FMT Swiss AG PREMAxx User manual

87 987 A802 GB

Electric pump

PREMAxx

230 V 1~AC • 24 V DC • 12 V DC

2

GOperating instructions electric pump PREMAxx

Contents

General details1. ______________________________________________________________________2

Intended use1.1. ________________________________________________________________________2

Construction and functional description1.2. _________________________________________________3

Technical data1.3. _______________________________________________________________________3

Area of application1.4. ___________________________________________________________________4

Operational Area Requirements1.5. ________________________________________________________4

General safety instructions2. ____________________________________________________________4

Information on safety at work2.1. __________________________________________________________4

Signs and symbols used in the safety instructions2.2. __________________________________________4

Hazards that may arise in connection with the electric pump2.3. PREMAxx________________________5

Assembly3. ___________________________________________________________________________6

Assembly of3.1. PREMAxx electric pump____________________________________________________6

Operation4. __________________________________________________________________________7

First operation and renewed operation4.1. ___________________________________________________7

Normal operation4.2. ____________________________________________________________________8

Emergency operation4.3. _________________________________________________________________9

Disassembly5. ________________________________________________________________________9

Maintenance6. ________________________________________________________________________9

Repairs/service7. ______________________________________________________________________9

Declaration of EC Conformity8. _________________________________________________________10

1. General details

1.1 Intended use

The PREMAxx electrical pump is designed exclusively for pumping diesel and fuel oil in areas that do

not carry a risk of explosion.

The intended use also includes the adherence to the instruction for assembly (see chapter 3), for the

operation ( see chapter 4), for disassembly (see chapter 5), and for maintenance

(see chapter 6).

Any use beyond these parameters (e.g. operation using fuels of dierent hazard classes) can lead to

serious risks and is regarded as use that is contrary to the intended purpose.

Unauthorized modications to the product by the user can be dangerous and are considered to be

improper.

The operator is liable for any damage arising out of use that is not for the intended purpose.

This instrument is not intended for use by persons (including children) with reduced physical, sensory

or mental abilities or lack of experience and/or knowledge of it, unless they are supervised by a person

responsible for their safety, or they receive from them instructions on how to operate it.

Children should be supervised to ensure that they do not play with the instrument.

3

Operating instructions electric pump PREMAxx G

1.2 Construction and functional description

The PREMAxx electric pump is an electrically powered delivery pump for diesel and fuel oil. It can be

screwed onto storage containers or tanks.

The PREMAxx electric pump is available with the following motor options:

Type 1: 230 V 1~AC

Type 2: 24 V DC

Type 3: 12 V DC

It is equipped with various nozzles:

with a standard nozzle valve or

with a self-closing automatic nozzle valve or

with a self-closing automatic nozzle valve with construction type approval (according to § 12 VbF,

tested by the PTB). We happily supply the construction type approval on request.

The pump is delivered as a set comprising:

PREMAxx

electric pump in one of the above mentioned motor options,

Set of hoses (suction hose, suction pipe with lter, delivery hose, hose clamps),

Nozzle valve in one of the above mentioned versions.

Although the PREMAxx electric pump is not a self-priming pump, it is quickly ready for use in

connection with the integrated priming stage. The priming stage enables manual priming of the

delivery uid before start of operation and secures emergency service for minimum quantities in the

event of power loss.

The pump housing is made from high quality knock-resistant plastic.

To avoid environmental damage, the PREMAxx electric pump is equipped with a siphon protector. If

the delivery hose should be damaged whilst the pump is inoperative, it will prevent the emergence of

diesel or fuel oil.

1.3 Technical data

Designation Type 1 Type 2 Type 3

Voltage 230 V 24 V 12 V

Frequency 50 Hz

Current type 1~AC DC DC

Power consumption 1,8 A 10 A 14 A

Length of connecting cable 2 m 3 m 3 m

Performance 320 W 240 W 180 W

Delivery performance* 52 l/min 43 l/min 38 l/min

Max. delivery height 15 m 10 m 9 m

Weight 2,5 kg 2,5 kg 2,5 kg

* for free run-o, suction height 1.6 m, DN 19

Table 1-1: Performance data

Designation Value

Temperature of delivery medium -10 °C to +35 °C

Length of suction hose 1,6 m

Length of delivery hose 4 m

Suction height max. 2 m

Container connection G 2“ and M 64 x 4

Protection type IP 34

Noise level 70 db (A)

Table 1-2: General technical data

4

GOperating instructions electric pump PREMAxx

1.4 Area of application

The PREMAxx electric pump is only designed for pumping diesel and fuel oil, if they are not heated

above the ash point.

The temperature of the delivered uid must be between -10 °C and +35 °C. The temperature limits

must not be exceeded.

As the motor and switches of the PREMAxx electric pump are not protected against explosion, the

pump must not

be operated in areas with a risk of explosion.

be used for dispensing of other liquids than indicated.

The PREMAxx electric pump is suitable for permanent operation up to 30 minutes only.

1.5 Operational Area Requirements

Fuel oil and diesel are materials hazardous to water. Therefore ensure that the relevant country and/or

local authority rules and regulations are complied with. For example in Germany observe the Provisions

of the Water Household Law (WHG) and the Facilities Provisions of the (German) States (VawS).

According to § 19g of WHG, facilities for lling must be designed, installed, erected, maintained

and operated in such a way that a contamination of waters or any other permanent change of their

characteristics is not possible.

According to § 19l of WHG, the operator of such a facility is obliged to monitor his plant at all times at

the place of installation, in order to check that the above mentioned requirements are met.

2. General safety instructions

2.1 Information on safety at work

The PREMAxx electric pump is designed and built according to the appropriate health and safety

requirements of the relevant EC guidelines.

This product can nevertheless produce hazards if it is not used according to its purpose or without the

necessary care (see chapter 1.1).

Please read therefore these operating instructions before operating the PREMAxx electric pump and

pass these on to any other users of the pump.

In any case, the local safety and accident prevention provisions apply for the operation of the

PREMAxx electric pump.

Please pay attention to the safety notes in these operating instructions.

2.2 Signs and symbols used in the safety instructions

The safety notes used in these operating instructions distinguish between various levels of hazard.

Various levels of hazard are marked in the instructions using the following signal words and icons:

Pictogram Keyword Consequences of not observing the safety provisions

Danger Death or most severe injuries

Caution Possible slight or lesser injuries, or material damage

Furthermore, another note is used giving general tips for the handling of the product.

Pictogram Keyword Meaning

Tip Background knowledge or tips for the correct handling of the

product

5

Operating instructions electric pump PREMAxx G

2.3 Hazards that may arise in connection with the electric pump PREMAxx

Danger!

Combustible fuels can cause explosions

Do

not smoke whilst handling the pump and fuels.

Danger!

Flying sparks can cause explosions

Do

not operate the pump in areas with a risk of explosions.

Use pump

only to deliver diesel and fuel oil.

Danger!

Hoses with insucient resistance can cause explosions

In order to deliver the fuel without risk, the delivery hose must have a certain resistance in order to

avoid static charge. The original delivery hose from FMT has the necessary resistance.

Use only FMT delivery hose.

When using delivery hoses by other manufacturers it must be ensured that the delivery hose

has a resistance of > 1011 Ohm.

Caution!

Leaking fuels can cause environmental damage

Observe the relevant country and/or local authority rules and regulations. For example

in Germany observe the provisions of the Water Household Law (WHG) and the Facilities

Provisions of the (German) States (VawS).

6

GOperating instructions electric pump PREMAxx

3. Assembly

Fig. 3-1: Overview of PREMAxx electric pump with accessories

1 Pump housing 11 Thread of standard nozzle valve

2 Hand lever 12 On/o switch

3Barrel screw joint 13 Pressure union

4Suction union 14 Union nut of delivery hose

5 Hose clamp 15 Delivery hose

6 Suction hose 16 External thread of delivery hose

7 Hose clamp 17 Automatic nozzle valve

8 Suction pipe with lter 18 Lock lever

9 Standard nozzle valve 19 Trigger of automatic nozzle valve

10 Trigger of standard nozzle valve 20 Thread of automatic nozzle valve

3.1 Assembly of PREMAxx electric pump

Push the transparent suction hose (6) onto the suction pipe with lter (8).

Push the hose clamp (7) over the suction hose (6) to the suction pipe (8) and tighten the hose clamp with a

screwdriver.

Tip

Before continuing with the next step, please note:

If the pump is mounted on the fuel container, the suction hose with the suction pipe must be long

enough to reach the fuel in the tank even if the fuel level is low.

7

Operating instructions electric pump PREMAxx G

Cut the suction hose (6) to the desired length.

Push the hose clamp (5) over the suction hose (6).

Push the suction hose (6) onto the vacuum union (4) on the pump.

Push the hose clamp (5) to the vacuum union (4) and tighten the hose clamp with a screwdriver.

Caution!

Risk of product damage

Mount and operate the pump only vertically on a fuel container.

Firmly screw the pump into the aperture of the fuel tank using the barrel screw joint (3).

The pump run-o can be brought into any position in the screwed-in state by twisting the pump housing

(1).

Screw the union nut (14) of the black delivery hose onto the pressure union (13) of the pump.

Screw in the free end of the delivery hose with the external thread (16) into the thread of the nozzle (11 or

20 respectively).

Caution!

Risk of product damage

The power source must have the correct voltage for the pump type.

Connect the pump to a power source using the main plug.

The pump is ready for operation.

4. Operation

4.1 First operation and renewed operation

Caution!

Risk of product damage

Before switching on the pump for the rst time, and in the event of a low uid head:

Manually prime with diesel or fuel oil, as a dry run of the pump can destroy the radial shaft

gasket.

Prepare pump for operation:

Hold the nozzle valve (9 or 17) in a collecting container.

Press and hold the nozzle trigger (10 or 19) or arrest it using the lock lever (18) (for automatic nozzle valve

versions).

Using the manual lever (2), prime the delivery uid until the uid emerges from the nozzle valve (9 or 17).

The pump is ready to be switched on.

8

GOperating instructions electric pump PREMAxx

4.2 Normal operation

Danger!

Flying sparks can cause explosions

Do

not operate the pump in areas with a risk of explosion.

Use pump

only to deliver diesel or fuel oil.

Caution!

Risk of product and environmental damage

Regularly check delivery hose and connection for damage in order to avoid leakage of diesel or

fuel oil.

Operate pump only under supervision.

Do not let the pump deliver for more than 2 minutes against a closed nozzle to avoid

exceeding the permitted temperature.

Avoid running the pump dry.

Delivering fuel (for standard nozzle valve version):

Switch on the pump (12).

Hold the nozzle valve (9) into the vehicle tank and press up the nozzle trigger (10), according to desired

delivery quantity.

To nish the delivery, release the nozzle trigger (10).

Switch o the pump (12).

Place the nozzle valve (9) on the container.

Delivery fuel (for automatic nozzle version):

Tip

With a locked nozzle trigger, the automatic nozzle switches o automatically, as soon as the tank

or container being lled is full.

Furthermore, the automatic nozzle switches o when the nozzle is held vertically or falls down

whilst the nozzle trigger is locked.

The automatic switch-o only functions when the nozzle exit containing the sensor jet is not

contaminated and the through ow quantity is no less than 12 l/min.

If the tank is not to be lled to the top, the lling procedure can be stopped manually at any time

(see action step 4 in the following section).

Switch on the pump (12).

Hold the nozzle valve (17) into the vehicle tank.

Press up the nozzle trigger (19) according to the desired delivery quantity

- or -

lock the nozzle trigger using the lock lever (18).

To end the delivery, release the nozzle trigger (19)

- or -

briey raise and release the locked nozzle trigger (19) to release the locking.

Switch o the pump (12).

Place the nozzle valve (17) on the fuel container.

9

Operating instructions electric pump PREMAxx G

4.3 Emergency operation

In the event of power failure, you can manually pump very small quantities of diesel or fuel oil.

Delivering fuel in manually operation:

Hold the nozzle valve (9 or 17) in the container or vehicle tank.

Press and hold the nozzle trigger (10 or 19), or lock it using the lock lever (18) (for automatic nozzle valve

version).

Pump the delivery uid into the container of vehicle tank using the manual lever (2) on the pump.

After nishing the delivery, place the nozzle valve (9 or 17) on the fuel container.

5. Disassembly

Disassembling the pump

Condition: The pump is switched o.

Disconnect the main plug.

Release the delivery hose (15) from the pressure union at the pump (13).

Unscrew the pump from the thread of the fuel container.

Slowly remove the pump with the suction hose (6) and the suction pipe (8). Let all diesel or heating fuel

run out completely from the suction hose and suction pipe.

Place the pump with hoses in an oil tray.

Let the emerging fuel oil or diesel run into the oil tray.

6. Maintenance

The PREMAxx electric pump is in principle low maintenance and low service.

Due to the operator duty according to § 191 WHG (in the case of Germany or the corresponding regu-

lations in other countries), the following parts of the pump must be checked regularly to avoid environ-

mental damage being caused by emerging fuel oil or diesel:

Pump housing (1)

Delivery hose (15)

Nozzle valve (9 bzw. 17)

In case of any damage the connecting cable has to be replaced or repaired by the manufacturer, by the

manufacturer’s service or by any other qualied person.

7. Repairs/service

The PREMAxx electric pump has been developed and manufactured according to the highest quality

standards.

If a problem should occur despite all quality measures taken, please get in touch with our service

contact partners:

FMT Swiss AG

Tel +49 9462 17-216

Fax +49 9462 1063

10

GOperating instructions electric pump PREMAxx

8. Declaration of EC Conformity

We herewith declare that the appliance described below corresponds with the EC guidelines with regards

to its design and type of construction as well as in the version as marketed by us. In the event of a change

to the appliances that has not been agreed with us, this declaration becomes null and void.

Name of appliance PREMAxx

230 V 1~AC • 24 V DC • 12 V DC

Appliance type electric pump

Year of construction see appliance sign

Applicable EC guidelines EC low voltage guideline (73/23/EWG)

EC guideline of electro magnetic compatibility (89/336/EWG) in

the version of 93/31/EWG

30.01.2013 FMT Swiss AG

Dipl.-Ing. Rudolf Schlenker

11

Operating instructions electric pump PREMAxx G

Other manuals for PREMAxx

1

Table of contents

Other FMT Swiss AG Water Pump manuals

Popular Water Pump manuals by other brands

aquanique

aquanique FPSeries operating instructions

YAMADA

YAMADA 140 Series instruction manual

Valex

Valex ESP551/3H operating instructions

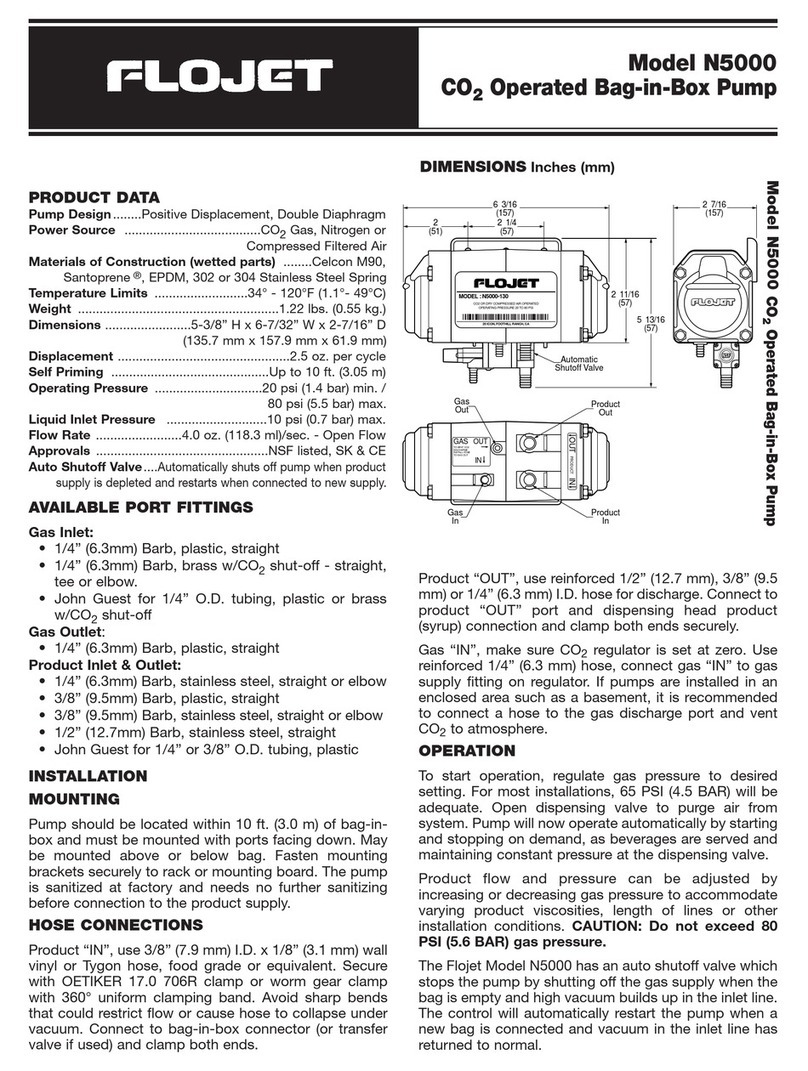

FLOJET

FLOJET N5000 manual

BLACKMER

BLACKMER SMVP50B Installation, operation and maintenance instructions

Wilo

Wilo Stratos ECO Series Installation and operating instructions