i

Table of C onten ts

Introduction......................................................................................................................... 1

Contact Fluke ..................................................................................................................... 2

Safety Information............................................................................................................ 2

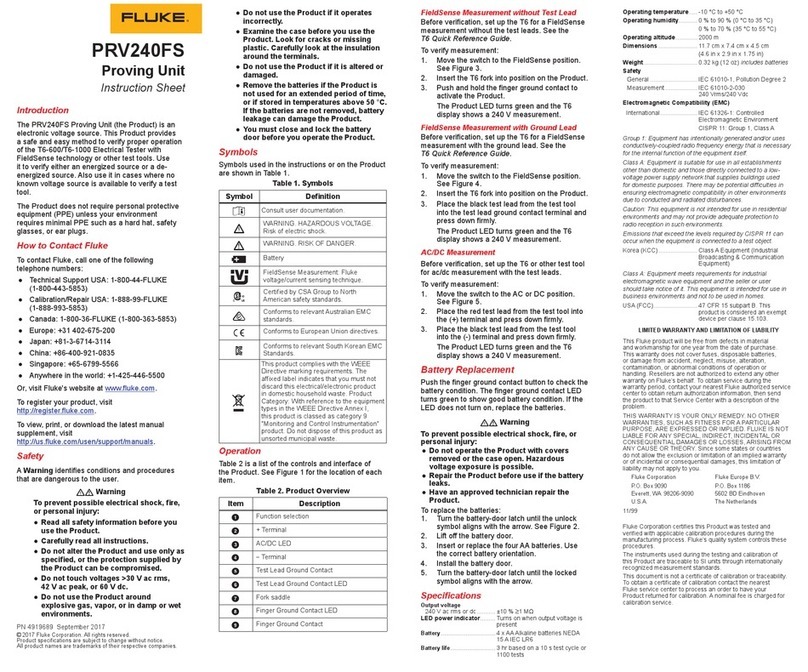

Symbols................................................................................................................................ 5

Unpack the Tester ............................................................................................................ 6

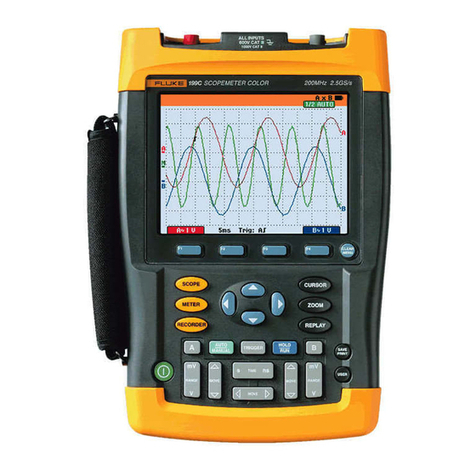

The Tester............................................................................................................................ 7

Pushbuttons............................................................................................................... 7

Tester On/Off............................................................................................................. 9

Display.......................................................................................................................... 10

Guard Terminal Use................................................................................................. 11

Test Circuit Connections ............................................................................................... 13

Before an Insulation Test ............................................................................................... 14

Preset Test Voltage Selection ............................................................................ 15

Program a Test Voltage (1537 only) ................................................................. 15

Select a Ramp or Steady-State Test (1537 only)......................................... 16

Set a Timed Test (1537 only) ............................................................................... 16

Polarization Index (PI).............................................................................................. 17

Dielectric Discharge (1537 only)........................................................................ 17

Dielectric Absorption Ratio .................................................................................. 18

Insulation Test.................................................................................................................... 18

Store Test Results (1537 only)............................................................................ 20

View Test Results Stored in Memory (1537 only)........................................ 21

Delete Test Results Stored in Memory (1537 only) .................................... 23

V ac / V dc / Resistance (1537 only)........................................................................... 23

1537 PC Software............................................................................................................. 24

Maintenance ....................................................................................................................... 25

Cleaning....................................................................................................................... 25

Battery Replacement.............................................................................................. 25

Parts and Accessories........................................................................................... 26

General Specifications.................................................................................................... 28

Electrical Specifications................................................................................................. 28

Principle of Measurement and Resistance ............................................................. 32