Flow Controller Systems FCS KA SS User manual

Other Flow Controller Systems Water Pump manuals

Flow Controller Systems

Flow Controller Systems FCS KA-DISP User manual

Flow Controller Systems

Flow Controller Systems FCS KA1 User manual

Flow Controller Systems

Flow Controller Systems FCS KA6/12 User manual

Flow Controller Systems

Flow Controller Systems FCS KA6 User manual

Flow Controller Systems

Flow Controller Systems FCS KA User manual

Popular Water Pump manuals by other brands

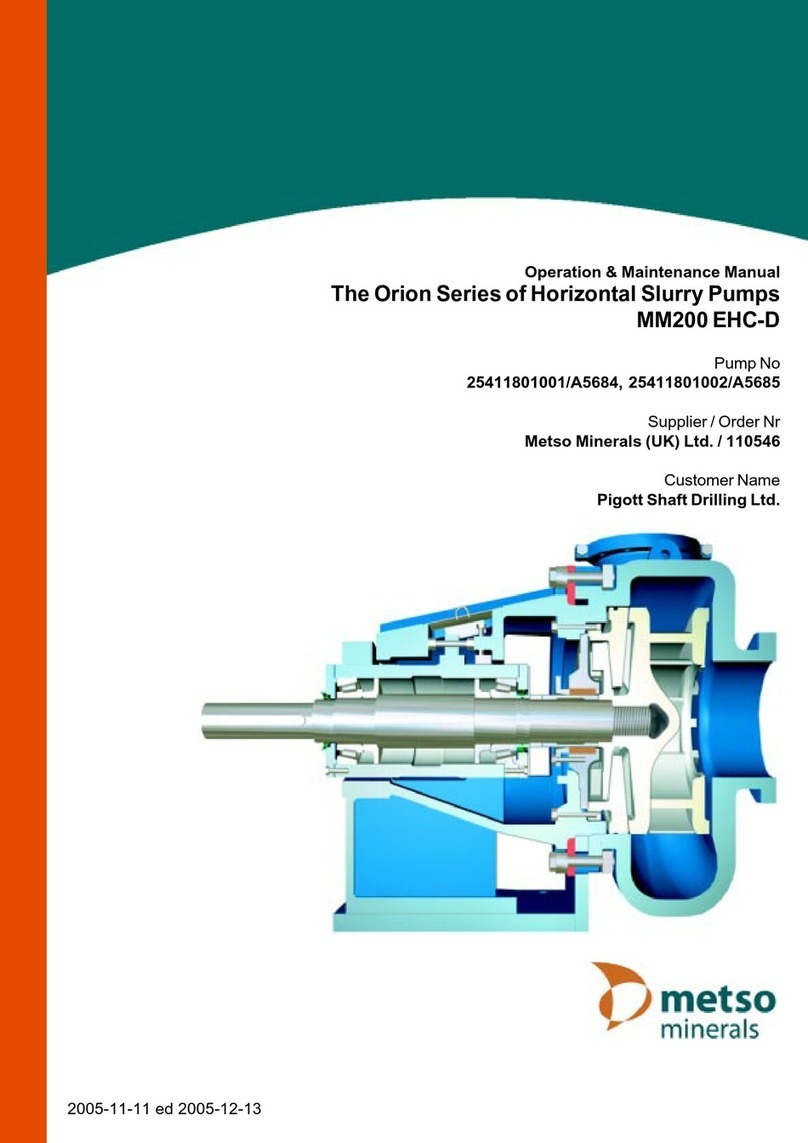

Metso

Metso Orion Series Operation & maintenance manual

Master Plumber

Master Plumber 220193 owner's manual

Grundfos

Grundfos CU 3x2 instructions

Perle

Perle MP-PRO Series Installation and maintenance instructions

Wacker Neuson

Wacker Neuson PG 3A Operator's manual

Pompetravaini

Pompetravaini TC Series Disassembly & Assembly Instructions

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS PA12A60-B-6068H Installation, operation, and maintenance manual with parts list

WilTec

WilTec 61962 Operation manual

Intex

Intex 128644GS owner's manual

Pentair

Pentair MYERS D65-16 Series manual

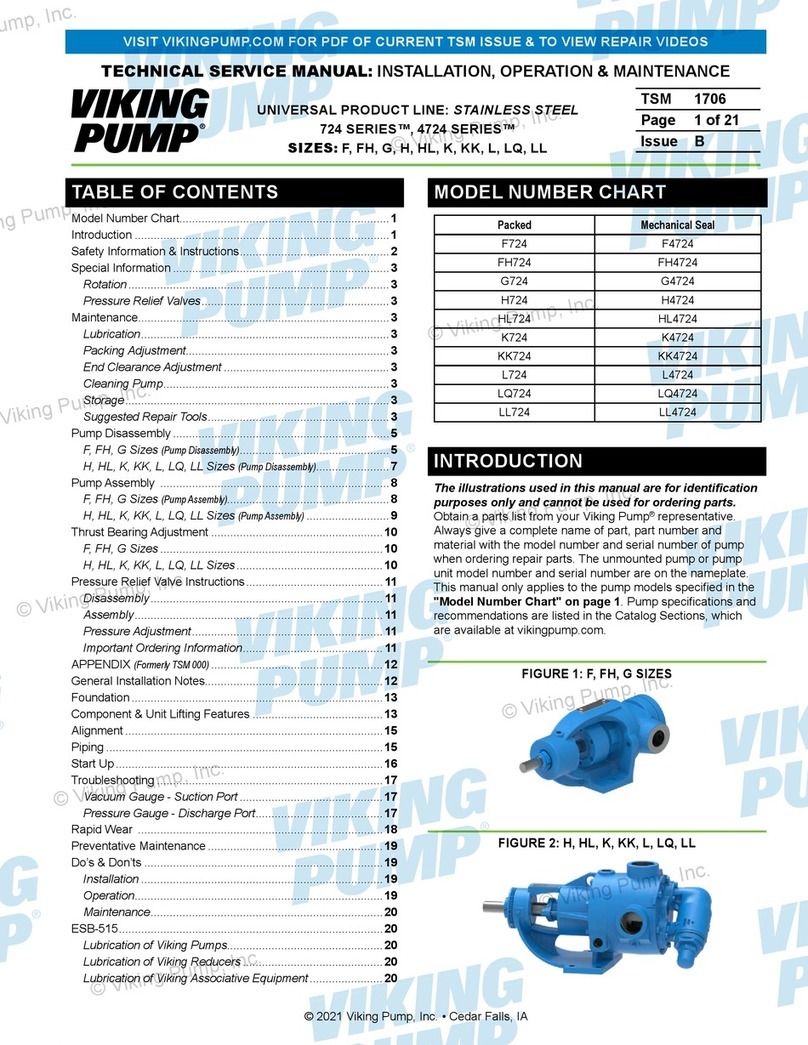

Viking pump

Viking pump 724 Series Technical & service manual

KNF

KNF N85.3 TRANSLATION OF ORIGINAL OPERATING AND INSTALLATION INSTRUCTIONS

Boss Hydraulics

Boss Hydraulics PE026 operating instructions

ULTIMATE SPEED

ULTIMATE SPEED 12 V UOP 12 C1 Operation and safety notes

DGSI

DGSI TR-974 manual

Aspen Pumps

Aspen Pumps Silent+ Mini Lime manual

Kessel

Kessel Aqualift F XL Mono Installation and operating manual

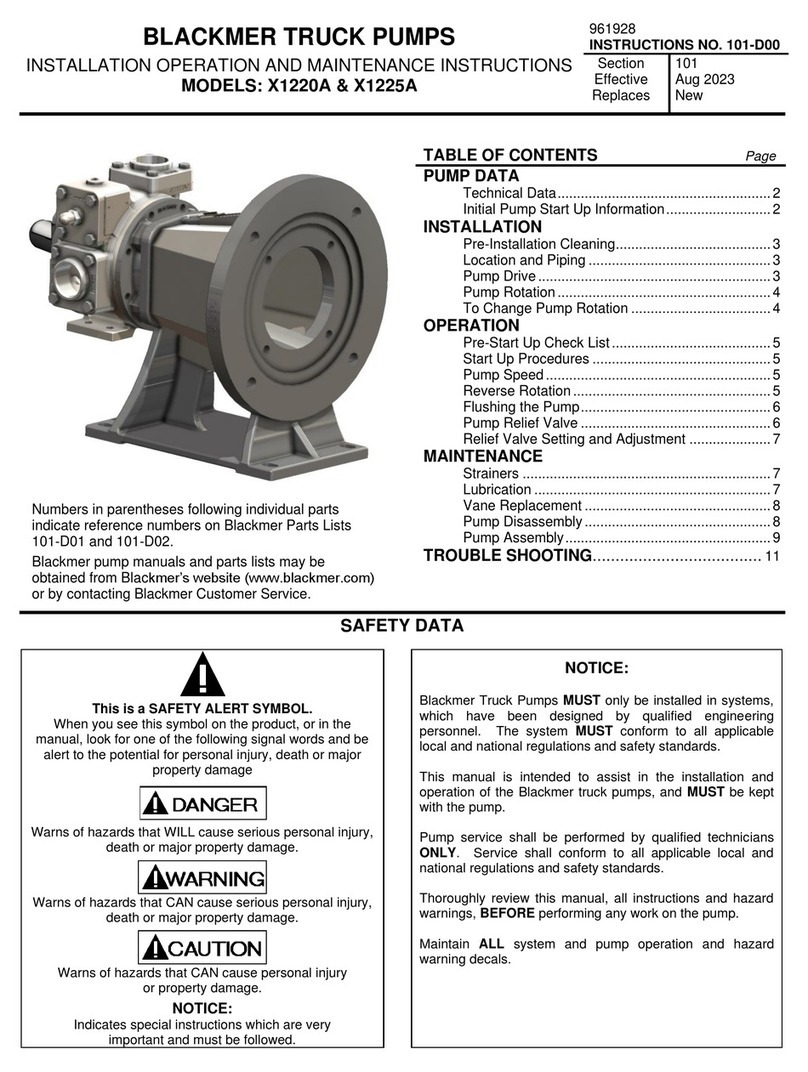

BLACKMER

BLACKMER X1220A Installation, operation and maintenance instructions