FLUXANA VITRIOX GAS Series User manual

FXBA‐0096‐10 1/18

USERMANUAL

VITRIOXGAS

Gas‐PoweredFusionMachine

Manufacturer:

FLUXANA GmbH & Co.KG

Borschelstr. 3

47551 Bedburg-Hau - Germany

Tel. +49 2821 / 48011-10

Fax. +49 2821 / 48011-99

www.fluxana.com

Service and Support:

FLUXANA GmbH & Co.KG

Borschelstr. 3

47551 Bedburg-Hau - Germany

Tel. +49 2821 / 48011-10

Fax. +49 2821 / 48011-99

www.fluxana.com

FXBA‐0096‐10 2/18

Content

1.0 TechnicalData

2.0 Instrumentviews

2.1Rearview

2.2Frontview

2.3Topview(4Stations)

3.0 UnpackingandSettingUp

4.0 GeneralDescriptionofFunction

5.0 Description:Touch‐Display

5.1FunctionKeys

5.1.1 FunctionkeyAppl

5.1.2 FunctionkeyLoad

5.1.3 FunctionkeyModify

5.1.4 FunctionkeySettings

6.0 CopyinganApplication

7.0 Changingthefusiontimesduringtherunningapplication

8.0 Applicationwithlowtemperature

9.0 Usingtheplatinumware

10.0 TimingofthepreinstalledApplication0&1

11.0 Service,ReplacingConsumables

11.1Replacingaburner

11.2 Changingthebelt

11.3 Replacingthetoothedbelt

12.0 WarrantytermsforVITRIOXGASseries

13.0 ECDeclarationofConformity

FXBA‐0096‐10 3/18

1.0 TechnicalData

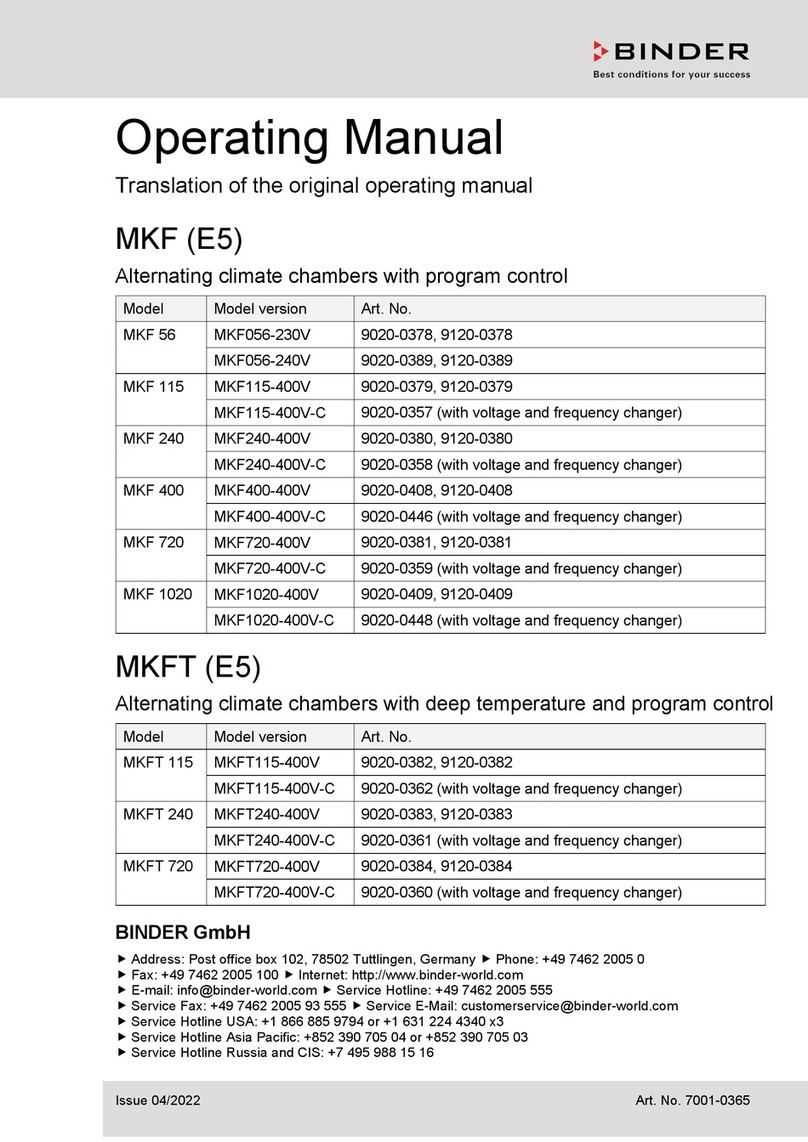

InstrumentType VITRIOXGAS2XRF VITRIOXGAS4XRF VITRIOXGAS6XRF

Numberoffusion

stations 2 4 6

Supplyvoltage 115or240VAC/50/60Hz 115or240VAC/50/60Hz 115or240VAC/50/60Hz

Powerconsumption 150W 200W 200W

Protectionclass IP2 IP2 IP2

Recommendedair

pressure 4bar 4bar 4bar

Maximumairpressure 8bar 8bar 8bar

Recommendedgas

pressure 250mbar 250mbar 250mbar

Minimum/maximum

gaspressure 200‐500mbar 200‐500mbar 200‐500mbar

Recommendedoxygen

pressure 2bar 2bar 2bar

Maximumoxygen

pressure 2bar 2bar 2bar

Maximumair

consumption 1m3/h 2m3/h 3m3/h

Maximumoxygen

consumption 0.3m3/hat2bar1 0.8m3/hat2bar1 1.2m3/hat2bar1

Maximumnaturalgas

consumptions 0.48m3/h1 0.98m3/h1 1.44m3/h1

Maximumpropane

gasconsumption 0.33m3/h1 0.48m3/h1 0.61m3/h1

Height 300mm 300mm 300mm

Width 650mm 650mm 650mm

Depth 500mm 500mm 500mm

Weight ca.35kg ca.40kg ca.45kg

1Maximumvaluesforhighoperatingtemperatures,lowvaluesforlowtemperatures

FXBA‐0096‐10 4/18

2.0 Instrumentviews

2.1 Rearview

1–Gasconnection(hosefitting9mm,outerdiameter)

2–Airpressuregauge

3–Airconnection(hosefitting9mm,outerdiameter)

4–Oxygenconnection(hosefitting6mm,outerdiameter)

5–Powerconnection

6–Fuse(4A)

7‐Networkconnection

1 3 4

2

5

6

7

FXBA‐0096‐10 5/18

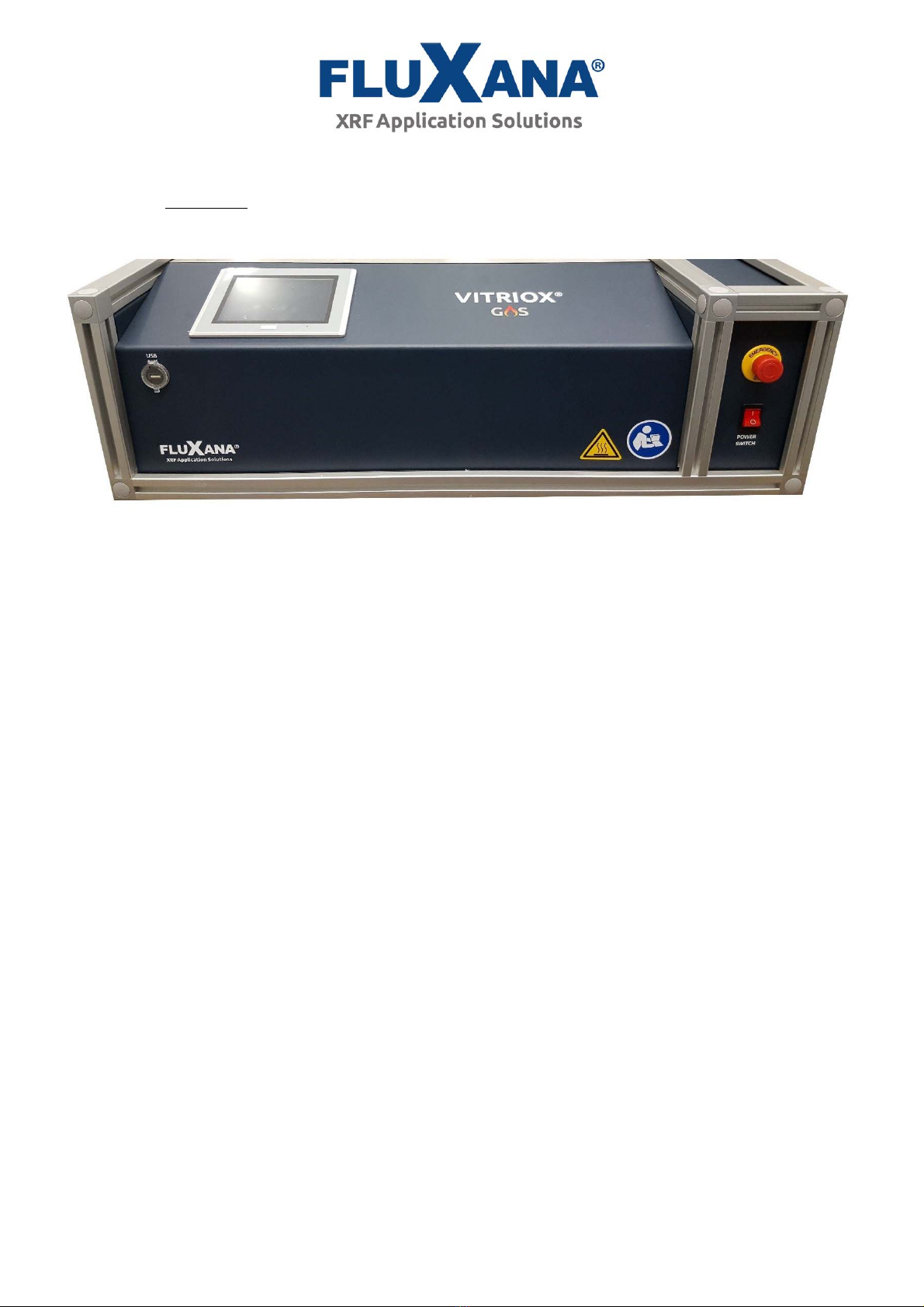

2.2 Frontview

1= Touchdisplay

2= Emergencystopbutton

3= Machinepowerswitch–Mainswitch,“Power”

4= USB‐port

1

2

3

4

FXBA‐0096‐10 6/18

2.3 Topview(4Stations)

1. Crucibleburner

2. Moldburner

3. Crucible

4. Mould

5. Ceramicbarformould

6. Ceramicstopformould

2

1

3

4

5

6

FXBA‐0096‐10 7/18

3.0 UnpackingandSettingUp

Examinethetransportboxforexternaldamage.Ifthereisvisualdamagewriteareport

andhaveitconfirmedbythecarrier.

Openthetransportboxandremovethetransportlocks.

Carefullyliftthemachineoutoftheboxandplaceitintheoperatingposition.

Warning!Donotraisethemachinebyliftingonthemobilecarriage(agitatingmechanism)!

Connectthepowercable(“Power”)115or240VAC/50/60Hz.

Connectthecompressedairtothe“Air”hosefittingwithahoseclamp.

Innerdiameterofthehoseforcompressedairis9mm.Airpressure:min.4bar,max.8bar

Connecttheoxygentothe“Oxygen”hosefittingwithahoseclamp.

Innerdiameterofthehoseforoxygenis6mm.Oxygenpressure:min.2bar,max2bar

Connectthegastothe“Gas”hosefittingwithahoseclamp.

Innerdiameterofthehoseforgasis9mm.Gaspressure:min.200mbar,max.500mbar

Theoperatingpositionmustbeselectedsothattheventilationslitsonbothsidesofthe

devicearenotobstructed.

Wehighlyrecommendtouseafumehood.

Theuseofanexternalgasdetectoratthesiteofoperationisstronglyadvised.

FXBA‐0096‐10 8/18

4.0 GeneralDescriptionofFunction

Switchthestationsyouwanttouseonoroff,usingthetouchdisplay.

Theignitionisstartsafterpressingthestartbutton.TheDisplaywillshowIgnition,

Targettime(30sec)andActualtime.

Theignitioncontinuesuntilthethermocouplesarehot,foramaximumof30sec.

Ifthethermocoupleshavenotbeenheatedenoughbythepilotflameswithinthistime,the

devicecanbestartedagain.Thepilotflameswillthenstartthecrucibleburners.

Afterthestartallburnerstationscanbeindividuallyorsimultaneouslyswitchedon/off

duringthefusionprocess.Thisisnotpossiblewithdeviceswithoptionalmouldsensors.

Herethestationsmustbeselectedbeforethestart.

Theagitationmechanismcanbealsoswitchedonintheprefusionprocess.

FromMainfusion1on,theagitatingisswitchedonasdefault.

Agitationtimesandresttimescanbesetseparately.

ThemoldburnersareautomaticallyswitchedonduringtheMainfusion2.Theyareignited

bythepilotburner.

Afterpouringthemeltoutofthecrucibleintothemoulds,theyarecooledfirstwith

lowpressureair(cooling1)andthencooledinthenexttwostepswithincreasingpressure.

Theflowofthecoolingairissetinthedisplay.

Thetargettimesinallapplicationsteps(preheating,prefusion,agitating,mainfusion1&2,

pouringandcooling)canbesetindividually‐10differentapplicationscanbestored.We

onlyrecommendchangingthetimesoftheapplicationsteps(preheating,pre‐fusion,main

fusion1andcooling3).Thetimesformainfusion2andcooling1&2haveproven

themselvesinourapplicationlaboratoryforyears.

Crucibleburner,moldburners,agitation,coolingandpilotburnerswitchoffautomaticallyat

theendoftheapplication.

Afterthelaststep:cooling3,themachinereturnstothebasescreen.ProgramEndisshown

inthedisplay.Acknowledgethismessagebypressing.

TheVITRIOXGASdevicesareequippedwithagassensorthatblocksthemaingasand

oxygensuppliesandstopstherunningapplicationimmediatelyifagasleakin/ornearthe

deviceisdetected.

Thedisplayshowsthemessage:Gasleakage.BesuretocontacttheFluxanaService(see

page1)beforerestarting.

FXBA‐0096‐10 9/18

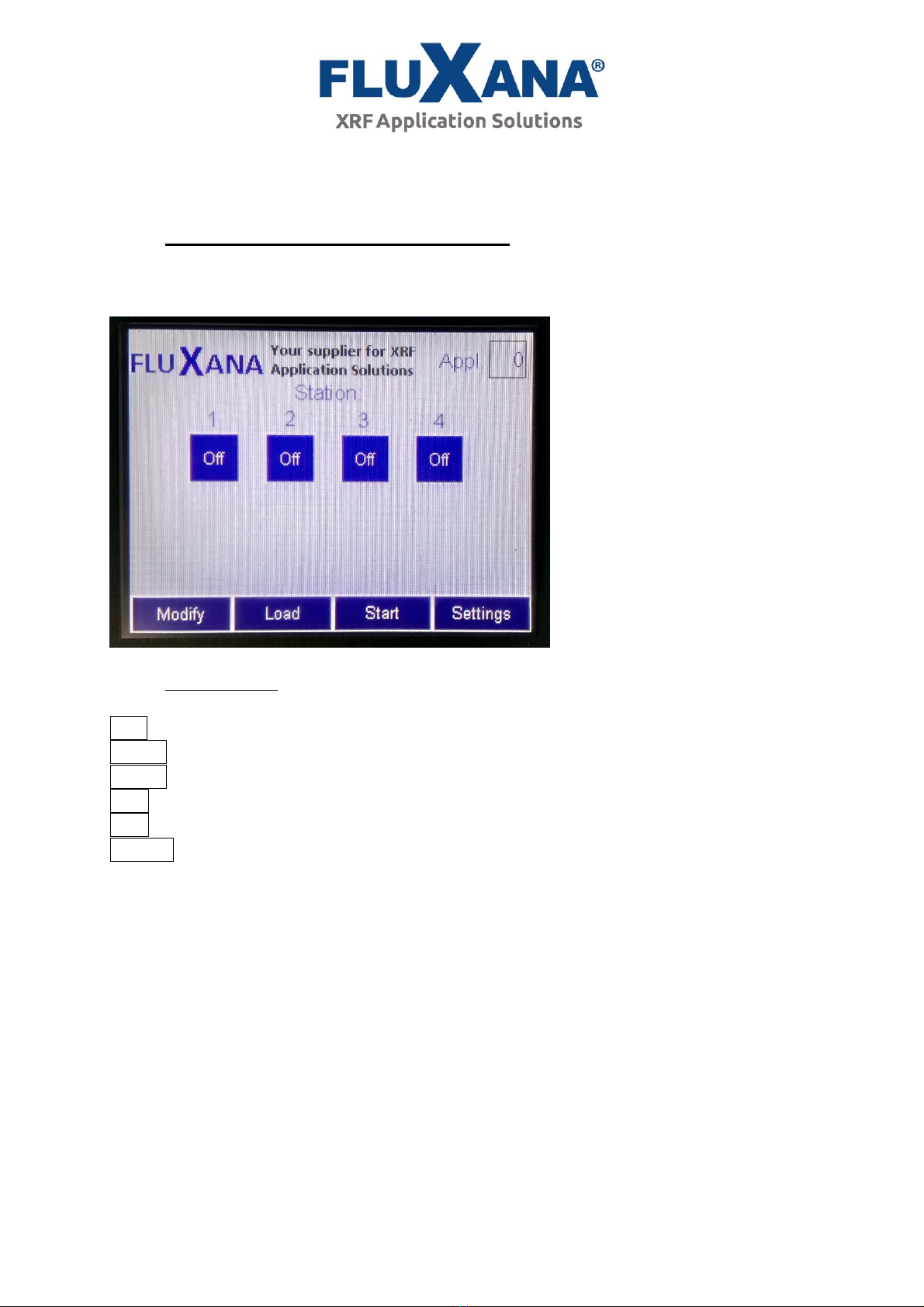

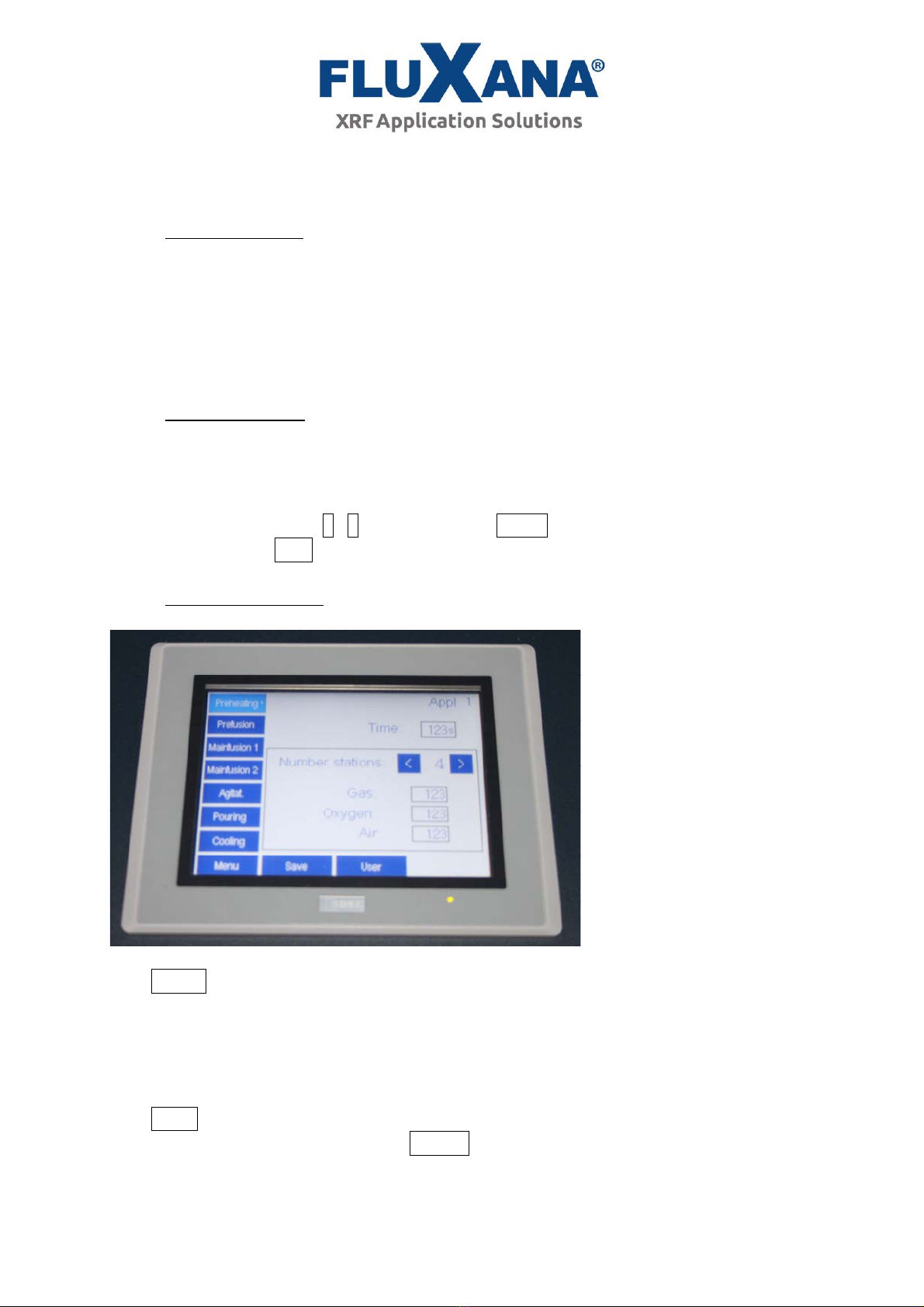

5.0 Description:Touch‐Display

Thebasescreenisdisplayedafterpressingthe“Power”button:

5.1 FunctionKeys:

Appl=Applicationcanbeselected

Station=stationscanbeswitchedonandoff

Modify=Applicationscanbechanged

Load=selectedapplicationisread

Start=Applicationisstarted

Settings=Settingsformould,gasandfeedsensor

FXBA‐0096‐10 10/18

5.1.1 FunctionkeyAppl

Application:individualstoredapplicationscanbeselectedviaanumerickeypad.

2applications(Appl.0&Appl.1)arepreinstalledasstandard.The8followingmemoryslots

areatyourdisposal.

Differenttimesandtemperaturesintheindividualapplicationstepscharacterizedifferent

materialsandmethods.

5.1.2 FunctionkeyLoad

ApplicationNo.0isautomaticallyloadedwhenthedeviceisswitchedon.

Afterselectingtheapplication,

typeapplicationnumber0‐9andconfirmwithENTER.

readapplicationwithLoad.

5.1.3 FunctionkeyModify

WithModifytherespectiveapplicationsteps(leftside)canbecalled.

Intheselectedapplicationstep,thetimecanbecheckedorchanged.

Anotherpossibilityistocheckorchangetheflowratesforgas,oxygenandairdependingon

thenumberofstations(consumers).

WithAgitat,theagitatingfunctions,aswellastheagitatingspeedandtimesarecheckedor

changed.ThepouringtimeissetunderPouring.

FXBA‐0096‐10 11/18

Tosavechangedentries,firstyouneedtologinasadmin.Todothis,pressModifyfromthe

basescreen,thenpressUser,inthenewwindowselectAdmin,enterthepasswordand

confirmwithEnter.

PressSavetostoreallnewentries(theseareretainedevenafterthedevicehasbeen

switchedoff).

ExitthispagewithMenu.

5.1.4 FunctionkeySettings:

Optionalmouldsensor:enable/disablefunction

Gassensor:unlocktheGasleakagemessage

Feedsensor:enable/disablefunction

FXBA‐0096‐10 12/18

6.0 CopyinganApplication

Thiscanbeusedtoshortenthecreationofanewapplication,ortocreateabackupofan

existingapplicationonafreememoryslot.

1.Loadastoredapplication,e.g.Appl.1‐(seefunctionkeyLoad).

2.EnterthenewapplicationnumberinAppl(donotpressLoad).

3.PressModify,changethedesiredvalues.

4.PressSave.

7.0 Changingthefusiontimesduringtherunning

application

Thedeviceallowstochangethetimesintheapplicationstepspreheating,prefusion,main

fusion1,mainfusion2,pouringandcoolingindividuallyduringtherunningapplication.This

enablestheusertoobservethemeltingprocessandintervenedependingontheprogress.

IntheMainfusion2,thetimeshouldALWAYSbe240sec,sincethemouldburnersaresetto

optimumtemperaturebeforepouring.

ExampleforshorteningtheMainfusiontime:

ThedeviceiscurrentlyintheMainfusion1,Target=240sec.Afterinspection,themain

fusionshouldendafter180seconds:

PressTargettime240andenterthenewtime,e.g.,180.ConfirmwithENTER.

Iftheactualtimeis≤Targettime,thisapplicationstepstopsandthenextstepbegins.

IncreasingtheMainfusiontimeworksinthesameway.

Accordingtotheexamplesabove,alldisplayedtimesinthedifferentapplicationstepscan

bechangedduringtheprocess.

Iftheentriesneedtobestoredforfutureusetheymustbesaved,thismustbedoneafter

theapplicationends(seeFunctionkeyModify).Unsavedchangeswillbelostafterswitching

offthedevice.

Iftheagitatingtimes(onoroff)aresetto10s,itmustbeensuredthatthetotaltime

(preheating,prefusionandmainfusion1&2)canbedevidedby20.

Thisistoensurethatafterthelastagitatingcycle,thesampleispoureddirectlyontothe

heatedmould.

FXBA‐0096‐10 13/18

8.0 Applicationwithlowtemperature

TheVITRIOXGASdevicenotonlyallowsthesettingofdifferenttimesequencesinthe

individualapplications,butalsodifferenttemperatureprofiles.

Thesetwoparametersenableatime‐optimizedand/ormaterial‐specificadjustmentofthe

fusionprocess.Thedevicethusallowsalargelyindividualadaptationtodifferent

requirements.

Inthepreheatingstep,e.g.alowtemperaturecanbesettoe.g.todrythecruciblecontents,

ortoperformanoxidation.Thereafter(fromprefusionon),thenormalmeltingtemperature

isused.

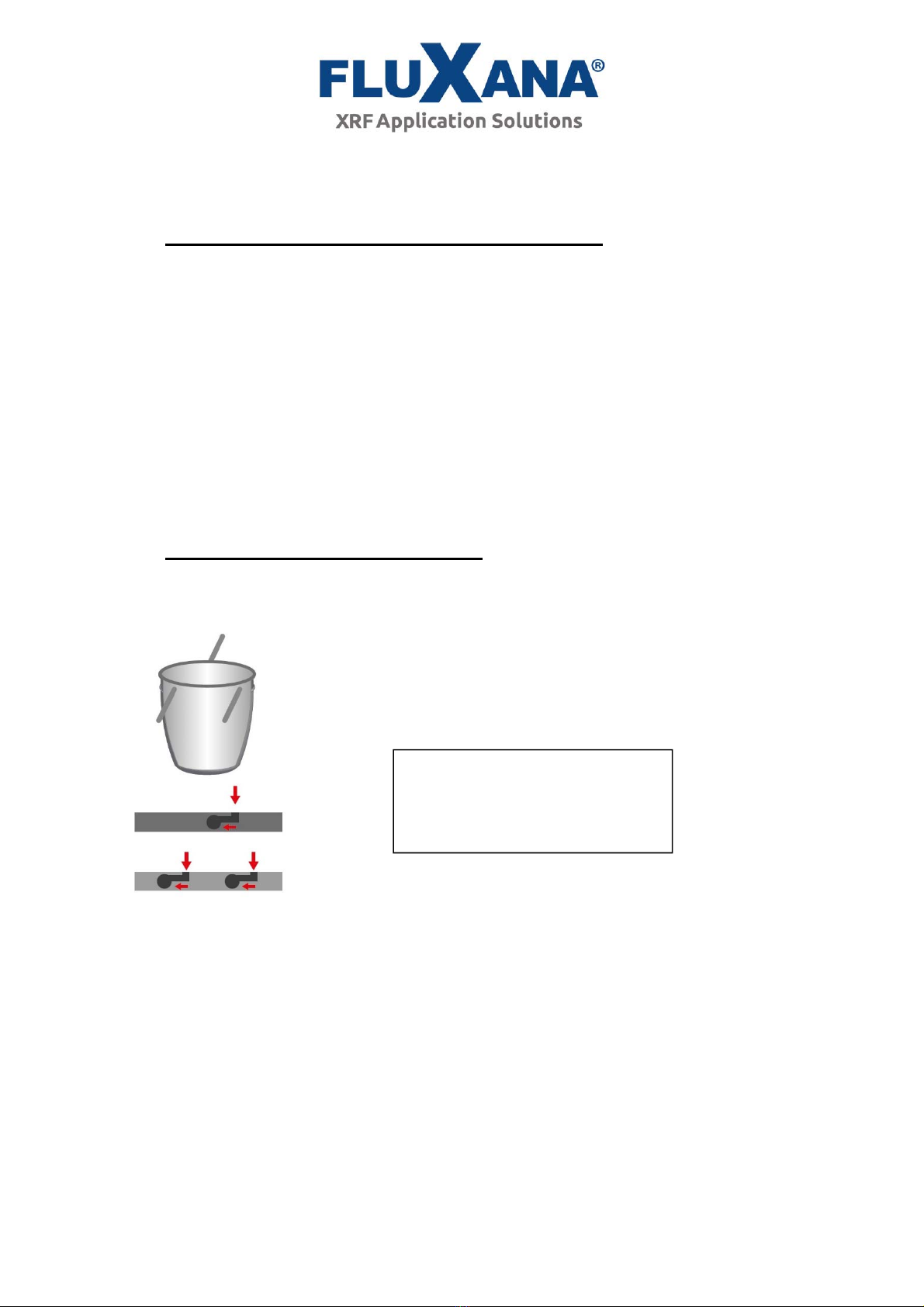

9.0 Usingtheplatinumware

Placetheplatinumcruciblewithsampleintothereceptacleholesinthecrucibleholder.

Placethemouldsontotheceramicbarsandpushthemuptotheceramicstop.

Hangthecruciblesonthe

notchesandpushthecrucibleto

theleftuntilitisinthecorrect

position.

FXBA‐0096‐10 14/18

10.0 TimingofthepreinstalledApplications0&1:

Application0:

„Preheating“ 180seconds

„Prefusion“ 240seconds

„Mainfusion1“ 120seconds

„Mainfusion2“ 240seconds

„Agitatingoff“ 10seconds

„Agitatingon“ 10seconds

„Pouring“ 7seconds

„Cooling“complete 360seconds(60/240/60)

Application1:

„Preheating“ 240seconds

„Prefusion“ 540seconds

„Mainfusion1“ 120seconds

„Mainfusion2“ 240seconds

„Agitatingoff“ 10seconds

„Agitatingon“ 10seconds

„Pouring“ 7seconds

„Cooling“complete 360seconds(60/240/60)

FXBA‐0096‐10 15/18

11.0 Service,ReplacingConsumables

11.1 Replacingaburner

Turnoffthedevice.Pulloutthepowerplugandletitcooldown,ifnecessary.

Loosenthecapnutwiththespecialwrenchdeliveredwiththedevice.Theburnercan

thenberemoved.Thenewburnerisinstalledinthereverseorder.

11.2 Changingthebelt(PD‐SKF0005c)oftheagitatingdevice(eccentric).

Pulltheeccentricupwardsoutofthemotorplate.

Putroundbeltonthemotorplateandputtheeccentricbackintheholesofthemotor

plate.

Nowplacetheroundbeltoverthegroovesofthedrivepulleys.

Figure:Agitationmechanism

11.3 Replacingthetoothedbelt(PD‐SKF0006)oftheagitatingdevice(eccentric)

Releasescrewsforcrucibleholder(1)fromeccentric,thenpulleccentricfromabove

outofthemotorplate.

Loosehexscrews(2),andnowpushtherightshaftwithgearinwarduntilthetoothedbelt

movesfreely

Lookoverthetopedge,bothshaftsshouldbeinthesameposition

(drawingbelow).

2

1

FXBA‐0096‐10 16/18

UpperedgePositionoftheshafts

Whenthepositionsarethesame,pushtherightshaftoutwardagainandtry

tofindoutifthetoothedbeltisintherightposition.Ifnot,adjustuntil

everythingfits.Nowtightenthescrewsslightlyandinserttheeccentricinto

themotorplate.Iftheshaftsrotateeasilyinthebearings,tightenthe

screws.Nowmountthecarriagebacktotheeccentric.

Werecommendanannualserviceforthedevice.

FXBA‐0096‐10 17/18

12.0 WarrantytermsforVITRIOXGASseries

Partsandequipmentmanufacturedbytheproducerarewarrantedfromdefectinmaterial

andworkmanshipforaperiodof12monthsfromthedateofinstallationbutnolongerthan

15monthsfromthedateofdelivery(dependingonwhatoccursfirst).Otherpartsor

equipmentarecoveredtotheextentofwarrantyprovidedbytheoriginalmanufacturer.

Theproducermakesnootherwarrantywithrespecttomerchantability,fitnessforpurpose,

orotherwise.Consumablesanditemsofsimilarnaturearenotcoveredbythiswarranty.

Theproducer'ssoleobligationunderthiswarrantyshallbetorepairorreplaceanypartor

partswhich,tooursatisfaction,provetobedefectiveuponreturnprepaidtotheproducer.

Thisobligationdoesnotcoveranyfailureduetoaccident,abuse,neglect,oruseindisregard

ofinstructionsfurnishedbytheproducer.Innoeventshalldamagesfordefectivegoods

exceedthepurchasepriceofthegoods,andtheproducershallnotbeliableforincidentalor

consequentialdamageswhatsoever.

Allclaimsinregardtothepartsorequipmentmustbemadeinwritingwithin10daysafter

thepurchaserlearnsofthefactsuponwhichtheclaimisbased.Writtenauthorizationmust

beobtainedfromtheproducerpriortoreturninganypartorparts.Thiswarrantyisvoided

byfailuretocomplywiththesenoticerequirements.

Thewarrantyonthemachineremainsvalidonlywhengenuinereplacementpartsare

employed.

Onlytechnicallyqualifiedstaffwhohavefullyreadandunderstoodtheseinstructionsshould

operatethismachine.Theoperatorshouldfollowallofthewarningsandcautionssetforth

inthismanualandshouldfollowtheapplicablesafetyprocedures.

Serviceandrepairsshouldbecarriedoutonlybythemanufacturerorbyitsappointedand

trainedrepresentatives.

13.0 ECDeclarationofConformity

FXBA‐0096‐10 18/18

ECDeclarationofConformity

AsdefinedinDirectives: MachineryDirective2006/42/EG

EMCDirective2014/30/EU

RoHSDirective2011/65/EU

InstrumentType: Attachtypelabelhere

hasbeendeveloped,constructedandmanufacturedinsatisfactionofthe

abovenameddirectivesby

FLUXANA

®

GmbH&Co.KG

Borschelstr.3

47551Bedburg‐Hau

Thisdeclarationrelatesexclusivelytothemachineryinthestateinwhichwas

placedonthemarketandexcludescomponentswhichareaddedand/or

operationscarriedoutsubsequentlybytheenduser.

Thefollowingharmonizedstandardapplies:DINENISO12100:2011‐03

Personauthorizedtocompilethetechnicalfileis:Mr.VolkerGossens,address

asabove.

Bedburg‐Hau,04.05.2017 Dr.RainerSchramm

(ExecutiveDirector)

This manual suits for next models

3

Table of contents

Other FLUXANA Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Spectra-Physics

Spectra-Physics InSight X3 user manual

Bioer

Bioer NPA-96 Operation manual

Advantech

Advantech EKI-2701HPI-AE user manual

Bibby Sterilin

Bibby Sterilin Lenton EF 11/8 Installation, operation & maintenance instructions

Biotech

Biotech FCS2 instructions

Thermo Scientific

Thermo Scientific PrintMate A79510100 Operator's guide