Flow Controller Systems FCS KA User manual

FCS KA (SS)

Compact Peristaltic Pump

Operation Manual

Note:

Please read the manual carefully before operating the product.

Warning:

Connect the power cord to the wall socket directly, and avoid using a power

extension cord.

If the power cord or plug has wear or other damage, please disconnect the plug.

(Hold the plug instead of the wire.)

If following situations happen, please turn off the power supply and disconnect

the plug. (Hold the plug instead of the wire.)

1. Fluid splash on the pump.

2. You think the pump needs to be maintained or repaired.

The user's power socket must have a ground wire with a reliable grounding.

Note: The foot pedal switch and other external control plugs must be connected and

disconnected in the power-off status to prevent the external control interface from

being burned.

Catalogue

1. Product Introduction ........................................................................................... - 1 -

2. Product Appearance ............................................................................................ - 1 -

3. Operation Panel .................................................................................................. - 2 -

4. External Control Instruction ............................................................................... - 3 -

5. Communication Function Instruction ................................................................. - 7 -

6. Technical Specification ....................................................................................... - 8 -

7. Main Function and Feature ................................................................................. - 9 -

8. Dimension Drawing ............................................................................................ - 9 -

9. Maintenance ..................................................................................................... - 10 -

10. Warranty & After-Sales Service ...................................................................... - 12 -

FCS KA (SS)

-1 -

1. Product Introduction

FCS KA (SS), with low noise and stable operation, is driven by an integrated stepper

motor with a compact structure. The product adopts OLED blue screen display and

has an external control interface, which can realize remote control. It can communicate

with a computer through standard Modbus communication protocol (RTU mode).

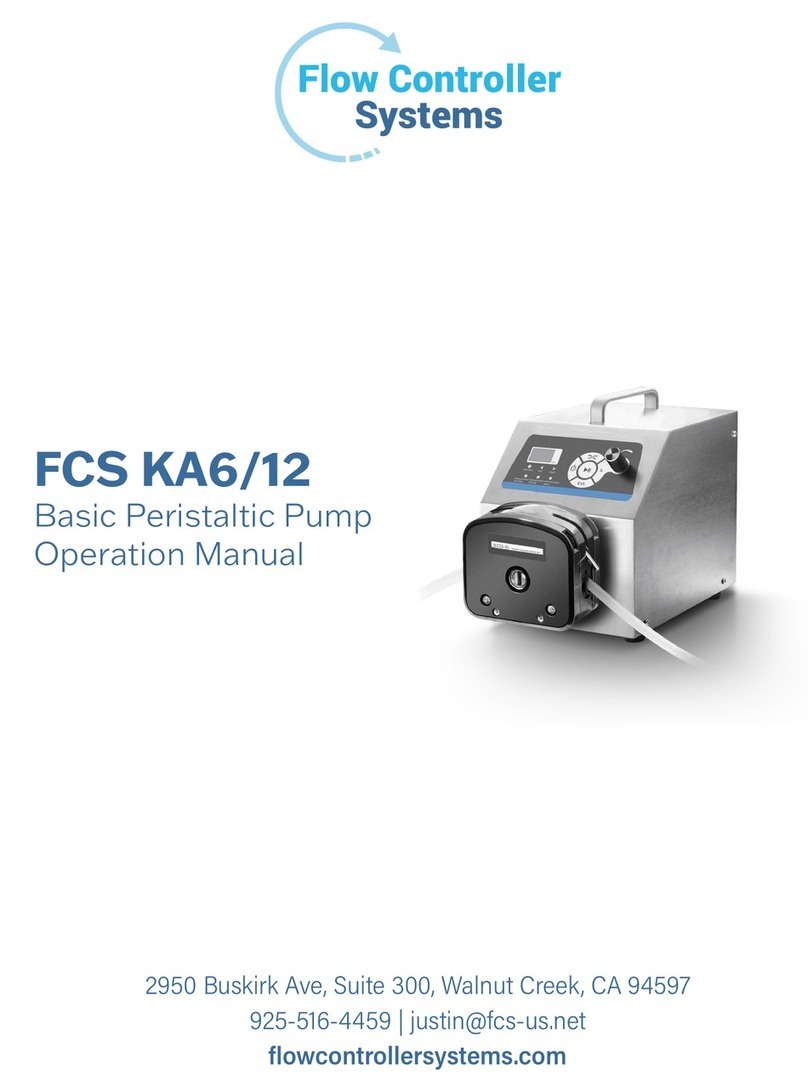

2. Product Appearance

A

B

C

DF

E

G

H

A—— Operation panel

B—— Drive

C—— Pump head

D—— Fan interface

E—— Power supply switch

F—— USB interface

G——External control interface

H——Power supply socket

-2 -

3. Operation Panel

Direction Digital Knob

EXT

Start/stop

Ext. control

100.0

V 01

转速

通信地址

模拟调速

运行状态

5V 01

Speed

Analog speed

control

Operation

status

Communication

address

Start/Stop Button

Pumps start/stop can be controlled by this button. Press this button once, the pump

working status change once. When the drive runs, the screen displays ‘▶’, when the

pump stops, the screen displays ‘■ ’.

Direction

This button is used to change the motor running direction. Press this button once and

the running direction of pump changes once.

External control button

This button is used to change the method of analog speed control. Press this button

once and that will cycle the display: Empty→5V→10V→mA→Empty. Respectively

corresponding to: Turning off analog speed regulation→0-5V→0-10V voltage analog

speed regulation →4-20mA analog speed regulation →Turning off analog speed

regulation.

Note: If you keep pressing this button and turn on the power supply of this device at

FCS KA (SS)

-3 -

the same time, it will initialize the device and all the parameters will be lost.

Digital Knob

The digital knob used to increase or decrease the motor speed.

(1) In the running state, the digital knob is used to adjust the speed. Turn

clockwise to increase the speed, turn counterclockwise to decrease the speed. If

you keep pressing the digital knob, the motor will run at the highest speed (full

speed), and release it to return to normal speed.

(2) In the stop state, press the digital knob, the lower right corner of the OLED

flashes and the value is RS485 communication address (1~32). At this time, you

can rotate the digital knob to change the value. After setting, press the digital

knob to save the data and the screen no longer flashes.

4. External Control Instruction

FCS KA (SS) series has a 15-pin interface for the external control interface, as the

below figure shows. That includes the function of external control start/stop, direction,

analog speed regulation, communication, and status output.

1

15

5

610

11

1

5

6

10

11

15

Pin 1, port of external control start/stop

Pin2, port of external control direction

Pin3, external control level mode switching

Pin4, RS485B-

FCS KA (SS)

-4 -

Pin5, RS485A+

Pin6, analog speed regulation 0-5V signal terminal

Pin7, analog speed regulation 0-10V signal terminal

Pin8, analog speed regulation 4-20mA signal terminal

Pin9, analog speed regulation common terminal AGND

Pin10, active external control isolated signal common terminal, factory defaults

passive external control signal, and this pin is empty

Pin11, status output negative terminal (POWER_GND)

Pin12, status output terminal (OUT_RUN)

Pin13, status output active terminal (POWER_VDD)

Pin14, internal isolated 5V output active terminal

Pin15, internal isolated 5V output negative terminal

(1) Passive external control start/stop, direction

Pulse mode:

Pin1 to Pin14, short circuit break (pulse mode) is start, short circuit break again is stop.

Pin2 to Pin14, short circuit break (pulse mode) is direction.

Level mode:

Pin3 is external control level mode switching. Short circuited Pin3 and Pin14 to switch

to external control level mode.

Pin1 to Pin14, short circuit is start, breaking them is stop.

Pin2 to Pin14, short circuited, motor is counterclockwise, breaking them, motor is

clockwise.

Note: External start/stop and direction is defaulted to passive signal when leaving

factory. This interface could be connected with a foot pedal equipped by our company.

(2) Active external control start/stop, direction

Pulse mode:

Pin10 connects with negative pole of active external control signal.

Pin1 connects positive pole of active external control signal, short circuit and then

disconnect, the motor will start. Do it again, the motor will stop.

FCS KA (SS)

-5 -

Pin2 connects positive pole of active external control signal, short circuit and then

disconnect, the motor will change direction. Do it again, the motor will change

direction again.

Level mode:

Pin10 connects with negative pole of active external control signal.

Pin3 is the pin of external control level mode switching. Short circuited Pin3 and

positive pole of active external control signal switches to external control level mode.

Short circuited Pin1 and positive pole of active external control signal is start, breaking

them is stop.

Short circuited Pin2 and positive pole of active external control signal, the motor is

counterclockwise, break them, the motor is clockwise.

Note: The active external control isolated signal is 5V, 12V, 24V (Universal)

(3) Analog speed regulation

0-5V voltage signal speed regulation

Choose the analog speed regulation signal of the pump to 0-5V voltage signal by

external control button. The analog signal is displayed “5V” in the screen.

Voltage 0-5V speed regulation, Pin6 connects to the positive pole of voltage analog 0-

5V signal. Pin9 to the connects negative pole. Change the voltage value of the analog

signal and the speed changes linearly. 0V corresponds to speed 0rpm, 5V corresponds

to maximum speed.

0-10V voltage signal speed regulation

Choose the analog speed regulation signal of the pump to 0-10V voltage signal by

external control button. The analog signal is displayed “10V” in the screen.

Voltage 0-10V speed regulation, Pin7 connects to the positive pole of voltage analog

0-10V signal. Pin9 connects to the negative pole. Change the voltage value of the

analog signal and the speed changes linearly. 0V corresponds to speed 0rpm, 10V

corresponds to maximum speed.

External control button for current signal speed regulation

Choose the analog speed regulation signal of the pump to current signal and the analog

FCS KA (SS)

-6 -

signal is displayed “mA” in the screen.

Current 4-20mA speed regulation, Pin8 connects to the positive pole of current analog

4-20mA signal. Pin9 connects to the negative pole. Change the current value of the

analog signal and the speed changes linearly. 4mA corresponds to speed 0rpm, 20mA

corresponds to maximum speed.

Note: DO NOT connect the 0-5V/0-10V signal with 4-20mA input terminal. Wrong

connections may cause damage to the device. The external control plugs must be

connected and disconnected in the power-off status to prevent the external control

interface from being burned.

(4) Output signal

1) Connect Power-VDD with the positive pole of external connection power supply

5 V.

2) Connect Power-GND with the negative pole of external connection power

supply 5V.

3) Start motor, relay pull-in; Motor stops, relay breaks.

FCS KA (SS)

-7 -

5. Communication Function Instruction

The pump supports standard modbus protocol (RTUmode), communication modes are

RS485 and USB. It can control the pump start/stop, direction and motor speed, and

can read the current running status.

USB communication mode: A USB cable is needed (one side is USB-A and the other

side is USB-B). Connect the pump with a computer through the USB interface.

Type-A connects computer USB interface

Type-B connects KA (SS) USB

interface

Type Type-A Type-B

Plug(male)

USB2.0

4 3 2 1

Type-A

1 2

4 3

Type-B

Connect with

computer Connect with external control USB interface

RS485 communication: Connect A+ (pin5) from external control interface (as shown

in Picture) to T/R+ of RS485 module; and connect B- (pin4) to T/R- of RS485 module.

Users can control the pump working according with the communication protocol.

FCS KA (SS)

-8 -

RS485 conversion

module

6. Technical Specification

Flow rate 0.0033~365.69

mL/min Power supply AC100V~240V(50HZ/60HZ)

Speed range 0.1~300rpm External control

Start/stop: Switch signal

Speed control: 0-5 V, 0 -10V, 4-

20mA for option

Speed

resolution 0.1rpm Communication RS485

Control

Digital knob/

pure imported

keypad

Temperature 0-40℃

Motor 57 closed -loop

stepper motor

Relative

humidity <80%

Display OLED Output interface Output motor working status

Power

consumption ≤75W IP rate IP31

FCS KA (SS)

-9 -

7. Main Function and Feature

Suitable Pump Head: FCS KA (SS) easy load pump head.

Digital knob control speed, control speed manually or by external control

interface automatically.

Multiple pumps can be controlled by one controller at the same time, RS485

address cannot be repetitive.

The circuit has excellent performance, good heat dissipation conditions, low

working noise, stable operation, and has power-off memory function.

RS485 standard Modbus protocol, that is more convenient to connect with PLC.

304 stainless steel shell, anti-corrosion, no rust, conforms to GMP requirements.

OLED displays motor speed and working status.

8. Dimension Drawing

Unit: (mm)

FCS KA (SS)

-10

9. Maintenance

9.1 Check the running status of the machine before starting it, ensure that the power

supply of the device is reliably grounded. Normal operation can be put into use. The

external wiring of the equipment must be operated in the power-off state to prevent

burning the equipment.

9.2 Check to see if the tubing is damaged or the equipment is leaking and ensure that

the liquid in the tubing is discharged to the container or discharge pipe. Wipe any

leaked liquid around the pump quickly and correct any possible faults promptly. Keep

the rollers of the pump head clean and dry, otherwise it can hasten tubing wear (it can

also damage the tubing causing solid substances in the liquid), reduce the useful life

of tubing, and lead to quicker damage and wear to the rollers. If the pump head gets

water on it accidently, use a soft, absorbent cloth to wipe it dry to prevent damage to

the pump head. If liquid splashes on the pump, please turn off the power supply and

unplug the power wiring. Check to see if there is liquid in the inner part of the

equipment, if so please contact the manufacturer.

9.3 The factors affecting the flow are as follows:

1) The inner diameter and wall thickness of tubing may have some deviations due

to its tolerance and different bathes.

2) Different liquid properties

3) It will decrease flow rate when input port and output port change incrementally

or there are suction and lift.

4) The speed of DC/AC motor will change according to load, temperature and

humidity.

This may influence product flow accuracy, please leave a margin when choose tubing.

9.4 This product has no waterproof measures. Please take protective measures when

using in a wet environment. When the product will not be in use for a long time, please

clean it and keep it in a dry and ventilated environment.

9.5 Pump head is not resistant to organic solvent (Except for special indication) and

strong corrosive liquids, please be attentive when using either near it.

FCS KA (SS)

-11

9.6 The data used for testing in this manual is all short duration and may change for

longer duration use.

9.7 The current will raise over the rated running current when DC/AC motor starts or

blocks, it may be about 3-5 times the rated operating current.

9.8 This product does not have special certification such as medical certification.

When it needs to be used in special fields such as medical and military, please self-

certify. Load changes will also cause changes in operating current. Therefore, please

conduct margin design for power supply power.

9.9 The company shall not bear the direct and indirect losses caused by the malfunction

or improper operation of this product.

FCS KA (SS)

-12

10. Warranty & After-Sales Service

We support 3 years warranty for the pumps, subject to the exceptions below. Our

company shall not be liable for any loss, damage, or expense directly or indirectly

related to or arising out of the use of its products. This warranty does not obligate

our company to bear any costs of removal, installation, transportation, or other

charges which may arise in connection with a warranty claim.

If the pump fails during the warranty period, after confirmation by our technical

department, we will provide spare parts free of charge. Customers will need to bear

the shipping cost.

Exceptions:

The warranty shall not apply to repairs or service necessitated by normal wear

and tear or for lack of reasonable and proper maintenance.

All tubing and pumping accessories as consumable items are excluded.

Electrical surge as a cause of failure is excluded.

Chemical attack is excluded.

Improper operation or man-made damage as a cause of failure is excluded

FCS KA (SS)

Flow Controller Systems

2950 Buskirk Ave Suite 300 Walnut Creek CA 94597

Tel: 925-516-4459

Website: flowcontrollersystems.com

Email: justin@fcs-us.net

This manual suits for next models

1

Table of contents

Other Flow Controller Systems Water Pump manuals

Flow Controller Systems

Flow Controller Systems FCS KA-DISP User manual

Flow Controller Systems

Flow Controller Systems FCS KA SS User manual

Flow Controller Systems

Flow Controller Systems FCS KA6 User manual

Flow Controller Systems

Flow Controller Systems FCS KA1 User manual

Flow Controller Systems

Flow Controller Systems FCS KA6/12 User manual