Seite von 51 Handbuch OSMOMAT 050

Version 1.1 (2011-10-12)

Table of contents

1

Introduction ....................................................................6

Overview of the OSMOMAT 050 .................................10

3

Setup and Initial Operation .........................................13

4

Preparing the Measuring cell for Measurement .......15

4.4.1

Selecting suit ble membr nes ............................................................................................. 18

4.4.2

Conditioning the membr ne ................................................................................................. 19

4.6.1

Initi l St rtup with Dry Me suring cell .................................................................................. 21

4.6.2

Removing the Membr ne When the Me suring cell is Filled ............................................... 21

5

Calibrating the OSMOMAT 050 ................................... 6

6

Measuring the Colloid Osmotic Pressure ................. 8

1.1

Applic tions of the OSMOMAT 050 ....................................................................................... 6

1.2

Applic tion Restrictions of the OSMOMAT 050 ..................................................................... 7

1.3

Me surement Method of the OSMOMAT 050 ....................................................................... 7

1.4

Reproducibility of the OSMOMAT 050 ................................................................................... 8

1.5

Unp cking the OSMOMAT 050 Colloid Osmometer ............................................................. 9

1.6

P ck ging Contents ............................................................................................................... 9

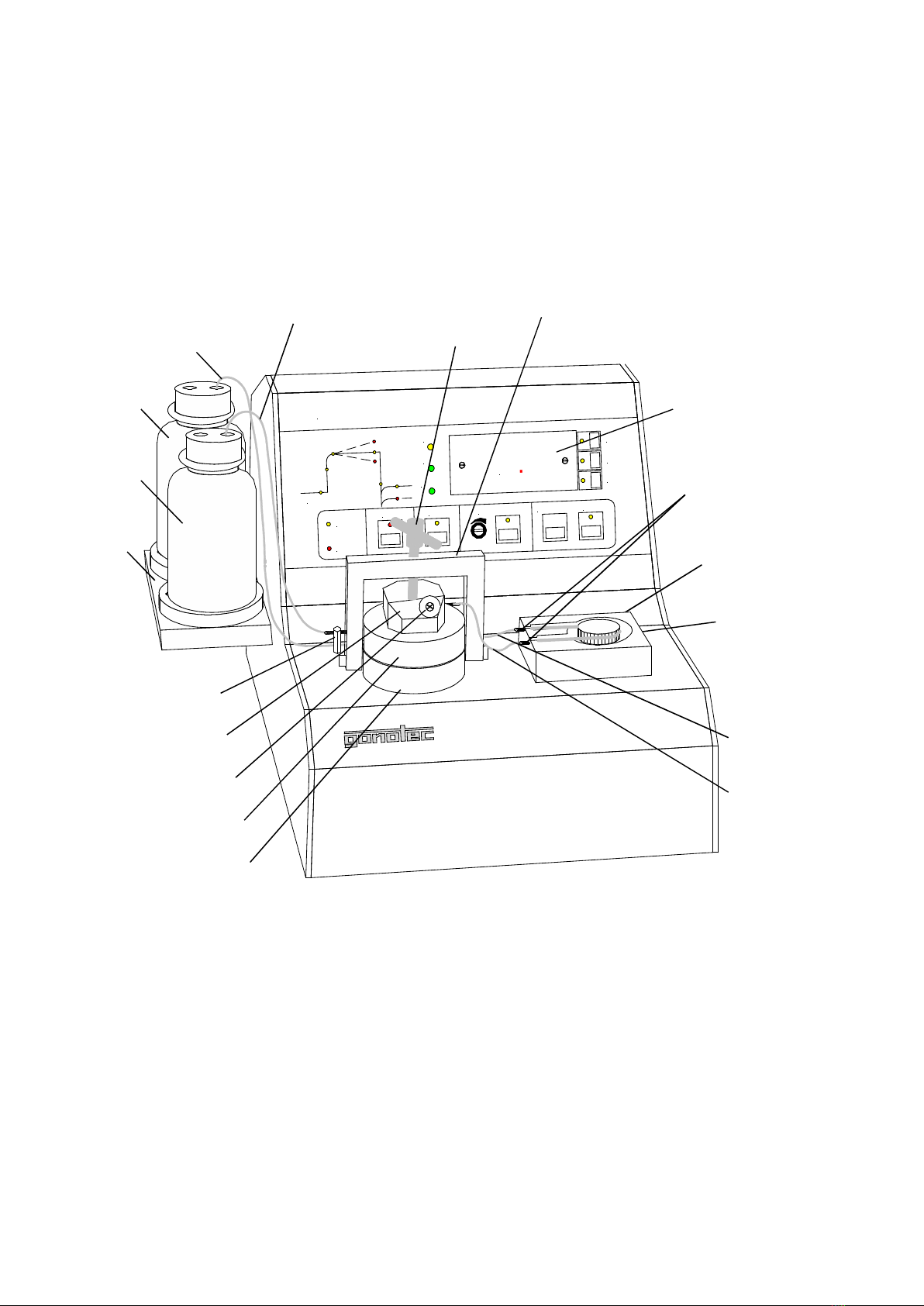

2.1

Overview of Displ y nd Connectors ................................................................................... 10

2.2

Power Supply ....................................................................................................................... 12

2.3

Dimensions nd Weight ....................................................................................................... 12

2.4

S fety nd H ndling Inform tion .......................................................................................... 12

2.5

Known Risks Associ ted with the Use of the OSMOMAT 050 ............................................ 12

4.1

M king the Tube Connections during Initi l St rtup ............................................................ 15

4.2

Ringer's Solution s Solvent ................................................................................................ 17

4.3

Filling the Supply nd W ste Bottles ................................................................................... 18

4.4

Prep ring the Semiperme ble Membr ne ........................................................................... 18

4.5

Prep ring the Filter P per nd Deg ssing the Solvent ........................................................ 20

4.6

Opening the Me suring cell ................................................................................................. 21

4.7

Cle ning nd Filling the Lower H lf of the Me suring cell ................................................... 21

4.8

Screwing Together the Me suring cell................................................................................. 23

5.1

C libr tion Using the Hydrost tic Pressure Difference ........................................................ 26

6.1

Prerequisites for Me surement ............................................................................................ 28

6.2

S mple M teri l ................................................................................................................... 29

6.3

Displ y of the OSMOMAT 050 ............................................................................................. 29

6.4

Performing the Me surement .............................................................................................. 30

6.5

Recording nd Storing the Second Me surement V lue ..................................................... 32