FlowCon FN.0.2 Owner's manual

Installation and Operation Instruction

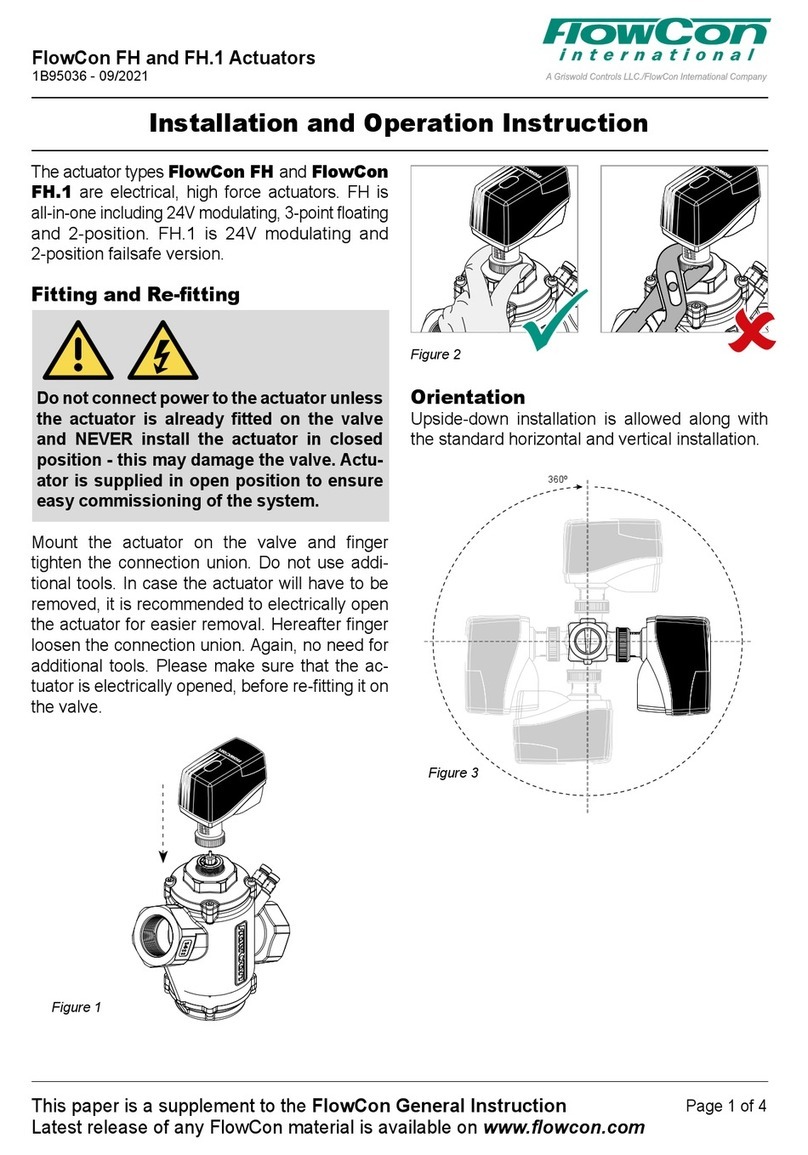

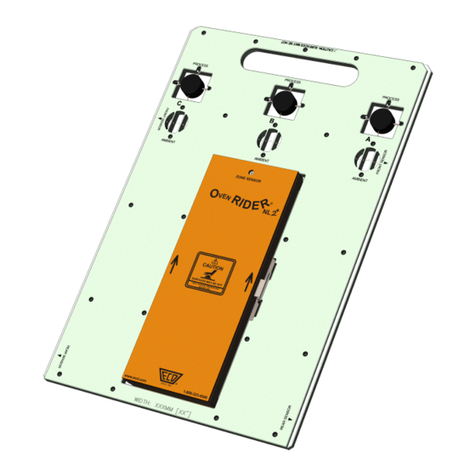

Figure 1

Figure 2

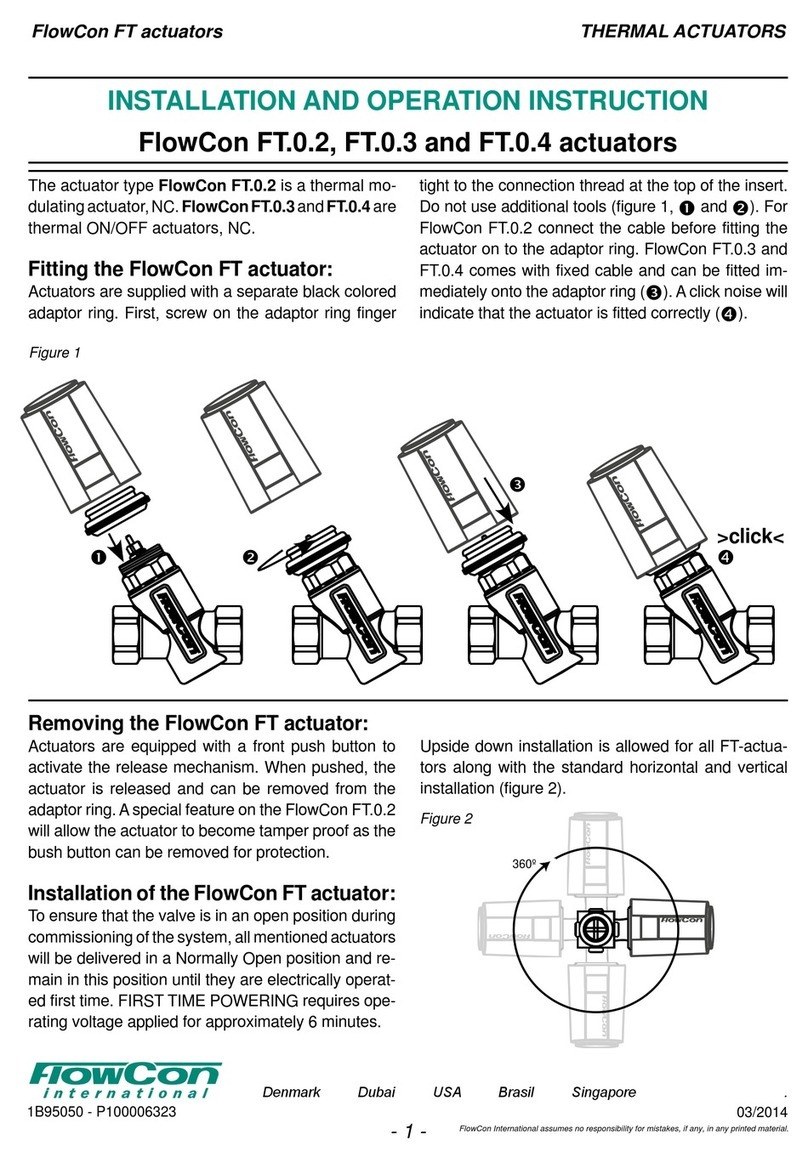

360º

Figure 3

The actuator types FlowCon FN.0.2, FN.0.2-

BUS

and

FN.0.4

are electrical actuators.

•FN.0.2 is 24V modulating.

• FN.0.2-BUS is 24V modulating with Modbus or

BACnet communication.

• FN.0.4 is 24V 3-point floating and 2-position.

Fitting and Re-tting

Do not connect power to the actuator unless

the actuator is already fitted on the valve

and NEVER install the actuator in closed

position - this may damage the valve. Actu-

ator is supplied in open position to ensure

easy commissioning of the system.

Mount the actuator on the valve and finger

tighten the connection union. Do not use addi-

tional tools.

In case the actuator will have to be removed, it is

recommended for FN.0.2 and FN.0.4 to electri-

cally open the actuator by activating DIP switch

#6 for easier removal.

For FN.0.2-BUS set DIP switch #1-6 to OFF and

wait until the LED indicator is blinking green.

Hereafter, disconnect power and finger loosen

the connection union. Again, no need for addi-

tional tools. Please make sure that the actuator

is electrically opened, before re-fitting it on the

valve.

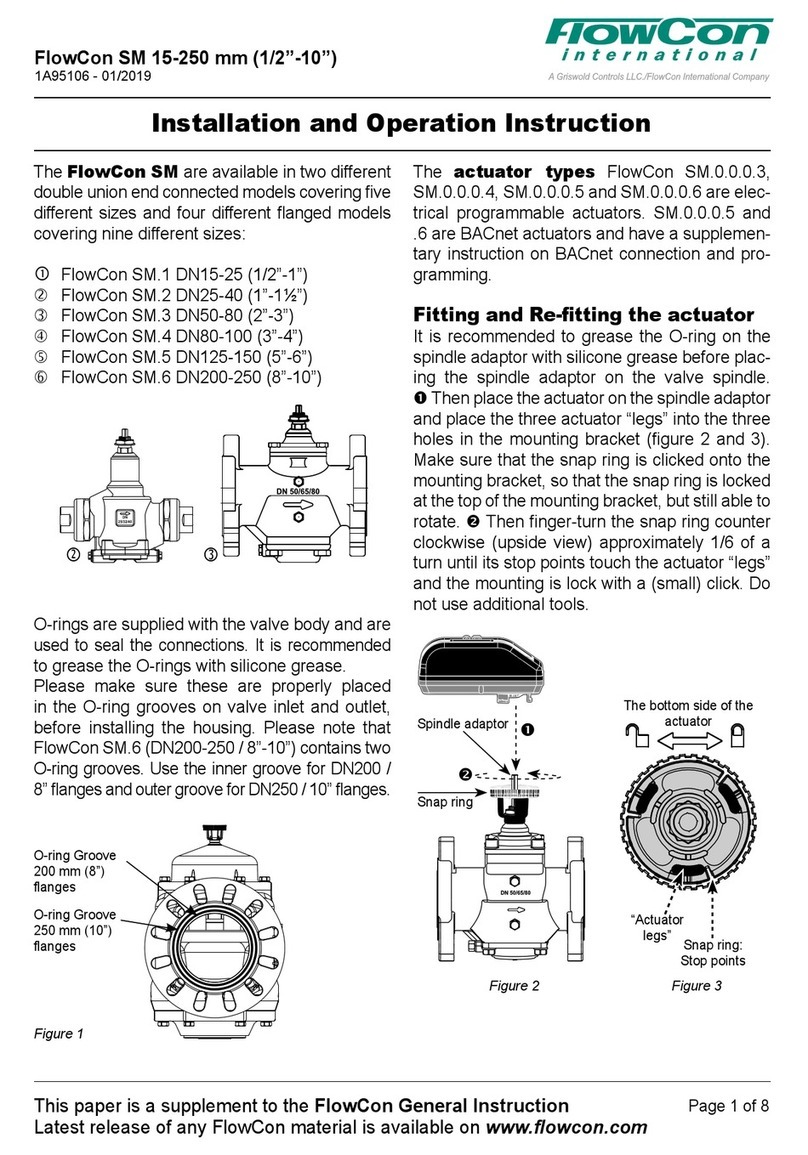

Orientation

Upside-down installation is allowed along with

the standard horizontal and vertical installation.

FlowCon FN.0.2, FN.0.2-BUS and FN.0.4

1B95080 - 01/2023

This paper is a supplement to the FlowCon General Instruction

Latest release of any FlowCon material is available on www.owcon.com

Page 1 of 8

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

Blue

Yellow

Power 24V AC/DC

Ground/common

Green

Grey

Feedback signal

0(2)-10V DC

Signal ground

Input signal

0(2)-10V DC

<0.5mA

Brown

FN.0.2 Actuator

0(2)-10V modulating

FlowCon FN (analog)

Black

Pink

Power 24V AC/DC

Ground/common

Yellow

D+

Red

FN.0.2-BUS Actuator

RS-485 Serial

Green

Violet

D-

White

Grey

P1 P2

FlowCon FN (digital)

Blue

Power 24V AC/DC

Ground/common

Grey

Brown

Open

FN.0.4 Actuator

2-Position, Normally Closed

Close

PLEASE NOTE: FN.0.4 has a reation time of 0.8 sec.

This is the time from giving a 24V power signal until

the actuator starts to move. This is particular important

if using apulse power signal.

Blue

Power 24V AC/DC

Ground/common

Grey

Brown

Open

Stop

FN.0.4 Actuator

3-Point Floating, Normally Closed

Close

Wiring

This paper is a supplement to the FlowCon General Instruction

Latest release of any FlowCon material is available on www.owcon.com

FlowCon FN.0.2, FN.0.2-BUS and FN.0.4

1B95080 - 01/2023

Page 2 of 8

Start-up Sequence

When power to the actuator is turned on, the

actuator will automatically calibrate to determine

closing point. Hereafter it will proceed to normal

operation mode (according to control signal).

For FN.0.2-BUS, bus address configuration is

required and must be done immediate after first

power on. Calibration mode and then normal op-

eration mode will follow thereafter.

Auto Cycle Sequence

Auto Cycle can be activated during commission-

ing. It prevents the valve from jamming when

the valve is not moved for a longer period of

inactivity. For FN.0.2 and FN.0.4 Auto Cycle is

activated by moving DIP switch #1 from OFF to

ON. The actuator will then perform 50% stroke

cycle every 3 weeks if not stroke movement has

occurred.

For FN.0.2-BUS Auto Cycle is activated and cy-

cle time configured via the bus (Modbus register

136 and BACnet AV.10; 0= not activated).

Override

For FN.0.2 and FN.0.4 electrical override is acti-

vated by moving DIP switch #6 from OFF to ON.

Then the valve will open fully. During override

mode the LED indicator will blink red and green.

When DIP switch #6 is moved back to OFF, the

actuator will re-calibrate and thereafter go into

normal operation mode. Electrical override is

performed with power supply on.

When performing the manually override proce-

dure on the FN.0.2-BUS, set DIP switches 1 to

6 to OFF and the spindle will fully retract, and

the LED will rapidly blink green. In this state the

valve can be manually close or opened using a

magnet.

To extend actuator spindle and fully close the

valve, briefly swipe the magnet along the right-

hand side of the actuator (top view and wires

downwards). LED indicator is blinking yellow

during this ‘manual spindle adjustment’ mode. To

retract the actuator spindle and open the valve

fully (mounting position), again briefly swipe the

magnet along the right-hand side of the actuator.

LED is blinking rapidly green to indicate ‘mount-

ing position’ mode. Manually override can be re-

peated as often as necessary.

Flush Mode (FN.0.2-BUS)

The automatic Flush Mode is activated and

cycle time configured via the bus (Modbus reg-

ister 132 and BACnet AV.35; 0= not activated).

In Flush Mode, the valve is temporarily fully

opened independent of the control signal to al-

low easy system flushing.

FlowCon FN.0.2, FN.0.2-BUS and FN.0.4

1B95080 - 01/2023

This paper is a supplement to the FlowCon General Instruction

Latest release of any FlowCon material is available on www.owcon.com

Page 3 of 8

DIP

switch Function ON Function OFF

#6 Electrical override ON Electrical override OFF

#5 No function No function

#4 Equal percentage Linear

#3 Normally Open Normally Closed

#2 Control signal 2-10V Control signal 0-10V

#1 Auto cycle ON Auto cycle OFF

6

5

4

3

2

1

%%

%%

%%

%%

%%

%%

%%

%%

%%

%%

DIP

switch Function ON Function OFF

#8 Terminal resistor active Terminal resistor inactive

#7 Modbus BACnet

#6 BIT 5 = 1 BIT 5 = 0

#5 BIT 4 = 1 BIT 4 = 0

#4 BIT 3 = 1 BIT 3 = 0

#3 BIT 2 = 1 BIT 2 = 0

#2 BIT 1 = 1 BIT 1 = 0

#1 BIT 0 = 1 BIT 0 = 0

6

5

4

3

2

1

8

7

Modbus

Address

setting Address

setting

BACnet

Modbus

Address

setting Address

setting

BACnet

Modbus BACnet

1

1

1

1

1

1 0

0

0

0

0

0

DIP Switch Settings

The valve functions are set on DIP switches found under the connection cover. PCB mounted electri-

cal components will not be directly exposed when DIP switches are to be set. Factory setting for all

switches is OFF.

FlowCon FN.0.2 Actuator

FlowCon FN.0.2-BUS Actuator

This paper is a supplement to the FlowCon General Instruction

Latest release of any FlowCon material is available on www.owcon.com

FlowCon FN.0.2, FN.0.2-BUS and FN.0.4

1B95080 - 01/2023

Page 4 of 8

DIP

switch Function ON Function OFF

#6 Electrical override ON Electrical override OFF

#5 No function No function

#4 No function No function

#3 Normally Open Normally Closed

#2 No function No function

#1 No function No function

6

5

4

3

2

1

%%

%%

%%

%%

FlowCon FN.0.4 Actuator

FN.0.2 FN.0.2-BUS FN.0.4

Normal operation mode Full on green Full on green Full on green

Charging mode (60 sec) n/a n/a n/a

Calibration mode

(closing point adjustment) Blinking green Blinking green Blinking green

Bus communication mode n/a Flickering green n/a

Mounting position mode n/a Rapid blinking green n/a

Electrical override mode Blinking red/green n/a Blinking red/green

Failsafe mode n/a n/a n/a

Manuel spindle adjustment n/a Blinking yellow n/a

Perpetual failure mode Full on red Full on red Full on red

LED Status

The LED indicator is visible through the dark colored transparent connection cover.

The LED indication will give the following statuses.

FlowCon FN.0.2, FN.0.2-BUS and FN.0.4

1B95080 - 01/2023

This paper is a supplement to the FlowCon General Instruction

Latest release of any FlowCon material is available on www.owcon.com

Page 5 of 8

Re-Calibration

FN.0.2

Re-calibration can be achieved in one of 2 ways:

1. Forced individual actuator re-calibration can also be performed by flipping DIP switch #6

from OFF to ON and back to OFF on the relevant actuator.

2. Forced concurrent re-calibration for all modulating actuators is electrically possible. Within 60

sec. provide the following electrical control signal sequence to the grey wire: 10V-2V-10V-2V-

10V-2V to achieve re-calibration.

After re-calibration the actuator will go into normal operation mode.

FN.0.2-BUS

For FN.0.2-BUS change MSV.1 to 2 (BACnet) or register 138 to 1 (Modbus).

After re-calibration the actuator will go into normal operation mode.

FN.0.4

Forced individual actuator re-calibration can also be performed by flipping DIP switch #6 from OFF

to ON and back to OFF on the relevant actuator.

After re-calibration the actuator will go into normal operation mode.

This paper is a supplement to the FlowCon General Instruction

Latest release of any FlowCon material is available on www.owcon.com

FlowCon FN.0.2, FN.0.2-BUS and FN.0.4

1B95080 - 01/2023

Page 6 of 8

BUS programming of

FlowCon FN.0.2-BUS

When using FN.0.2-BUS actuator and BUS

communication, setting on the Green/GreEQ in-

sert MUST BE be 5.0.

In this instruction default values are underlined.

Please see FlowCon FN.0.2-BUS Modbus Data

Point List or BACnet PICS for more detailed in-

formation.

Initiate by setting Baud Rate (register 105 or

MSV.7). Set actuator DIP switches 1-6 to write-

able mode, i.e. 1-1-1-1-1-1-1 and set MAC Ad-

dress via bus communication (register 104 or

AV.28) and proceed by selecting your PICV

valve in register 110 or MSV.8:

Reg. 110 MSV.8 Selected valve

0 1 (generic linear)

1 2 Green.0

2 3 Green.1

3 4 Green.2

4 5 Green.1HF

5 6 GreEQ.0

6 7 GreEQ.1

7 8 GreEQ.2

8 9 (generic EQ%)

9 10 user-valve

And select your PICV control mode in register

103 or MSV.13:

Reg. 103 MSV.13 Selected control mode

0 0 (linear)

1 1 Equal%

Set Operating Mode in register 200=0 or

MSV.4=1 and provide Control Signal in register

400 or AV.1 (0% to 100%).

Condition of the FN.0.2-BUS

through BUS

Check the Current Flow (not measured) in

register 402 or AI.7.

Status Information is available in BI.3 and

Error Information is available in BI.4, BI.5,

BI.6 and BI.7. This is combined for Modbus in

register 318 and 407.

Service Commands and resetting is avail-

able in register 138 or MSV.1

FlowCon FN.0.2, FN.0.2-BUS and FN.0.4

1B95080 - 01/2023

This paper is a supplement to the FlowCon General Instruction

Latest release of any FlowCon material is available on www.owcon.com

Page 7 of 8

This manual suits for next models

2

Table of contents

Other FlowCon Controllers manuals