8588A/8558A

Operators Manual

ii

DC Current ........................................................................................ 25

AC Current ......................................................................................... 27

ACI Measure Setup ....................................................................... 28

Measure AC Current ...................................................................... 30

Resistance ......................................................................................... 31

Measure Resistance .......................................................................... 36

2-Wire Measurements ................................................................... 36

4-Wire Measurements ................................................................... 36

4-Wire High-Resistance Measurements ........................................ 37

4-Wire Resistance Zero ................................................................. 37

Ω Guard ......................................................................................... 38

Digitize ............................................................................................... 39

More ...................................................................................................... 48

Capacitance (8588A only) ................................................................. 48

RF Power (8588A only) ..................................................................... 50

RF Power Softkeys ........................................................................ 52

Connect a Power Sensor to the Product ....................................... 53

Connect a Power Sensor to a Unit Under Test ............................. 54

Set the Measurement Frequency .................................................. 54

Frequency Counter ............................................................................ 55

Measure Frequency ........................................................................... 58

DCI Ext Shunt (8588A Only) .............................................................. 59

ACI Ext Shunt (8588A Only) .............................................................. 62

Measure AC Current with ACI Ext Shunt ........................................... 68

PRT ................................................................................................... 69

Measure PRTs ................................................................................... 69

Thermocouple ....................................................................................... 71

Measure Thermocouples ................................................................... 71

Features ................................................................................................ 74

Input Terminal Selection .................................................................... 74

Use the Scan Operations .............................................................. 75

Scan Sequences ........................................................................... 76

4W Tru Ohm Scan Mode (Tru Ohms Ratio) .................................. 76

External Guard .............................................................................. 78

Output Signal ................................................................................. 79

TRIG OUT ..................................................................................... 80

Zero ................................................................................................... 83

Math ................................................................................................... 85

Analyze .............................................................................................. 88

Memory Setup ....................................................................................... 95

Instrument Setup ................................................................................... 97

Display Settings Submenu ................................................................ 98

Instrument Settings ............................................................................ 99

Remote Settings ................................................................................ 100

Calibration Adjust .............................................................................. 101

Diagnostics ........................................................................................ 103

Triggering Measurements ..................................................................... 104

Details of the Triggering Subsystem .............................................. 105

Trigger Indicator ................................................................................ 115

Examples of Using the Trigger Subsystem ................................... 116

Special Event Qualifiers ................................................................ 123

Guidelines to Avoid Measurement Errors .............................................. 125

Maintenance .......................................................................................... 127

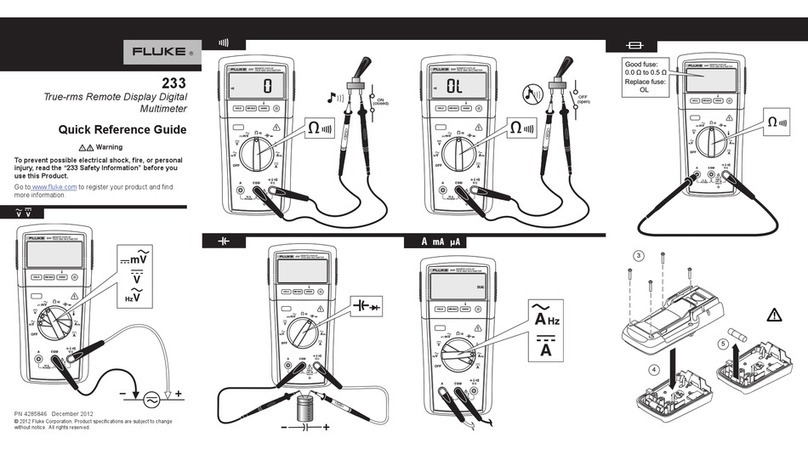

Fuse Replacement ............................................................................ 127

Clean the Exterior .............................................................................. 128

Accessories ........................................................................................... 129