Floor iQ VLFR-220R User manual

1

!

!

FLOOR!IQ!VLFR)220R/VLFR)380R!

User Guide

2

!

TABLE OF CONTENTS

1 INTRODUCTION page 2

2 DEVICE DESCRIPTION page 2

Applications

Accessories

Safety device

3 SAFETY INSTRUCTIONS page 3.4

Environmental requirements

Protective equipment

Electrical hazards

Cutting blades

Warning symbols

4 COMPULSORY CHECKS BEFORE START-UP page 5

5 OPERATION page 6.7

Removing the cutting blade

Fitting the cutting blade

Setting the depth

Enable/Disable

6 MAINTENANCE page 7

7 TECHNICAL DATA page 8

8 FAULT OVERVIEW page 8

9 PARTS LIST FOR MACHINE page 9

3

1 INTRODUCTION

Thank you for choosing a Floor IQ floor milling machine.

This user guide describes the VLFR semi-self-propelled floor milling machine. This user

guide contains important information to ensure your machine is operated correctly and

safely.

Read this user guide carefully before using the semi-self-propelled floor milling machine.

Always keep this user guide with the machine so you have the guidelines and safety

instructions to hand at all times.

2 DEVICE DESCRIPTION

Application

The VLFR semi-self-propelled milling machine is a motorised floor milling machine that is

to be used for milling slots in sand cement and anhydrite floors. The machine has a

diamond cutting blade. The upper half of the cutting blade is protected by a metal cover

equipped with a vacuum cleaner connection. When working dry with this machine, you

can work fully dust-free if you have a suitable vacuum cleaner attached.

In connection with currently applicable regulations, you must ensure your vacuum

cleaner is equipped with an M-class filter cartridge or higher.

Accessories

This floor milling machine can use cutting blades of different widths.

A size/distance guide and larger dust cover are optional and do not form a part of the

standard equipment for this machine.

Safety device

To prevent the floor milling machine becoming overloaded, the machine is equipped with

thermal protection. This thermal protection can be set to 14 A for a 230V machine and 9

A for a 400V machine. These values must never be set higher and the thermal protection

must never be overridden.

4

3 SAFETY INSTRUCTIONS

Read the following safety instructions carefully before using the floor milling machine.

Follow these safety instructions during use.

STORE THE SAFETY INSTRUCTIONS with the machine so they can be consulted whenever

required.

Environmental requirements

•!NEVER use the floor milling machine in the vicinity of flammable liquids

or gases.

•!Before beginning to mill the floor, ensure there are no water and/or

electric lines under the surface by means of construction drawings or

detection.

•!NEVER use the milling machine unless the workplace is clean and tidy

and there are no trip hazards. Also ensure the workplace is well lit.

•!Ensure there are no other people in the vicinity. NEVER allow children in

the vicinity in particular. Ensure no one touches the floor milling

machine.

•!NEVER allow yourself to be distracted while working with the machine.

•!Ensure you retain an easy body posture.

•!Ensure you always use the proper Personal Protective Equipment, as

listed below.

Loading and unloading

•!Lifting the machine with two persons is forbidden; this is due to the

total weight of the machine being above 50 kg.

Personal Protection Equipment

The following Personal Protective Equipment must be worn.

•!hearing protection

•!safety shoes

•!a class P3 dust mask

•!Do not wear jewellery or loose clothing.

5

Electrical hazards

•!Always connect your power cord to a fuse box with a circuit breaker.

Use a fuse with a rating up to 16 A.

•!NEVER use the milling machine in a wet or damp location.

•!Never work with the machine outside in the rain.

•!The milling machine is an electrical device. To prevent electrical shock,

injuries and a possible fire hazard, the safety instructions must ALWAYS

be followed.

•!The floor milling machine is equipped with an earthed plug; NEVER

replace this for a plug without an earthed connection.

•!Ensure you plug the machine into an earthed electrical socket at all

times.

Cutting blades

•!Only use Flooriq cutting blades because these are manufactured under

the OSA standard. This means they meet the highest safety standards

that can be required of a diamond cutting product.

•!Do not use cutting blades with an incorrect shaft opening size or a

diameter smaller or larger than recommended.

•!Ensure the floor milling machine is clean. Keep the handles dry and free

of oil and grease.

•!The cutting blades are sharp, work diligently and carefully.

•!When changing a cutting blade, the plug must always be removed from

the socket before the plastic nuts holding the dust cover in place are

removed.

Warning symbols

The following warning stickers can be found on the floor milling machine

with the following ban and warning pictograms (you will only find the

rotation direction arrow on the 400V version):

6

4 COMPULSORY CHECKS BEFORE START-UP

The following checks are required before starting up the floor milling

machine.

The milling machine must NEVER be used if one or more of the following

checks show either the power supply or the machine is not working

correctly.

Check the power supply to ensure:

Safety extension cables are suitable for the intended work.

Electrical cables have been completely rolled out of the reels, the length of

the cable to your power point must not be more than 20 metres for a 230

V supply and must be at least 2.5 mm2thick.

Electric cables are not damaged or broken.

There is no water on the work floor.

You have an earthed electricity supply on the work location.

Check the milling machine to ensure:

The operation switch is in the OFF position; this is to ensure the milling

machine does not switch on as soon as it is plugged in.

The safety device and operation switch are working correctly.

A component with a safety device or operation switch that is not working

correctly is replaced before starting work.

The cutting blade is not deformed or cracked; replace the cutting blade if it

is damaged, not working correctly, or if you have any doubts about the it's

soundness.

The cutting blade and the clamping bush are tightened.

The protective cover for the cutting blade is correctly fitted and securely

tightened.

There are no keys or other tools on the milling machine.

7

5 OPERATION

During the operation of the milling machine, the following additional safety

instructions must be followed.

Only work with an earthed power cable of the proper thickness (at least 2.5

mm2).

Ensure the machine is NEVER placed under undue load while milling.

NEVER stop the cutting blade movement by applying pressure to the sides.

Only use original Flooriq cutting blades.

Removing the cutting blade

Always remove the plug from the socket before replacing the cutting blade.

And ensure you are wearing a (class P3) dust mask.

1!Unscrew the two plastic nuts on the dust cover.

2!Remove the dust cover.

3!Using a suitable spanner, loosen the nut from the shaft.

4!Remove the packing bush.

5!Removing the cutting blade.

Fitting the cutting blade

Fitting a cutting blade is carried out in the reverse order of the removal.

1!Slide the cutting blade over the drive shaft.

2!Slide the packing bush over the shaft.

3!Screw the nut onto the shaft and tighten it firmly with a suitable

spanner.

4!Fit the dust cover and tighten the two plastic nuts.

Adjusting the milling depth

1!Loosen the lock lever to the left.

2!Rotate the plastic spindle to bring the cutting blade to the desired

depth.

3!Tighten the lock lever to the right so the cutting blade remains at

the same depth. (Note: the cutting blade wears down during milling,

this affects the milling depth).

8

Switching the machine on and off

Switching on

1!Always turn on your vacuum cleaner before the milling machine.

2!Pull the red emergency stop button outwards.

3!Press the black button beside the emergency stop.

4!Allow the machine to reach the operating speed.

5!Set the desired cutting depth.

6!Start milling. Move the machine over the floor slowly and at a

constant speed.

7!If you want to use the auxiliary motor, squeeze the handle and turn

the potentiometer to the desired position. Ensure the ammeter does

read above 14 A (230 V) or 9 A (400 V).

Switching off

1!Press the red emergency stop button.

2!Do not raise the cutting blade out of the floor before it has stopped

moving completely.

3!Now switch the vacuum cleaner off.

6. Maintenance

Check the cutting blade is in good condition on a regular basis. Replace the cutting blade

if it appears to be damaged, deformed or worn.

To avoid premature wear of the machine, keep it as free from dust as possible. Clean the

machine with a vacuum cleaner regularly.

Repairs to the machine may only be performed by your supplier or professionally trained

mechanics. If Flooriq has not carried out the repairs on the machine, your warranty will

be void.

This will ensure your machine remains safe and reliable.

9

7 Technical data

Number of cutting blades : 1

Max. blade width : 18 mm

Max. cutting blade diameter : 120 mm

Min. cutting depth : 1 mm

Max. cutting depth : 24 mm

Blade (shaft hole) : 22.2 mm

Power supply : 230 V or 400 V

Revolutions per minute : approximately 6,800 rpm

Noise level : 86 dB(A)

Weight : approximately 75 kg

Flooriq reserves the right, without prior warning, to change the technical data described

above in connection with the ongoing, innovative development of the machine.

8 Fault Overview

Fault

Possible cause

Solution

The cutting blade cannot be

properly secured.

The cutting blade does not

meet the specifications.

Replace the cutting blade

with an original cutting

blade.

The dust cover will not

close.

The diameter of the cutting

blade is too large.

Remove the cutting blade

and replace it with a blade

that has a max. diameter of

120 mm.

Milling creates a lot of dust.

The vacuum cleaner.

Check whether the vacuum

cleaner filter is clean

enough; if not, clean the

filters.

The machine motor is

turning, but the cutting

blade remains stationary.

Toothed belt or clamping

nut of the cutting blade.

Check whether the toothed

drive belt has not broken,

and ensure the cutting

blade clamping nut has

been tightened sufficiently.

The thermal protection of

the machine keeps cutting

out.

The floor may be too hard,

the machine may be pushed

too fast, or the auxiliary

motor is set too high.

Replace the cutting blade

with a cutting blade that is

suitable for hard floors, let

the machine do the work.

Go slower, or turn the self-

propelling system down

using the potentiometer.

(Only available on the 400

V version)

Cutting blade is turning in

the wrong direction

The phase is not set

correctly.

Turn the machine off,

unplug the power cord and

reset the phase converter

using a screwdriver.

(Keep the connector

unplugged at all times).

10

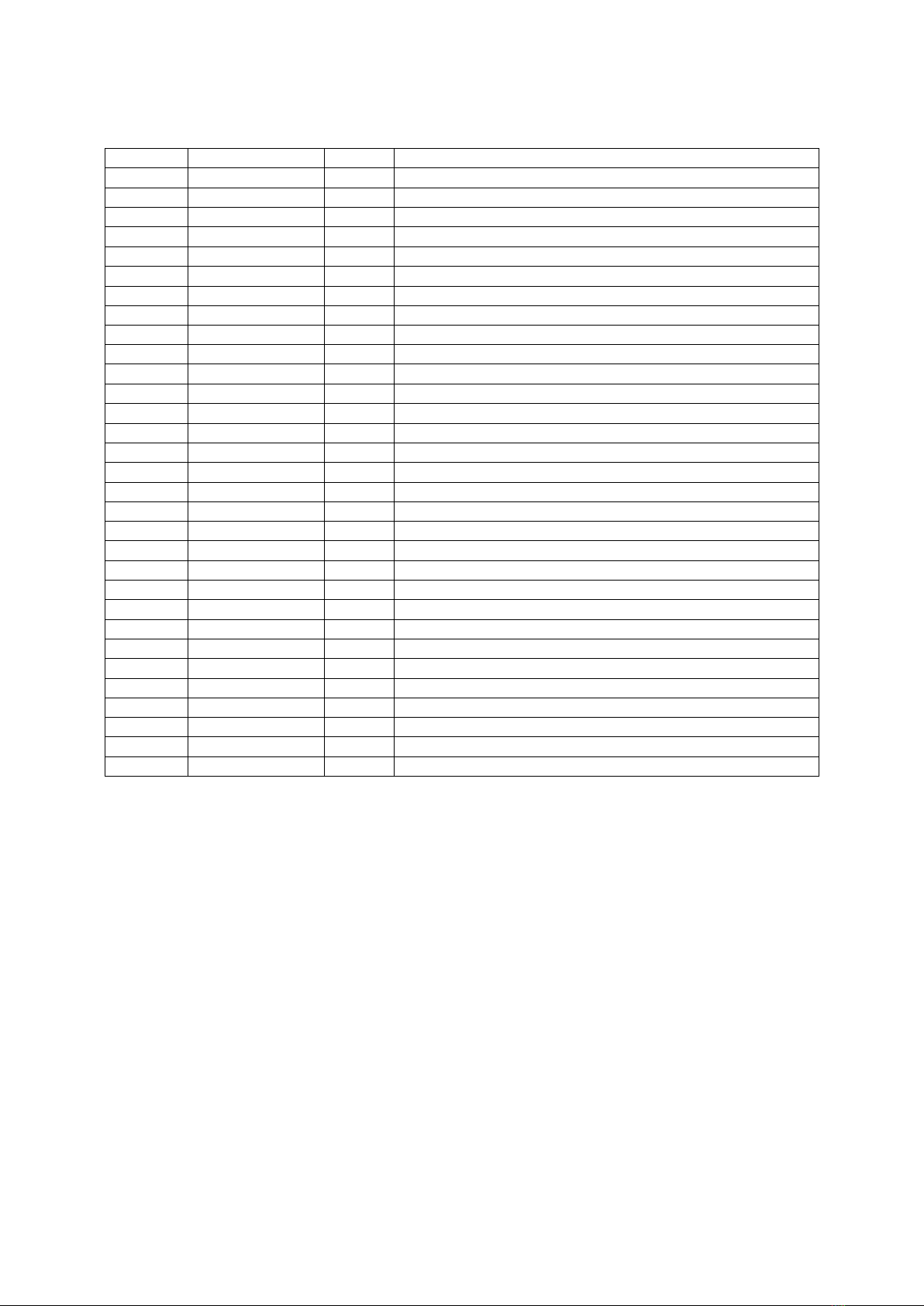

9 Parts list for machine

number

article number

amount

Description

1

VLFR1

2

Plastic handles

2

VLFR2

1

Thermal protection and emergency stop switch

3

VLFR3

1

Nut for the articulation mechanism

4

VLFR4

1

Articulation rod, two-piece

5

VLFR5

1

Bottom plate for machine

6

VLFR6

1

Bolt for rear wheels

7

VLFR7

1

Ball bearing for rear wheels

8

VLFR8

8

Rings for rear wheels

9

VLFR9

4

Rear wheels

10

VLFR10

1

Axle for rear wheels

11

VLFR11

1

Rear mounting plate for motor

12

VLFR12

1

Drive motor

13

VLFR13

1

Drive mounting plate

14

VLFR14

1

Drive protective cover

15

VLFR15

1

Protective cover bolt

16

VLFR16

1

Upper sprocket

17

VLFR17

1

Clamping bush for upper sprocket

18

VLFR18

2

Allen screws for upper sprocket clamping bush

19

VLFR19

1

Plastic handle

20

VLFR20

2

Rings for handle

21

VLFR21

2

Allen bolts for handle

22

VLFR22

2

Allen bolts for middle wheel

23

VLFR23

1

Axle for middle wheel

24

VLFR24

1

Middle wheel

25

VLFR25

2

Rings for middle wheel

26

VLFR26

2

Bearing including housing for drive shaft

27

VLFR27

1

Lower sprocket

28

VLFR28

1

Clamping bush for lower sprocket

29

VLFR29

2

Allen screws for lower sprocket clamping bush

30

VLFR30

1

Cutting blade drive shaft

31

VLFR31

1

Cutting blade dust cover

This manual suits for next models

1

Table of contents

Other Floor iQ Power Tools manuals