Flomec EasyBatch User manual

EB11 ‘EasyBatch’ Batch Controller

Instruction Manual

Version 12.21

2

General Information

This manual provides the necessary information for installation and operation of

your flow instrument; for detailed information on any flowmeters or accessories

supplied with your instrument please consult the relevant flowmeter product

manual. This instrument should only be installed and maintained by persons familiar

with local regulations, particularly those for workplace Health and Safety.

For best results, please make yourself familiar with the contents of all relevant

product manuals prior to installation and commissioning. If further assistance is

required please consult the distributor from whom you purchased your device.

DISPOSAL WITHIN THE EUROPEAN UNION - WEEE

The WEEE Directive requires that this product be recycled

when disposed of within the European Union

The crossed out wheelie bin symbol shown in this manual

signifies that this product should not be disposed of in general

waste or landfill.

Please contact the local dealer or national distributor from

whom this product was purchased for information on recycling

electronic equipment within your region.

3

Table of Contents

1. Introduction ................................................................................................... 4

1.1 Product Overview.............................................................................................4

1.2 Specifications ...................................................................................................5

2. Operation ....................................................................................................... 6

2.1 Key Functions ...................................................................................................6

2.2 Operator Functions ..........................................................................................7

3. Mechanical Installation .................................................................................. 9

3.1 General Requirements .....................................................................................9

3.2 Conduit Entries .................................................................................................9

3.3 Integral Meter Mounting .................................................................................9

3.4 Wall and Pipe Mounting ................................................................................10

3.5 Panel Mounting .............................................................................................10

4. Electrical Installation .................................................................................... 12

4.1 Input Connections ..........................................................................................12

4.1.1 Sine-wave signal (coil input) ...................................................................12

4.1.2 NPN Signal Input .....................................................................................13

4.1.3 Reed-switch Signal Input ........................................................................13

4.1.4 NAMUR Signal Input ...............................................................................14

4.2 Digital Outputs ...............................................................................................14

4.2.1 NPN Transistor Outputs ..........................................................................14

5. Programming Parameters ............................................................................ 15

5.1 Preset Menu ...................................................................................................15

Explanation of SETUP-menu 1 – Preset .......................................................................15

5.2 Overrun Menu ................................................................................................16

Explanation of SETUP-menu 2 – Overrun ....................................................................16

5.3 Meter Menu ...................................................................................................16

5.3.1 Signal Type ..............................................................................................16

5.3.2 Explanation of SETUP-menu 4 – Other ...................................................17

5.4 Setup Menu Parameters ................................................................................18

6. Problem Solving ........................................................................................... 19

7. Spare Parts ................................................................................................... 20

8. Manufacturer’s Declaration ......................................................................... 23

4

1. Introduction

1.1 Product Overview

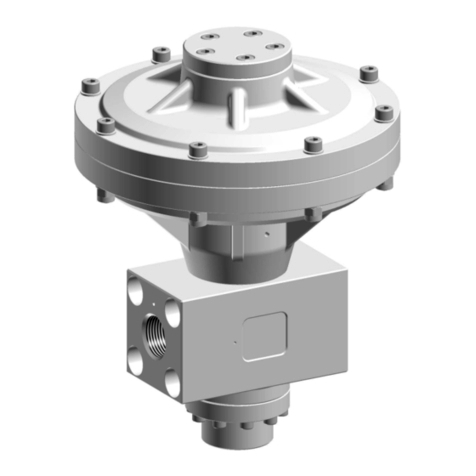

The FLOMEC EB11 “Easy Batch” is a dual stage batch controller designed to create an efficient

and accurate dispensing experience. Mountable either directly onto a FLOMEC flow meter or

remotely, and compatible with multiple types of industry signals, the EB11 allows the user to

control the volume of fluid dispensed into their process. The large 7-digit display with backlight

enables easy reading of the batch status is either light or dark conditions. Housed in an IP66/67-

NEMA4X Glass Reinforced Nylon enclosure for increased impact and corrosion resistance

particularly in wet washdown environments. The EB11 contains 2 digital NPN outputs with a

current rating of up to 300mA for direct control of solenoid valves, or to connect to relays to

allow for the control of large valves and pumps.

Environments

The Easybatch is designed to suit harsh indoor and outdoor industrial environments and

conforms to EMC directives. The instrument housing is made from UV resistant, glass reinforced

nylon (GRN) and is weatherproof to IP66/67 (Nema Type 4) standards. The Easybatch is suitable

for use in temperatures ranging between -200C and 600C and can handle up to 90% relative

humidity. However, condensation in the instrument should be avoided at all times.

Features

• Easy to use 2 button controller

• Dual stage operation

• Weather resistant and durable IP66/67 - NEMA4X Enclosure

• Easy to read backlit 7-digit display

• Settings retained after power loss meaning no reprogramming

Installation

Specifically engineered to be directly mounted on a variety of flowmeters, wall or surface

mounted, pipe or panel mounted. Various mounting kits are available. The instrument can be

self-powered or powered by an external DC supply.

5

1.2 Specifications

Physical

High impact glass reinforced nylon

and

nitrile O

-

Ring providing an IP rating of

IP66/67

Operating Temperature Range is -20oC ~ 60oC (-4oF ~ 140oF)

LCD

Display:

Dimensions: 54 x 29mm (2.13” x 1.14”)

7 digit primary alpha-numeric LCD display with 12mm characters

7-digit secondary alpha-numeric LCD display with 7mm characters

White LED backlight available with external DC power

8 times/sec refresh rate during operation which reduces to 1time/sec after 30

seconds

Units

Total units are selectable for litres, cubic metres, kilograms, pounds, gallons, US

gallons, barrels or NONE.

Signal

Input:

Options for signal

input

include: Reed switch (120Hz), NPN (6kHz), PNP (6kHz),

coil (30mVpp) and NAMUR (4kHz).

Sensor

Power

8.2V regulated sensor supply (terminal 4) is available when external DC power is

applied. 1.2V for coil pick-up (terminal 3) and 3V for low power pulse signals

Max current out = 63µA

Battery

Power

AA 3.6V Lithium Battery

Expected battery life under ideal conditions is 2 years. However, this is dependent

on settings and configuration

External

DC Power Regulated 10V ~ 30V DC

Maximum consumption is 625mW

Digital

Outputs

Passive NPN digital output, not isolated.

Max Voltage: 30VDC

Max Current: 300mA

Directives

and

standards

EMC directive (2014/30/EU; FCC 47 CFR part 15), Low voltage directive

(2014/35/EU), restriction of hazardous substances directive (2011/65/EU)

6

2. Operation

2.1 Key Functions

The following keys are available:

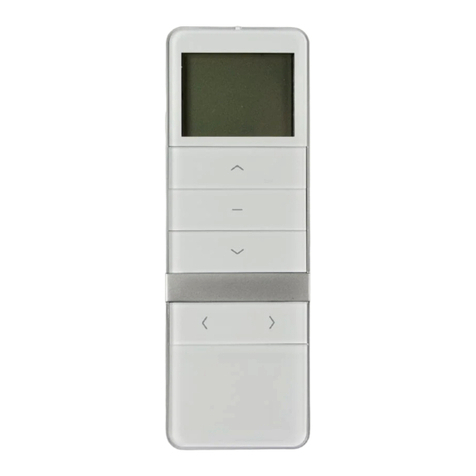

Fig. 2: Control panel

Functions of the keys

START-key

This key is used to:

START the batch process.

to enter the preset value during programming.

to reset the total value.

gain access to SETUP-level; please read chapter 5.

STOP-key

This key is used to:

STOP / interrupt the batch process.

during the “READY”-status to select total and accumulated total.

during programming to select the digit.

START + STOP-key

Press both keys simultaneously to program and save the

PRESET value or settings.

7

2.2 Operator Functions

By default, the EB11 will act at Operator level. For the Operator, the following functions are

available:

To enter a batch quantity

To change the PRESET-value, following procedure must be followed:

1)

press START + STOP quickly and simultaneously: the word "PROG" will be

flashing, If the buttons are held too long there will be no response

2)

use STOP to select the digit position and START to increase that value,

3)

set the new PRESET-value by pressing START + STOP quickly and

simultaneously.

Fig. 3: Example display information during programming preset value.

When data is altered but START + STOP has not been pressed yet, then the alteration can

still be cancelled by waiting for 20 seconds: the former value will be reinstated.

The PRESET-value can be used time after time till a new value is programmed.

Starting up the batch process

The batch process can only be started up when "READY" is displayed. The batch process is

started-up by pressing the START-key.

Fig. 4: Example display information during the process.

8

Interrupting and ending the batch process

When STOP is pressed once, the batch process will be temporarily interrupted; the actual

values are not lost. At the display, the word "RUN" will be flashing. From this stage, the

batch process can be resumed with the START-key.

The process can be ended entirely at all times by pressing STOP twice in which case the

actual values are "lost" and the system returns to steady state: the batch cannot be

resumed.

When the batched quantity approaches the preset quantity, it might be that one of the two

outputs will be switched-off due a pre-close quantity.

Once the preset quantity is fully batched, the second or both outputs will be switched off.

This is the end of the batch process.

After batching, following functions are available:

Display information Function

MAIN SCREEN Actual and Preset value

SCREEN 1 Total and reset Total

SCREEN 2 Accumulated Total

Display total and accumulated total

A resettable Total and non-resettable Accumulated Total are available. Both, Total value

and Accumulated total can count up to 9.999.999 before rolling over to zero.

The unit and number of decimals are displayed according to the configuration settings for

Total.

Clear total

The value for Total can be cleared and reset to zero. This action does not influence the

value of Accumulated Total.

To clear Total, press the START-key when Total is shown on the display and the display will

show the flashing text “CLEAR NO YES”. When the START-key is pressed a second time,

Total is set to zero. To avoid clearing Total at this point, press the STOP-key or wait for 20

seconds.

9

3. Mechanical Installation

3.1 General Requirements

Installation of this product should only be carried out by suitably qualified/trained personnel

with an understanding of local regulations regarding electrical installations. It is recommended

that the instrument is installed in a location where it is shielded from extreme varying weather

conditions, and from chances of physical impact. Never install the instrument in an area which

will expose it to temperatures outside its specified operating temperature range.

3.2 Conduit Entries

Each instrument is equipped with three conduit entries which are factory sealed to maintain the

IP rating of the enclosure. To gain access to a conduit entry the integral moulded plug must be

broken out of the electrical entry. Inserting a suitably sized screw-driver or Allen-key into the

centre of the conduit entry plug and bend the plug back and forth until it breaks away from the

enclosure.

Always use IP rated cable glands when fitting cable to the instrument. If any electrical entries

are opened using the method above and are later not used, these must be sealed using a

threaded conduit plug with an appropriate IP rating (IP66 or IP67 is recommended)

3.3 Integral Meter Mounting

This instrument may be purchased as a meter mount display which will mount on the top of any

Flomec flow meter. For any instruments purchased as field mount, these may be converted to a

meter mount instrument by purchasing a new rear enclosure.

For mounting this instrument on a Flomec flowmeter with a process temperature of over

80oC/1760F there is a ‘Cooling Fin Kit’ available from the manufacturer which will allow this;

these may be retro-fitted in the field with minimal effort.

10

3.4 Wall and Pipe Mounting

Mounting of the instrument on a pipe or flat surface (such as a wall) can be accomplished using

the Wall Mount Kit (part no. 1522001) or Pipe Mount Kit (part no. 1522002) – see next page for

diagram.

3.5 Panel Mounting

Mounting of the instrument in a panel requires a 106mm (±2mm) / 4.10” - 4.25” round hole to

be cut in the panel – maximum panel thickness 6mm (1/4”). The Panel Mount Seal Kit (part no.

1504003) must be used to maintain weather protection when panel mounted. IP65 is possible

with the seal kit used. If the instrument is installed indoors the instrument may be panel

mounted without the seal kit.

11

The rear enclosure of the instrument should be mounted behind the panel (as per diagram

above) to protect the electronics module from damage and provide separation from any

conductive components inside the panel/cabinet.

12

4. Electrical Installation

All wiring connections should be made with good quality shielded instrument cable; wiring

between terminals which are inside the instrument enclosure, or between a flowmeter and an

integrally mounted instrument may use non-shielded wire. Cable shields or drain wires should

be connected to the instrument ground (GND) at the instrument end only – isolate the

shield/drain wire at the flowmeter end of the cable.

The terminal connections on the instrument will allow for usage of wiring up to 1.5mm2 cross

section (16AWG) – if two wiring connections into the same terminal are required the maximum

cross section of each wire is 0.75mm2. Wire insulation should be stripped to a length of 6.5mm

and conductors should be fitted to the terminals so that there is minimal exposed conductor.

Terminals can be tightened with a 2.5mm or 3/32” flat blade screw-driver.

4.1 Input Connections

The EB11 can take a variety of common industrial inputs, including coil, NPN and reed. A 8.2V

DC power supply terminal with current capacity of 10mA is available for powering low-power

flowmeter electronics. This is available at terminal 4.

4.1.1 Sine-wave signal (coil input)

The EB11 is suitable for use with flowmeters with a coil output, such as the FLOMEC TP

series turbines, or the Weigand sensor on the FLOMEC DP Insertion meters. The minimum

sensitivity level is 30mVpp. Note, 2 wire coil sensors are not polarity sensitive.

13

4.1.2 NPN Signal Input

The EB11 is suitable for use with flowmeters which have a NPN output signal such as the

hall effect output on the OM series flowmeter. The sensor supply (terminal 4) can power

the electronics on OM series flowmeter PCBs. If the EB11 is ordered as the integral option

for an OM series flowmeter, it will come in this configuration.

4.1.3 Reed-switch Signal Input

The EB11 is suitable for use with flowmeters which have a reed-switch. For non-Flomec

meters make sure the contact resistance of the reed switch is less than 10k Ohm.

14

4.1.4 NAMUR Signal Input

The EB11 is suitable for flowmeters with a NAMUR signal. The EB11 is able to power the

NAMUR sensor via the 8.2V sensor supply (terminal 4).

4.2 Digital Outputs

4.2.1 NPN Transistor Outputs

The functionality of the digital outputs is to control a valve, pump or other device.

Two passive transistor outputs are available that switch either simultaneously or

sequentially depending on the valve programmed for preclose. Maximum current of

300mA and maximum voltage of 30V. Outputs can be connected to external relays to

allow switching of high current/voltage devices and AC devices.

15

5. Programming Parameters

To enter programming mode, hold the START key down for 7 seconds until the SETUP indicator

stops flashing. Once programming mode has been entered the STOP key can be used to cycle

through the four sub-menu options and the START key can be used to view the screens within

each sub-menu. When you wish to enter a screen to update a setting press both the START and

STOP buttons simultaneously and rapidly. When you have successfully entered a screen, the

PROG signal will flash to indicate that you are now able to edit the setting.

5.1 Preset Menu

Explanation of SETUP-menu 1 – Preset

1 PRESET

1.1 UNIT

This setting determines the measurement unit for Preset and

(Accumulated) Total.

The following can be selected:

L– m3 – kg – LB – GAL – USGAL – bbl – (no unit).

1.2 DECIMALS The decimal point determines Preset and (Accumulated) Total the

number of digits following the decimal point.

The following can be selected:

0 – 0.1 – 0.02 – 0.003

1.3 K-FACTOR With the Total K-Factor, the flowmeter pulse signals are

converted to a total unit. The Total K-Factor is based on the

number of pulses generated by the flowmeter per selected

measurement unit (SETUP 1.1). Use SETUP 1.4 to set the decimal

point.

The more accurate the Total K-Factor, the more accurate the

functioning of the system will be.

1.4 K-FACTOR DECIMALS This decimal point determines for K-Factor (SETUP 1.3) the

number of digits following the decimal point.

The following can be selected:

0 – 0.1 – 0.02 – 0.003 – 0.003 – 0.0004 – 0.00005 – 0.000006

16

5.2 Overrun Menu

Explanation of SETUP-menu 2 – Overrun

Overrun can occur at the end of the batch process, as a result of a slow acting valve or

pump. Consequently, the accuracy is reduced. With this function, the Easybatch analyses

the actual overrun characteristic after every batch and corrects the overrun automatically.

2 OVERRUN

2.1 TIME Enter the expected time in the range of 0 – 99 seconds, needed by the

system to stop a batch.

With value 0, the overrun function is disabled.

It is advised to provide extra time in order to avoid an incorrect overrun

correction.

2.2 Preclose In case two-stage batch control is desired, output 2 can be used to be

switched-off before output 1. This switch moment is based on the remaining

quantity before the end of batch.

If pre-close is set to zero, output 2 will switch simultaneously with output 1.

5.3 Meter Menu

5.3.1 Signal Type

The input type can be selected from the following; coil, reed switch, NPN, PNP or NAMUR. The

following table should be referenced when selecting the correct software setting for your

flowmeter. Instruments delivered integrally mounted to a flowmeter will have this parameter

factory set and do not require user adjustment.

Sensor Type Used in: Software

Setting

Maximum

Frequency

Reed Switch OM Meters

DP Meters REED

NPN Sensor

OM Meters – Hall Effect

DP Meters – Hall Effect

EGM Meters – Hall Effect

NPN

PNP Sensor Other manufacturer’s

Flow Meters PNP

Variable Reluctance Coil Turbine Flowmeters Coil

Wiegand Sensor DP Meters - Voltage Pulse Coil

17

5.3.2 Explanation of SETUP-menu 4 – Other

4 OTHER

4.1 MODEL For support and maintenance it is important to

have information about the characteristics of the

Easybatch. Your supplier will ask for this

information in the case of a serious breakdown or

to assess the suitability of your model for upgrade

considerations.

4.2 SOFTWARE VERSION

4.3 SERIAL NO.

4.4 PIN All SETUP values can be password protected.

This protection is disabled with value 0000 (zero).

A 4 digit PIN can be programmed, for example

1234.

4.5 BL BACKLIGHT This submenu is used to switch the backlight on or

off. Due to a lack of sufficient power, the backlight

does not come on at battery power only.

18

5.4 Setup Menu Parameters

1. PRESET

1.1 unit Unit -----(no unit); L; m3; kg; lb; GAL; USGAL; bbl

1.2 decs Decimals 0; 0.1; 0.02; 0.003

1.3 k-f K-Factor 0.000010 - 9999999

1.4 kf-d K-Factor Decimals 0; 0.1; 0.02; 0.003; 0.0004; 0.00005; 0.000006;

2. OVERUN

2.1 time Time 0 99 sec

2.2 Preclose 0000.000-9999999

3. METER

3.1 sign Signal Coil; Reed; NPN; PNP; NAMUR

4 OTHERS

4.1 modl Model BASIC61

4.2 v-no Software version nn.nn.nn

4.3 s-no Serial number nnnnnnn

4.4 pin Pin code nnnn

4.5 bl Backlight on; off

19

6. Problem Solving

In this appendix, several problems are included that can occur when the Easybatch is going

to be installed or while it is in operation.

Flowmeter does not generate pulses

Check:

Signal selection SETUP 3.1.

Pulse amplitude (paragraph 4.6.1).

Flowmeter, wiring and connection of terminal connectors (paragraph 4.6.1).

Power supply of flowmeter (paragraph 4.4.2).

Flowmeter generates "too many pulses"

Check:

Settings for Total and Flowrate.

Type of signal selected with actual signal generated (paragraph 3.3.4),

Sensitivity of coil input.

Proper grounding of the Easybatch, avoid ground loops.

Use screened wire for flowmeter signals and connect screen to the ground input

terminal of the flowmeter input.

The password is unknown

If the PIN cannot be retrieved, there is only one possibility left: call your supplier.

ALARM ####

When the alarm flag starts to blink an internal alarm condition has occurred. Press the STOP

key several times to display the error code. The codes are:

0001 = display error

0002 = data-storage error

0004 = initialization error

When multiple alarms occur, the error code shown is the sum of the error codes as given

above.

E.g. 0005 is a combination of error code 0001 and 0004.

If the alarm occurs more often or stays active for a long time, please contact your supplier.

20

7. Spare Parts

Spare parts for your instrument are available from the local dealer or national distributor

from whom you purchased the instrument; see spare parts list below to determine which

parts numbers you require.

Description: Includes: Part No:

Bezel Cover 1 x Bezel Cover 1306014

Front Housing Kit Complete replacement front housing with

facia. 1502058

Meter Mount

Rear Housing Kit

(M20)

Rear housing for meter mounted instrument

(M20 electrical entries). Includes the required

fasteners and seals for meter mounting

1502001

Meter Mount

Rear Housing Kit

(NPT)

Rear housing for meter mounted instrument

(NPT electrical entries). Includes the required

fasteners and seals for meter mounting

1502002

Field Mount Rear

Housing Kit (M20)

Rear housing for field mounted instrument

(M20 electrical entries) 1502003

Field Mount Rear

Housing Kit (NPT)

Rear housing for field mounted instrument

(NPT electrical entries) 1502004

Fastener Kit All internal and external fasteners, including

meter mount screws. 1508128

Housing Seal BS046 Buna-N (Nitrile) O-Ring BS046B

Safe Area Battery 3.6V AA Lithium Battery 1312035

Alternative Replacement Battery for Safe Area Units Only Tekcell SB-AA11

Tadiran TL5903/S

Note: Use of a battery which is not a 3.6V Lithium Thionyl Chloride type will void the

instrument warranty.

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

Carrier

Carrier XCT7 40VCW117FQEE Installation and owner's manual

CBE

CBE PRS300 BUS user manual

Märklin

Märklin 51099 User instructions

Lucent Technologies

Lucent Technologies Lineage 2000 ECS-6U product manual

Pratissoli

Pratissoli PNR1520 operating instructions

Leroy-Somer

Leroy-Somer R220 VSG+CCM Installation and Maintenance