FLS FlowX3 series User manual

ULF Ultra Low Flow Sensor

1

ULF Ultra Low Flow Sensor

INSTRUCTION MANUAL

EN 10-11

Table of Contents

1. Introduction………………………………………………………………… 2

1.1. Safety Instructions……………………………………………………………… 2

1.2. Unpacking………………………………………………………………………… 2

2. Description…………………………………………………………………. 3

2.1. Design…………………………………………………………………………….. 3

2.2. Technical Features……………………………………………………………… 3

2.3. Operating Principle……………………………………………………………... 3

2.4. Connection to FlowX3 Instruments………………………………………….. 3

2.5. Output Devices…………………………………………………………………... 4

2.5.1. K315U – Frequency Output and MIN Alarm KIT………………………….….. 4

2.5.2. K330U – 4…20mA Output KIT………………………………………………..… 4

2.5.3. Installation………………………………………………………………………… 4

3. Specifications……………………………………………………………… 5

3.1. Technical Data…………………………………………………………………… 5

3.2. Dimensions………………………………………………………………………. 8

4. Installation………………………………………………………………….. 8

4.1. Location………………………………………………………………………….. 8

4.2. Wiring…………………………………………………………………………….. 8

5. Ordering Data……………………………………………………………… 10

ULF Ultra Low Flow Sensor

2

1. Introduction

1.1. Safety Instructions

General Statements

The sensors ULF01.X.X and ULF03.X.X have only been designed to measure

the flow of liquids.

Do not install and service the sensors without following the Instruction Manual.

These sensors are designed to be connected to other instruments which can be

hazardous if used improperly. Read and follow all associated instrument

manuals before using with this sensor.

Sensor installation and wiring connections should only be performed by qualified

staff.

Do not modify product construction.

Installation and Commissioning Statements

Remove power to the sensor before wiring any connection.

Depressurize and vent the system before installing or removing the sensor.

Check and confirm the chemical compatibility of the materials in contact with the

liquid.

Do not exceed maximum temperature/pressure data.

To clean the sensor, use only chemical compatible products.

1.2. Unpacking

Please verify that the product is complete and without any damage. The following

items must be included:

ULF Ultra Low Flow Sensor

Instruction Manual for ULF Ultra Low Flow Sensor

Instruction Manual for K330U or K315U Output KIT (only for ULF3.30 or

ULF3.15 version)

ULF Ultra Low Flow Sensor

3

2. Description

2.1. Design

The compact ultra-low flow sensor type ULF is designed for use with every kind of

aggressive and solid-free liquids. The sensor can be fixed to flexible or rigid pipes via

¼” GAS threaded process connections. The paddlewheel sensor produces a frequency

output proportional to the flow velocity that can be easily transmitted and processed.

The ULF sensor offers two different flow ranges starting from 1.5 or 6 l/h (0.0066 or

0.0264 gpm). The construction materials, POM or ECTFE (Halar), provide high

strength and chemical resistance.

2.2. Technical Features

Halaris a registered trademark of Ausimont-Solvay.

2.3. Operating Principle

The flow sensor consists of a transducer and a five-blade paddlewheel. The

paddlewheel is equipped with a permanent magnet integrated into each blade. As the

magnet passes close to the transducer a pulse is generated. When liquid flows into the

sensor body, the paddlewheel is set in rotation producing a square wave output signal.

The frequency is proportional to the flow velocity.

2.4. Connections to FlowX3 Instruments

FlowX3 Instruments

FlowX3

Sensors F9.00 F9.01 F9.02 F9.03 F9.20 F9.50 F9.51

ULF01.H X X X X X

ULF01.R X X

ULF03.H X X X X X

ULF03.R X X

ULF3.15* X X X X X

ULF3.30*

*with Output KIT mounted

ULF Ultra Low Flow Sensor

4

2.5. Output Devices

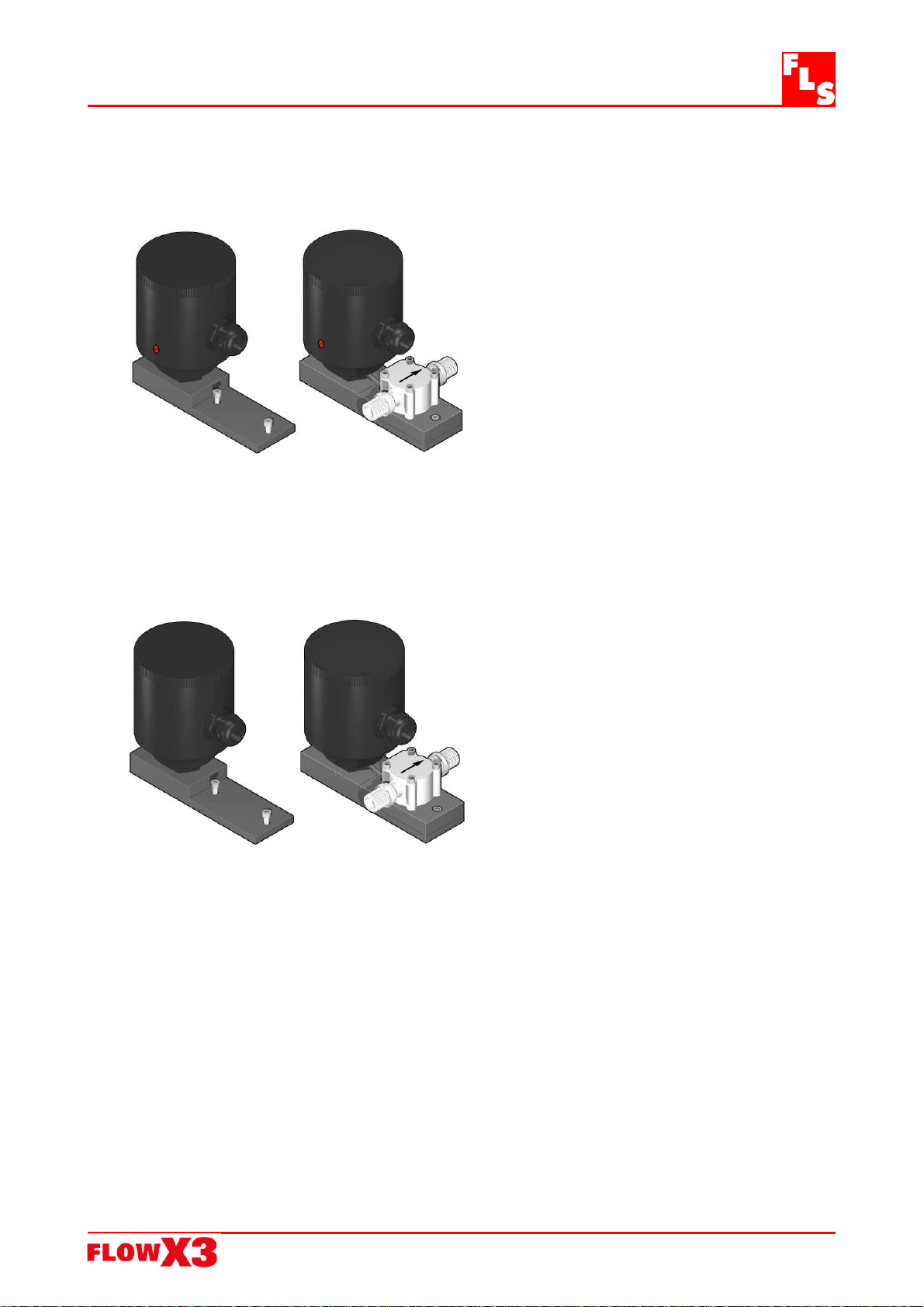

2.5.1. K315U – Frequency Output & MIN alarm KIT

This Kit consists of an additional IP65

housing mounted aside the sensor via a

PVC plate. It is equipped with an open

collector frequency output and a

mechanical SPDT contact. The MIN alarm

set-point can be freely set by a

potentiometer up to 21 l/h (0.09 gpm) for

ULF01 and 53 l/h (0.23 gpm) for ULF03.

When the flow velocity drops below the

adjusted limit the relay output opens and

the Local Status Indicator changes colour.

It has been designed to protect a pump

from running dry or pumping against a

closed valve in the main pipeline.

2.5.2. K330U – 4…20 mA Output KIT

This Kit consists of an additional IP65

housing mounted aside the sensor via a

PVC plate. It is a blind transmitter

designed to convert the signal from the

sensor into a 4…20 mA output for long

distance transmission.

2.5.3. Installation

The K315U and K330U Kits can be ordered directly mounted on top of the flow sensor

or separately and then simply installed on the proper sensor.

Please refer to the Instruction Manual of the Output KIT for proper installation and

calibration.

ULF Ultra Low Flow Sensor

5

3. Specifications

3.1. Technical Data

General (Hall and Reed)

Flow Rate Range:

- ULF01 version: 1.5 to 100 l/h (0.0066 to 0.44 gpm)

- ULF03 version: 6 to 250 l/h (0.0264 to 1.1 gpm)

Linearity: 1 % of full scale

Repeatability: 0.5 % of full scale

Working Temperature: -10° to 80°C (14° to 176°F)

Working Pressure: 5 bar (70 psi) max. @ 22°C (72°F)

Viscosity of fluid: 1 to 10 cST

Enclosure:IP65

Wetted Materials:

POM version:

Sensor Body: POM

O-ring: FPM

Rotor: POM

Shaft: core point

Magnets: ceramic

ECTFE version:

Sensor Body: ECTFE (Halar)

O-ring: FPM or KALREZ

Rotor: ECTFE (Halar)

Shaft: sapphire

Bearings: sapphire

Connections: ¼” GAS male

Cable length: 2 m (6.5 ft) standard

Standards & Approvals

Manufactured under ISO 9002

CE

ULF Ultra Low Flow Sensor

6

Specific for ULF01.H / ULF03.H (Hall version)

Supply voltage: 5 to 24 VDC regulated

Supply current: < 15 mA @ 24 VDC

Output signal: square wave

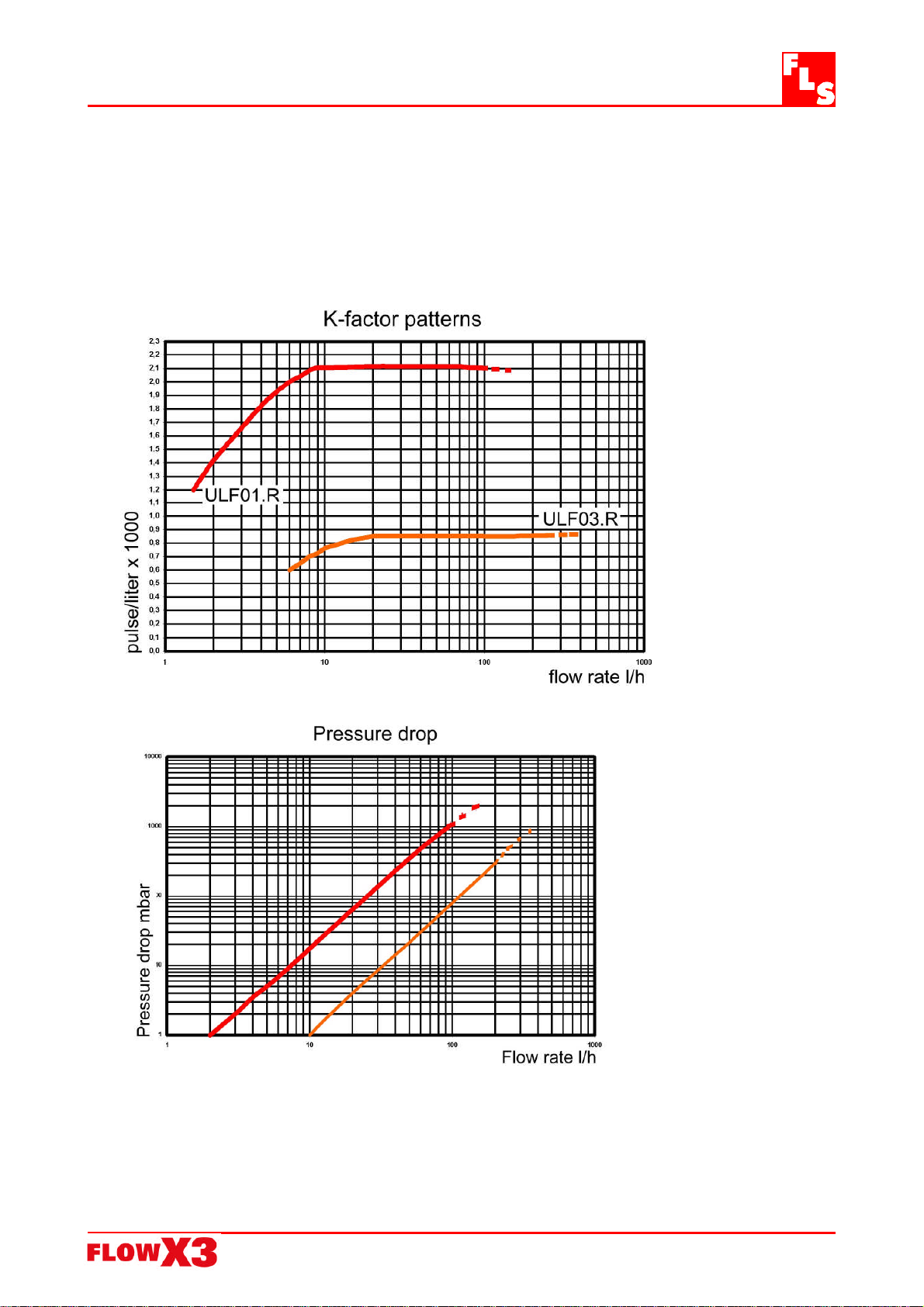

Calibration Data:

- ULF01 version: K-factor = 8431 Pulses/Liter (31569 Pulses/U.S. Gallon)

- ULF03 version: K-factor = 3394 Pulses/Liter (12846 Pulses/U.S. Gallon)

ULF Ultra Low Flow Sensor

7

Specific for ULF01.R / ULF03.R (Reed version)

Supply voltage: none

Output signal: square wave

Output type: Reed Contact

Calibration Data:

- ULF01 version: K-factor = 2108 Pulses/Liter (7978 Pulses/U.S. Gallon)

- ULF03 version: K-factor = 848 Pulses/Liter (3210 Pulses/U.S. Gallon)

ULF Ultra Low Flow Sensor

8

3.2. Dimensions

4. Installation

4.1. Location

The sensor can be installed in any position, both horizontally or vertically, although

horizontal flow is preferred. A non horizontal installation may cause a greater error in

the lower part of the measurement range.

Install the sensor with the arrow pointing the direction of the flow.

Always maximize distance between sensor and pump. Do not install the sensor

immediately downstream of valves, elbows or any kind of obstacles: 150 mm of

straight pipe are suggested before and after the sensor.

4.2. Wiring

Always ensure the power supply is switched off before working on the sensor.

Always use a high quality (regulated) DC voltage supply.

ULFXX.H Sensor Connection to FlowX3 Instruments

Brown

Gree

n

White

ULF Ultra Low Flow Sensor

9

ULFXX.H Sensor Connection to Other Brand Instruments

ULFXX.R Sensor Connection to FlowX3 Instruments

The capacitor C and the resistor R are already included if the sensor is bought together

with the FlowX3 Battery Powered Monitor F9.20.XX and the F9.00.XX .

ULFXX.R Sensor Connection to Other Brand Instruments

Brown

Gree

n

White

Brown

Green

White

Brown

White

Green

ULF Ultra Low Flow Sensor

10

5. Ordering Data

FlowX3 ULF01.X.X

Part No. Version Power

supply Material Flow Rate Range

ULF01.H.0 Hall 5 - 24 VDC POM / FPM 1.5 to 100 l/h (0.0066 to 0.44 gpm)

ULF01.H.2 Hall 5 - 24 VDC ECTFE / FPM 1.5 to 100 l/h (0.0066 to 0.44 gpm)

ULF01.H.3 Hall 5 - 24 VDC ECTFE / KALREZ 1.5 to 100 l/h (0.0066 to 0.44 gpm)

ULF01.R.0 Reed None POM / FPM 1.5 to 100 l/h (0.0066 to 0.44 gpm)

ULF01.R.2 Reed None ECTFE / FPM 1.5 to 100 l/h (0.0066 to 0.44 gpm)

ULF01.R.3 Reed None ECTFE / KALREZ 1.5 to 100 l/h (0.0066 to 0.44 gpm)

FlowX3 ULF03.X.X

Part No. Version Power

supply Material Flow Rate Range

ULF03.H.0 Hall 5 - 24 VDC POM / FPM 6 to 250 l/h (0.0264 to 1.1 gpm)

ULF03.H.2 Hall 5 - 24 VDC ECTFE / FPM 6 to 250 l/h (0.0264 to 1.1 gpm)

ULF03.H.3 Hall 5 - 24 VDC ECTFE / KALREZ 6 to 250 l/h (0.0264 to 1.1 gpm)

ULF03.R.0 Reed None POM / FPM 6 to 250 l/h (0.0264 to 1.1 gpm)

ULF03.R.2 Reed None ECTFE / FPM 6 to 250 l/h (0.0264 to 1.1 gpm)

ULF03.R.3 Reed None ECTFE / KALREZ 6 to 250 l/h (0.0264 to 1.1 gpm)

FlowX3 ULF3.15.XX.X (with O.C. output & MIN alarm)

Part No. Version Power

supply Material Flow Rate Range

ULF3.15.01.0 Hall 12 - 24 VDC POM / FPM 1.5 to 100 l/h (0.0066 to 0.44 gpm)

ULF3.15.01.2 Hall 12 - 24 VDC ECTFE / FPM 1.5 to 100 l/h (0.0066 to 0.44 gpm)

ULF3.15.01.3 Hall 12 - 24 VDC ECTFE / KALREZ 1.5 to 100 l/h (0.0066 to 0.44 gpm)

ULF3.15.03.0 Hall 12 - 24 VDC POM / FPM 6 to 250 l/h (0.0264 to 1.1 gpm)

ULF3.15.03.2 Hall 12 - 24 VDC ECTFE / FPM 6 to 250 l/h (0.0264 to 1.1 gpm)

ULF3.15.03.3 Hall 12 - 24 VDC ECTFE / KALREZ 6 to 250 l/h (0.0264 to 1.1 gpm)

FlowX3 ULF3.30.XX.X (with 4…20 mA output)

Part No. Version Power

supply Material Flow Rate Range

ULF3.30.01.0 Hall 12 - 24 VDC POM / FPM 1.5 to 100 l/h (0.0066 to 0.44 gpm)

ULF3.30.01.2 Hall 12 - 24 VDC ECTFE / FPM 1.5 to 100 l/h (0.0066 to 0.44 gpm)

ULF3.30.01.3 Hall 12 - 24 VDC ECTFE / KALREZ 1.5 to 100 l/h (0.0066 to 0.44 gpm)

ULF3.30.03.0 Hall 12 - 24 VDC POM / FPM 6 to 250 l/h (0.0264 to 1.1 gpm)

ULF3.30.03.2 Hall 12 - 24 VDC ECTFE / FPM 6 to 250 l/h (0.0264 to 1.1 gpm)

ULF3.30.03.3 Hall 12 - 24 VDC ECTFE / KALREZ 6 to 250 l/h (0.0264 to 1.1 gpm)

ULF Ultra Low Flow Sensor

11

Output Devices

Part No. Housing Gaskets Enclosure Description

ULF.K315U PVC EPDM IP65 Frequency Output & MIN Alarm KIT

ULF.K330U PVC EPDM IP65 4-20 mA Output KIT

Spare Parts

Item Part No. Name Description

1ULF.SP1U PVC Plate PVC Adapter for K315U or K330U Kit

F3.SP6 Electrical cable Cable (per meter), 3cond., 22AWG

2F3.SP7 PG11 PG11 Cable Gland for K315 or K330 Kit

ULF Ultra Low Flow Sensor

12

F.I.P.

Formatura Iniezione Polimeri S.p.A.

Loc. Pian di Parata, 16015 Casella (GE) – Italy

Tel +39 010 96211 – Fax +39 010 9621209

www.flsnet.it

Other manuals for FlowX3 series

1

This manual suits for next models

2

Table of contents

Other FLS Accessories manuals

Popular Accessories manuals by other brands

DANA

DANA 2000-10 parts list

S+S Regeltechnik

S+S Regeltechnik KYMASGARD AFTF-HK-FSE Operating Instructions, Mounting & Installation

Burster

Burster 8625 Operation manual

Furuno

Furuno FI-3002 Operator's manual

Teledyne

Teledyne TIENet 350 Installation and operation guide

Air Naturel

Air Naturel Airom user manual