Power-up Options and Tests

3.

To take a measurement, make the proper contacts with the test lead

probes, inserting the meter in the circuit (in series for current

or in parallel for voltage measurements). Read the measurement on

the display. If you did not manually select a range (by using the

RANGE button), the range which provides the best resolution is

automatically selected for you.

This simple procedure will allow you to take basic measurements. However, to

use your meter to full advantage, read the remainder of this manual.

POWER-UP OPTIONS AND TESTS

To power up the meter, turn the rotary function selector switch from OFF to

any position. The meter then performs a selftest and battery check. During

the selftest all display segments are switched on for about 1 second, then

the display blanks. The meter is now operational.

The battery test performed at power up (and each time you select a different

function with the rotary switch) determines if the voltage is below 6.3V. If

it is, the C-2 annunciator comes on and remains on until the battery

recovers or is replaced (i.e, voltage is above the above the 6.3V.)

The meter powers up in the autorange mode. In autorange, the meter

automatically selects the appropriate range for the measurement being taken.

If the function selected has only one range, then the

ED

symbol is

displayed. The operating range is indicated by the decimal point position

and range indicator in the display, and in the

n

function by the presence

of the M or k annunciators. There is no annunciator for the autorange mode.

The meter is in autorange unless the manual range annunciator is on.

Manual ranging can be selected at power up by pressing and holding the RANGE

button while the function switch is moved from OFF to any ON position. To

return to the autorange mode, press RANGE for approximately two seconds.

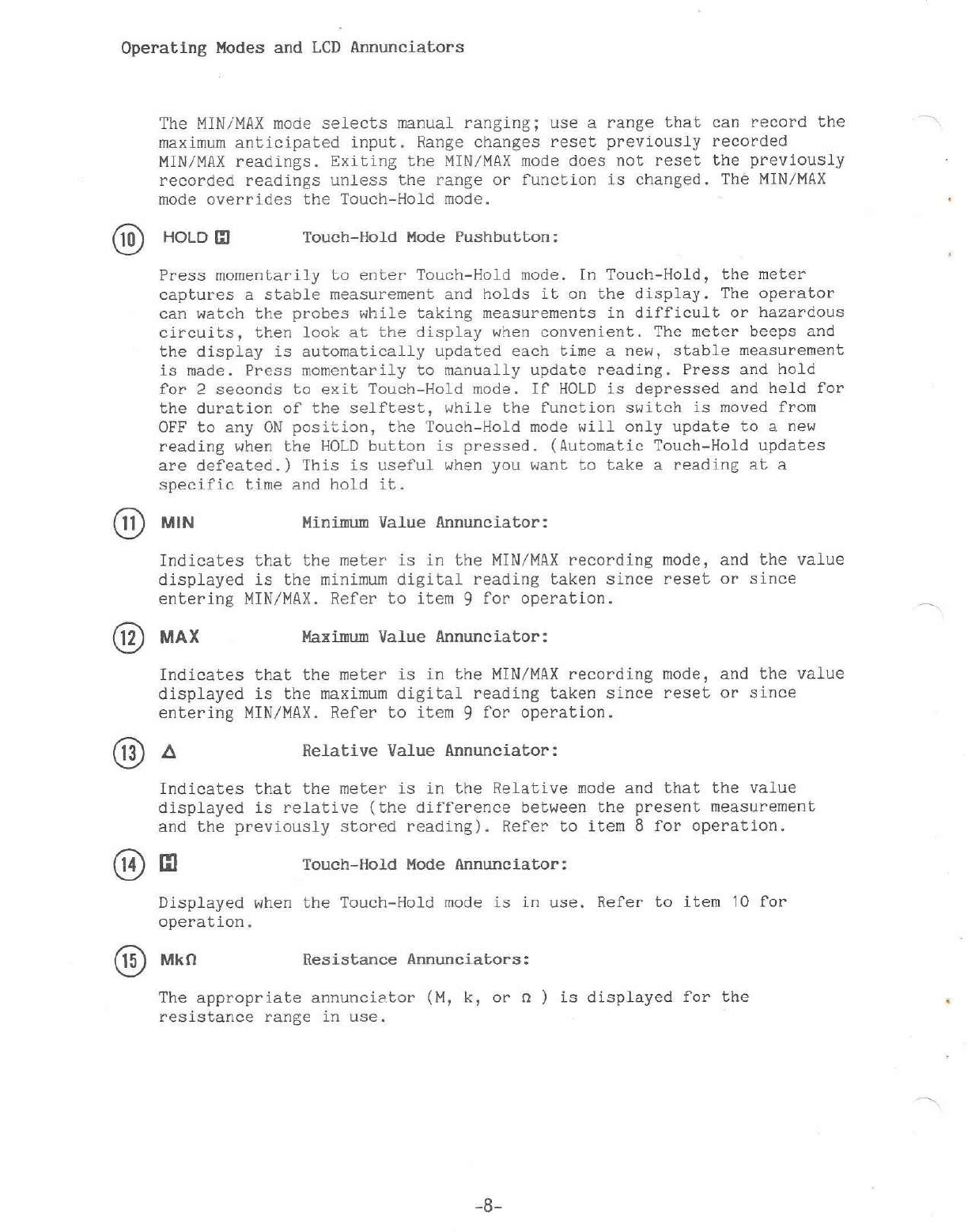

If the HOLD push button is pressed while the function switch is moved from

OFF to any ON position, automatic updates in the Touch-Hold* mode are

defeated and the Touch-Hold mode only displays a new reading when HOLD

button is pressed. This is useful when you want to take a reading at a

specific time and hold it.

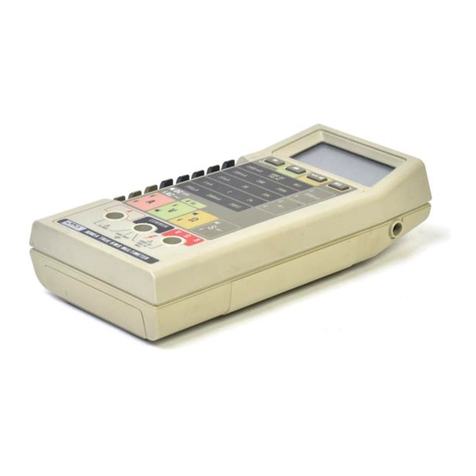

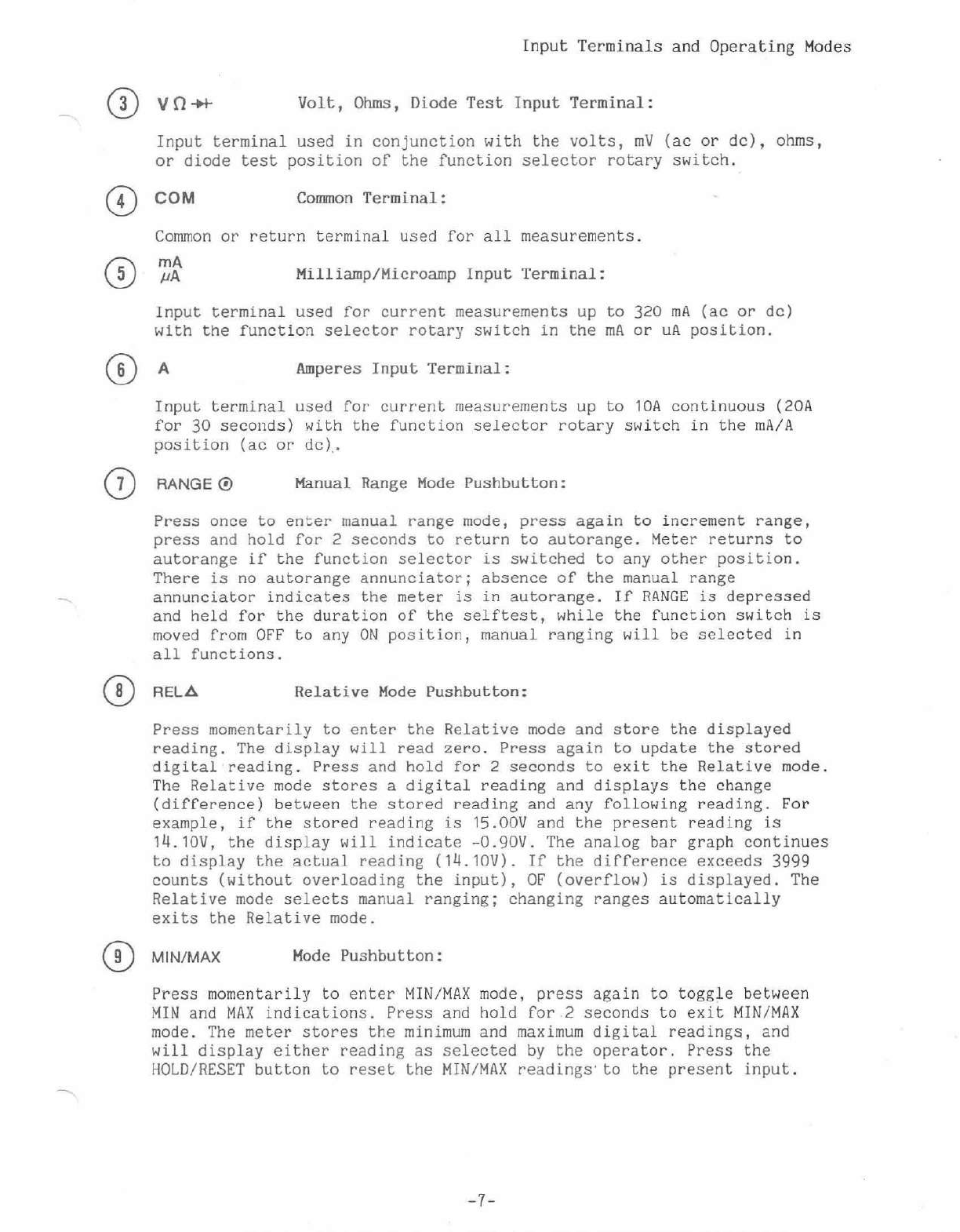

OPERATING FEATURES

The meter is operated from the front panel. All operating features and

functions are described below and are keyed by number to the illustration

inside the front cover.

(DDigital Display:

3200-count, liquid crystal display (LCD) with automatic decimal point

positioning. Updated two times per second. When the meter is first

turned on, all display segments appear while the instrument performs a

brief power-up self-test.

* Touch-Hold is a trademark of the John Fluke Manufacturing Co., Inc.