flsun SuperRacer User manual

SR (SuperRacer)

User Manual • Uživatelský manuál •

Užívateľský manuál • Használati utasítás •

Benutzerhandbuch

Dear customer,

Thank you for purchasing our product. Please read the following instructions carefully

before first use and keep this user manual for future reference. Pay particular attention

to the safety instructions. If you have any questions or comments about the device,

please contact the customer line.

✉www.alza.co.uk/kontakt

✆+44 (0)203 514 4411

Importer Alza.cz a.s., Jankovcova 1522/53, Holešovice, 170 00 Praha 7, www.alza.cz

Advice and Guidance

•The printer’s default power input voltage is 230V, if your local voltage is 115V,

please switch the input voltage of the power supply before turning on the printer

for the first time.

•The assembly videos, firmware and slicing software are included in the SD card,

please back up the files of the SD card to your computer before using.

•Do not touch the hot bed and nozzle while the printer is running, as the heat

would cause the burn injuries to your skin.

•The printer’s environment can affect the print quality, please ensure the printer is

not placed in too hot/cold temperature, high humidity or near drafts. To ensure

optimum printing, place the printer on an even and firm surface.

•Failures caused by changes to the printers mechanical components are not

covered by the printers warranty.

•Keep young children away from the printer due to the hot components while

printer is running.

•Please use the recommended filaments, poor quality filaments may cause poor

print quality or damage the printer.

•Typical maintenance would be useful.

•Please wait for the hot bed to cool down completely before removing the print.

•In case of emergency, turn off the printer and pull it from the main power to

prevent damage to the printer then contact our technical support.

•To avoid damage to printer and property, do not misuse printer. Printer has been

designed for it’s intended purpose only.

•All printers have been tested before leaving the factory. As a result of these tests,

some filament and stain might remain in and around nozzle, this is normal.

•In order to make the model stick to the hot bed well, please clean the hot bed

before each print.

•When the printer has to be restored to factory settings, please restart the printer

first, and then click “Restore”.

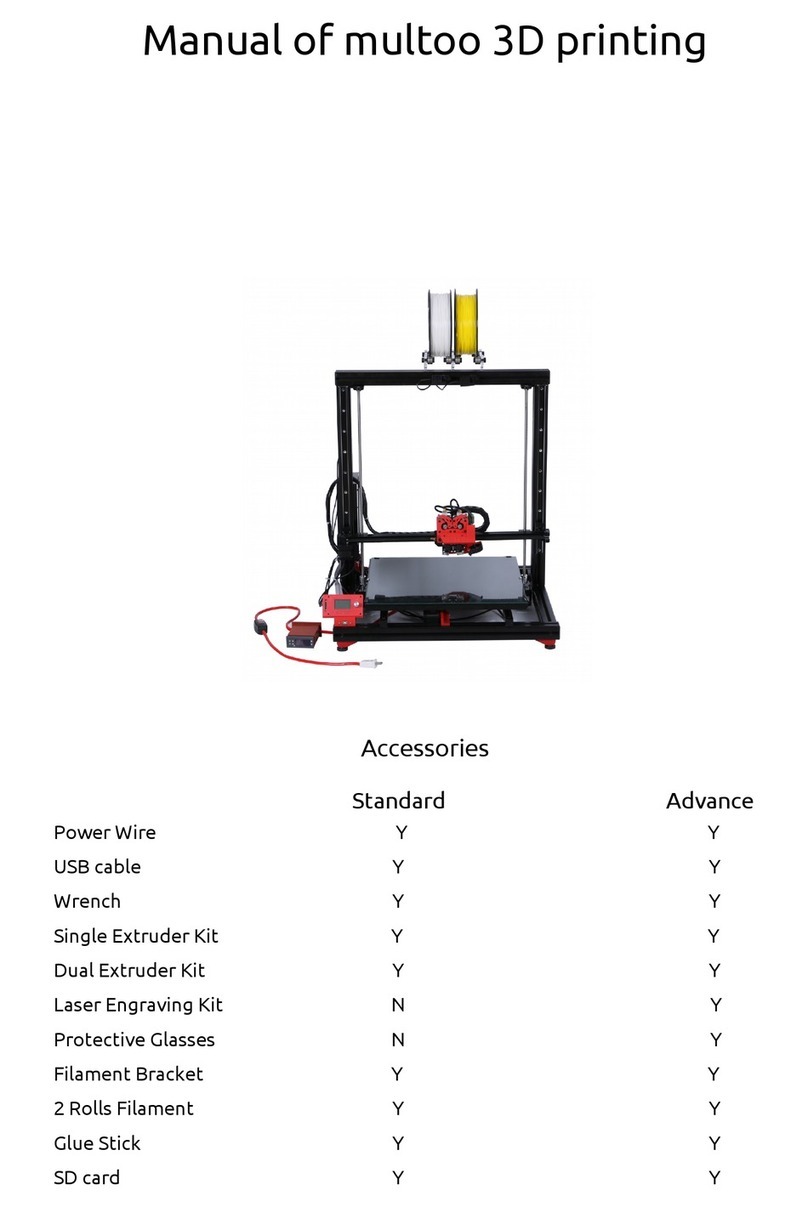

Parameters

Model

FLSUN SuperRacer

Printing Size

Φ260*330 (Max) mm

Molding Tech

Delta FDM

Nozzle Diameter

Standard 0.4mm

Slice Thickness

0.05-0.3mm

Precision

±

0.1mm

Filament Support

PLA/ABS/PETG/WOOD

File Format

STL/OBJ/AMF/3DS

Print Speed

Default Speed 150mm/s

Nozzle Type

Single Nozzle

Environment Temp

5-40°C

Nozzle Temp

⩽

255°C

Hot Bed Temp

⩽100°C

Slice Software

Cura/Repetier-Host/Simplify3D

Working Power

300W

Resume Printing

YES

Auto-Leveling

YES

Filament Detection Sensor

YES

Introduction

1 Filament Holder

5 BMG Extruder

9 Air Guide Nozzle

13 Tool Box

2 Axis

6 Slider

10 Nozzle Kit

14 USB Port

3 Filament Detector

7 Parallel Arm

11 Belt Adjustment

Nut

15 SD Card Slot

4 Linear Guide

8 Touch Screen

12 Hot Bed

16 Power Switch

Main Parts

Bottom Shell Top Shell and

Touch Screen

Axes Levelling

Switch

Parallel Arms

Effector

Module

Extruder and

Filament

Detection sensor

Filament

Holder

USB Line

Power Line

Gift Parts List

Diagonal Pliers

Spatula

SD Card and

Reader

Touch Screen

Bracket

Screwdriver

Allen

Wrench

Nozzle Kit

Heating Rod

Thermistor

Clean Needle

Screws

Grease

Open-End

Wrench

Brush

200g Filament

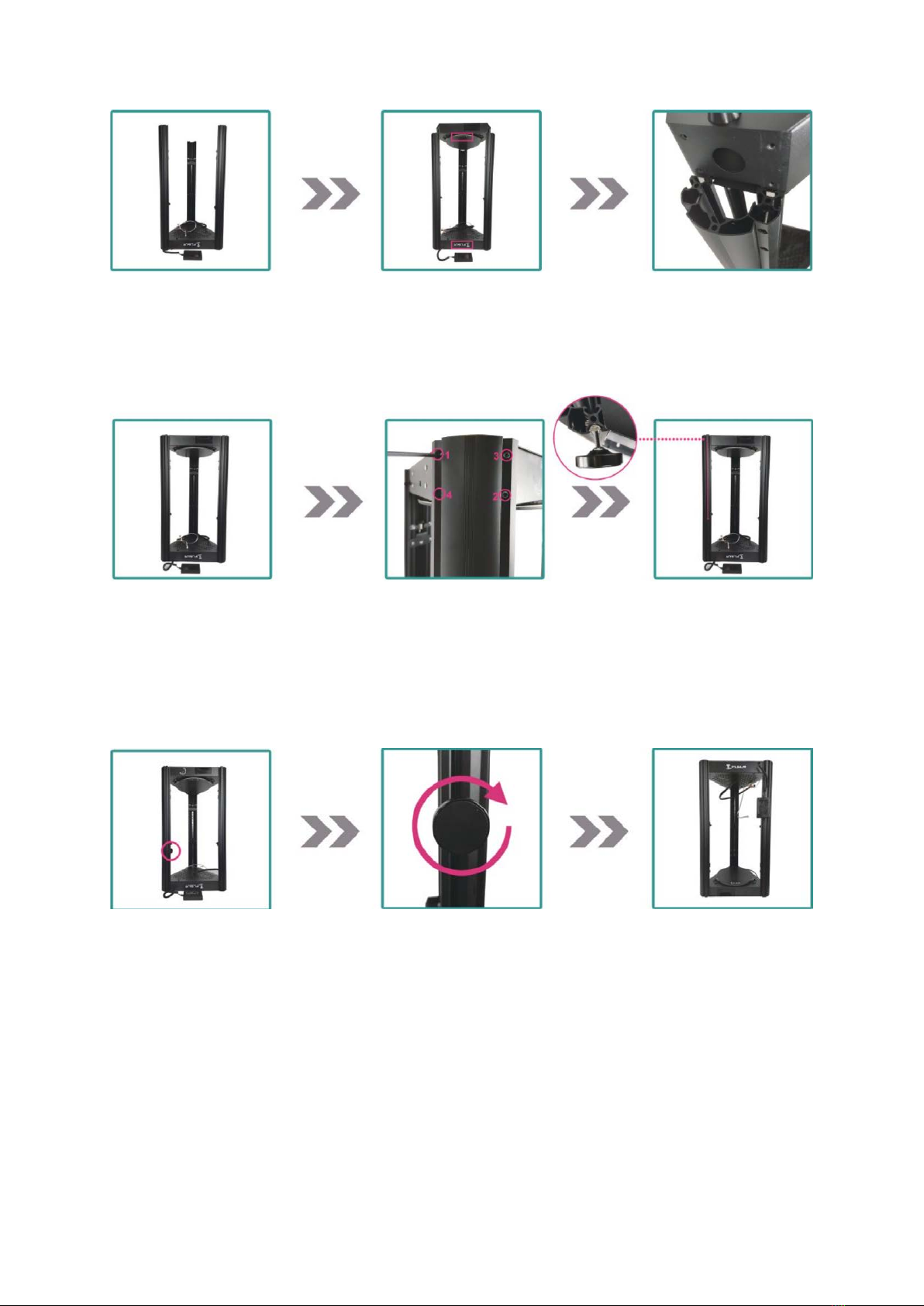

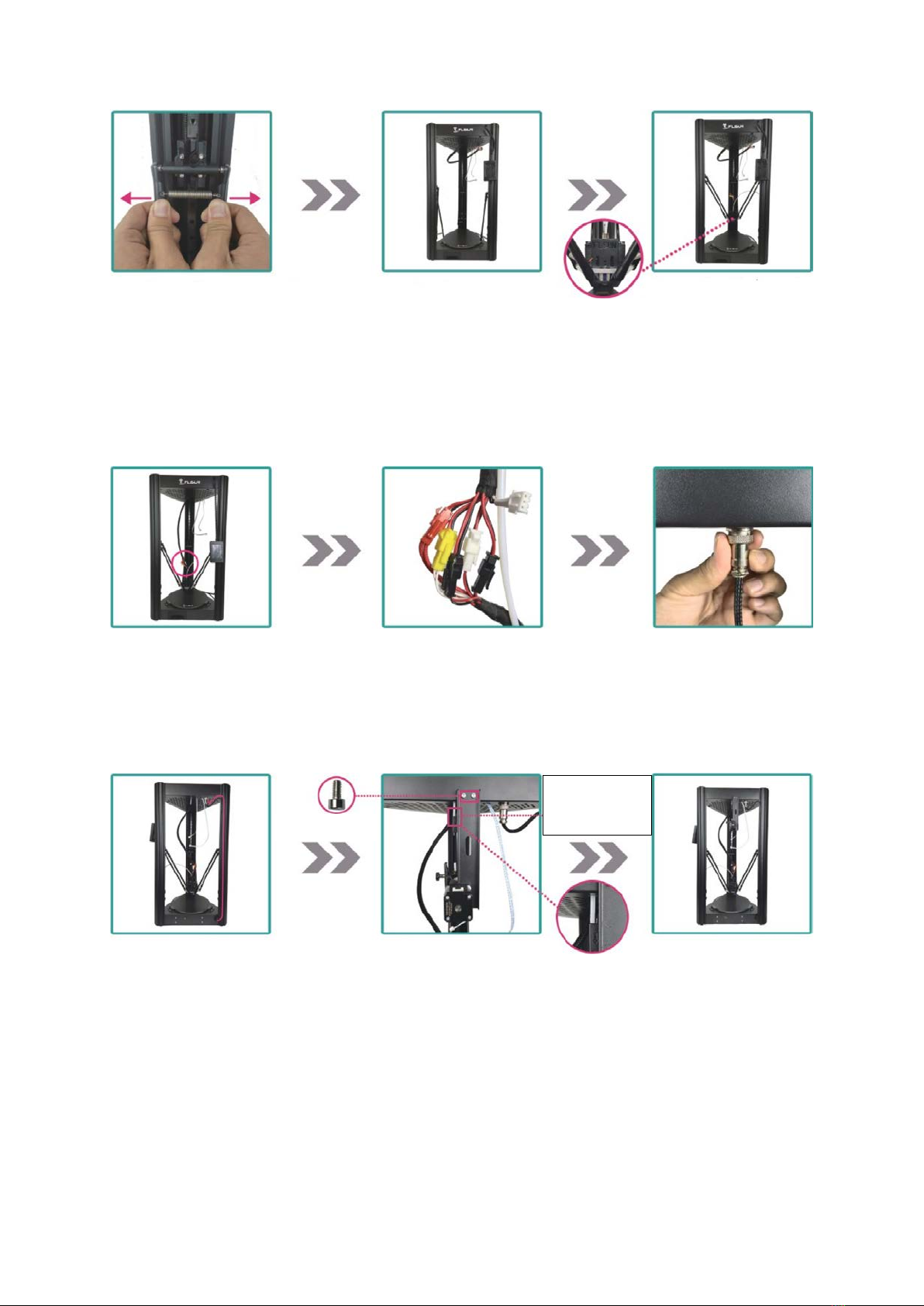

Assembly Instructions

1. Take out all main

parts and screws

2. Put the top shell on a flat surface.

Please prevent the screen from being

bumped during the assembly

3. Install the axis

4. Plug the motor cable

before putting the motor

into the top shell

5. Install the screws in the order

from 1 to 4

6. One axis completed

M4*22 (Long)

7. Install the other two

axes in the same way

8. Install the bottom shell. The two

logos marked in the photo should

be facing the same direction

9. The top shell

should be installed

in the guide rail

10. Push the bottom

shell down to the

correct position

11. Install the

screws for each axis

in order from 1 to 4

12. Slide the touch

screen bracket

nut into the guide

groove of the left

axis

13. Move the touch

screen bracket to

one-third of the

distance from the

top shell

14. Rotate the knob

clockwise to fix the

touch screen bracket

15. Rotate the printer

180 degrees the logo

is facing the front

16. Pull the parallel

arm to both sides

and install it on the

slider

17. Install the other

two parallel arms in

the same way

18. Install the

effector module the

logo on the effector

module must face

forward

19. Connect the

connectors of the

effector module

to the main cable

20. The color of the

connectors must match

two black connectors can

be connected arbitrarily

21. Install the main

cable connector

22. Put the main

cable into the

groove in the axis

23. Install the extruder

24. Extruder

installation finished

M4*8 (short)

The PTFE tube and the

filament detection

sensor entrance must

be

aligned

25. Plug the

filament detection

sensor cable

26. Plug the extruder

cable

27. Push the PTFE

tube to the

position marked

with an arrow in

the photo

28. Fix the

pneumatic

connector with a

buckle

29. Tie the PTFE tube

and the main cable

together at the

location marked in

the photo

30. Assemble the

filament holder

31. Install the

filament holder to

the top case

32. The orientation

of the filament

holder should be as

shown in the photo

33. Remove the

protective film from

the hot bed. The

assembly is finished

M4*8 (short)

M4*8 (short)

View from the

Front

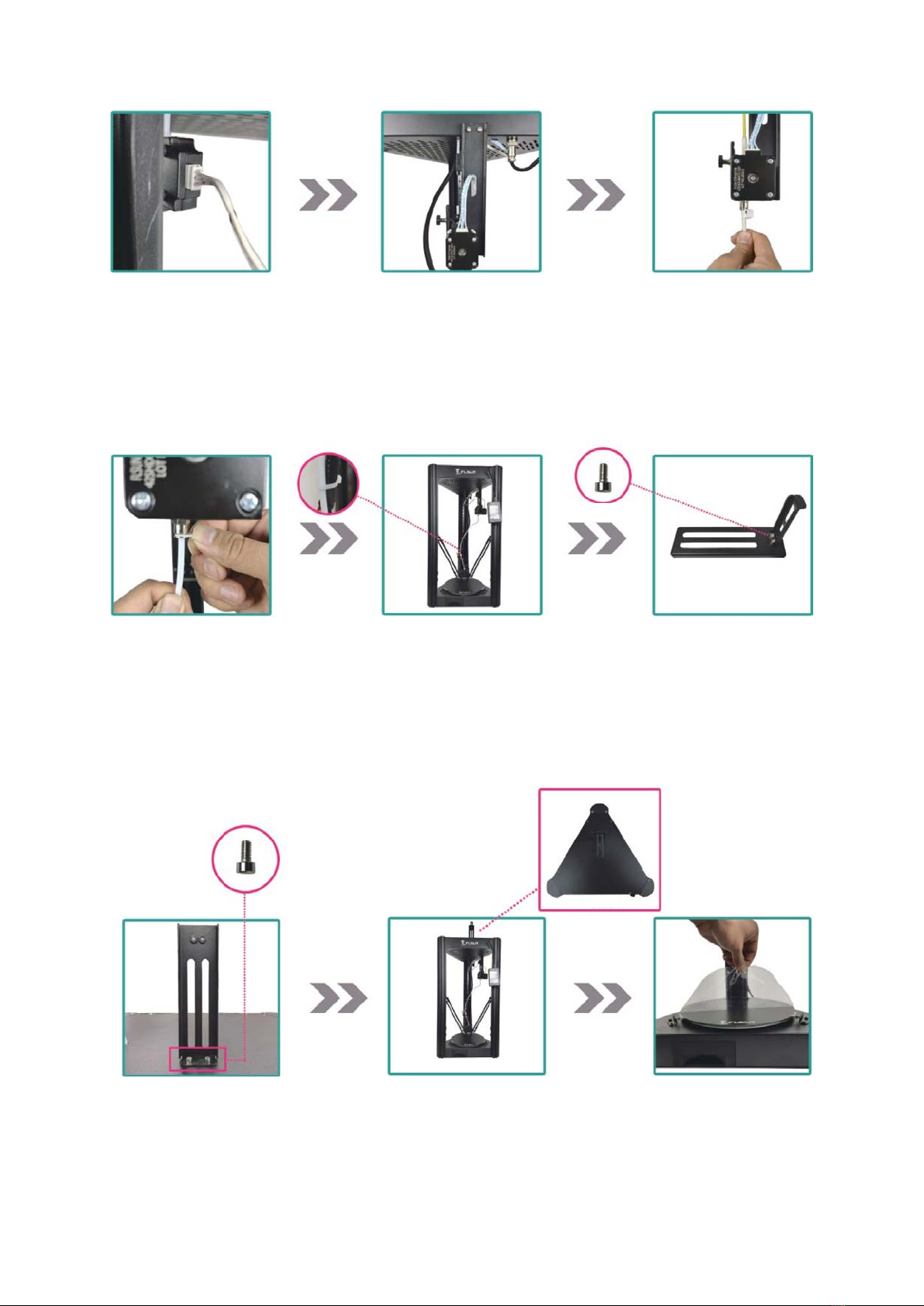

Switch Input Voltage

Auto Levelling

1. Use diagonal pliers

to clean up the

filaments on the

nozzle

2. Connect the levelling

switch

3. Install the

levelling switch

according to the

direction on the

photo

●The default input voltage of the printer is 230V, please

make sure the printer is switched to your local voltage

before turning on the power switch for the first time.

If your local voltage is 115V, flip the red switch to

the right to switch the voltage to 115V

View from the right

4. Click “Tools”

icon on the

homepage

5. Click “Auto-Level” 6. Click “Auto

Levelling” on the

subpage

7. Click “Confirm”

8. Auto levelling

takes about two

minutes, please wait

9. Remove the

levelling switch and

disconnect the

connector after the

auto levelling finished

10. Click “Move Z0” 11. Make sure the

levelling switch has

been removed before

click “Confirm”

12. The nozzle

moves closer to the

hot bed

13. Put an A4 paper

between the hot

bed and the nozzle

14. Click “Adjust Z0”

15. Click “Z+” and “Z-“ to

set the distance

between the nozzle and

the hot bed to the

thickness of one layer

A4 paper

16. The distance is optimal,

when you feel a slight

friction between the nozzle

and the bed while slowly

moving the paper

backwards and forwards.

17. Click “Save”

18. Return to the

homepage

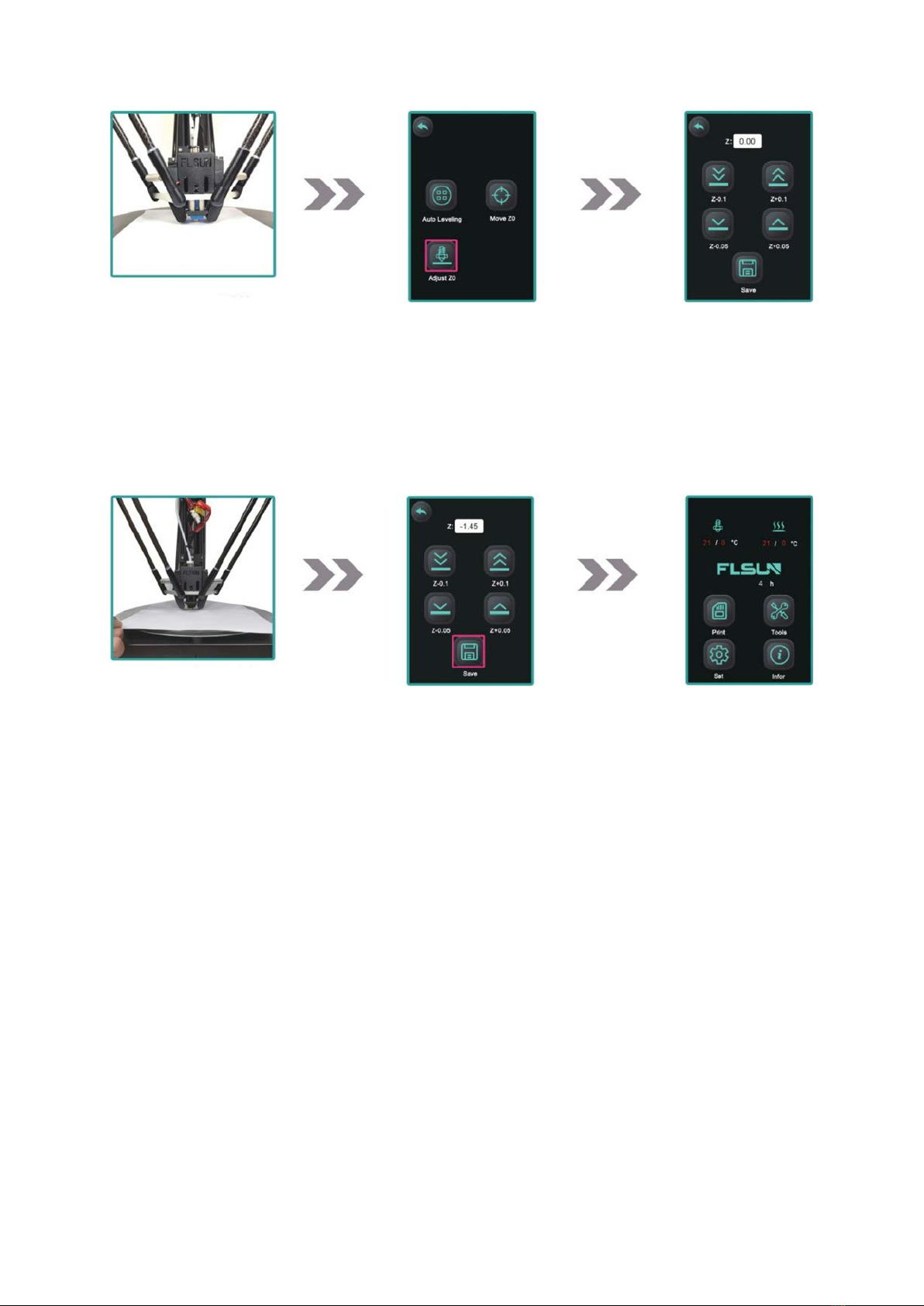

Load Filament

1. Straighten the

end of the filament

10cm. Use diagonal

pliers to cut the

end of the filament

into a bevel

2. This is how the

filament should

look after cutting

3. Push the

filament through

the PTFE tube in

the top shell

4. Push the filament

through the filament

detection sensor and

insert it into the

extruder

5. Turn on the power

6. Click “Tools” on

the homepage

7. Click “Change”

8. Click the

white input

box

9. If you use PLA

please enter 200

and click “OK”

10. Wait for the

nozzle to heat

up to 200°C,

then click “in”

11. Push down the

filaments at the

same time

12. When the

filament is

extruded from

the nozzle, click

“Stop”

First Layer Verification

1. Insert SD

card

2. Click “Print”

3. Select a test

gcode to print

4. Monitor the

extruded

filament of the

first layer

5. If the nozzle is too close or too far away from

the hot bed you can continue to adjust the height

of Z0 while printing and the adjustment will be

automatically saved

1. The nozzle is

too close to

the hot bed

2. Proper distance

3. The nozzle is

too far from

the hot bed

Filament

Filament

Filament

6. Click “Adjust Z”

7. Click “Z-0.05”

or “Z+0.05” to

adjust the

height of the Z

8. Adjust the

distance between

the nozzle and

the hot bed to a

proper distance

then click “Cancel”

9. Clean the hot bed

Install Slicing Software

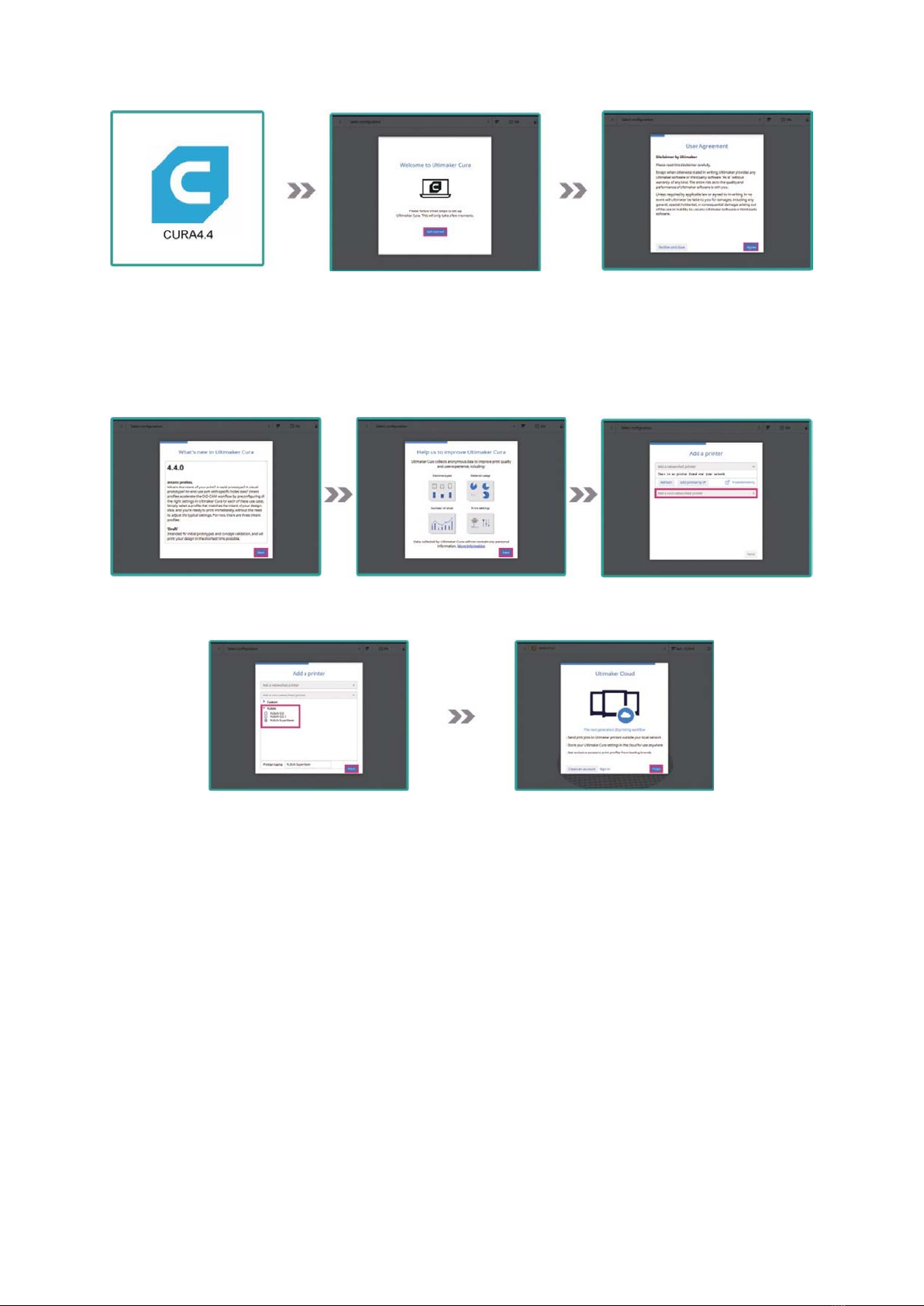

1. Copy the CURA

slicing software

from the SD card

your computer

then double-click

to install

2. Select an installation

location and click “Release”

3. Wait for the

installation to complete

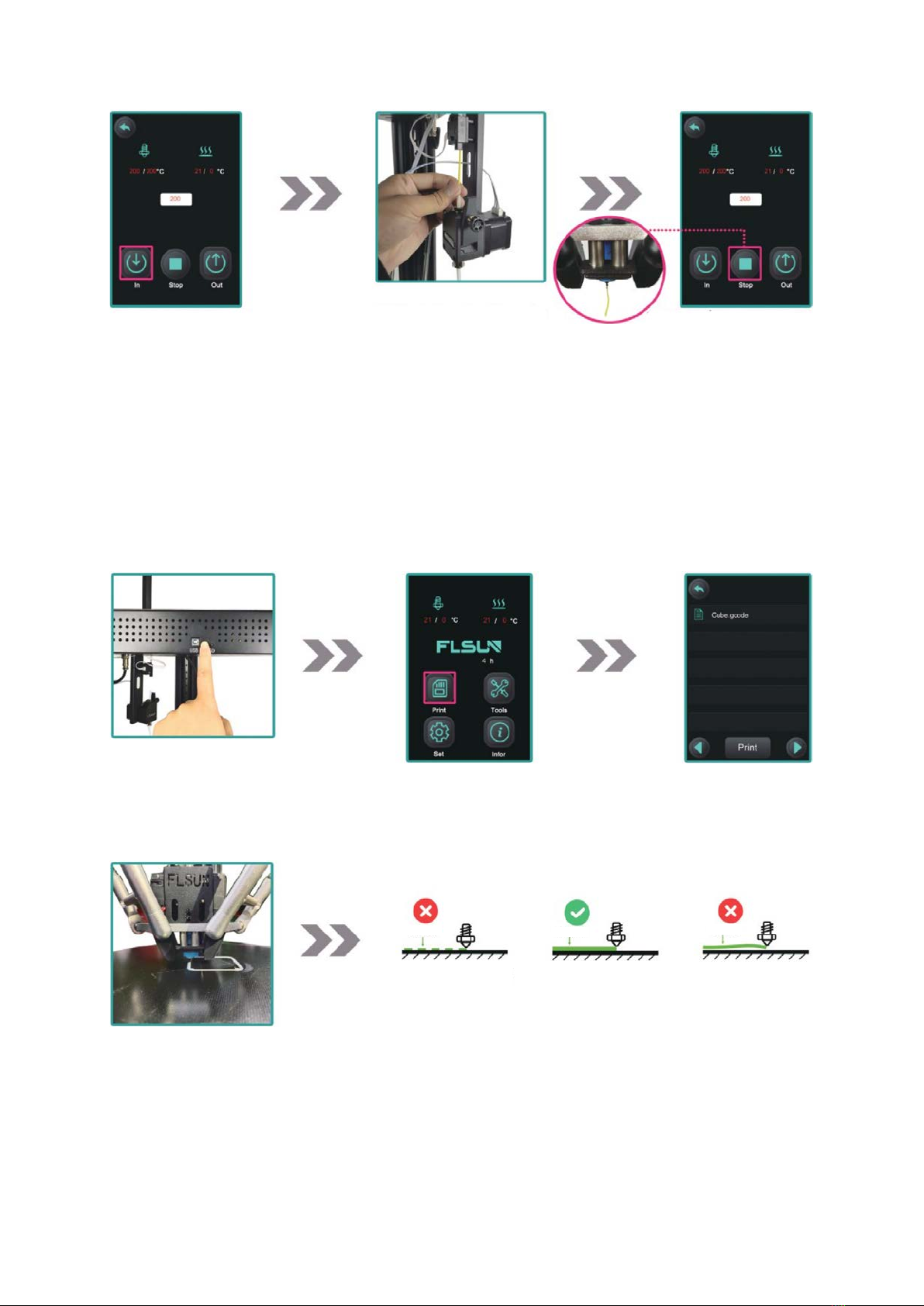

Auto-Levelling

done !

4. Double-click the

Cura shortcut on

the computer

desktop

5. Click “Get Started”

6. Click “Agree”

7. Click “Next”

8. Click “Next”

9. Click “Add a non-

networked printer”

10. Select

“FLSUN>Flsun

SuperRacer”

11. Click “Finish” to

complete the

installation

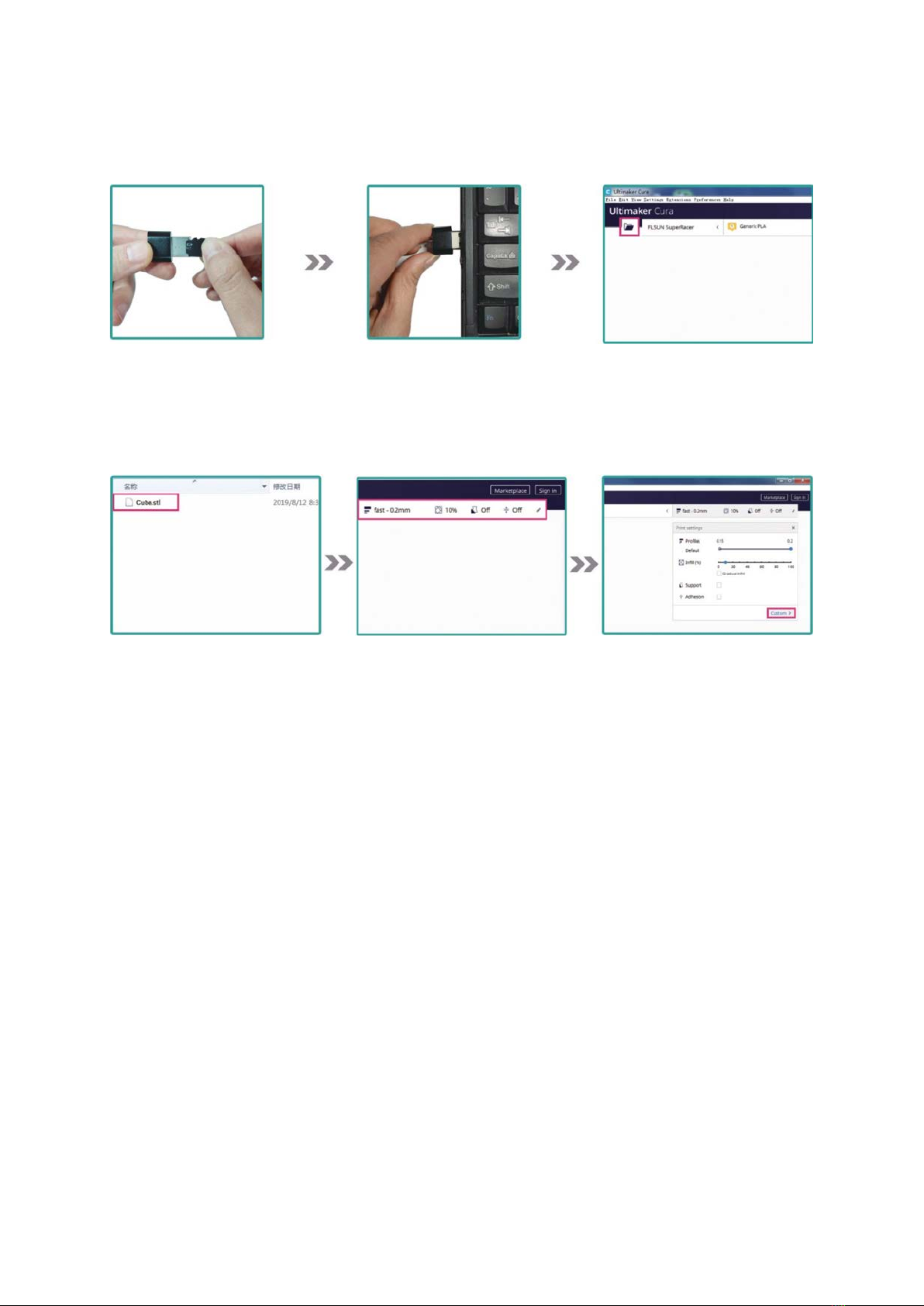

Printing

1. Insert the SD

card into the

card reader

2. Insert the card

reader into the

USB port of the

computer

3. Double-click to open

CURA, then click the

folder icon in the upper

left corner of the window

4. Select a supported

file the CURA supports

STL/OBJ/AMF/3DS

format files

5. Click on the marked

area in the photo to

open the slice parameter

configuration page

6. Click “Custom” to

open more parameter

configuration

1. Set the printing height of each layer, SR supports a minimum layer height of 0.05mm.

2. The thickness of the walls in the horizontal direction, this value is divided by the wall

line width defines the number of walls.

3. The number of walls when calculated by the wall thickness, this value is rounded to a

whole number.

4. The thickness of the top/bottom layers in the print.

5. The thickness of the top layers in the print.

6. The number of the top layers.

7. The thickness of the top layers in the print.

8. The number of the bottom layers.

9. Amount of offset applied to all polygons in each layer. Positive values can compensate

for too big holes, negative values can compensate for too small holes.

10. Set fill rate.

11. Set the infill patterns, when the filling density is greater than 20%, the infill pattern

should be “Lines”

12. Set the printing temperature of the nozzle, when printing PLA, due to the high speed

the nozzle temperature should be set to 220°C.

13. Set the printing temperature of the hot bed.

14. Enable retraction, to avoid stringing or oozing during printing.

15. Set the printing speed, the default printing speed of SR is 150mm/s, and the

maximum printing speed is 200mm/s.

16. Whenever a retraction is done, the build plate is lowered to create clearance

between the nozzle and the print. It prevents the nozzle from hitting the print during

travel.

17. Turn on the turbo fan. When printing a smaller model, turn on the turbo fan to

prevent the model from warping.

18. Set the fan speed.

19. Enable generate support.

20. Support placement style, “Everywhere” means that support is not only generated

from the hot bed, but also from the model itself, “Touching Buildplate” means the

support will be generated only from the hot bed.

21. Support will be generated only when the angle between the model and the vertical

direction is greater than this degree.

22. Build plate adhesion type. Select “Brim” mode to make the model better stick to the

hot bed.

7. After adjusting to

appropriate

parameters, click

“Slice”

8. Click “Save to

Removable driver”

9. Insert the SD

card into the

printer card

reader slot

This manual suits for next models

1

Table of contents

Languages:

Other flsun 3D Printer manuals