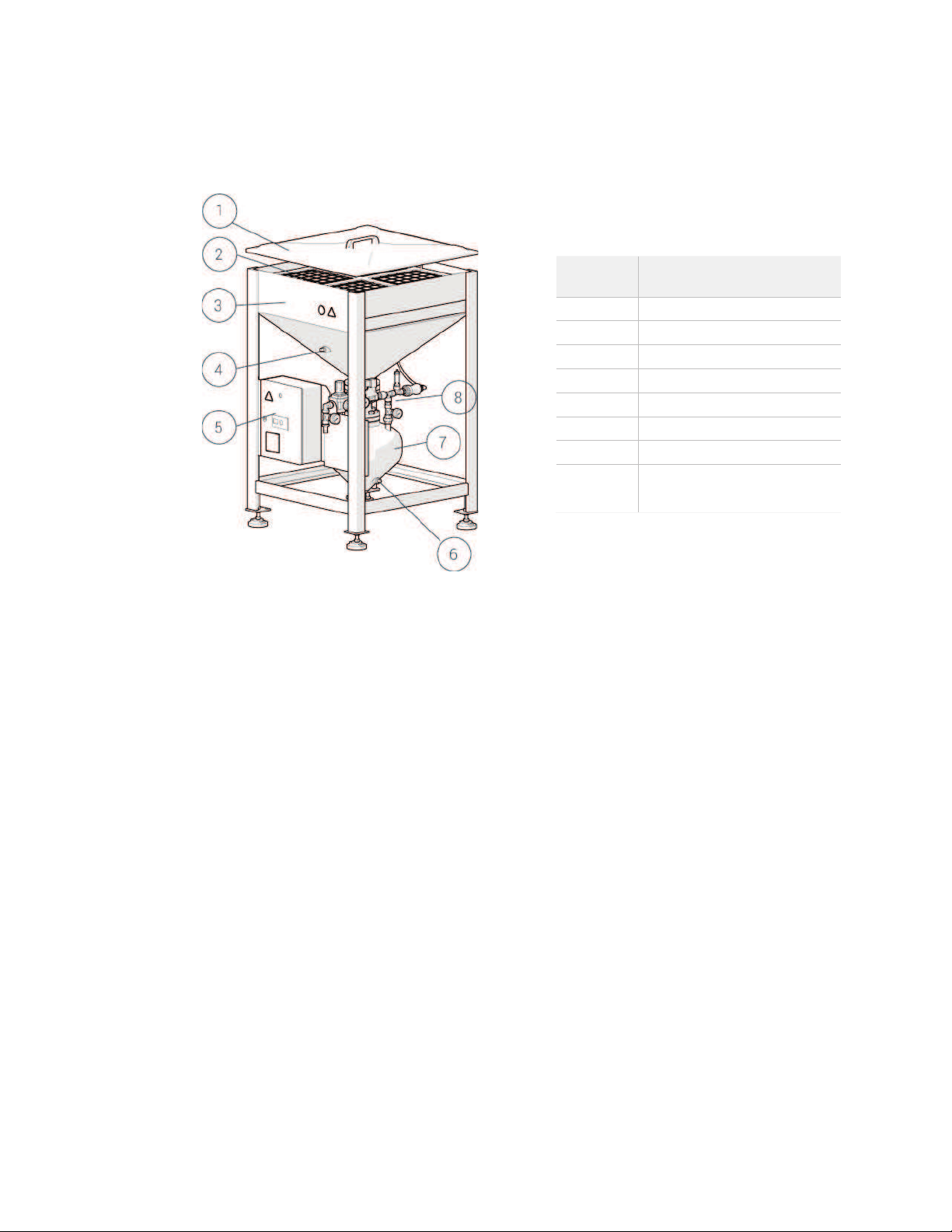

Specifications

Dimensions (Length¯Width¯Height) ................858¯858¯1392 mm (33.8¯33.8¯54.8 in.)

Weight...............................................................................................................112 kg (247 lb) empty

................................................................................................................................537 kg (1184 lb) full

Abrasive capacity ........................................................................................................425 kg (937 lb)

Customer air supply......................................................................... has lockout/tagout capability

Customer air supply line ........................................................................................ >20 mm (3/4 in.)

Operating pressure/volume ............................................ 5.5 bar (80 psi) @ 566 lpm (20 scfm)1

Surge pressure/volume....................................5.5–6.5 bar (80–94 psi) @ 2250 lpm (80 scfm)

Maximum compressed air volume.................. dependent on abrasive material and flow rate

Quality of compressed air........................................................................FT[CPFHKNVGTGFVQO

Supply voltage.......................................................................100–240 VAC, 50/60 Hz, or 24VDC2

AC Frequency.........................................................................................................................50/60 Hz

Full-Load current ................................................................................................... 0.20 A@ 240 VAC

.................................................................................................................................. 0.48 A @ 100 VAC

.......................................................................................................................................2.0 A @ 24 VDC

Largest-load current..................................................................................................................... 2.0 A

Rating (SCCR) ..............................................................................................................................2.5 kA

Site..................................................................................................................................Level and solid

Operating environment temperature..................................................... 0°C–55°C (32°F–131°F)

Operating environment relative humidity ..........................................................................5%–95%

Operating environment elevation................................. 0–2500 m (0–8200 ft) above sea level

Service clearance ................................................................................1 m (3 ft) on front and sides

1Requires a minimum of 2 bar (30 psi) difference between the supply pressure and the operating pressure.

© 2016–2017 Flow International Corporation