FLS FlowX3 series User manual

F3.2

0 Paddlewheel Flow Sensor

1

F3.20 High Pressure Paddlewheel Flow Sensor

INSTRUCTION MANUAL

EN 12-02

Table of Contents

1. Introduction………………………………………………………………… 2

1.1. Safety Instructions……………………………………………………..……………2

1.2. Unpacking……………………………………………………………………….…… 2

2. Description…………………………………………………….……………. 2

2.1. Design…………………………………………………………………..……………..2

2.2. Operating Principle………………………………………………………………..... 3

2.3. Connection to FlowX3 Instruments……………………………………………... 3

3. Specifications……………………………………………………………… 3

3.1. Technical Data…………………………………………………………………….… 3

4. Installation………………………………………………………………….. 4

4.1. Location…………………………………………………………………………….... 4

4.2. Mounting Position………………………………………………………………..… 5

4.3. Process Connection……..……………………………………………………...… 5

4.4. Wiring…………………………………………………………………………………. 6

5. Installation Fittings……………………………………………………….. 7

6. K-Factor Tables……………………………………………………………. 7

7. Ordering Data……………………………………………………………… 8

8. Weld-on Adapters installation procedure …………………………….. 9

F3.2

0 Paddlewheel Flow Sensor

2

1. Introduction

1.1. Safety Instructions

General Statements

The sensor F3.20.X.XX has only been designed to measure the flow of liquids.

Do not install and service the sensor without following the Instruction Manual.

This sensor is designed to be connected to other instruments which can be

hazardous if used improperly. Read and follow all associated instrument

manuals before using with this sensor.

Sensor installation and wiring connections should only be performed by qualified

staff.

Do not modify product construction.

Installation and Commissioning Statements

Remove power to the sensor before wiring any connection.

Depressurize and vent the system before installing or removing the sensor.

Check and confirm the chemical compatibility of the materials in contact with the

liquid.

Do not exceed maximum temperature/pressure data.

To clean the sensor, use only chemical compatible products.

1.2. Unpacking

Please verify that the product is complete and without any damage. The following

items must be included:

F3.20 Paddlewheel Flow Sensor

Instruction Manual for F3.20 Flow Sensor

2. Description

2.1. Design

The simple and reliable paddlewheel flow sensor type F3.20 is designed for use with

every kind of solid-free liquids and to be installed on high pressure plants. The sensor

can measure flow from 0.15 m/s (0.5 ft/s) producing a frequency output signal highly

repeatable. A rugged construction and a proven technology guarantee exceptional

performances with little or no maintenance required. A specially designed family of

fittings ensures an easy and quick installation into all pipe materials in sizes from DN40

to DN200 ( 1 ½” to 8”.).

F3.2

0 Paddlewheel Flow Sensor

3

2.2. Operating Principle

The flow sensor consists of a transducer and a five-blade open cell paddlewheel using

insertion technology. The paddlewheel is equipped with a permanent magnet

integrated into each blade. As the magnet passes close to the transducer a pulse is

generated. When liquid flows into the pipe, the paddlewheel is set in rotation

producing a square wave output signal. The frequency is proportional to the flow

velocity. The sensor is installed into the pipe using a wide range of insertion type

fittings supplied by the flow sensor manufacturer.

2.3. Connections to FlowX3 Instruments

FlowX3 Instruments

FlowX3

Sensors F9.00 F9.01 F9.02 F9.30 F9.20 F9.50 F9.51 PLC

F3.20.H X X X X X X

F3.20.P X

*with Output KIT mounted

3. Specifications

3.1. Technical Data

Pipe Size Range: DN40 to DN200 ( 1 ½” to 8” ) . Refer to Installation Fittings section for

more details

Flow Rate Range: 0.15 to 8 m/s (0.5 to 25 ft./s)

Linearity: 0.75 % of full scale

Repeatability: 0.5 % of full scale

Minimum Reynolds Number Required: 4500

Temperature : 120 °C ( 248 °F )

Pressure : 110 bar ( 1600 psi)

Enclosure: IP68

Wetted Materials:

Sensor Body: 316L SS

Flat Gasket : graphite

Rotor: ECTFE (Halar)

Shaft: 316L SS

Standards & Approvals

Manufactured under ISO 9002

CE

F3.2

0 Paddlewheel Flow Sensor

4

Specific for F3.20.H

Supply voltage: 5 to 24 VDC regulated

Supply current: < 30 mA @ 24 VDC

Output signal: square wave

Output frequency: 45 Hz per m/s nominal (13.7 Hz per ft/s nominal)

Output type: transistor NPN open collector

Output current: 10 mA max.

Cable length: 8 m (26.4 ft) standard, 300 m (990 ft) maximum

Specific for F3.20.P

Supply voltage: 12 to 24 VDC regulated

Supply current: < 30 mA @ 24 VCC

Output signal: square wave

Output frequency: 45 Hz per m/s nominal (13.7 Hz per ft/s nominal)

Output type : Push – Pull (digital input NPN or PNP)

Output current : IOut Max < 20 mA

Cable length: 8 m (26.4 ft) standard, 300 m (990 ft) maximum

4. Installation

4.1. Location

Different pipe configurations and obstacles in the flow line such as valves, elbows, pipe

bends and strainers create variations on the flow profile.

Whenever possible follow the EN ISO 5167-1 installation recommendations to locate

the sensor.

Always maximize distance between flow sensor and pump.

F3.2

0 Paddlewheel Flow Sensor

5

4.2. Mounting Position

Make sure the pipeline is always full.

Horizontal pipe runs:

Fig. 1: installation with no sediments present

Fig. 2: installation with no air bubbles present

Fig. 3: installation if sediments or air bubbles may be present

Vertical pipe runs:

Install sensor in any orientation. Upward flow is preferred to ensure full pipe.

4.3. Process Connection

1. Place the flat gasket, sensor, and the

screws with washers making sure that the

arrow is in line with the slot milling of the

weld on adapter

2. tighten the screws with a force equal to 15

Nm

F3.2

0 Paddlewheel Flow Sensor

6

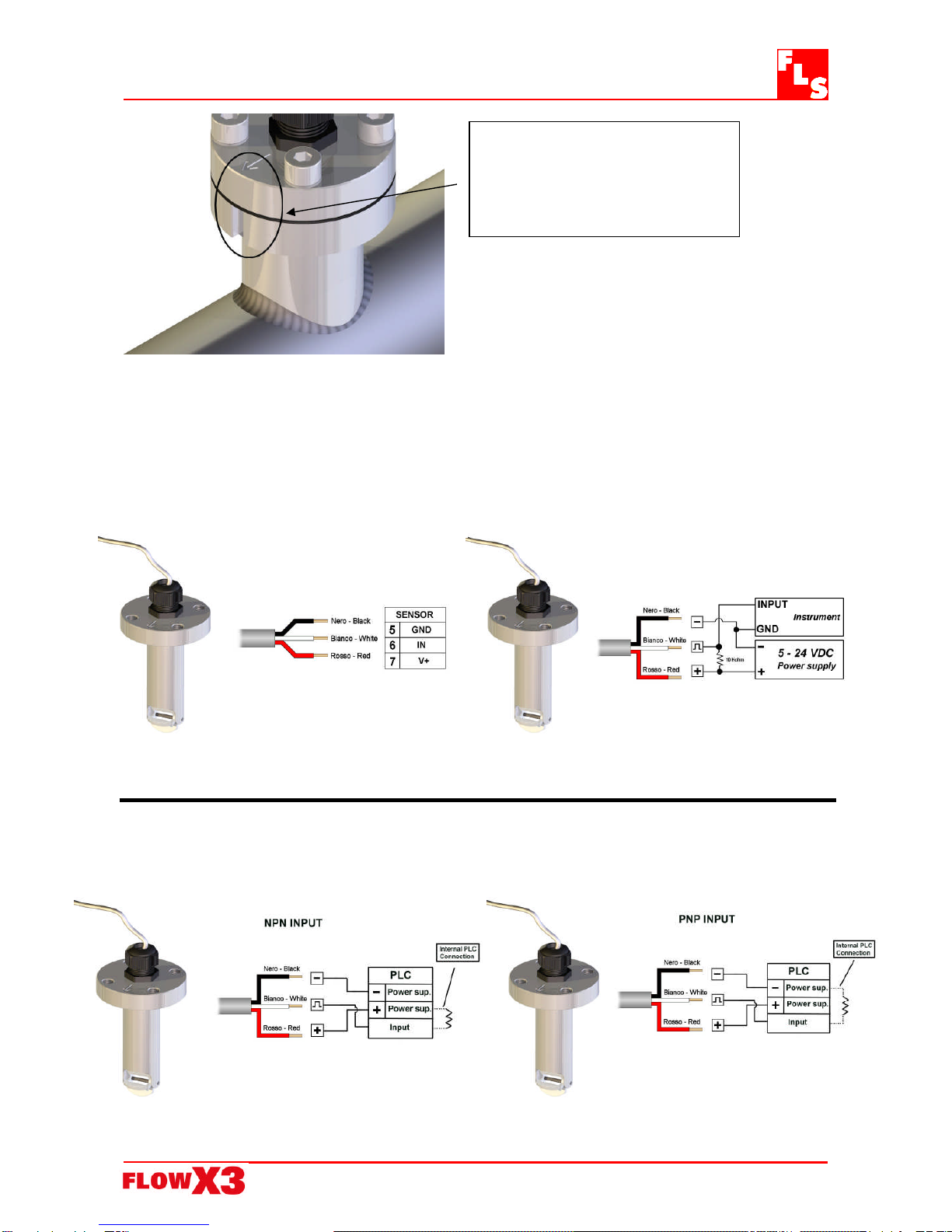

4.4. Wiring

Always ensure the power supply is switched off before working on the sensor.

Always use a high quality (regulated) DC voltage supply.

2.7Kohm Pull-up resistor may be required.

N.B. The slot milling of the weld

on adapter must be parallel to

the flow. The arrow on the

sensor must be close to the

milling weld on adapter.

F3.20.H IP68 Sensor Connection to

FlowX3 Instruments

F3.

2

0.H IP68 Sensor Connection

to Other Brand Instruments

F3.

2

0.P IP68 Sensor to PLC with

NPN Input

F3.2

0.P IP68 Sensor to PLC with

NPN Input

F3.2

0 Paddlewheel Flow Sensor

7

5. Installation Fittings

Type Description

316L SS Weld-on

Adapters Size: DN 40 to DN 200 ( 1 ½” to 8” )

6. K-Factor Tables

K-Factor is the number of pulses a sensor produces for one liter of fluid measured. Here

all K-Factors for water at ambient temperature are listed.

K-Factor values can depend upon the installation conditions.

Please contact your dealer for K-Factor values not included in the tables.

316L SS Weld-on Adapters mounted on 316L SS Weld-on Adapters mounted on

Cast Iron pipes Other Metal pipes

Part No. DN K-Factor Part No. DN K-Factor

WAIXL0 40 --------- WAIXL0 40 36,17

WAIXL0 50 --------- WAIXL0 50 23,71

WAIXL0 60 19,78 WAIXL0 60 ---------

WAIXL0 65 --------- WAIXL0 65 13,93

WAIXL0 80 10,22 WAIXL0 80 9,61

WAIXL0 100 6,01 WAIXL0 100 5,22

WAIXL0 110 --------- WAIXL0 110 ---------

WAIXL0 125 3,64 WAIXL0 125 3,31

WAIXL0 150 2,46 WAIXL0 150 2,22

WAIXL0 175 --------- WAIXL0 175 ---------

WAIXL0 200 1,28 WAIXL0 200 1,23

F3.2

0 Paddlewheel Flow Sensor

8

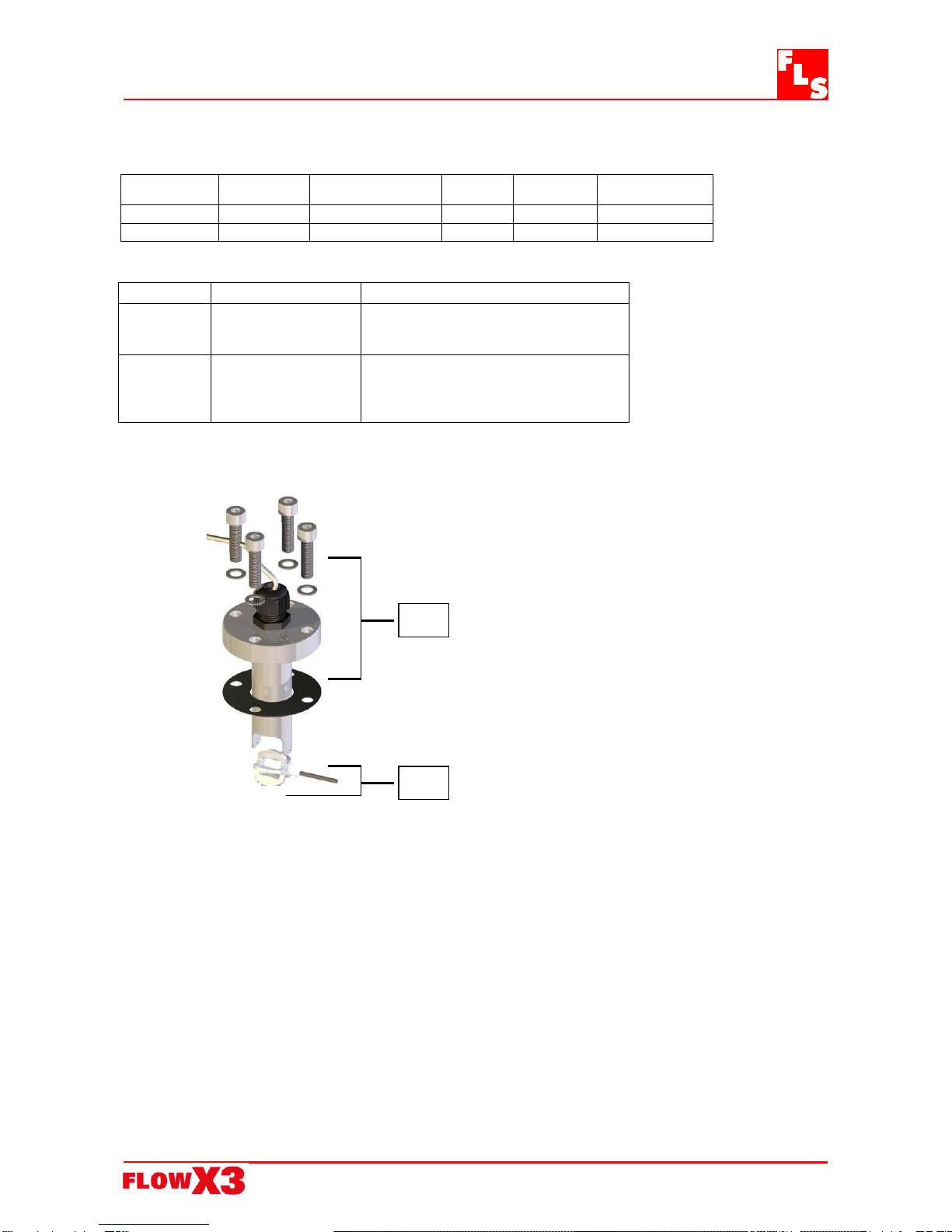

7. Ordering Data

FlowX3 F3.00.H.XX (Remote version)

Part No. Version Power supply Length Body Enclosure

F3.20.H.01 Hall 5 - 24 VDC L0 INOX IP68

F3.20.P.01 Push-Pull 12 - 24 VDC L0 INOX IP68

Spare Parts

Item Part No. Description

A-1 F3.SP4.3 ECTFE (Halar) rotor with Inox Shaft

A-2 F3.SP8 flat gasket + screws

A-2

A-1

F3.2

0 Paddlewheel Flow Sensor

9

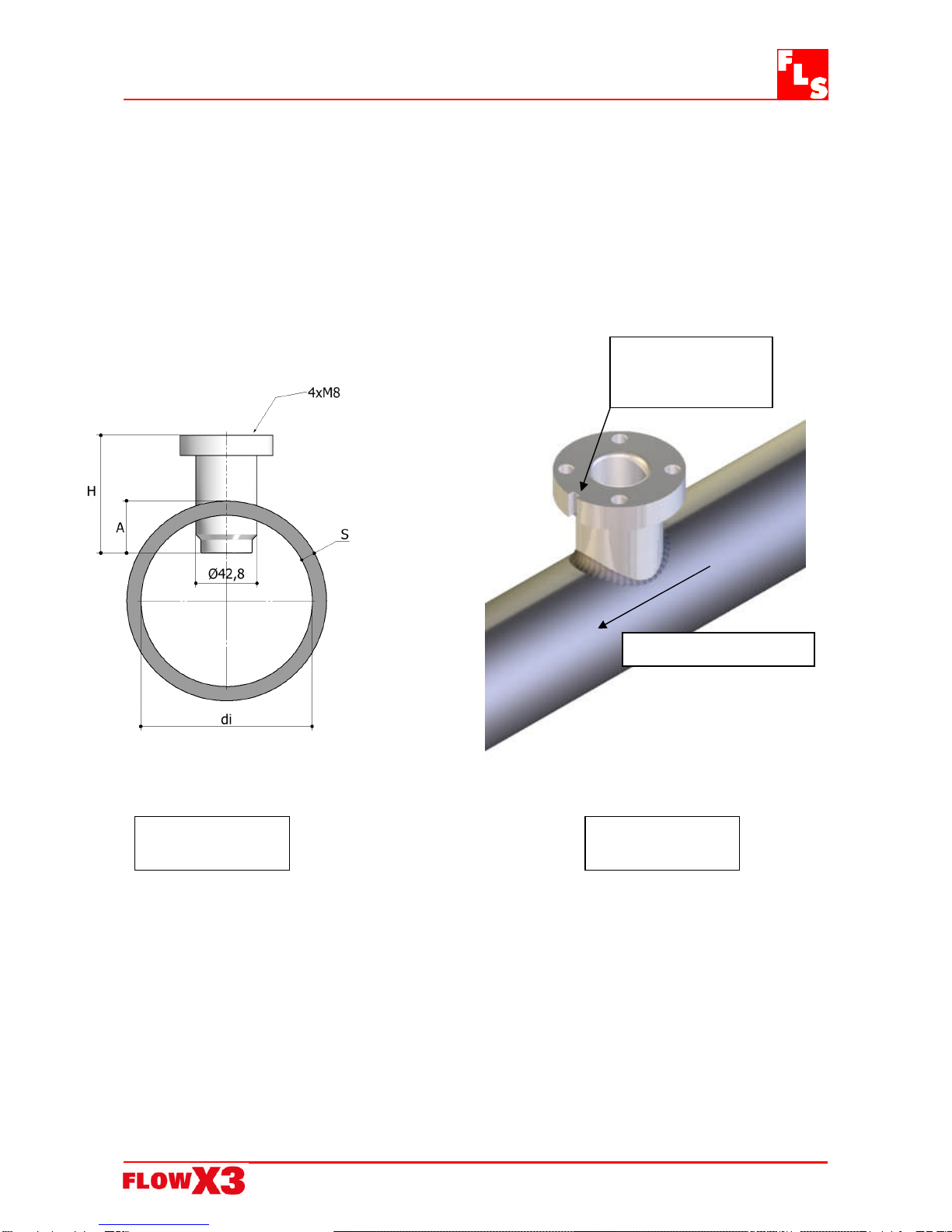

8. Weld-on Adapters installation procedure

Calculate the length A and mark it on the adapter.

Measure the adapter diameter at the mark level and drill the hole in the pipe with

such diameter.

Insert the adapter into the pipe and to be sure that the milling slot is parallel to the

flow (see drawing n°2)

Weld the adapter at the above mark reference.

See drawing n°1.

Drawing n°1 Drawing n°2

The milling slot

must be parallel

to

the flow

Flow rate direction

A = 0.12 x di + 3.5 + S

F3.2

0 Paddlewheel Flow Sensor

10

F3.2

0 Paddlewheel Flow Sensor

11

F3.2

0 Paddlewheel Flow Sensor

12

F.I

.P.

Formatura Iniezione Polimeri S.p.A.

Loc. Pian di Parata, 16015 Casella (GE) – Italy

Tel +39 010 96211 – Fax +39 010 9621209

www.flsnet.it

Other manuals for FlowX3 series

1

This manual suits for next models

3

Table of contents

Other FLS Accessories manuals