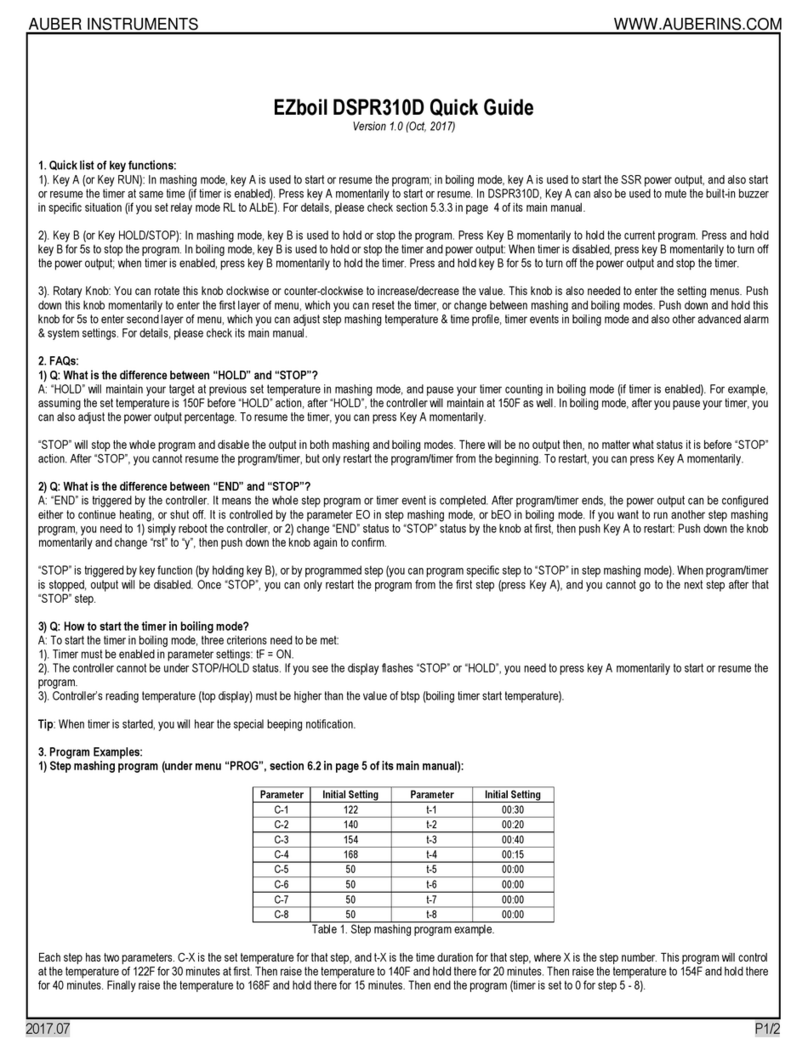

Blue

Yellow

Power 24V AC/DC

Ground/common

Green

Grey

Feedback signal

0(2)-10V DC

Signal ground

Input signal

0(2)-10V DC

<0.5mA

Brown

FH / FH.1 Actuator

0(2)-10V modulating

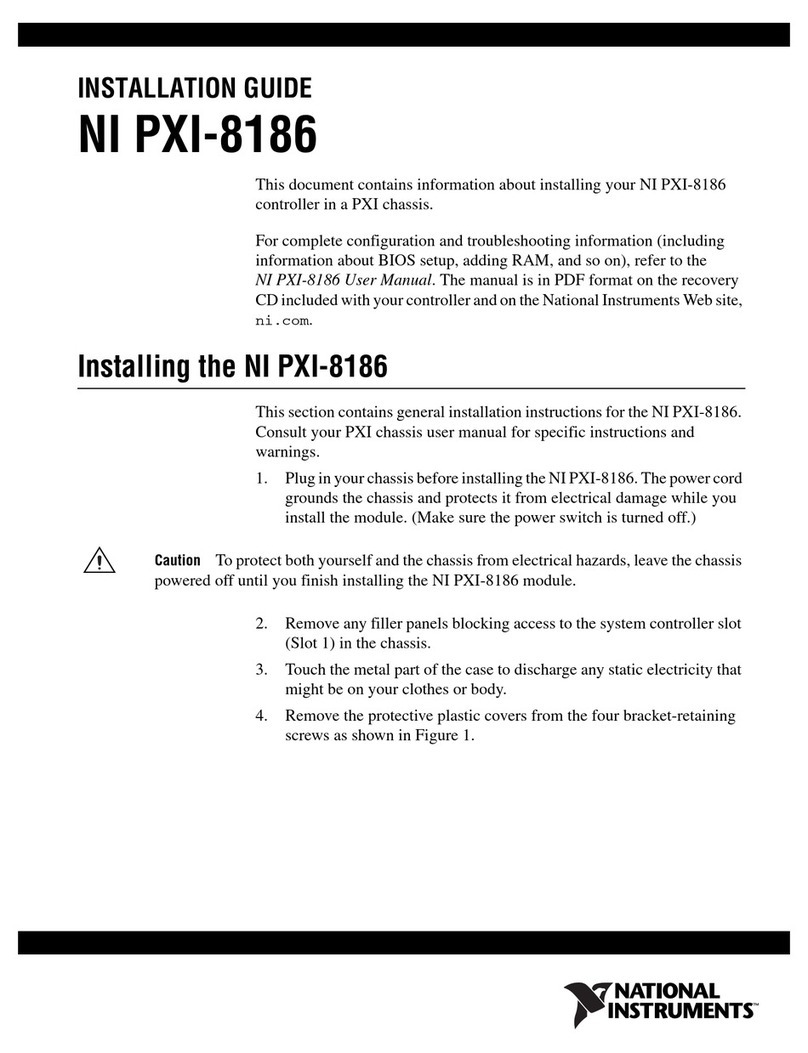

Blue

Power 24V AC/DC

Ground/common

Grey

Open

Stop

FH / FH.1 Actuator

3-Point Floating, Normally Closed

Brown

Close

Yellow

Green

Feedback signal

0(2)-10V DC

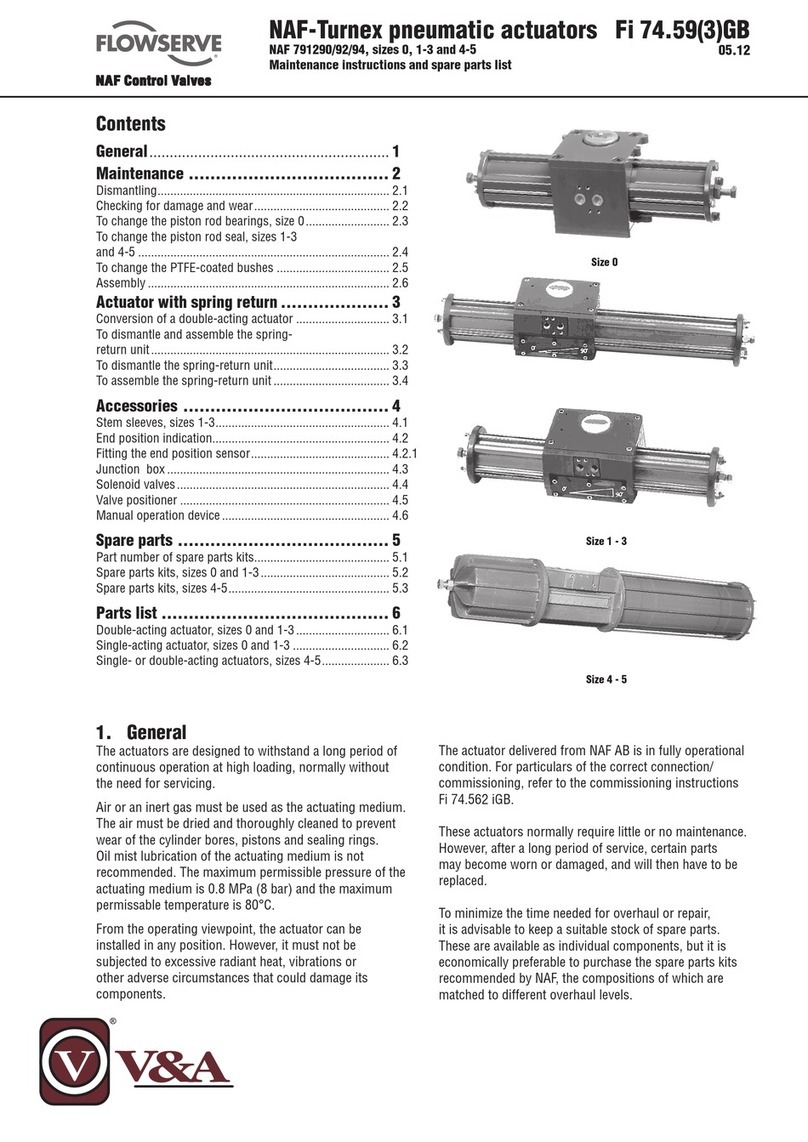

Blue

Power 24V AC/DC

Ground/common

Grey

Brown

Open

FH / FH.1 Actuator

2-Position, Normally Closed

Close

Yellow

Green

Feedback signal

0-10V DC

FlowCon FH (analog)

FlowCon FH (digital)

Wiring

Start-up Sequence

When power to the actuator is turned on, the

actuator will automatically calibrate to determine

closing point. Hereafter it will proceed to normal

operation mode (according to control signal).

For the failsafe version (FH.1), capacitor charg-

ing will be prioritized (max. 215 sec depending

on capacitor energy level) during start-up and

re-powering. After completion of charging mode

followed by calibration mode, the actuator will

proceed to normal operation mode.

Auto Cycle Sequence

Auto Cycle can be activated during commis-

sion

ing. It prevents the valve from jamming when

the valve is not moved for a longer period of in-

activity. By moving DIP switch #1 from OFF to

ON, Auto Cycle is activated. Actuator will then

perform 50% stroke cycle

every 3 weeks if no

stroke

movement has occured.

Re-Calibration (FlowCon FH)

By flipping DIP switch #6 from one setting to the

other (starting position indifferent) re-calibration

is activated. After completed re-calibration the

actuator will automatically go into normal ope-

ration. During re-calibration mode the LED will

blink green.

Manual Override (FlowCon FH)

Before performing manual override, please turn

off the power supply. Lift the silicone cap on the

top of the actuator to get access to manual over-

ride. Manual override is performed by a 4 mm

(~5/32”) hex key. Clockwise turning will open the

valve and counter-clockwise turning will close

the valve.

Electrical Override (FlowCon FH.1)

By moving DIP switch #6 from OFF to ON, elec-

trical override is activated and the actuator will

open valve fully. During electrical override the

LED indicator will blink red and green. When DIP

switch #6 is moved back to OFF, the actuator will

re-calibrate and thereafter go into normal opera-

tion mode. Electrical override is performed with

power supply on.

Failsafe Mode (FlowCon FH.1)

When power is lost, the actuator will go into fail-

safe mode after a few seconds, mandatory that

capacitor charging and start-up sequence are

completed. The actuator will perform failsafe ac-

tion (open or close) and stay in failsafe final posi-

tion until return of power. Upon power, the actua-

tor remains in the final failsafe position until charg-

ing mode is reached (max. 215 sec). Hereafter the

actuator will return to normal operation mode.

This paper is a supplement to the FlowCon General Instruction

Latest release of any FlowCon material is available on www.owcon.com

FlowCon FH and FH.1 Actuators

1B95036 - 09/2021

Page 2 of 4