FlowMotion 2001V Series User manual

2001V Series

Peristaltic Chemical Feed Pump

Installation and Operation Manual

2001V

Peristaltic Chemical Feed Pump

July 2020

Flomotion Systems, Inc.

3 N Main St, Middleport, NY 14105

Toll Free: (800)909-3569 (U S & Canada)

Tel: (716)691-3941

Fax: (716)691-1253

info@flomotionsystems com

www flomotionsystems com

TABLE OF CONTENTS

1 0 - System Overview 5

1.1 SAFETY...............................................................................................................................................................................................5

1.2 WARRANTY.........................................................................................................................................................................................5

1.3 RECEIVING..........................................................................................................................................................................................6

1.4 CUSTOMER MODIFICATION...................................................................................................................................................................6

1.5 INFORMATION FOR RETURNING PUMPS ................................................................................................................................................6

2 0 – 2001V Series Pump and Pumphead 7

2.1 TUBING, SPINDLE AND COVER INSTALLATION.......................................................................................................................................8

2.2 MOUNTING PUMP ON GEARBOX, INSTALLATION OF COLLET.................................................................................................................

2.3 PUMP MOUNTING AND COLLET INSTALLATION PROCEDURE................................................................................................................10

2.4 HOSE AND ROLLER INSTALLATION.....................................................................................................................................................10

2.5 TUBING & CONNECTIONS...................................................................................................................................................................16

3 0 – 2001V Series Gearbox 18

3.1 RUN-IN PERIOD.................................................................................................................................................................................18

3.2 MAINTENANCE..................................................................................................................................................................................18

3.3 2001V SERIES MOTOR / GEARBOX SPECIFICATIONS ..........................................................................................................................18

3.4 2001V SERIES POWER & MOTOR WIRING.........................................................................................................................................18

4 0 – 2001V Series Drive Controller 20

4.1 OPERATION AND WIRING...................................................................................................................................................................20

4.2 PROGRAMMING .................................................................................................................................................................................20

4.3 MANUAL SPEED / AUTO SPEED / RESTART TOGGLE SWITCH...............................................................................................................20

5 0 - 2001 Series Tubing Rupture Detector 21

5.1 ALARM CAUSES.................................................................................................................................................................................21

5.2 WHAT TO DO IN AN ALARM CONDITION...............................................................................................................................................21

5.3 RESETTING THE ALARM......................................................................................................................................................................21

5.4 RESUMING SERVICE...........................................................................................................................................................................21

5.5 INTERFACING.....................................................................................................................................................................................22

5.6 CALIBRATION....................................................................................................................................................................................22

1 0 - System Overview

The 2001V Chemical Feed Pump consists of a controller, motor, gearbox and peristaltic pump

1.1 Safety

In the interests of safety, this pump and the tubing selected should only be used by competent, suitably trained

personnel after they have read and understood this manual, and considered any hazard involved Any person

who is involved in the installation or maintenance of this equipment should be fully competent to carry out the

work

Maintenance and repair should be performed by qualified personnel only. Make sure that no

voltage is applied while work is being carried out on the pump or motor. The motor must be

secured against accidental start up.

1.2 Receiving

Inspect all cartons for damage, which may have occurred during shipping Carefully unpack equipment and

inspect thoroughly for damage or shortage Report any damage to carrier and/or shortages to supplier All

major components and connections should be examined for damage and tightness, with special attention given

to PC boards, plugs, knobs and switches

1.3 Customer Modification

Flomotion Systems, Inc , its sales representatives and distributors, welcome the opportunity to assist our

customers in applying our products Many customizing options are available to aid in this function Flomotion

Systems, Inc cannot assume responsibility for any modifications not authorized by its engineering department

1.4 Information for Returning Pum s

Equipment that has been contaminated with, or exposed to, body fluids, toxic chemicals or any other

substance hazardous to health must be decontaminated before it is returned to Flomotion Systems or its

distributor A certificate included at the rear of these operating instructions, or signed statement, must be

attached to the outside of the shipping container This certificate is required even if the pump is unused If the

pump has been used, the fluids that have been in contact with the pump and the cleaning procedure must be

specified along with a statement that the equipment has been decontaminated

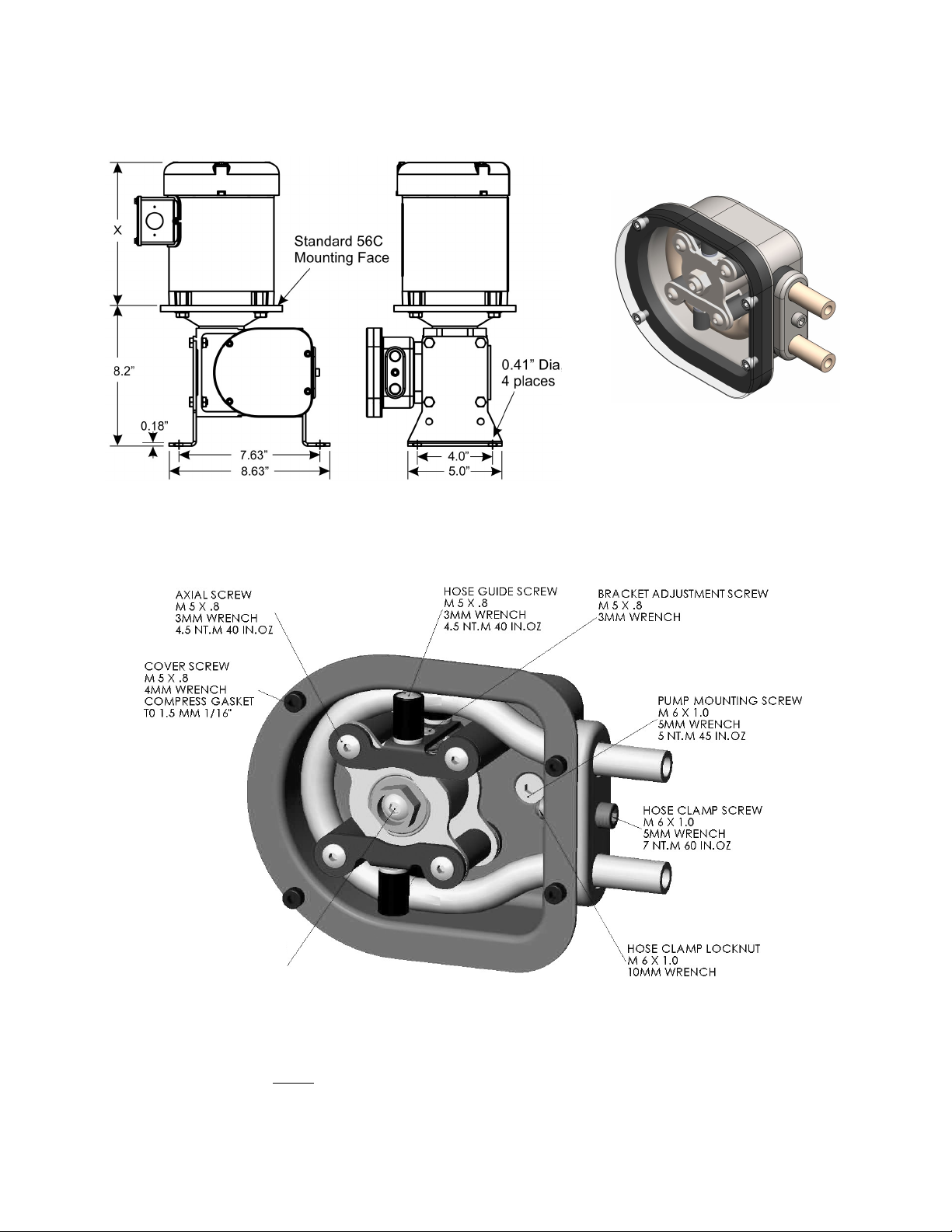

2 0 – 2001V Series Pump and Pumphead

The 2001 Series pumphead has two spring-loaded working rollers, which automatically compensate for minor

variations in tubing wall thickness, giving extended tube life

IMPORTANT: The 2001V Series is equi ed with a um cover for safety and rotection against

chemical s ills. The cover must be installed whenever the um is in use.

ROLLER ASSEMBLY

COLLET SCREW

4MM HEX WRENCH

7 NT M 60 IN OZ

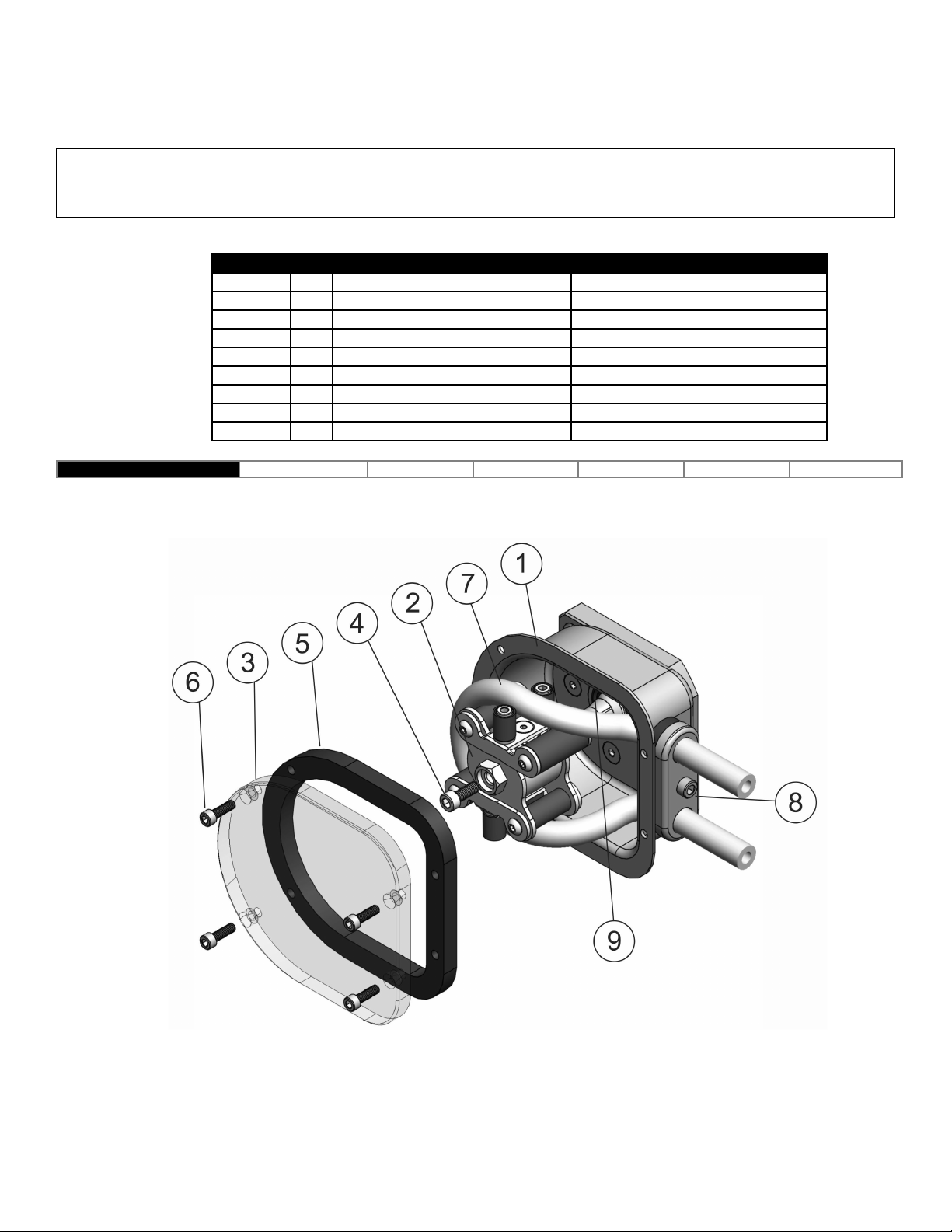

2 1 Tubing, Spindle and Cover Installation

! IMPORTANT: Disconnect um controller from ower su ly BEFORE changing tubing!

Item No Qty Part No Description

1 1 n/a Pump Collet & Hose Assy

2 1 100329 Roller Assembly

3 1 100330 Cover

4 1 100324 Collet Screw

5 1 100305C Cover Gasket

6 4 100307C Cover Screw

7 1 n/a Tube

8 1 Varies with tubing selection* Tube Seal

9 1 Shaft Seal 10x28x7 Shaft Seal

*Tube Seal PN 100329 100330 100331 100332 100333 100334

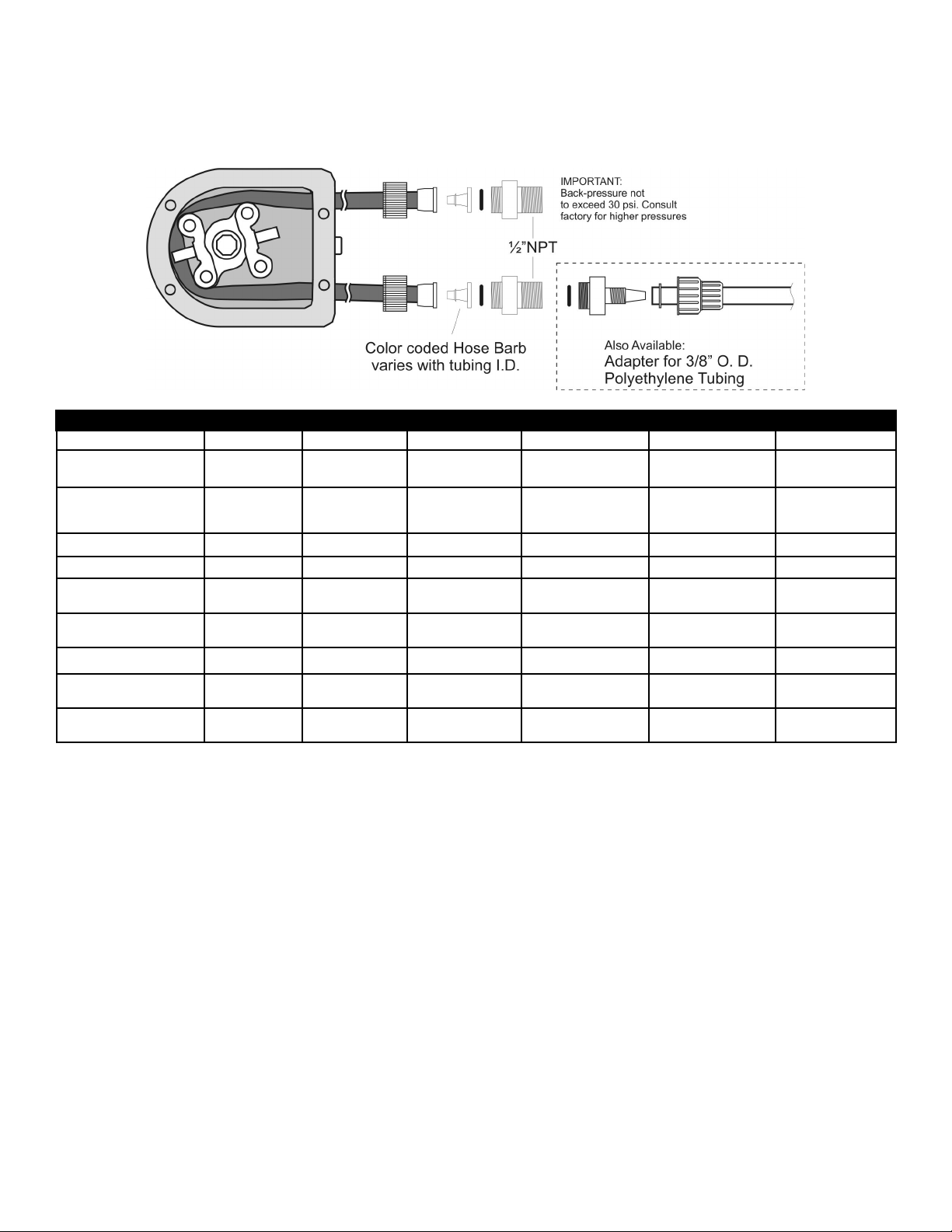

Hose is shown bent forward out of the pump housing to illustrate the correct hose

and roller assembly position, prior to sliding the hose and spindle into the housing

and over the collet

2.2 Mounting Pum on Gearbox, Installation of Collet

Item No Qty Part No Description

1 1 NA Pump Housing with Tube Seal

2 1 100306 Collet

3 2 100330 Pump Mounting Screws

4 1 NA Tubing

2.3 Pum Mounting and Collet Installation Procedure

1 To install the pump housing on the gearbox, slide it over the central pilot on the gearbox adaptor plate

Next install and torque the mounting screws to 5 NT M (45 in oz)

2 Next install the collet on the gearbox shaft There is a slot in the collet that the flat drive tang on the

gearbox shaft must slide into Orient the collet to allow the drive tang to slide into the slot and push the

collet completely onto the gearbox shaft When the collet bottoms out it is in the correct position

2.4 Hose and Roller Installation

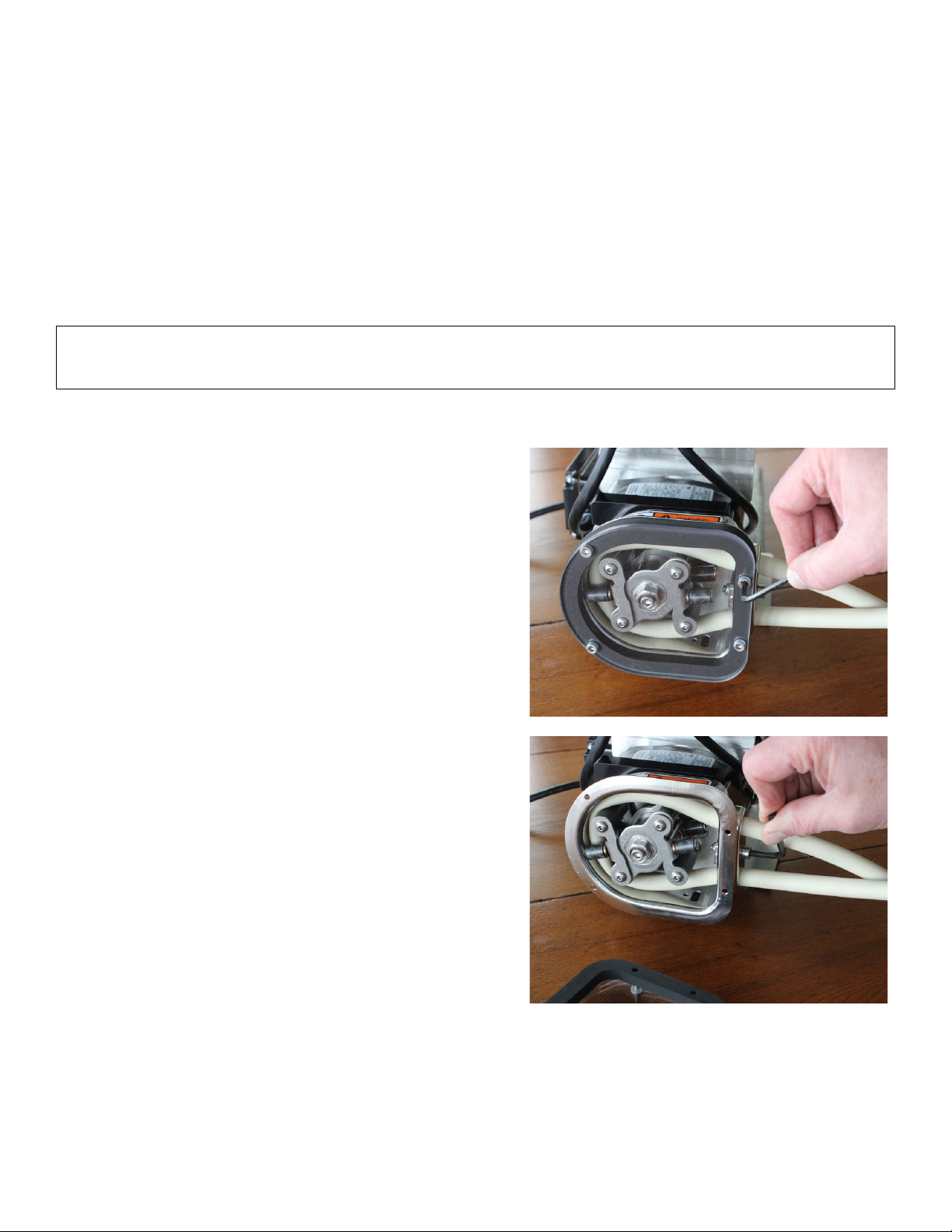

! IMPORTANT: Disconnect um controller from ower su ly BEFORE changing tubing!

Make sure um suction and discharge lines are com letely drained and isolated.

Note that the hose seal size must match the selected tubing size.

Disassembly:

1. Remove four (4) 4mm pump cover screws

2. Loosen Tube Seal Clamp Screw with 5mm hex wrench

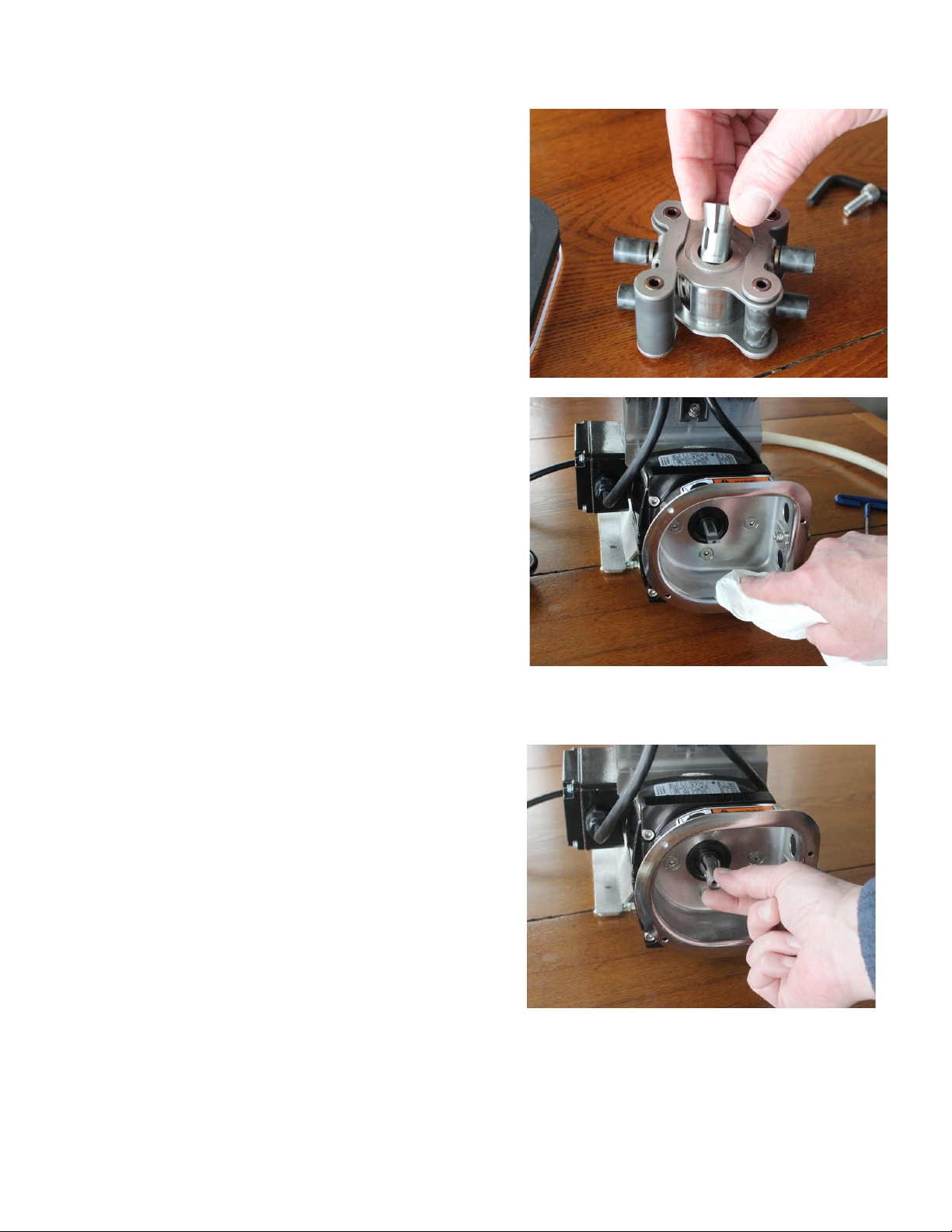

3. Remove 5mm collet screw

4. Remove the roller assembly

5. Remove worn pump tubing from pumphead

6. Remove and inspect collet for wear Note that the collet

may remain in the roller assembly when the roller

assembly is removed from the pump shaft

7. Clean inside of pump housing with damp rag or an

appropriate cleaning solution to remove any chemical or

tubing residue

Reassembly:

1 Reinstall the collet onto the pump shaft

There is a slot in the collet that the flat drive tang on the

gearbox shaft must slide into Orient the collet to allow the

drive tang to slide into the slot and push the collet completely

onto the gearbox shaft When the collet bottoms out it is in the

correct position

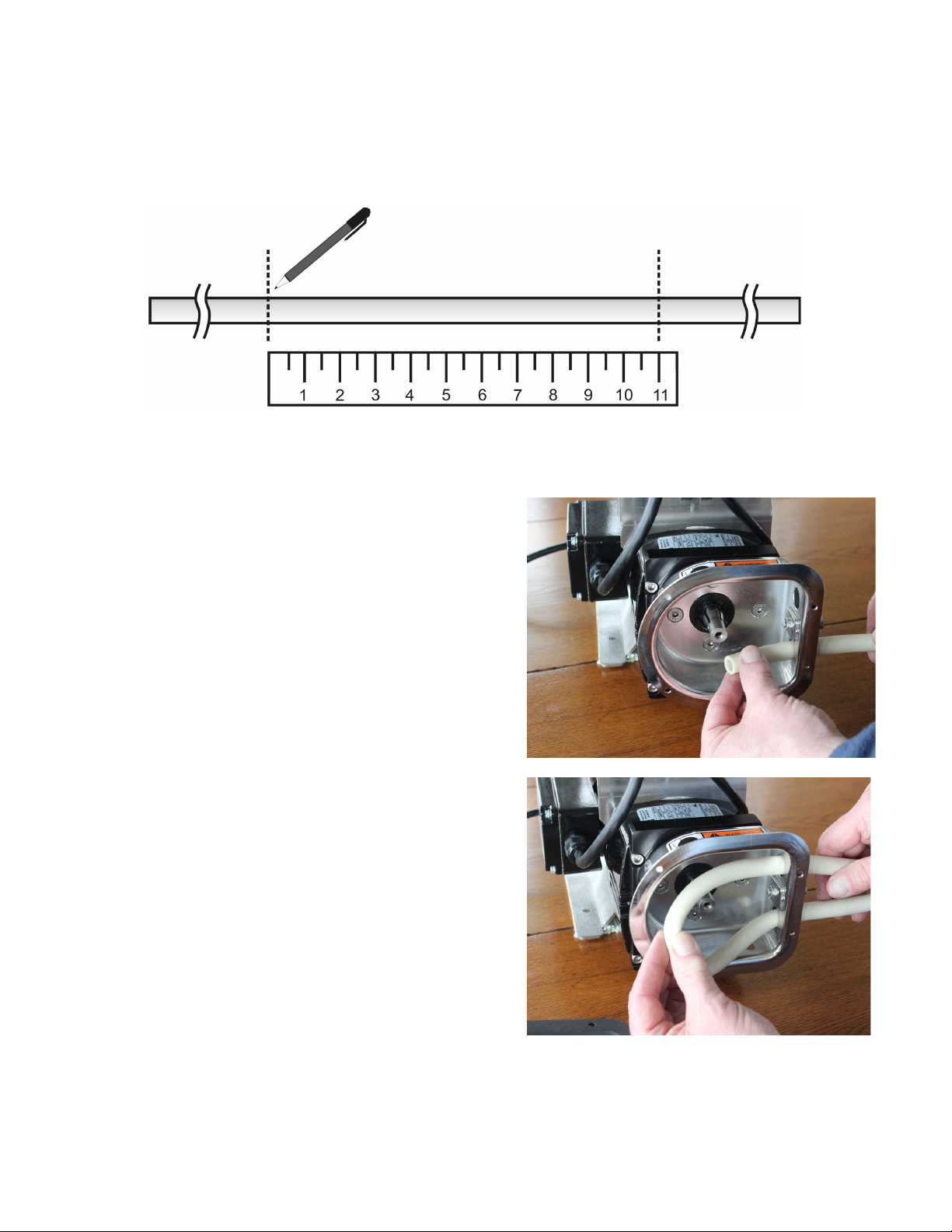

2 Mark an 11” section of hose, which will be the portion, contained within the pump Leave sufficient

excess on the suction and discharge sides of the pump for the desired connections If you leave the

excess intake tubing in a coil near the pump it will make it easy to feed a new section of tubing through

the rollers when the section in the pump becomes worn

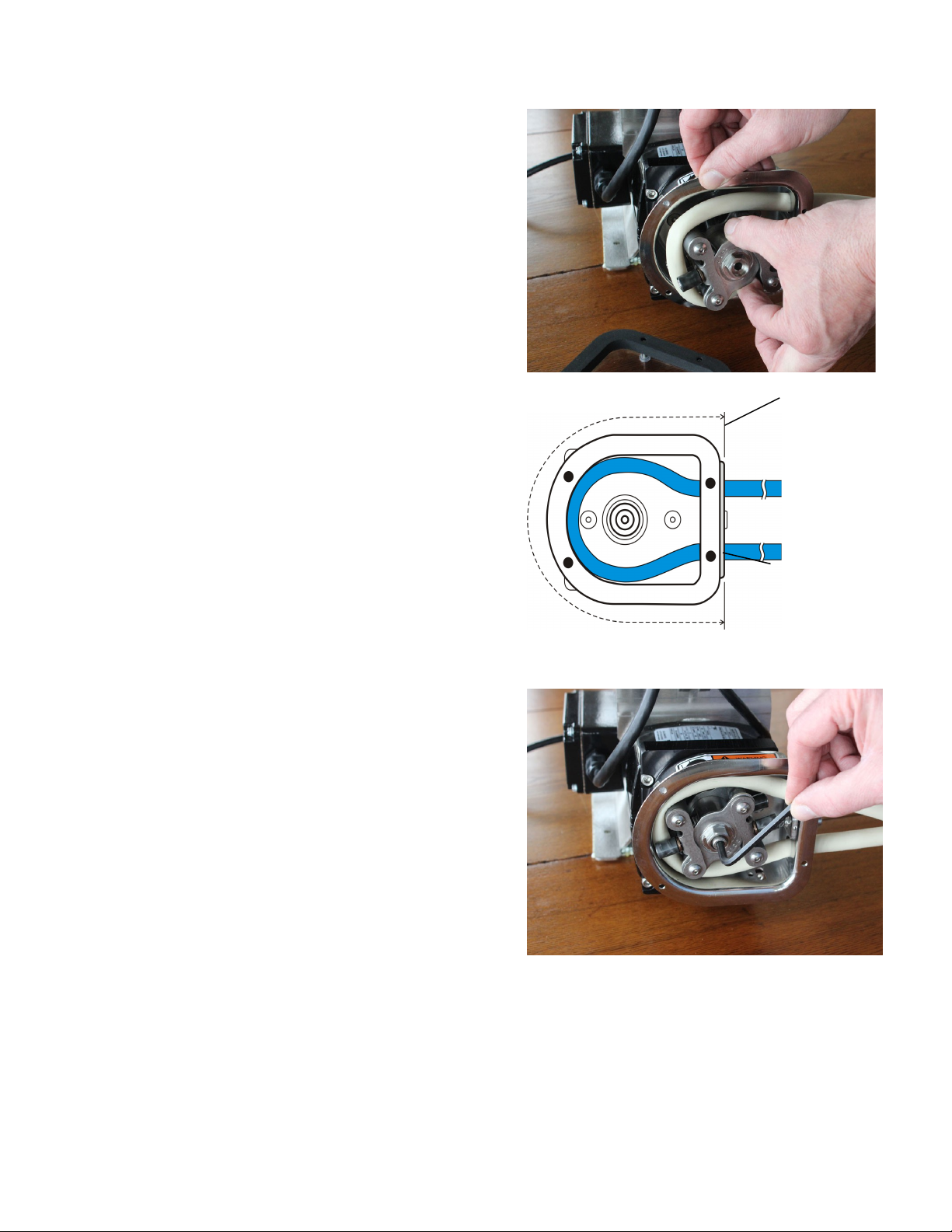

3 Install tubing into the pumphead

Note: During hose installation the loop of tubing may

develop a twist Examine the hose for this condition and

if needed turn one end of the hose where it exits the

tubing clamp to eliminate the twist Correctly adjusted

the tubing loop will be flat and parallel to the front face

of the pump housing

Mark an 11”

section of pump hose

4 Loop tubing around roller assembly between guides as

shown Remove slack in tubing while rotating roller

assembly and sliding onto collet

5 Align marks on tubing with outside edge of the tubing

clamp

6 Reinstall collet screw firmly

Tubing seal size

varies with the

selected tubing size

See tables on

following pages for

details

Mark an 11 inch

length of tubing

and locate the

marks at the

outside edge of

the tubing seal

(see arrows)

7 Tighten tube seal clamp screw Be sure to tighten firmly

to prevent “tubing walk ” Tubing walk can occur when

the tube seal is the wrong size or is not sufficiently tight

to keep the rollers from pulling the tubing through the

pump as it rotates

8 Inspect pump cover gasket Replace if damaged

Reinstall pump cover gasket and cover

Align the tubing marks

with the outside edge

of the Hose Seal

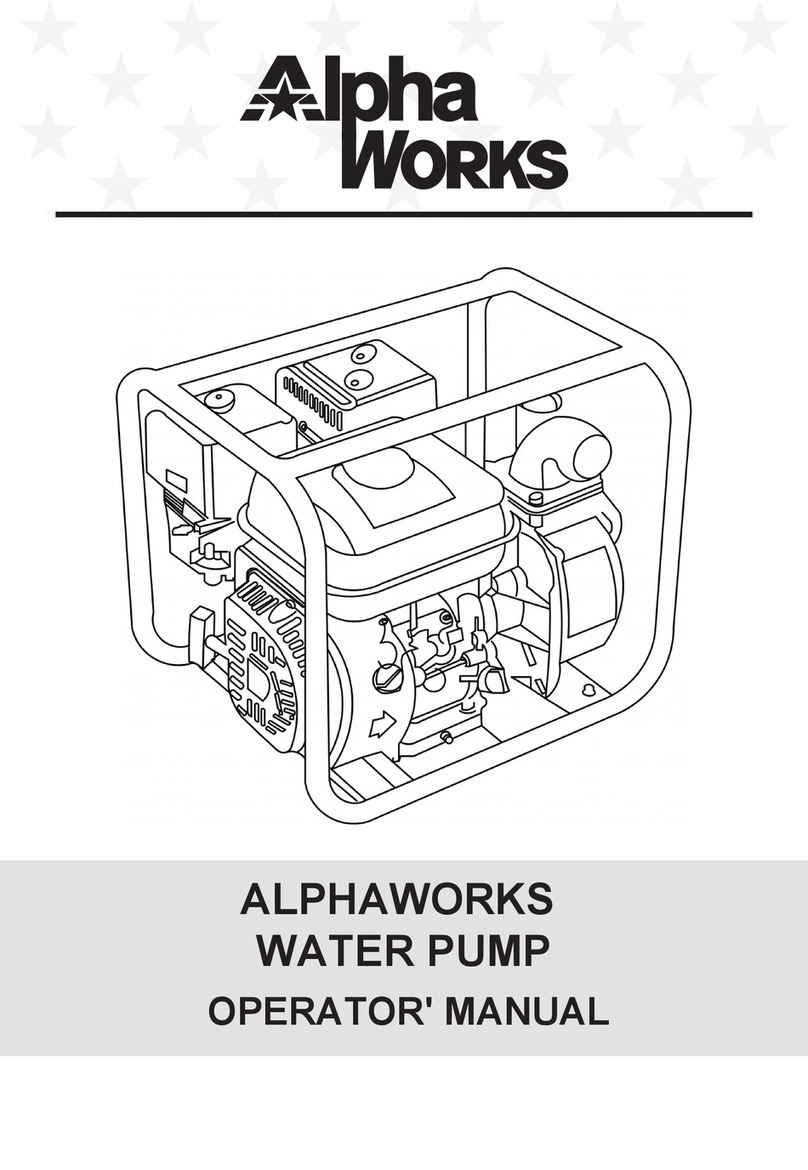

2.5 Tubing & Connections

Tubing adapters are available for many configurations See the drawing below for details

2001V SERIES ESTIMATED PUMPING CAPACITY* *Actual flow rates may vary

Tubing No. #119 #120 #15 #24 #35 #36

Tubing Size 1.6mm bore

(1/16”) 3.2mm bore

(1/8”) 4.8mm bore

(3/16”) 6.4mm bore

(1/4”) 8mm bore

(5/16”) 9.6mm bore

(3/8”)

GPH @ 1.6 - 300 rpm 0.01 - 2.1

(0.7 - 135 ml/m) 0.05 - 9.5

(3.2 - 600 ml/m) 0.1 - 14.9

(6.4 - 1200 ml/m) 0.2 - 38.0

(12.8 - 2400 ml/m) 0.2 - 53.7

(18.0 - 3390 ml/m) 0.3 - 70.3

(23.6 - 4440 ml/m)

Max Pressure (psi) 100 100 80 60 30 30

l/rev 0.45 2 4 8 11.3 14.8

Hose Barb - PVC

Color / PN

Black

HBCS2416P Gray

HBCS2432P White

HBCS2448P Black

HBCS2464P Gray

HBCS2480P White

HBCS96P

Hose Barb - PTFE

Color / PN

White

HBCS2416T White

HBCS2432T White

HBCS2448T White

HBCS2464T White

HBCS2480T White

HBCS96T

Tube Seal PN 100329 100330 100331 100332 100333 100334

Pu p Tubing

FLOPRENE FLO.016.024 FLO.032.024 FLO.048.024 FLO.064.024 FLO.080.024 FLO.096.024

Pu p Tubing

VITON VIT.016.024 VIT.032.024 VIT.048.024 VIT.064.024 VIT.080.024 VIT.096.024

3 0 – 2001V Series Gearbox

3.1 Run-in Period

The maximum efficiency of worm reducers is obtained after a “Run-In” period The length of time required will

depend on the load applied and may be two to four hours at rated load and will be considerably longer at

lighter loads During Run-In a slightly higher than normal current and temperatures along with lower efficiency

and output torque can be expected The gear box is sealed and does not require additional lubrication

3.2 2001V Series Motor Wiring

Motor Type: Permanent Split Capacitor or 3-Phase Inverter Duty

Rotation: Reversible

Insulation: Class B minimum

Finish: Powder-coat gloss black

To reverse rotation, interchange any two line leads

4 0 – K4 Pump Controller

4.1 O eration and Wiring

For complete details about the motor drive controller please refer to the included K4 SERIES Operating

Instructions booklet

IMPORTANT: Make sure the Mains voltage jum er is in the correct location for the su lied

voltage. See the K4 drive o erating instructions booklet for details.

Shown here are program settings specific to the operation with the 2001H Peristaltic Pump

4.2 Programming

The programming differs from the factory defaults shown in the SM Vector Operating Instruction booklet only in

relation to the following parameters:

KB Default Program Settings

0 04 = 0000 GFCI disabled, enable if power pump through GFCI mains circuit (some additional noise from the drive is

normal)

1 00 = 0001 Remote Start/Stop contacts enable (CHANGE TO 0000 to use 4-20 with manual start/stop)

1 05 = 0003 Power fail auto restart

2 00 = 0003 Freq Control Analog 2 (4-20mA)

2 01 = 0001 Speed change w/o pressing enter

2 02 = 0002 Enable external Local/Remote switching

3 00 = 0005 Stored Set Frequency (5hz)

3 02 = 0100 Upper Frequency Limit

4 00 = 0000 Display in user defined units (Hz)

5 00 = 0000 Enable Run Relay N O

7 03 = 0010 Remote Start/Stop - N O Start

7 04 = 0000 External Local/Remote Select OFF (13 for remote auto select)

7 06 = 0008 External Fault input select

8 00 = 0001 NC Fault Relay

8 01 = 0009 Enable Status Output

9 07 = 0020 4-20mA Input

8 09* = 0002 When speed feedback 4-20ma output is connected

NOTES:

*8 09 = 0000 to avoid fault when 4-20mA Output is disconnected when not using 4-20mA output

Keypad speed can only be changed in local mode

For manual speed with remote start/stop set 2 00 to 0000

For remote (4-20ma) speed with manual (keypad) start/stop set 1 00 to 0000

Large hose pumps - Boost Value 3 11 default 7, up to 12 or higher

6 05 = 1010 reset to Flomotion Defaults

4.3 To dis lay s eed in GPH:

Fill a calibration cylinder (best to use water, not chemical for testing and calibration)

Run the pump at full speed and time the drawdown for 30 sec (from zero level in cylinder)

Note the level in the calibration cylinder when 30 seconds has elapsed That will be your full scale pumped flow

rate

Set menu 4 00 to 0001 (custom units)

Set menu 4 01 to the GPH of the pump at full speed

4.4 Setting the maximum um ing rate

1. Fill a calibration cylinder (best to use water, not chemical for testing and calibration)

2. Run the pump at full speed and time the drawdown for 30 sec (from the zero level in the cylinder)

3. Note the level in the calibration cylinder when 30 seconds elapses That will be your full scale pumped flow rate

4. Divide the full scale pumped flow volume by the maximum hertz setting for your pump* to get volume for 1HZ

EXAMPLE:

1 Assuming the full speed drawdown test above shows 50GPH and your maximum pump frequency is 80HZ*

2 Then divide 50 / 80 = 0 625 GPH per 1 Hz

3 If your desired maximum pumping rate is to be 35GPH then divide 35 / 0 625 = 56HZ

4 Change Menu 3 02 to 56

5 Now a 20mA speed control input to the pump will equal 35GPH pumping rate

*Upper Frequency Limit; Menu 3 02

4.5 Controller Wiring Exam les

5 0 - 2001 Series Tubing Rupture Detector

Ru ture Detector System Overview

5.1 Alarm Causes

A rupture alarm is triggered by the presence of a conductive fluid in the pump When the fluid bridges the two

stainless steel electrodes in the LIQUID SENSOR in the pump the alarm is triggered

5.2 What to do in an alarm condition

To clear the alarm, first stop the pump and disconnect power from the pump controller Remove the pump

cover and remove the ruptured pump tubing Clean the inside of the pump with a soft rag Remove any liquid

or tubing debris from the inside of the pump and the area around the LIQUID SENSOR Inspect rollers and

clean if necessary

5.3 Resuming Service

Install a fresh tubing insert and the pump is ready to resume service

5.4 Resetting the alarm

Press the pushbutton (Red LED leak indicator and reset switch) on the front of the Tubing Rupture Detector to

reset the alarm

! IMPORTANT: Resetting the Tubing Ru ture Detector will cause the um to resume turning !

! ALWAYS reinstall the um cover BEFORE resetting the tubing ru ture detector !

Table of contents

Popular Water Pump manuals by other brands

IWAKI PUMPS

IWAKI PUMPS APN-110-D4 instruction manual

ALPHA WORKS

ALPHA WORKS HPT50 Operator's manual

Grundfos

Grundfos MAGNA1 D Installation and operating instructions

GORMAN-RUPP

GORMAN-RUPP SFS4C Installation, operation, and maintenance manual with parts list

Champion Power Equipment

Champion Power Equipment 66520 owner's manual

Simer

Simer BW85 Series owner's manual

Edwards

Edwards HV30000 instruction manual

Graco

Graco Lube Pro 24Z020 instructions

Ingersoll-Rand

Ingersoll-Rand ARO PD20E Series Operator's manual

Wacker Neuson

Wacker Neuson PS2A 800 Operator's manual

BEKA

BEKA Stream E 2520 Series Original operating and assembly manual

World Chemical

World Chemical SUBMERSE YD-GWN Series instruction manual