5100 Series

1-11. Modification of the output to measure the devia-

deviation in apercent of error figure is displayed for

each change of the output from the base. The frequency

may be altered for AC outputs to cover arange of fre-

quencies; however, there is no percent of error display.

The modifications can be programmed from either the

Front Panel or aRemote Source.

1-12. Storage System Models

1-13. The storage system consists of astorage memory

and amini-cassette tape system. The storage memory

holds up to 61 separate fixed length instructions. Any

field not filled when an instruction is created is filled with

the default condition; i.e., either the allowable maximum

or minimum, as is applicable. Data stored in the memory

to form atest program for an instrument, or instruments,

may be read out as desired or transferred, through the use

of the integral tape system, to atape for apermanent

record. The storage memory may be loaded from a pre-

recorded tape through the tape system to perform a

standard calibration procedure. Aprogram must be

loaded into the storage memory to be run, the instrument

is not able to operate directly from the prerecorded tape.

Aprinted listing of the program or the data from the step

in progress can be obtained from storage system models

equipped with an optional Remote Interface and an ex-

ternal printer.

1-14. Element Resistive Models

1-15. The environmental element-resistive case is a

fiberglass shell with removable front and rear covers.

The case has handles to provide ease of transportation

and seals on the case openings to resist entrance of the

elements when the case is closed. The covers must be

removed to operate the system. The only change in inter-

nal circuitry is the substitution of all position relays so

that the instrument can be operated while sitting at any

angle. Operation of the instrument is identical with the

standard instrument.

1-16. OPTIONS

1-17. Analog Options

1-18. The Wideband Option (-03) allows outputs of

300 gV (-57.5 dBm) to 3.1623V rms (4-23 dBm) at fre-

quencies from 10 Hz to 10 MHz into aload impedance of

50 ohms. The output impedance is 50 ohms and 50 ohm

coaxial cable should be used to transfer the output signal.

1-19. interface Options

1-20. Two system interface options are available for

the 5100 Series. Option -05 interfaces the instrument to

the IEEE 488-1975 Bus System. Option -06 interfaces the

instrument to asystem using aRS232 interface. Only one

of the interface options can be installed at atime; how-

ever, they are easily exchanged with aminimum of opera-

tor training and time.

1-21. SPECIFICATIONS

1-22. Summarized Specifications

1-23, Table l-l summarizes the 5100 Series accuracy

specifications when they are used in atypical meter cali-

bration service. The tolerances in the table are valid

provided the ambient temperature is between 20 degrees

and 30 degrees Celsius, the relative humidity is less than

85% and the input line voltage is within 10% of nominal.

In addition, they are applicable only when the instrument

being calibrated is an analog voltmeter with more than

1000 ohms/ volt sensitivities, aTVM or DVM with great-

er than 1Megohm input impedance or analog or digital

ammeter with less than 1volt total voltage drop.

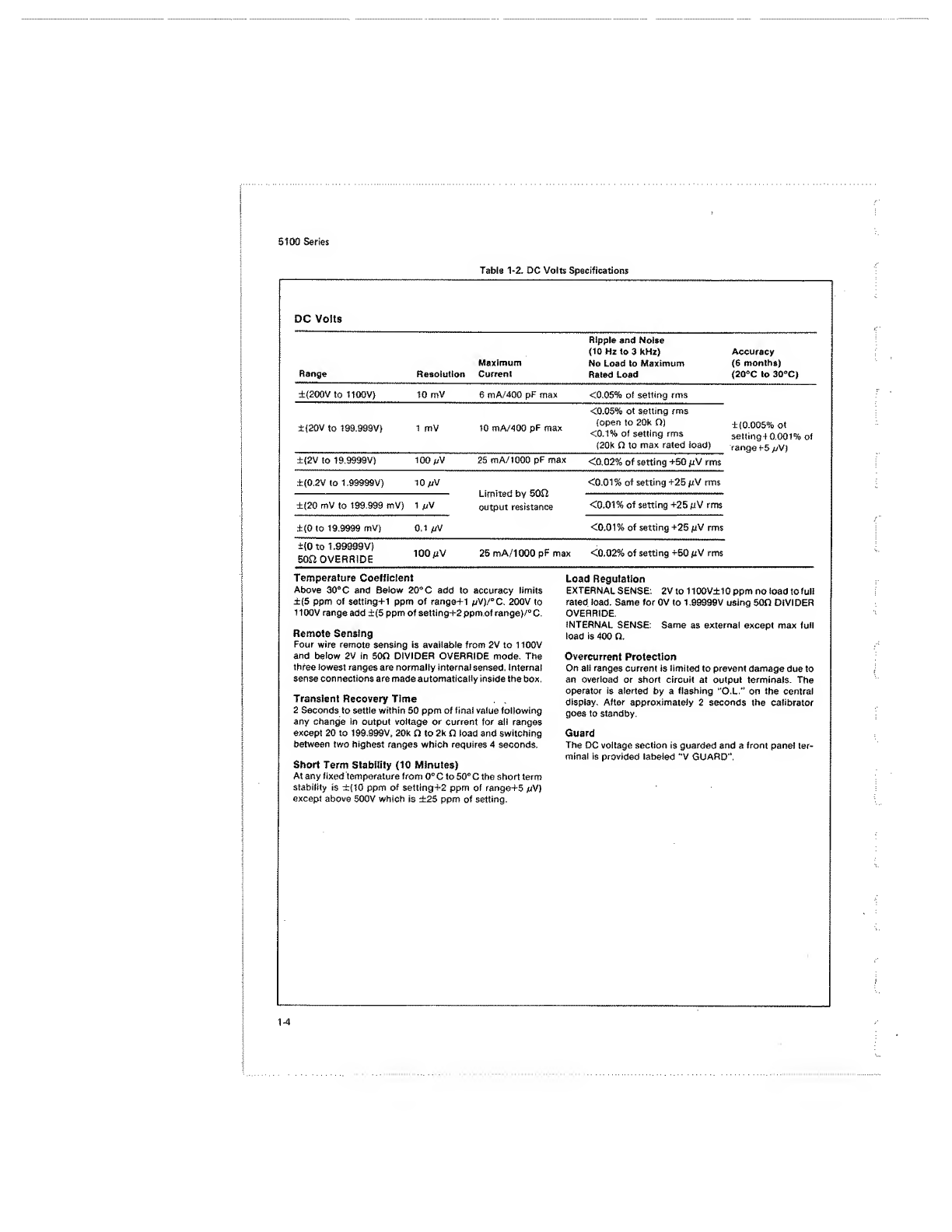

1-24, Complete Specifications

1-25. The complete specifications for the 5100 Series

Calibrators are listed in Tables 1-2 through 1-7, with each

table covering aspecific portion of the specifications.

Refer to Table 1-2 for detailed listings on DC Volts;

Table 1-3 for AC Volts; Table 1-4 for Current, both direct

and alternating; Table 1-5 for Resistance; Table 1-6 for

the Wideband Option -03; and Table 1-7 for the General

Specifications, including environmental information.

1-2