FXBA‐0072‐17 3/42

1.Overview

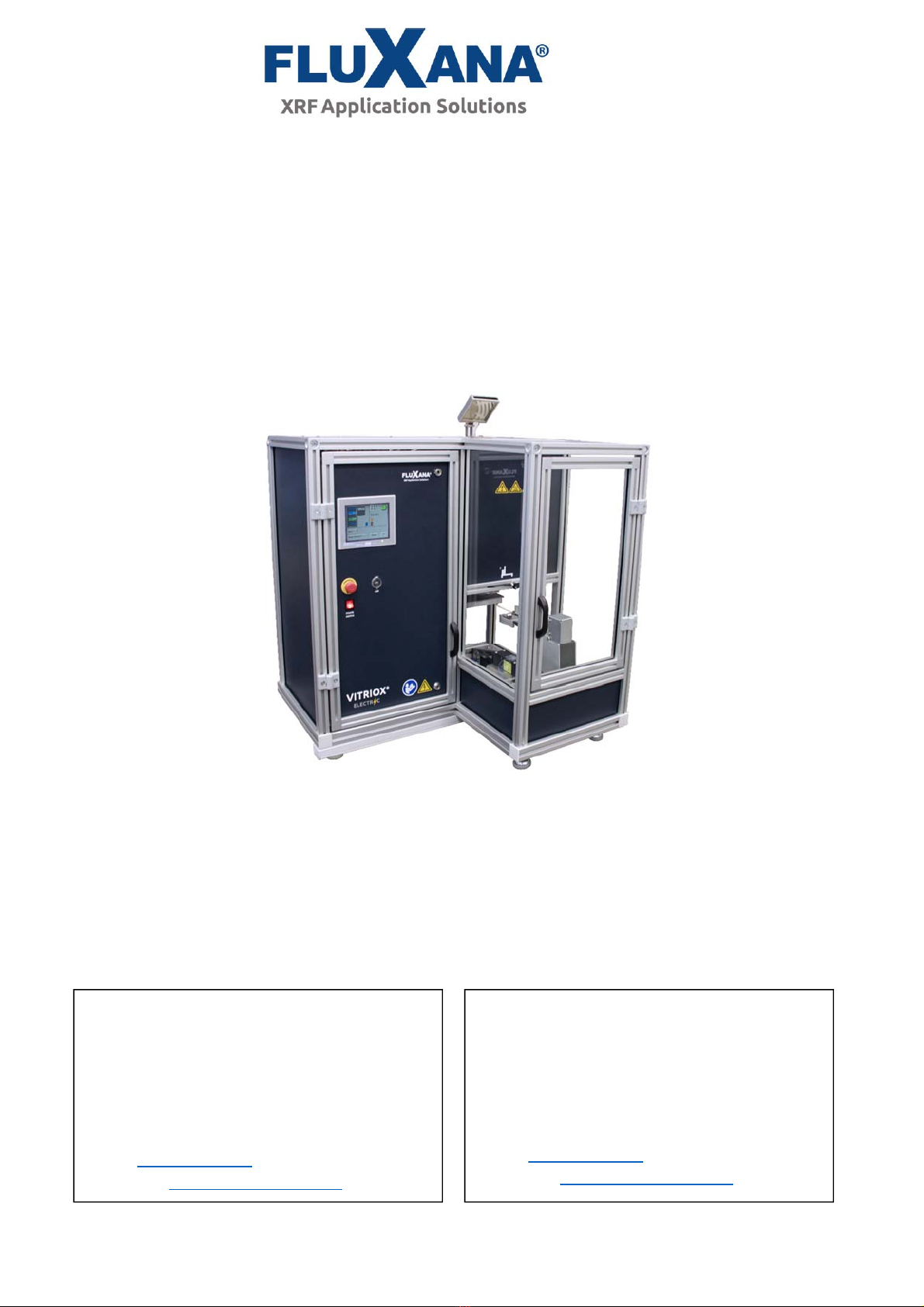

1.1ProductDescription

TheVITRIOX®ELECTRICisafusioninstrumentforsamplepreparation for X‐ray

fluorescence analysis. Thefusionchamberisheated by systematically arranged

heatingelementsthatareisolatedfromthefusionchamber.Inthisway,itispossible

toachieveidealheatingofthefusionchamber.Temperaturedetermination is

conductedwithaspecialthermoelement.Thefusionchambercanbeheatedtoupto

1250°C.

Withthecoldtocoldoperation,eachindividualsampleexperiencesthesameenergy.

Rotationmixingenablesthemachinetoachieveideallymixedhomogeneoussamples.

Themachineisdeliveredwithaprotectivehousing(personnelandprocessprotection)

andamirrorontheceilingoftheovenforobservationoftheovenchamber.

Additionalcharacteristicsoftheproductinclude:

Microprocessorcontrolforthestorageofupto10differentapplicationprograms

Heatgenerationbyheatingelements

Ovenwiththermallyinsulatingmaterials(Inside:fusiontemperature;Outside:

lukewarm)

Temperaturedistributionthroughall‐roundheatingoftheovenchamber

Exhaustventintheceiling

TypeBorSthermoelements(dependingonmodel)

Switchingsystemwithphase‐anglefiringthyristors

Liftwithflooropening

Mixingbyhighspeedrotation(upto250rpm,bidirectional)

CrucibleholderandovenfloormadefromfusionresistantFLUXinert®ceramic(no

attackfromlithiumtetraborate;easilycleanedwithdilutedHCl)

Autosamplerforautomaticprocessingofupto6samples

Modularsystemenablesupgradetoupto6positions

Optional:additionalstationforcontinuousoperation(loadingandunloadingof

samplesduringthefusionispossible)

Optional:Useofcruciblelidsfortheanalysisofvolatileelements,likeF,ClorS

Optional:OvenceilingmadefromFLUXinert®ceramic