INSTALLATION

MOUNTING

Pump should be located within 10 ft. (3.0 m) of bag-in-

box and must be mounted with ports facing down. May

be mounted above or below bag. Fasten mounting

brackets securely to rack or mounting board. The pump

is sanitized at factory and needs no further sanitizing

before connection to the product supply.

HOSE CONNECTIONS

Product “IN”, use 3/8” (7.9 mm) I.D. x 1/8” (3.1 mm) wall

vinyl or Tygon hose, food grade or equivalent. Secure

with OETIKER 17.0 706R clamp or worm gear clamp

with 360° uniform clamping band. Avoid sharp bends

that could restrict flow or cause hose to collapse under

vacuum. Connect to bag-in-box connector (or transfer

valve if used) and clamp both ends.

Product “OUT”, use reinforced 1/2” (12.7 mm), 3/8” (9.5

mm) or 1/4” (6.3 mm) I.D. hose for discharge. Connect to

product “OUT” port and dispensing head product

(syrup) connection and clamp both ends securely.

Gas “IN”, make sure CO2regulator is set at zero. Use

reinforced 1/4” (6.3 mm) hose, connect gas “IN” to gas

supply fitting on regulator. If pumps are installed in an

enclosed area such as a basement, it is recommended

to connect a hose to the gas discharge port and vent

CO2to atmosphere.

OPERATION

To start operation, regulate gas pressure to desired

setting. For most installations, 65 PSI (4.5 BAR) will be

adequate. Open dispensing valve to purge air from

system. Pump will now operate automatically by starting

and stopping on demand, as beverages are served and

maintaining constant pressure at the dispensing valve.

Product flow and pressure can be adjusted by

increasing or decreasing gas pressure to accommodate

varying product viscosities, length of lines or other

installation conditions. CAUTION: Do not exceed 80

PSI (5.6 BAR) gas pressure.

The Flojet Model N5000 has an auto shutoff valve which

stops the pump by shutting off the gas supply when the

bag is empty and high vacuum builds up in the inlet line.

The control will automatically restart the pump when a

new bag is connected and vacuum in the inlet line has

returned to normal.

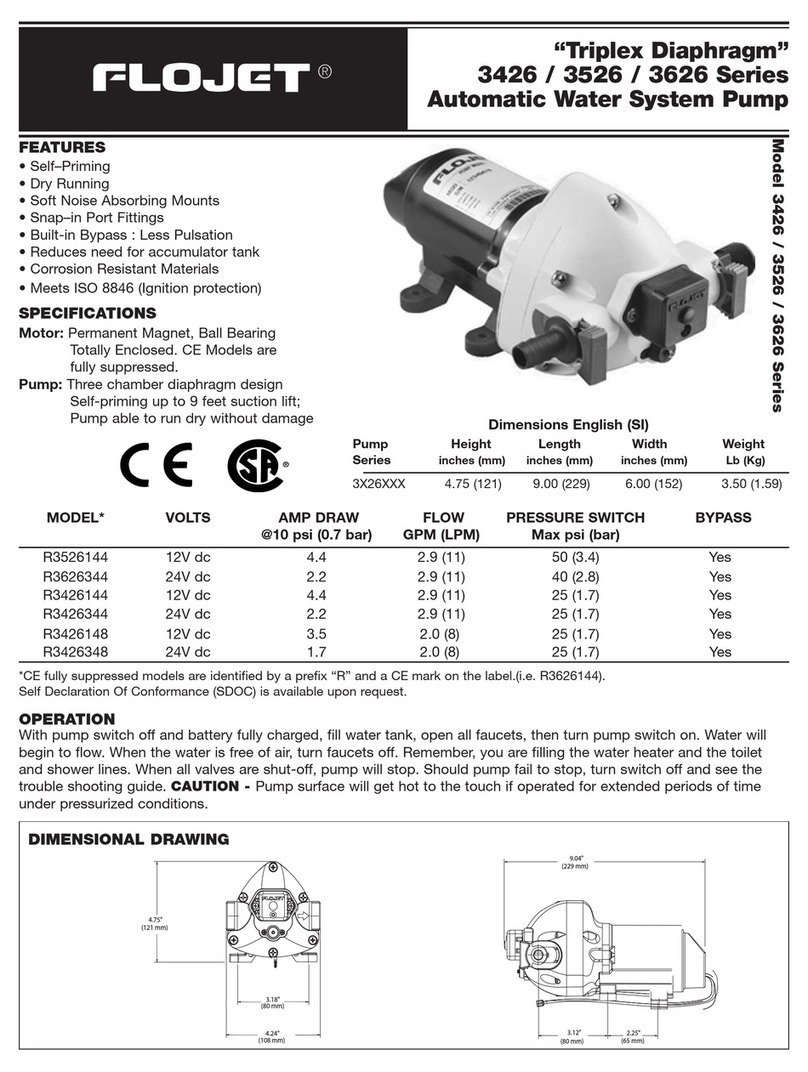

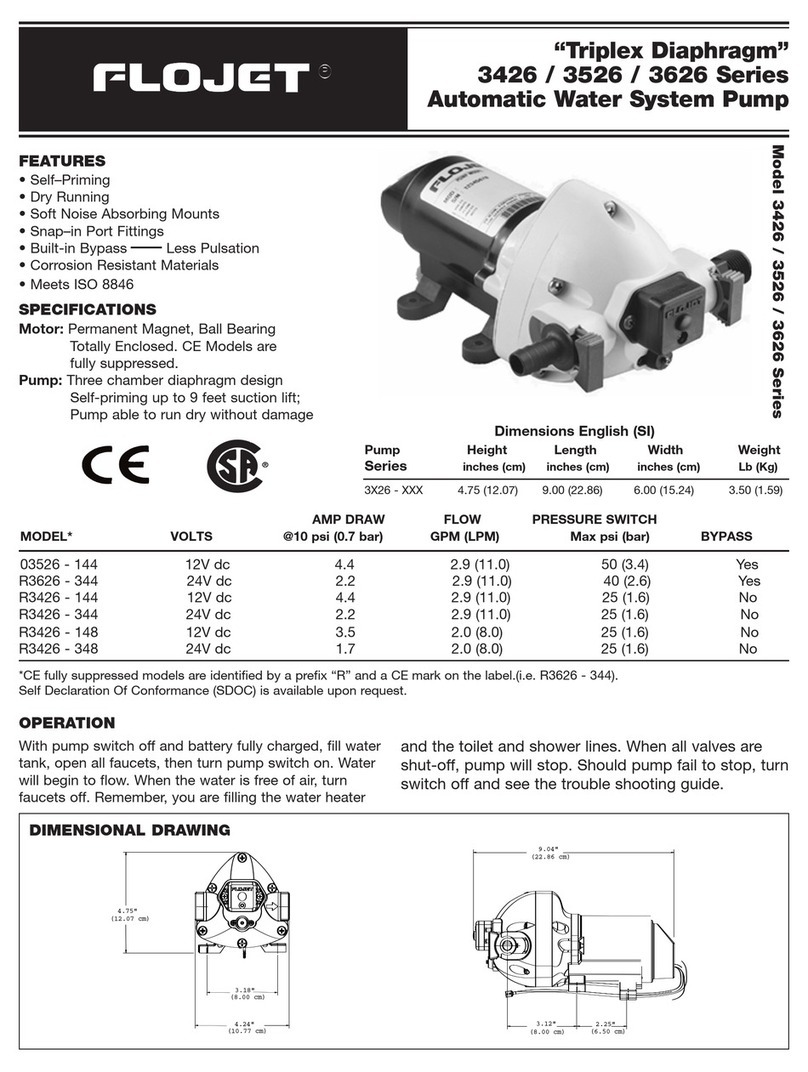

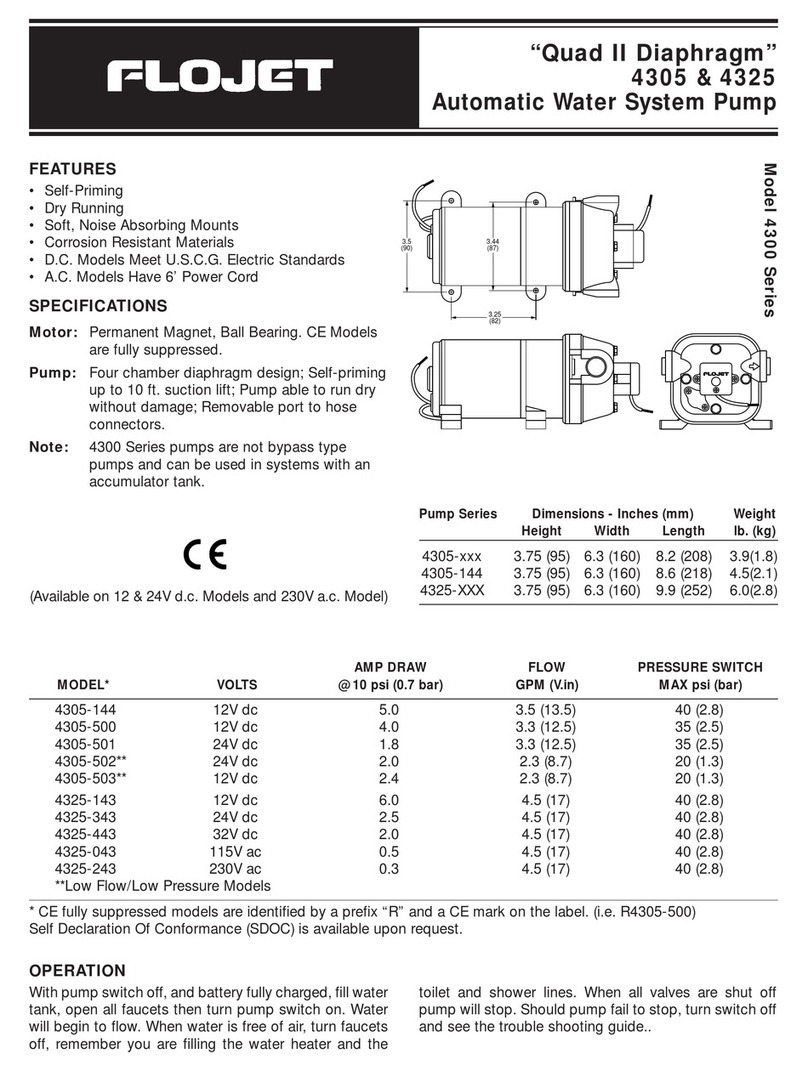

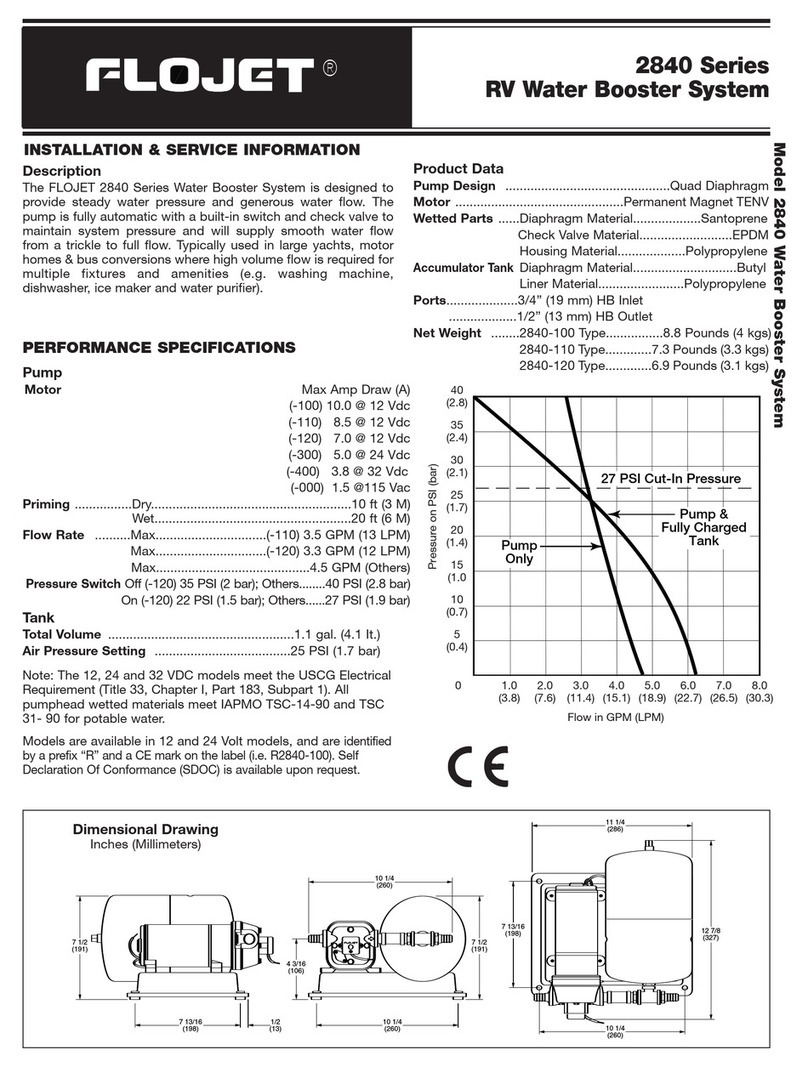

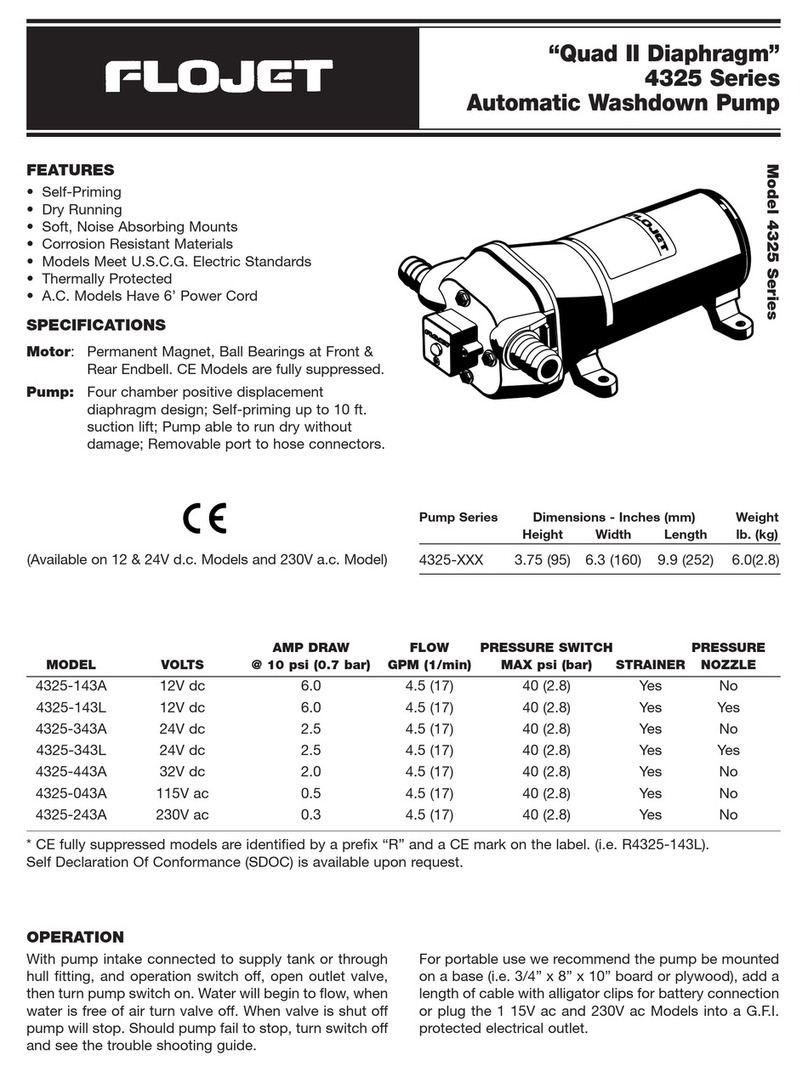

DIMENSIONS Inches (mm)

PRODUCT DATA

Pump Design ........Positive Displacement, Double Diaphragm

Power Source ......................................CO2Gas, Nitrogen or

Compressed Filtered Air

Materials of Construction (wetted parts) ........Celcon M90,

Santoprene ®, EPDM, 302 or 304 Stainless Steel Spring

Temperature Limits ..........................34° - 120°F (1.1°- 49°C)

Weight ........................................................1.22 lbs. (0.55 kg.)

Dimensions ........................5-3/8” H x 6-7/32” W x 2-7/16” D

(135.7 mm x 157.9 mm x 61.9 mm)

Displacement ................................................2.5 oz. per cycle

Self Priming ............................................Up to 10 ft. (3.05 m)

Operating Pressure ..............................20 psi (1.4 bar) min. /

80 psi (5.5 bar) max.

Liquid Inlet Pressure ............................10 psi (0.7 bar) max.

Flow Rate ........................4.0 oz. (118.3 ml)/sec. - Open Flow

Approvals ................................................NSF listed, SK & CE

Auto Shutoff Valve....

Automatically shuts off pump when product

supply is depleted and restarts when connected to new supply.

AVAILABLE PORT FITTINGS

Gas Inlet:

• 1/4” (6.3mm) Barb, plastic, straight

• 1/4” (6.3mm) Barb, brass w/CO2shut-off - straight,

tee or elbow.

• John Guest for 1/4” O.D. tubing, plastic or brass

w/CO2shut-off

Gas Outlet:

• 1/4” (6.3mm) Barb, plastic, straight

Product Inlet & Outlet:

• 1/4” (6.3mm) Barb, stainless steel, straight or elbow

• 3/8” (9.5mm) Barb, plastic, straight

• 3/8” (9.5mm) Barb, stainless steel, straight or elbow

• 1/2” (12.7mm) Barb, stainless steel, straight

• John Guest for 1/4” or 3/8” O.D. tubing, plastic