LNC T6 Series User manual

寶元數控精密股份有限公司 1

LNC Technology Co., Ltd.

LNC- New T6-Series

O

Op

pe

er

ra

at

to

or

r’

’s

s

M

Ma

an

nu

ua

al

l

Leading Numerical Controller

LNC Technology Co., Ltd.

2013/9 Ver:V01.00.000(4408110124)

LNC-Lathe New T6-Series

Table of Content

LNC Technology Co., Ltd. I

Table of Content

1CNC Operation ......................................................................................1

1.1 Operation Devices Type ............................................................................................................... 1

1.2 LCD Display Device ......................................................................................................................2

1.3 Screen and Function Description ................................................................................................. 8

1.3.1 Display Screen Layout .....................................................................................................8

1.4 POS Function ...............................................................................................................................9

1.4.1 DIRMNG (File Management) .........................................................................................27

1.4.2 PROCHK (Program Checking) ......................................................................................38

1.4.3 MDI.................................................................................................................................40

1.4.4 COMM (Communication of Files(RS232)) ................................................................41

1.5 WEAR .........................................................................................................................................43

1.5.1 WEAR ............................................................................................................................43

1.5.2 GEOM (Geometry OFFSET)..........................................................................................46

1.5.3 W. SHIFT (Work Coordinate Shift) ................................................................................. 47

1.5.4 MACRO..........................................................................................................................48

1.5.5 WORK ............................................................................................................................50

1.6 LATHE EASY-CAM .....................................................................................................................51

1.6.1 Function Description ......................................................................................................51

1.6.2 Operation Procedure of How to Produce Working Path Program .................................51

1.6.3 Operation Screen and Function Key Instruction ............................................................53

1.7 GRAPH .......................................................................................................................................76

1.7.1 Function Introduction......................................................................................................76

1.7.2 GRAPH ..........................................................................................................................76

1.7.3 SET ................................................................................................................................77

1.8 DGNOS.......................................................................................................................................79

1.8.1 ALARM...........................................................................................................................79

1.8.2 IOCSA ............................................................................................................................83

1.8.3 MLC2..............................................................................................................................84

1.8.4 SYSTEM ........................................................................................................................87

1.8.5 Working Parameter Page...............................................................................................89

1.8.6 SYSUPD ........................................................................................................................90

1.9 SOFTPL ......................................................................................................................................99

1.10 PARAM .....................................................................................................................................101

1.10.1 PARAM.........................................................................................................................101

LNC-Lathe New T6-Series

Table of Content

II LNC Technology Co., Ltd.

1.10.2 USROPT ......................................................................................................................102

1.10.3 TLIM ............................................................................................................................. 104

1.10.4 NET SET ......................................................................................................................105

1.10.5 【Change password】................................................................................................. 111

1.10.6 【Switch user】........................................................................................................... 112

2OP Panel Operation........................................................................... 113

2.1 OP............................................................................................................................................. 113

2.2 LED SIGNAL............................................................................................................................. 114

2.3 AXIS SELECTION .................................................................................................................... 114

2.4 MODE SELECT ........................................................................................................................ 114

2.5 SPINDLE ROTATION& SPINDLE SPEED ADJUSTMENT SWITCH....................................... 116

2.6 Additional Function Selection ................................................................................................... 117

2.7 EMG-STOP............................................................................................................................... 119

2.8 CYCLE START&FEED HOLD .................................................................................................. 119

2.9 Feedrate/Rapid Rate Adjusting Button .....................................................................................120

2.10 PROGRAM PROTECTION LOCK............................................................................................121

2.11 POWER ON/OFF......................................................................................................................121

3RS232 COMMUNICATION SOFTWARE ............................................123

3.1 Transmission line preparation...................................................................................................123

3.2 PC end installation (use LNC ReCON 232 software) ...............................................................124

3.3 NC end......................................................................................................................................126

3.4 Communication (RS232)-【DNC file upload and download functions 】........................ 140

3.4.1 Path Program Upload & save (using ReCON software) ..............................................140

3.4.2 Path Program Upload & save (using ReCON software) ..............................................143

3.4.3 Path Program Upload & save (using general software)...............................................146

3.4.4Path Program Upload & save (using general software)...............................................150

3.5 Setting & Attention for USB to RS232 port ...............................................................................155

LNC-Lathe New T6-Series

CNC Operation

LNC Technology Co., Ltd. 1

1 CNC Operation

1.1 Operation Devices Type

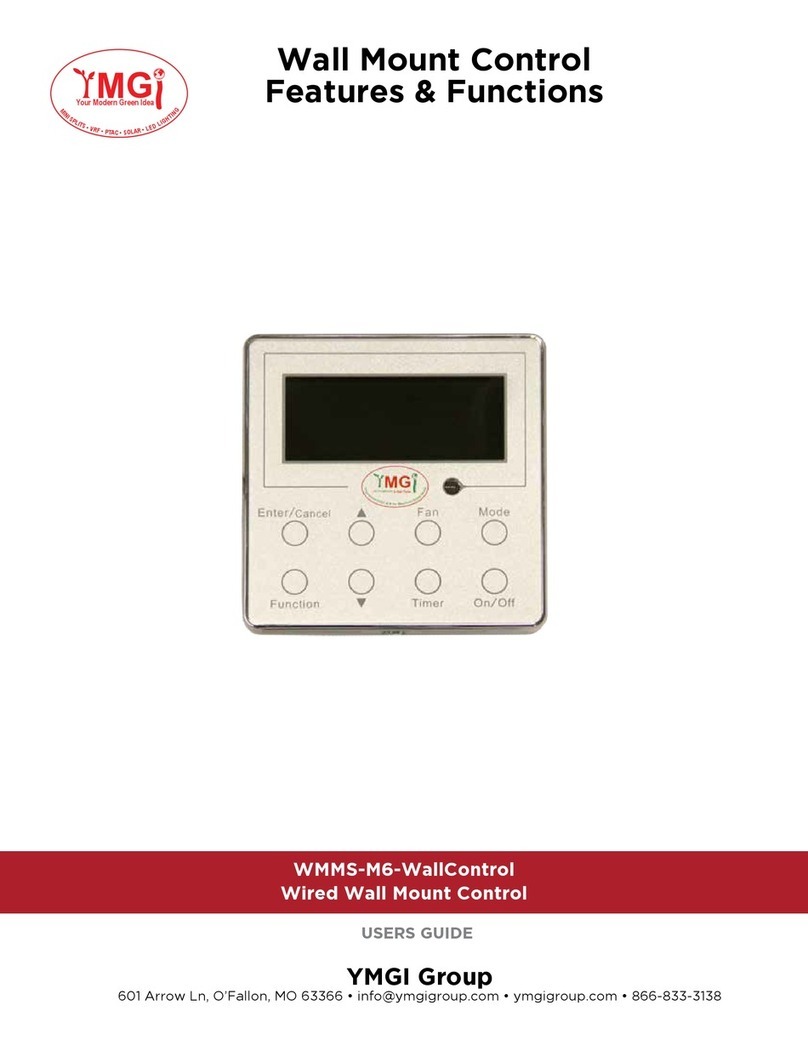

The control panels can be divided into two units: LCD MONITOR and MDIOP. The MDIOP data input area is for

users to edit programs word by word, or edit setting. And MDIOP operation area is a panel for achieving different

working process, such as multiple function keys, keys and pulse generator (hand wheel) and etc. OP will have

different designs due to different tool machine designs. But, this system has one standard panel that can be

selected by tool machine producers. At below we will introduce LCD display device and MDIOP data input

area.MDIOP operation area will be introduced at the Chapter Two.

LCD MONITOR

MDIOP VERTICAL

LNC-Lathe New T6-Series

CNC Operation

2 LNC Technology Co., Ltd.

1.2 LCD Display Device

You will three types of function keys at the LCD display device:

1. Main Function Keys:There are 6 horizontal function buttons at bottom of LCD screen. Users can

choose the desired function button corresponding to those function selections at bottom of the display

screen by press them.

2. Sub-Function Keys:After choosing the main function button, there will be 5 vertical type buttons at the

left side of the monitor. It will show the content of sub-function. Pressing the corresponding function

button to select the wanted function.

3. Additional function keys:

(1). LCD switches(power ON/OFF)

(2). PS/2 Keyboard, can connect with keyboard to control.

(3). PS/2 Mouse, no support now.

Figure 1.2-1 LCD Display Device

Main

Sub

LNC-Lathe New T6-Series

CNC Operation

LNC Technology Co., Ltd. 3

MDIOP can divide into two sections.

1. MDI DATA INPUT AREA:For users to input data.

2. OP OPERATION AREA :For users to control operation.

1

1

2

1

LNC-Lathe New T6-Series

CNC Operation

4 LNC Technology Co., Ltd.

MDI DATA INPUT AREA:

A. CNC Function Keys

Name

Functions

Description

POS

POS

to display positions

PROG

PROG

to edit and to display program (with 1.Edit Mode2.Auto

Mode3.Manual Mode)

OFFSET

OFFSET

to set and to display tool offsest

GRAPH

GRAPH

to draw tool path

DGNOS

DGNOS

to display instance messge at DGNOS page

PARAM

PARAM

to display parameter screen

CNC Function Keys

LNC-Lathe New T6-Series

CNC Operation

LNC Technology Co., Ltd. 5

B. Character & Symbol Keys:

These characters, symbols and numbers are used for program editing and data key-in. There are some symbols

that are diminished down at right-bottom of these keys. If want to use these symbols, please press SHIFT and

the symbol key at the same time.

C. Editing Keys:

Alphabetical symbols

Numbers symbols

Editing Keys

Editing Keys

LNC-Lathe New T6-Series

CNC Operation

6 LNC Technology Co., Ltd.

Using these keys with cursor on the screen will be able to modify program, to set data and to change page.

Name

Editing

Description

RESET

Reset

/ /

/ /

Reset

/ /

/ /

1. To reset system to return default.

2. When alarm removing, cancel alarm.

3. When start working, to cancel working.

4. At edit mode, cursor returns to program head.

PAGE↑

To turn to the previous page.

PAGE↓

To turn to the next page.

Enter

1. Input at the data input area, press enter to confirm. The column

will be filled with the data.

2. At file management, move cursor to the file location, press

enter to open the file.

3. At edit mode, press enter to insert space line.

ESC

Esc

Esc

Return back

Note: this function will be valid under BIOS mode.

↑

Under edit mode, move cursor upper.

To move cursor upper.

↓

Under edit mode, move cursor down.

To move cursor down.

←

Under edit mode, move cursor left.

To move cursor left.

LNC-Lathe New T6-Series

CNC Operation

LNC Technology Co., Ltd. 7

Name

Editing

Description

→

Under edit mode, move cursor right.

To move cursor right.

Insert

Insert

To switch enter/replace characters modes.

Delete

Delete

To delete.

Space

Space

To key-in into empty space.

Shift

Shift

To key-in special symbols with use of symbol number keys.

Note: you need to press SHIFT and symbol buttons at the same

time.

Home

Home

To return cursor to the beginning of the sentence when editing

program.

End

End

To return cursor to the end of the sentence when editing program.

TAB

TAB

When editing program, to move cursor right with 8 space.

CAN

CAN

To cancel the previous character.

LNC-Lathe New T6-Series

CNC Operation

8 LNC Technology Co., Ltd.

1.3 Screen and Function Description

8 function groups in this controller: POS, PROG, OFFSET, CAM, GRAPH, DGNOS, SOFTPL and PARAM.

Using 【….】to indicate function keys at bottom and at right of the screen and using <….> to indicate keys on

MDI panel.

1.3.1 Display Screen Layout

1:Present designate file name

Note: Means the file name that controller is using now.

2:Present single block that is executed by controller

Note: Means the controller is using program to execute N file.

3:CNC mode signal

Note: 1.Edit mode 2.auto mode 3.manual mode 4.MPG 5.quick locate 6.continuous jog 7.return reference

point

4:Machine condition signal

Note: 1.Preparation unfinished 2.preparation complete 3.start to work 4.machine pause 5.block stop

5:Wrong alarm/warning message

Note: 1.Alarm 2.Waring

1

2

3

4

5

6

7

8

9

10

LNC-Lathe New T6-Series

CNC Operation

LNC Technology Co., Ltd. 9

6:Simply message hint area

Note: Controller offers a simple message to remind users.

7:Input area

Note: Controller offer users to input data.

8:Display range

Note: Each function groups to display changes

9:Main function button display

Note: This area is for main function buttons to use.

10:Sub-function button display

Note: This area is for sub-function buttons to use.

1.4 POS Function

You will see POS page when you enter this system, or you can press <POS> key to enter into the coordinate

display screen. Users will be able to choose 6 screen displays by pressing those function keys which are

【ABS.】, 【REL.】, 【MAC.】, 【RST】and 【QUIT】. There are some command information that will is displayed

in those screens, which will be described separately as following:

POS Function Display Screen

ABS

situation

LNC-Lathe New T6-Series

CNC Operation

10 LNC Technology Co., Ltd.

Actual Feed Rate

Feedrate(mm/min):Feed rate of servo structure-is the composite speed for each servo axis. Unit is mm/min.

Feedrate percentage(%):Feedrate percentage-with the federate dial to choose 15 selections from 0% to 150%.

Quick feed percentage (%):Quick feed percentage-with the quick feed button to have 4 selections of <LOW>、

<25%>、<50%>、<100%>.

Time:Current time.

Rotation situation

Rotational speed (rpm/min):Current spindle actual rotation. Unit is rpm/min.

Rotational speed percentage(%):Rotational speed percentage-with rotation button<UP>、<DOWN> to have 12

selections of 0%~120%.

Hint message display situation

Message:According to system situation, there are 7 messages as below :F0(current federate is 0)、 SBK(single

block)、 BDT(selective block jog)、 DRN(dry run)、 MLK(machine lock)、 OPS(optional program pause)、

ABS(absolute encoder reader)

Situation of CUT, RUN, CNT

CUT(H”M”S):Every time when users press Cycle Start button, cutting time will reset(return zero) and start to time

again until this working process finish.

RUN(H”M):Running time is the total cutting time after every booting, until the system shuts down, the time will be

reset to be zero. You can also use【TIME CLEAR】to make it to be zero.

LNC-Lathe New T6-Series

CNC Operation

LNC Technology Co., Ltd. 11

CNT(current working pieces/max working pieces):when CNC program reads M02, M30 or other M code at the

end, system will sum up working pieces, this function need to use Pr.0089 and PLC to work.

【ABSOLUTE COORDINATE】

Pressing【ABS.】to enter into absolute coordinate screen. Details will be shown in bigger words at the upper left

side of the screen. Using the program home (means the workpiece coordinate) to show tool’s current location,

the absolute coordinate will be changed according to the movement of tool. This is called absolute coordinate

Absolute coordinate is the program coordinate, which is [present value –tool offset = program value.]

ABS

LNC-Lathe New T6-Series

CNC Operation

12 LNC Technology Co., Ltd.

【Time Clear】

Press 【Time Clear】to delete current total running time.

【Workpiece Clear】

Press 【Workpiece Clear】to delete current workpiece-make it to be zero.

LNC-Lathe New T6-Series

CNC Operation

LNC Technology Co., Ltd. 13

【Initial Workpiece】

Press 【Initial Workpiece】to change current workpiece-make it to be ten.

【Max Workpiece】

Press 【Max Workpiece】to change current max. workpiece-make it to be 100. When it comes to be 100 pieces,

the controller will notify the workpieces have reached target.

LNC-Lathe New T6-Series

CNC Operation

14 LNC Technology Co., Ltd.

【RELATIVE COORDINATE】

Pressing 【REL.】to enter into the relative coordinate screen. Details will be shown in bigger words at the upper

left side of the screen. The relative coordinate system means the distance between the present position and any

point that is decided by users. So users can set the relative coordinate value to zero at anytime, or enter the

non-zero value directly.

The way for relative coordinate to return zero:

If want to set the 3 axes relative coordinate values to zero separately or at the same time, users only need to

press the corresponding sub-function buttons 【CLR. X】, 【CLR. Y】, 【CLR. Z】, 【CLR. ALL】to execute

the corresponding clean.

Setting way for relative coordinate:

If you want to reset the coordinate value and to let X coordinate to 100.00, Y coordinate to 200.000 and Z

coordinate to 300.000, only need to set X100, Y200, Z300. Then, pressing <INPUT> to reset the coordinate

value immediately.

REL

LNC-Lathe New T6-Series

CNC Operation

LNC Technology Co., Ltd. 15

【MACHINERY COORDINATE】

Pressing【MAC.】to enter into the relative coordinate screen. Details will be shown in bigger words at the upper

left side of the screen.

Machine coordinate is the distance of the present position corresponding to the reference point

Note:Each machine has its own reference point. For safety concern, please looking for the reference point

whenever reboot machine before executing work.

MAC

LNC-Lathe New T6-Series

CNC Operation

16 LNC Technology Co., Ltd.

【HANDLE】

At the auto mode to press【HANDLE】, users can use MPG interruption to increase or decrease the movement

of tool to change the tool path.

Note:Because the absolute coordinate will not be changed by MPG interruption, therefore the tool path later will

have certain offset with original program path. This offset need to be modified by manual return zero to

clear. And about the offset value, you can refer to MPG coordinate.

About this detailed function, you can refer to maintenance manual-MPG interruption signal selection chapter.

(C BITS 066 ~ 071)and MPG rates(REGISTER 014)

ABS

will not change because of MPG interruption to show program coordinate.

REL

will not change because of MPG interruption.

MAC

will change because of MPG interruption to chow exact position of machine.

HANDLE

coordinate

Table of contents

Other LNC Controllers manuals

Popular Controllers manuals by other brands

Phocos

Phocos CIS-N-MPPT 85/15 user manual

Mitsubishi Electric

Mitsubishi Electric MR-JET user manual

KMC Controls

KMC Controls MEP-3001 Installation and operation guide

Victron energy

Victron energy SmartSolar MPPT 150/35 manual

PRECISION DIGITAL

PRECISION DIGITAL ProVu Series instruction manual

JUMO

JUMO DICON touch manual