flsun QQ User manual

Instruction Manual

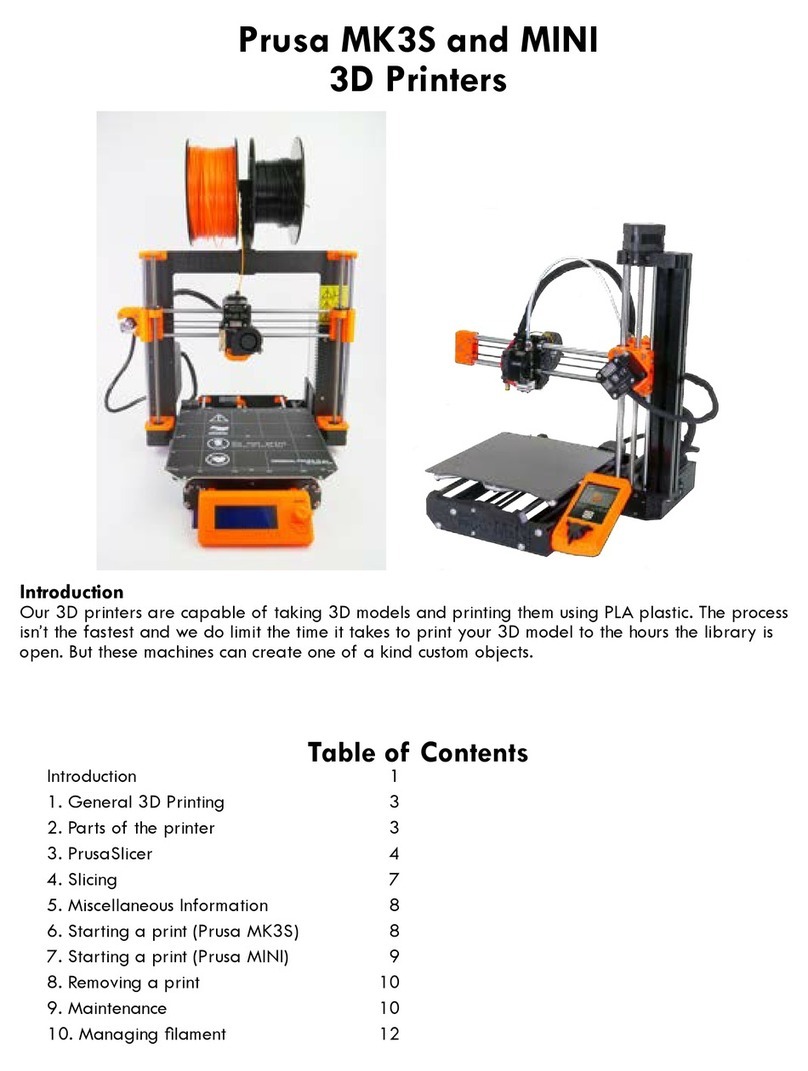

FLSUN-QQ

Zhengzhou Chaokuo Electronic Technology Co., Ltd.

VK-3D

принтер Flsun Facebook-Flsun

3D Printer

(QQ-S)

Basic part A

A-1.

Equipment Introduction ------------1

A-2. 3D Printer Parameters --------------2

A-3. Cautions ------------------------3

A-4. Packing List ---------------------4

Use part B

B-1.

Assembly Instructions ---------------5

B-2. Using Instructions ------------------9

B2-1. Auto Leveling --------------------9

B2-2. Adjust Z0 -----------------------11

B2-3. Filaments Installation -----------------13

B2-4. Software Installation ----------------15

B2-5. First Printing --------------------16

B-3. Precise Leveling --------------------17

B-4. Touch Screen Introductions -----------19

B-5. Common Problems -----------------21

B-6. Troubleshooting --------------------23

B-7. After-sales Service ------------------24

Dear Customer:

Thank you for choosing the FLSUN 3D Printer.For your con-

venience, please read this manual carefully before using and

follow the instructions.

Our team always be ready to provide you with quality service.

In the process of installation and use, no matter what kind of

problems you encounter, you can contact us according to the

contact information provided at the end of the manual.

You can find detailed instructions , videos, and FAQs in the SD

card.

Pre-Face Cont

ents

Equipment Introduction

A

Basic Part

A-1

3D Printer Parameters A

Basic Part

A-2

1

Filament

SD card slot

USB interface

Parallel arm

Slider

Side shell

Belt fixing nut

Power socket

Shell screws

Heating block

Optical axis

Touch screen

Filament frame

Extruder

Turbo fan

Nozzle

Hot bed

1

7

16

17

15

11

12

13

14

8

9

10

2

3

4

5

6

Molding technology FDM

Print size φ255×360mm

Print accuracy 0.05-0.3mm

Positional accuracy XYZ 0.01mm

Nozzle type Single nozzle

Nozzle diameter 0.4mm

Print speed 10-300mm/s

3.2 inches

Material support

Touch screen

1.75mm PLA/ABS/

NYLON/PVA/TPU/

PETG/WOOD

Hot bed TEMP

Slicing software

Input format

Output format

Connection type

Input

Output

0-110℃

Cura

STL/OBJ/AMF/3DS

Gcode

SD card,USB

110 / 220v

24V

Nozzle TEMP 0-260℃

ENV TEMP 5-40℃

Printing

parameters Software

parameters

Power

parameters

Temperature

parameter

2

Cautions

A

Basic Part

A-3

Packing List A

Basic Part

A-4

1. The printer default selection voltage is 220V,if you need to use 110V,please change

it before using.

2. The assemble and user manual,software and other files are in the SD card with printer.

3. The nozzle part and heated bed can produce high temperature when the printer is

working ,so do not touch them by hand to avoid being scalded.

4. Before the automatic leveling, prepare the leveling sensor and an A4 paper and clean

the nozzle, insert the leveling line; After the Autoleveling , remove the

leveling sensor, then adjust Z0.

5. In the event of an emergency, please turn off the power immediately and contact our

technical support.

Bottom shell Upper shell Side shell Optical axis

N0.

Wrench

Screwdriver

Limit switch

Scissors

Shovel

Nozzle wrench

Photo Name Qty

1 1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

3

4

5

6

N0.

SD card

Temp Sensor

Nozzle

Clean Needle

Level sensor

Conductive cloth

Photo Name Qty

7

8

9

10

11

12

N0.

Spare Screws

Assemble Screws

Power cable

USB wire

Filament

Gloves

Photo Name Qty

13

14

15

16

17

18

34

Assembly instructions

B

Use Part

B-1

1.Preparation

3.Install top shell

4.Assembly belt

2.Install optical axis

Open package All the components

for assembly

Place the Bottom shell Insert optical axis through

slider to shaft seat bottom

Belt must be in the middle

of two axis

Logo and touch screen

are at the same direction

Align all axis with seat

holes then press to bottom Upper shell completed

Untie the belt and

straighten it to make sure

they are parallel.

Insert the metal pulley

into the slot

Make screw head and nut

are at the same height

The same method installs

other belts

Optical axis completed

All screws and wrenches

for assembly

56

6.Connection bus section

7.Install the side shell and bracket

8.Tighten the screws

5.Connection limit switch and Titan extruder

Tighten axis fixing screws

of upper shell

Tighten axis fixing screws

of bottom shell

Untie the wire Connect the set of

connectors

Connect others in the

same way Install the Titan extruder

Connect airline

Put side shell from top

then insert to bottom shell

Tighten fixing screw of

the side shell

Filament holder mounted

on the upper shell

Complete the assembly

Tighten the nut Connecting extruder

motor line Connect feed tube

78

Auto Leveling

B

Use Part

B-2-1

1.Install leveling Sensor 2.Leveling

Ready autolevel sensor Click TOOLS→Autolevel Click LEVEL →Autolevel

(When autoleveling, In order to ensure

the accuracy of data ,the nozzle

moves very slowly)

910

Connecting magnet After autoleveling, remove

the leveling sensor

Connecting the autolevel

sensor

Adjust Z0 before printing

After auto leveling, put

an A4 paper and adjust

the position of Z0

Click ‘Move Z0’ Click ‘Save’

Click ‘Adjust Z’

(The distance between the

nozzle and the platform is

an A4 paper.)

‘+’ nozzle move up

‘-’ nozzle move down

‘0.01mm’ adjust move range

Make sure the leveling sensor has been removed before adjusting Z0

B

Use Part

B-2-2

1211

Move the A4 paper to test

the distance of nozzle from

the platform

Filaments Installation

B

Use Part

B-2-3

1.Install filaments 2.Automatic feeding

Install the filament

and cut a triangle

Press hard in the

direction of the arrow

Insert the filament

through the small hole

The filament pass

through the quick

connector will be ok

Click

TOOLS→CHANGE

Choose EXTRUDER 1

Click IN

Click Confirm to

automatic feeding

After completed Click

Confirm

13 14

Software Installation

B

Use Part

B-2-4

1.Slice

2.Machine Operation

1.Dual click to install Cura

3.Click Settings→Printer→Add Printer→FLSUN QQ→Add Printer→Finish

2.Open Cura

Open Cura

Insert SD card Click PRINT Automatic printingChoose file

Click Load to load

STL file

Software auto-slice ,

save Gcode to anywhere

First Printing B

Use Part

B-2-5

15 16

Precise Leveling

B

Use Part

B-3

1.After automatic leveling, maybe the nozzle is too close or too far from the platform. 2.You can adjust the Z-offset while printing .The value can save

Automatically, There is no need to repeat the operation.

17 18

Nozzle Nozzle Nozzle

filament filament filament

①The nozzle is too

low from the platform

③The nozzle is too

far from the platform

③The nozzle is middle

from the platform

Click Z+0.1

nozzle moves up 0.1

Click Z-0.1

nozzle moves down 0.1

Click Option Click More Z+0 .1 nozzle moves up 0.1

Z-0.1 moves down 0.1

Touch Screen Introductions

B

Use Part

B-4

1.Print 2.More Operations

Stop print

Resume print

Adjust fan

speed

Pause print

Adjust temp

Adjust speed

Preheat bed

nozzle

Close heat

Change Filament

Feeding Take out filament

E1 change

filament Home

Auto level Moves

down 0.1

Moves

up 0.1

Close all

motors

Move

Add 1℃Add 10℃

Heat

nozzle1 Heat bed Extrude

Filament

Filament

move10mm Extrude Back

Nozzle1

extrude

Adjust

speed

X/Ydirection

increase in

size 0.1

Curvature

down

X/Ydirection

decrease in

size 0.1

Curvature

up

Pause for

change filament

19 20

3.Preheat

5.Change Filament 6.Other Buttons

4.Extrusion

Common Problems

B

Use Part

B-5

1. What to do after automatic leveling?

3. What is the printing temperature of the common materials?

4. The first layer can not normally stick to the platform.

5. The nozzle block

2.When the nozzle is too close or too far away from the hot bed after leveling?

Remove the leveling sensor, then adjust Z0,install the filament, then preheat the nozzle to 210 ° C,

preheat the hot bed to 60 ° C, feed filament and start printing.

Click once to move the nozzle 0.1, Z+ nozzle moves up, Z-head moves downwards, the software automatically saves

the value after clicking, and the value is saved until it is leveled again.

①. The nozzle is too far away from the hot bed,please refer to the nozzle is too close or too far

away from the hot bed

②. Select the Brim when attaching platform to slice,increasing the value of the line according

to your neded,Set hot bed temperature to 65°

Number Material Nozzle Hot bed Number Material Nozzle Hot bed

1 PLA 195-210 50-60 5 PVA 190-210 50-60

2 ABS 220-250 80-100 6 TPU 210-230 40-60

3 Nylon 200-220 50-60 7 WOOD 190-220 50-60

4 PETG 240-260 70-80 8 HIPS 230-250 60-80

①. Heating the sprinkler to 240 degrees, click fast extrusion.

②. Heating the sprinkler to 200 degrees, clean it with a sprinkler cleaning needle (hot, pay attention).

③. Replace a new sprinkler

Click during the printing process: Operate → More → Z+0.1 or Z-0.1

*

21 22

After-sales Service B

Use Part

B-7

1.Customers who purchase FLSUN 3D printers have a shelf life of 12 months.

2.The warranty period for all products is from the date of purchase.

3. You can find a solution from the user's manual, or contact the customer service of the

website where you bought the printer.

please attach the purchase website and order number, and we will also solve the problem for

you at the first time.

5. After-sales and pre-sale support time: Monday to Saturday: 9.00-18.00 (Beijing time).

Troubleshooting

B

Use Part

B-6

Start

Can identify

files

Other Gcode

is normal

Filament

is normal

Run

NO

YES

YES

YES

YES

YES YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

SD card

SD card

Motor

Silce

Limit switch

Temp sensor

Connection

Temp sensor

Heat bar

Extruder motor

Filament

Nozzle block

Room temp

Extruder run

Room temp

SD card

can print

HOME

Heated

bed heat

Nozzle heat

Print

Finish

1.Is there Gcode 2.Format SD card 3.Change SD card

1.Format SD card 2.Change SD card

Slice again

Check the connection of motor

Check the connection

1.Check connection 2.Change temp sensor

Heated bed and board connection

1.Check board and heat bar connection2.Change heat bar

Check connection

Check connection

Change filament

Clean nozzle

Steps Troubleshooting Reasons Solutions

23 24

Type:

Name:

Address:

Phone:

Purchase date:

Damage date:

Damage details:

Amazon/AliExpress/Ebay/Others:

If you have any questions, please contact us at the first time and we will solve it for you.

Email: [email protected]

Facebook group: FLSUN QQ 3D Printer Owners

Warranty Card

B

Use Part

B-7

2625

This manual suits for next models

2

Table of contents

Other flsun 3D Printer manuals