Flowcine Black Arm User manual

BLACK ARM SET UP INSTRUCTIONS V0.75

Please read through the full documentation, before using the arm for the first time! The documentation includes configurations and

help for troubleshooting most problems encountered on set.

QUICK GUIDE SETUP AND CONFIGURATIONS FOR: BLACK ARM STANDARD & BLACK ARM COMPLETE

NOTE! The current manual contains instruction/placement

for the first generation dampeners. There is another manual

out soon for second generation (shorter) dampeners soon.

You can tell difference by looking at the soft end stops on the

dampeners. ALL first generation dampeners will be replaced

by Flowcine, as soon as possible, due to production errors

emailed earlier. If you have a urgent problem with your

dampener, please email info@flowcine.com. Thank you!

1st gen dampener (thin rubber end stop opposite end of ball joint)

2nd gen dampener (thick rubber end stop)

337mm

297mm

BLACK ARM SET UP INSTRUCTIONS V0.75

SINGLE SPRING 7.0 (Pre-installed for BLACK ARM STANDARD users): 2 x 7 mm (1x7 per side) for payload up to 14kg / 31 lbs payload. Max extension 25mm.

NOTE! Always insert tension screw equally on each side when mounting a new spring.

Dual nuts (Optional). Keeps the spring from unintentionally wind/un-wind itself.

And keep track on which side to tension from.

Single nut & washer (Optional). Helps keep the dual spring bracket to align straight and not rotate, while there is no load on the springs. Always loosen these

before ANY tensioning is done. You can use a nut&washer on each side, on one side or not use them at all (not necessary when the arm is in action).

Dual nuts (Optional ). Helps you keep track of the maximum safety tension limit of 25mm.

The distance is set, from a relaxed spring (before any tensioning). Use a caliper

or equal to check distance between spring and nut before usage or change of springs.

BLACK ARM SPRING GUIDE:

Single 7.0

SINGLE SPRING 7.5 (Pre-installed for BLACK ARM COMPLETE users): 2 x 7.5 mm (1x7.5 per side) for payload up to 19 kg / 42 lbs payload. Max extension 25mm.

Single 7.5

DUAL SPRING 7.0: 4 x 7.0 mm (2x7.0 per side) for payload up to 28 kg / 62 lbs payload. Max extension 25mm per side.

To change to DUAL SPRING configuration. User the dual spring brackets, and insert the supplied M8x25 screws on each side. Then attach the dual spring

brackets on the tension screws. Please always ensure to grease the tension screws before usage, to minimize friction when tensioning.

Dual 7.0

DUAL SPRING 7.5: 4 x 7.5 mm (2x7.5 per side) for payload up to 38 kg / 84 lbs payload. Max extension 25mm per side.

Dual 7.5

BLACK ARM SET UP INSTRUCTIONS V0.75

1. Lessen the tension on the tension screw on the backside of the BLACK ARM (near the clamps). And follow along

moving the dual nuts that sets the tension safety limit until the tension screw is completely removed.

2. Be sure, not to drop the thrust bearings at the end of the tension screw. These are necessary to enable smooth friction when turning the knob.

3. Once one tension screw is removed, you can easily unwind the spring, and remove the dual nuts on the other side.

4. Rotate the shaft/tension screw and drag it out from below.

BLACK ARM SPRING/TENSION SCREW REPLACEMENT ILLUSTRATION:

BLACK ARM SET UP INSTRUCTIONS V0.75

5. Note correct shaft direction! The shafts should always have the flat surface facing from centre of the arm.

6. Incorrect direction of shafts. If being used the thrust bearings will be bent and lead to problem.

7. Tooless tension knobs. Usually used when using single 7.0 or 7.5 spring configuration when friction isnt to large. You can use hexagon tension screw

on one side, and knob on the other if you like.

8. Heaxgon nut tension screw. Four of these are shipped and packed in the BLACK ARM case, if you prefer to use the supplied ratchet wrench nr 13 for tensioning.

BLACK ARM SET UP INSTRUCTIONS V0.75

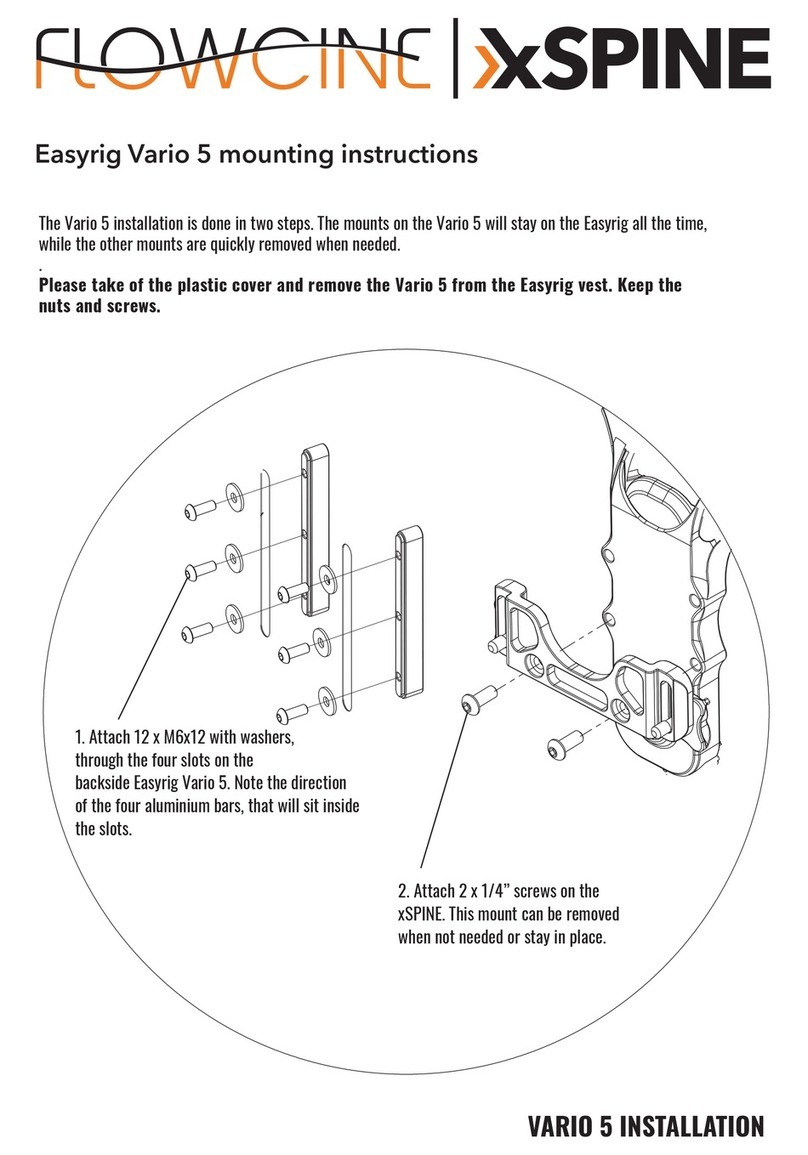

3. If you have a toad-in-the hole or cinemilled mount, you insert the screws from the backside of the base plate. Other mounts can either be mounted directly

from the front of the base plate, using the 3/8”-16 threads. IF you have a gimbal/gyrohead with non-compatible pattern, please let us know and we try to help

you out as soon as possible.

2. Once your vibration mount is removed from the BLACK ARM, remove bottom 4x M6x16 screws using a allen key #5.

Be sure to use mild/medium Loctite thread gluewhen fastening them again (we recommend Loctite 243).

VIBRATION MOUNT / GIMBAL INSTALLATION:

BLACK ARM SET UP INSTRUCTIONS V0.75

4. Put back your bottom 4x M6x16 screws using a round head allen key #5.

Be sure to use mild/medium Loctite thread glue when fastening them again

(we recommend Loctite 243).

5. End by inserting your male mitchel mount into the female mitchell, and lock the

mitchell nut. NOTE! Please check the standard dimension we use for mitchell mount

to see that your male mitchel is compatible. If not, compatible, please let us

know your dimensions and the brand of your mitchell mount.

1. To install your optional mitchell mount. Remove bottom 4x M6x16 screws

using a round head allen key #5. Be sure to use mild/medium

Loctite thread glue when fastening them again (we recommend Loctite 243).

2. Insert your mitchell castle nut between the mitchell rods on the mitchell mount.

Because of limited spacing we don’t allow the mitchell nut to be slided in from

the side afterwards. Flowcine will release a trimmed down Mitchell nut with

slim sides that enables you to insert the mitchell nut after installation soon

(Please note, the compatible thread size on our mitchell nut will be 2-3/4”-12UN)

3. Use the supplied 4x M8x16 screws mounting

the mitchell mount on the base plate. Be sure to

use Loctite when fastentening these screws.

MITCHELL MOUNT INSTALLATION:

73.03

175.00

108

17.00

6.00

6.40

BLACK ARM SET UP INSTRUCTIONS V0.75

DAMPENER, CHANGE INSTRUCTIONS:

2. Remove the Vibration mount, and remove the top M6 screw

on the cheese plate, and the two M6 bottom screws holding the cheese

plate.

3. To insert a extra tilt dampener. Place the supplied extra tilt shafts and

spacer at the front ball joint and tilt shaft at the main tube ball joint, and

put back the cheese plate. Don’t forget to use Loctite.

4. If you want to replace the current dampener with a extra spare,

use the same instructions, but remove the tilt shafts/spacer first

(note! You might need to tap out the shafts due to loctite)

1. For BLACK ARM complete

users, we ship 1pcs spare/extra

dampener. The main tube grip

is positioned for spare/replacement

usage. To use it as a extra dampener

for rough terrain/heavy weight setup,

simple remove the M6 screw, and flip

the grip in mirror position.

2. To insert a extra roll dampener. Place the

supplied extra roll shafts and lock nut on each

side of the roll mount.

3. If you want to replace the current dampener

with a extra spare, use the same instructions,

without flipping the main grip ball joint first.

1. For BLACK ARM complete

users, we ship 1pcs spare/extra

dampener. The main tube grip

is positioned for spare/replacement

usage. To use it as a extra dampener

for rough terrain/heavy weight setup,

simple remove the M6 screw, and flip

the grip in mirror position.

BLACK ARM SET UP INSTRUCTIONS V0.75

1. The roll dampaner can be placed in

four different configurations. When shipped the dampener

is fastened in hole nr 2. on the roll bracket.

2. There are the different options your can mount the roll

dampener to:

Position 1. Not currently being used.

Position 2. Enables minimum force of the dampener and limited

end stop positions (around 40 degrees) on left/right swing.

Position 3. Enables medium dampener force (more momentum

due to longer distance to centre), and larger end stop position.

Position 4. Enables maximum dampener force, and largest swing

angle. Change angle also by adjusting position of the dampener

clamp that is fastened on the main tube.

4 3 2 1

ROLL DAMPENER CONFIGURATIONS:

1. You can change angle of the dampener to get more or less

friction or avoid collision on any object placed behind the BLACK

ARM. The following configurations are usuable for the vertical dampener.

NOTE! This is NOT the correct position for 2nd generation dampeners,

only for 1st generation dampener.

VERTICAL DAMPENER CONFIGURATIONS:

BLACK ARM SET UP INSTRUCTIONS V0.75

1. Mount your gimbal / gyro-head on the black arm following previous installation description.

2. Tilt the head until it reach the soft stop. The head should NOT swing back and forth, but be tensioned just enough so it goes back into neutral position.

Of course, this tension might be altered depending on road surface and scenario (speed, terrain and so forth).

Correct motion

Incorrect (to soft) motion

TILT DAMPENER TENSION PRE-SETTING:

Dampener tension knob

BLACK ARM SET UP INSTRUCTIONS V0.75

1. Mount your gimbal / gyro-head on the black arm following previous

installation description.

2. Bank the head on roll axis until it reach around 40 degree. The head should NOT swing back and forth, but be tensioned just enough so it goes back into neutral position.

Of course, this tension might be altered depending on road surface and scenario (speed, terrain and so forth).

Correct motion

Dampener tension knob

Incorrect (to soft) motion

ROLL DAMPENER TENSION PRE-SETTING:

BLACK ARM SET UP INSTRUCTIONS V0.75

Quick setup instructions:

1. Mount the arm

Mount the black arm to the 50 mm tube with the two Burton clamps at the back of the arm.

Make a quick estimation of the mounting height, so that the set up isn’t mounted too low on the tube.

his could result in the camera hitting the ground at the bottom of the arms boom range.

At this point, a quick estimation is all that is needed. You can fine tune this later, when you have the gimbal and camera rigged.

2. Mount the gimbal and camera

Mount your gimbal and camera with all the accessories needed for your shoot, batteries lenses cables etc, and let it float freely on the black arm.

3. Spring adjustments

Begin with adjusting the vertical arm dampener to it’s softest position. This is where the dampener provides the least force. This is done by turning the +/- knob on the dampener.

Let the system hang freely on the Black arm, and look at the boom angle of the arm. If the arm is booming up that means that the springs are adjusted to strong and you will need

to release some tension. Unscrew each spring equally until the arm floats in horizontal position.

If the arm, on the opposite, is booming down you need to tension the spring knobs. Tension them equally on each side until the arm (the larger bones) is horisontal.

At this point, push the arm to it’s lowest, most boomed down position, and make sure the rig can’t touch the ground.

Keep in mind that in very uneven terrain, there may be bumps sticking up, so make sure to have proper clearance based on your conditions.

4. Damping adjustment

Each damper on the Black has a knob with a +/- sign, that you can turn to release or add resistance force on the dampener.

First you need to adjust the dampener for the vertical movement. It's located on the dampener in the center of the arm. From the softest position, lift the total set up by booming

the Black arm all the way up, and force it with a sudden push to boom down and see it’s reaction. If the arm swings up and down a few times after return to center then your

dampener is adjusted too soft and you need to add force. Add a few clicks on the dampener knob and try again, repeat until the arm swings only once when forced and then it

stops in center. Excessive swing is not ideal for the vertical stabilization. Also excessive force adjustment will make the boom action very stiff and make the arm less reactive.

That means that you need to be somewhere in between. That is also relative to the nature of shot. If you intend to shoot on very rough terrain, for example, it’s better to be adjusted

little stiffer than usual as the bumps will have more effect on the set up. If the road is flat and smooth, you can have a little softer adjustment.

After your adjustment, make a quick test run and correct if necessary.

Roll and tilt dampeners - The same method of adjustment applies for both roll and tilt dampeners. Tilt back all the way with your hands, and let the system return to center.

If it swings 2-3 times, overpassing the center, then the adjustment is too soft. Repeat adding adjustment clicks until the load only swings one time, passing the center position

and returns to center. The same applies to the roll adjustment.

This is a general rule, and again, if the terrain is very rough, or if you’re shooting at higher speeds you will need to add damping force. Do another test run and adjust if needed.

Precautions

Always clean the dampener piston rods with a wet cloth to remove mud and/or dust.

Always adjust the height of the set up, so that the camera is kept at a safe distance from the ground.

When you add safety straps for the camera, make sure they’re long enough to allow for the arms total boom range. If the strap is too short it will keep

the arm of doing it’s job and might result in damage and vibrations.

Always run an quick check before and after the shot to locate loose screws etc.Especially if you’re shooting in rough terrain.

Always make sure your gripping tubes and clamps are safely and securely configured, and that the grip set up is safe.

BLACK ARM SHOCK AND VIBRATION MOUNT

Available mounting points:

A) 4 x 1/4”-20 UNC - 25mm CC

B) 5 x 3/8”-16 UNC - 25,4mm (1”) CC

C) 4 x 8mm holes - 98,99mm CC

D) 6.5mm holes - 2”x1.5” CC (Cinemilled DJI Ronin Universal)

E) 3.2mm holes - 32mm CC (toad-in-the-hole)

25.00

25.4 (1”)25.4 (1”)

98.99

32.00

38.10 (1.5”)

50.80 (2”)

BLACK ARM SET UP INSTRUCTIONS V0.75

Extra / Spare

tilt dampener

Extra / Spare

roll dampener

2x Roll shafts 2x M8 locking nuts

Roll lower

shaft (shorter than upper shaft)

Roll upper

shaft

Roll lower spacer

Note!

Roll dampener

has its tension

knob placed 90

degrees from

main tube ball joint. Note! Tilt dampener

has no washer

placed on end

of ball joint.

4x M8 nuts + M8 washers

Extra / Spare

vertical dampener

Longer

vertical shaft

Short

vertical shaft

8x M8 25mm

4x Dual brackets

4x 7.0 springs

2x 7.5 springs

(2 pcs are already

mounted on the arm,

unless you ordered

with heavy vibratoin mount

configuration. Then all

7.5 springs are already

assembled)

4x M4 12mm

Short

vertical spacer

(Note! There are

also 4pcs of orange

shims that can be placed

between shaft/spacer

to make the ball joint

connection tight)

Long

vertical spacer

INCLUDED AS EXTRAS IN BLACK ARM COMPLETE PACKAGE

INCLUDED IN BLACK ARM

STANDARD PACKAGE

(AND COMPLETE PACKAGE)

0 kg 10 kg 20 kg 30 kg 40 kg

0 lbs 22 lbs 44 lbs 66 lbs 88 lbs

0 lbs 22 lbs 44 lbs 66 lbs 88 lbs

0 lbs 22 lbs 44 lbs 66 lbs 88 lbs

0 lbs 22 lbs 44 lbs 66 lbs 88 lbs

0 lbs 22 lbs 44 lbs 66 lbs 88 lbs

0 kg 10 kg 20 kg 30 kg 40 kg

0 kg 10 kg 20 kg 30 kg 40 kg

0 kg 10 kg 20 kg 30 kg 40 kg

0 kg 10 kg 20 kg 30 kg 40 kg

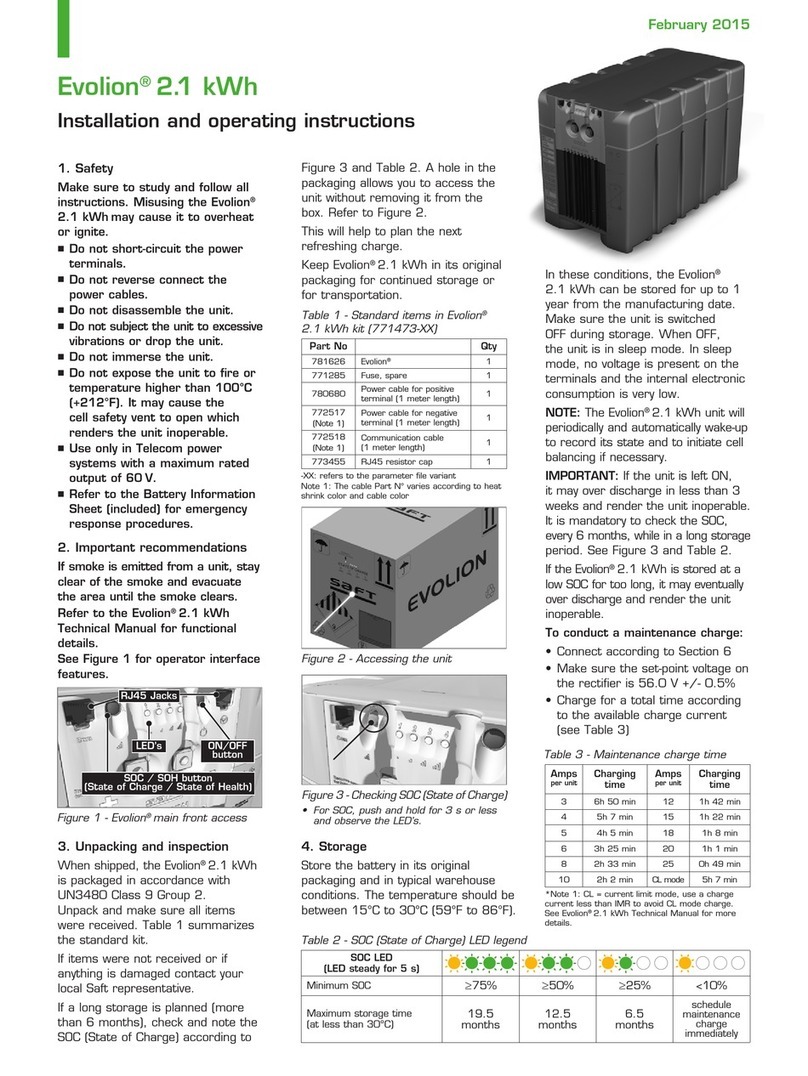

WIRE ROPE ISOLATOR CHART

BLACK ARM SHOCK AND VIBRATION MOUNT

Range 7-10kg payload (15-22lbs)

Vibration mount #01

Range 10-14kg payload (22-31lbs)

Vibration mount #02

Range 14-19kg payload (31-42 lbs)

Vibration mount #03

Range 19-26kg payload (42-57 lbs)

Vibration mount #04

Range 26-34kg payload (57-75 lbs)

Vibration mount #05

WIRE ROPE ISOLATOR CHART

BLACK ARM SHOCK AND VIBRATION MOUNT

WIRING INDENTIFICATION;

Range 7-10kg payload (15-22lbs)

All wires in a angle.

Wire diameter 2.0mm

Range 10-14kg payload (22-31lbs)

1 straight wire on each end.

Wire diameter 2.0mm

Range 14-19kg payload (31-42 lbs)

2 straight wires on each end.

Wire diameter 2.0mm

Range 19-26kg payload (42-57 lbs)

3straight wires on each end.

Wire diameter 2.5mm

Range 26-34kg payload (57-75 lbs)

4 straight wires on each end.

Wire diameter 2.5mm

Vibration mount #01

Vibration mount #02

Vibration mount #03

Vibration mount #04

Vibration mount #05

Table of contents

Other Flowcine Camera Accessories manuals

Popular Camera Accessories manuals by other brands

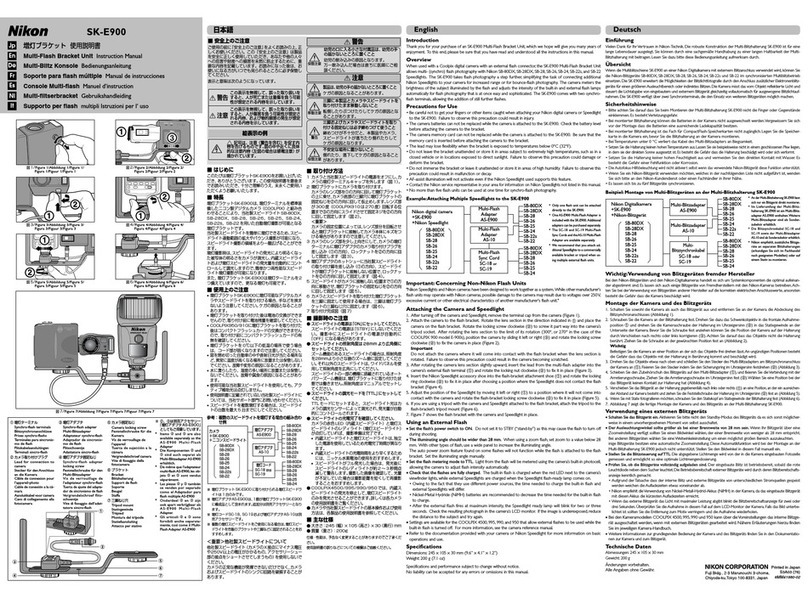

Nikon

Nikon SK-E900 instruction manual

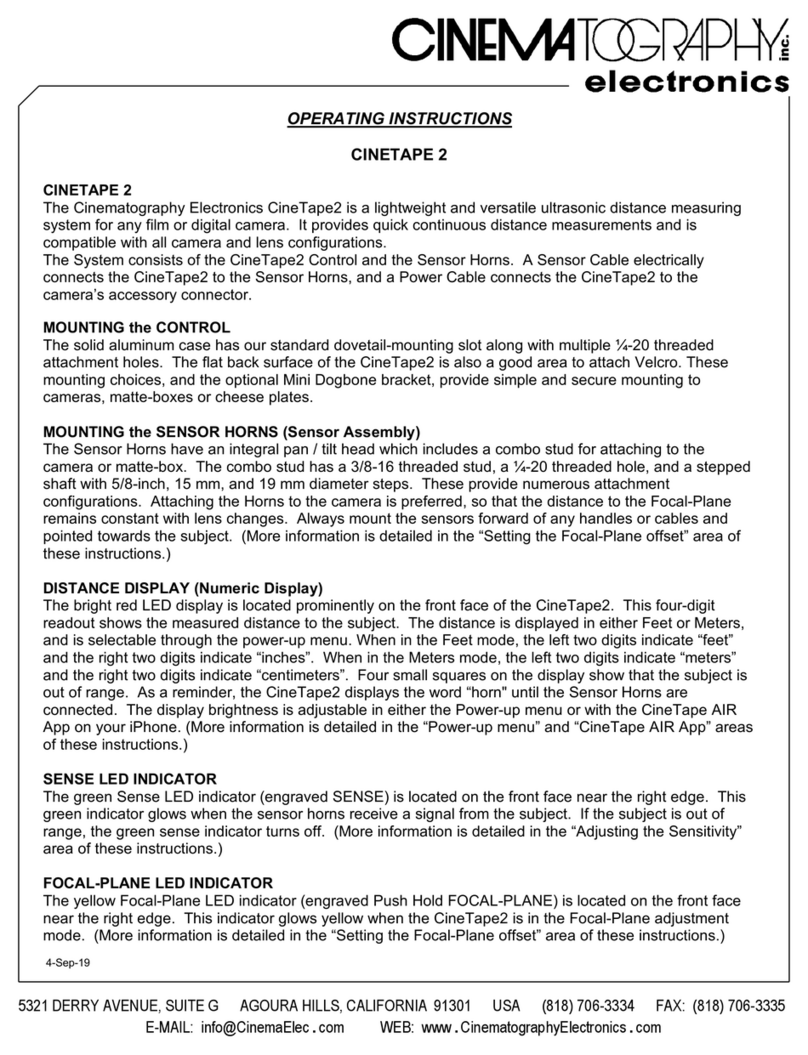

Cinematography Electronics

Cinematography Electronics Cinetape 2 operating instructions

Eaton

Eaton Oxalis XP Series Installation & maintenance instructions

Image Engineering

Image Engineering iQ-Align XL user manual

Joby

Joby SeaPal instruction manual

Sanyo

Sanyo KR-1800SCE Cadnica Specifications