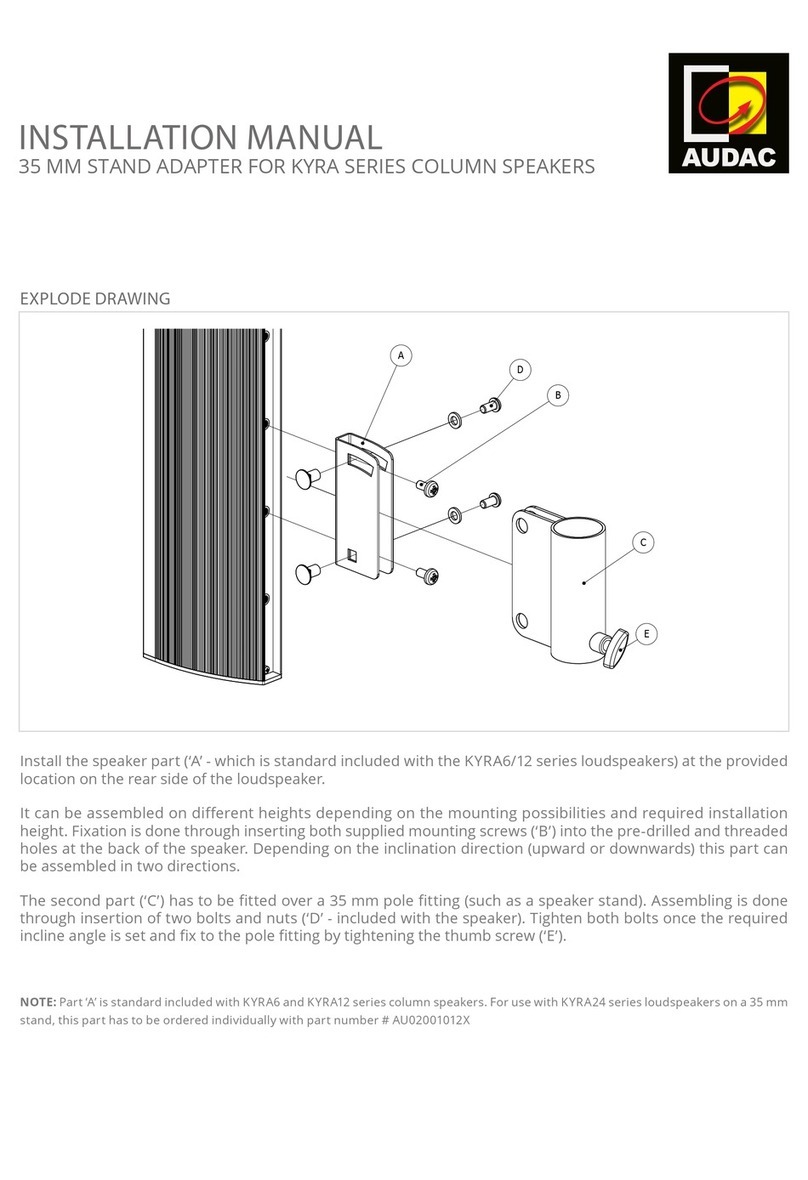

AUDAC

AUDAC MBK260 installation manual

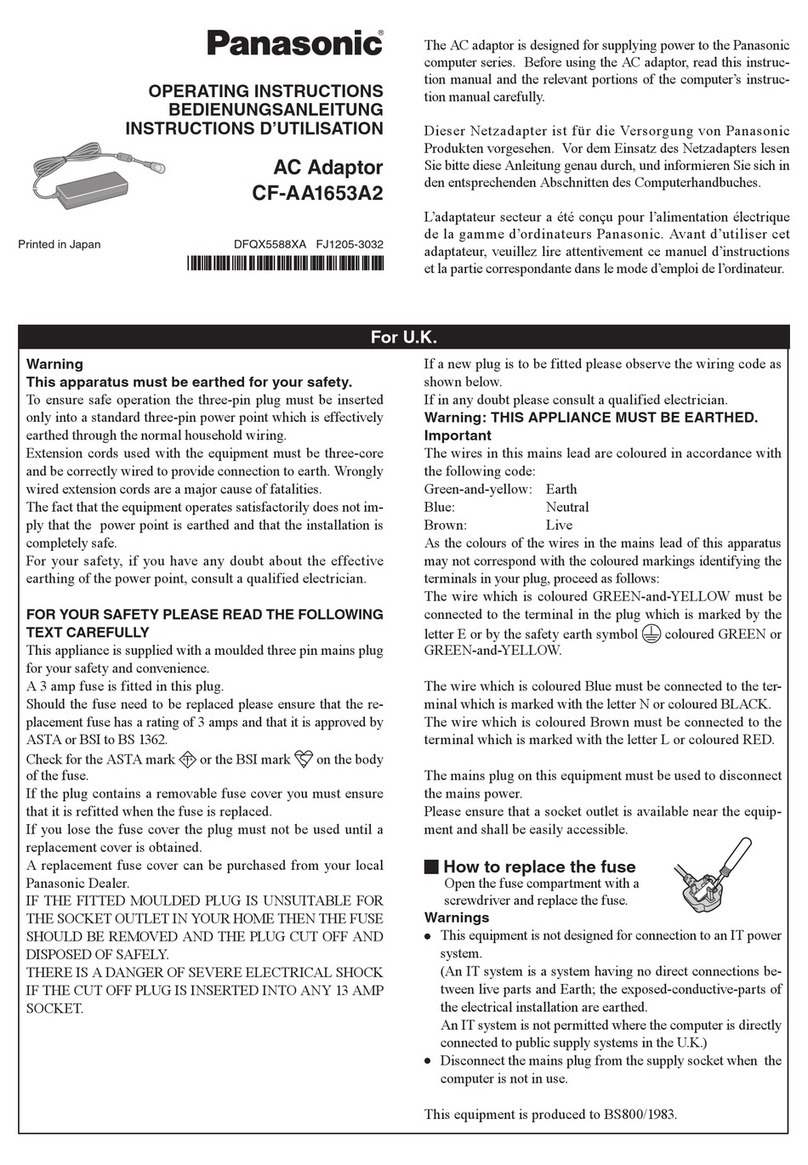

Panasonic

Panasonic CF-AA1653A2 operating instructions

ZyXEL Communications

ZyXEL Communications NWD210N user guide

Dragino

Dragino LA66 user manual

Airlink101

Airlink101 AWLC3026T Quick installation guide

Texas Instruments

Texas Instruments Serial Programming Adapter MSP430 user guide

Exibel

Exibel ADD009 quick start guide

oticon

oticon FittingLINK 3.0 Instructions for use