FNW ASD Series Guide

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

PNEUMATIC ACTUATORS

ASD SERIES

SPRING-DIAPHRAGM ROTARY ACTUATORS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

This instruction manual includes installation, operation

and maintenance information for FNW Pneumatic Spring-

Diaphragm Actuators. Please read these instructions

carefully and save them for future reference. It is important

that only properly trained personnel disassemble or

assemble the actuator.

GENERAL PRODUCT DESCRIPTION

The FNW Spring-Diaphragm Actuator is specifically

designed for the safe and reliable operation of quarter turn

valves under minimal media supply pressure. The design

separates the supply media chamber from the spring sets,

allowing for usage of unfiltered air, gas, water or mineral-

based hydraulic fluid. The housing is constructed from

ductile iron and carbon steel castings coated in a

UV-resistant polyester powder coating for exceptional

corrosion resistance in the field. The independent media

chamber is also equipped with a standard LNBR diaphragm

reinforced with a special compound polyamine fabric.

Optional diaphragm materials allow for working temperature

ranges as low as -40°C (-40°F) or as high as 170°C (338°F).

1. CAUTION/IMPORTANT SAFETY WARNINGS

• Only authorized and properly trained personnel should perform installation and maintenance of the actuator. Proper PPE

should be used as required.

• Before working on a FNW Spring-Diaphragm Actuator, please note that all fasteners and screw threads are metric except

for the JB mount screw threads which are imperial.

• For correct and safe operation, pneumatic actuators must be sized adequately and with sufficient safety margin of torque

output for the correct operating conditions of the valve or application.

• Operating the actuator beyond its stated maximum operating limits of temperature, pressure or recommended operating media

can cause damage to the internal components, actuator housing or result in personal safety risks involving death or injury.

• Before carrying out any installation, repair or maintenance on the actuator, make sure that the electrical connections have

been safely isolated, removed or disconnected by authorized personnel. All pneumatic supply lines should be shut-off,

removed and completely bled. The actuator must not be pressurized at any time during installation, repair or maintenance

unless otherwise noted in the instructions, as injury may result.

• Never put any part of your body in the opening or port of the controlled valve or device.

• Special attention and precautions should be observed due to the stored energy contained in the spring cartridge. Do not

attempt to disassemble the spring cartridge. Disassembly may result in damage or personal injury. If maintenance is required for

the spring cartridge, the entire actuator should be returned to FNW for assistance. Please contact FNW for additional information.

• When servicing a valve actuator assembly, the best practice is to remove the entire assembly from service. If the actuator

is removed from the valve, it should be remounted on the same valve after servicing is completed. The actuator must be

readjusted for proper open and close position each time it is remounted.

• Before installing the valve and actuator, be sure that the indicator pointer () on top of the actuator and the indicator plate

() are correctly indicating the valve position. Failure to assemble the valve and actuator to the correct valve position could

result in damage or personal injury.

• Do not lift actuators using the /" NPT in the diaphragm cover. Actuators should be handled using lifting straps as seen in

Section .

• Use only FNW-recommended spare parts for maintenance.

• To ensure safety and to maintain warranty, never modify the actuator in any way not indicated in this manual without prior

approval from FNW.

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

PNEUMATIC ACTUATORS

ASD SERIES

SPRING-DIAPHRAGM ROTARY ACTUATORS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

2. STORAGE

ATTENTION: If the actuators are not destined for immediate use, the following storage precautions should be taken:

• Ensure the actuators are completely dry and water free.

• Protect openings of air passages by fitting the original or replacement plastic corks if required.

• If possible, leave the actuators in their packaging during storage. Actuators should be protected to safeguard against humidity,

moisture, dust, dirt, sand, mud, salt spray, sea water or other forms of corrosive and erosive environments.

3. OPERATING CONDITIONS

The operating pressure, output torque and drive type are determined by the actuator designation as shown in the below table.

Actuator designation example:

ASDC-MJ-FS-MN is an ASD spring diaphragm actuator that has a - psi (. - . Bar) spring, an end of spring stroke output

torque of in-lbs ( Nm), uses a × mm female double square and F + JB + F mount configuration to connect and drive

the valve. This actuator is with NAMUR stem.

Actuator

Series

Flange Mount Configuration

Spring

Version

Operating Pressure

psi (Bar)

End of Spring

Stroke Torque

in-lbs (N-m)

Drive Type

MI MJ

Female

Double

Squares

(FS)

Female

Keyed (FK)

Female

Double D

Flat

Dimension

(FD)

Male

Square /

Star (MQ/

MT)

Male

Double D

Flat

Dimension

(MD)

ASD2 F05 + F07 F05 + JB51 + F07

A12 - 20 (0.8 - 1.3)*133 (15)

14 mm 14 mm 14 mm 14 mm 14 mm

B1 30 - 50 (2.0 - 3.4)460 (52)

B2 40 -60 (2.8 - 4.1)593 (67)

C50 - 70 (3.4 -4.8)682 (77)

D60 - 90 (4.1 - 6.2)885 (100)

ASD3 F07 + F10 JB76 + F10

A12 - 20 (0.8 - 1.3)*310 (35)

22 mm 22 mm 17 mm 19 mm 17 mm

B1 30 - 50 (2.0 - 3.4)912 (103)

B2 40 -60 (2.8 - 4.1)1174 (133)

C50 - 70 (3.4 -4.8)1372 (155)

D60 - 90 (4.1 - 6.2)1752 (198)

ASD4 F10 + F12 F10 + JB108 + F12

B1 30 - 50 (2.0 - 3.4)1832 (207)

27 mm 36 mm 22 mm 25 mm 22 mm

B2 40 -60 (2.8 - 4.1)2366 (267)

C50 - 70 (3.4 -4.8)2752 (311)

D60 - 90 (4.1 - 6.2)3532 (399)

ASD5 F10 + F14 F10 + JB108 + F14

B1 30 - 50 (2.0 - 3.4)3664 (414)

36 mm 40 mm 27 mm 25 mm 27 mm

B2 40 -60 (2.8 - 4.1)4720 (533)

C50 - 70 (3.4 -4.8)5496 (621)

D60 - 90 (4.1 - 6.2)7045 (796)

ASD6 F16 F16

B1 30 - 50 (2.0 - 3.4)6595 (745)

46 mm 50 mm 46 mm 46 mm 46 mm

B2 40 -60 (2.8 - 4.1)8496 (960)

C50 - 70 (3.4 -4.8)9893 (1118)

D60 - 90 (4.1 - 6.2)12680 (1433)

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

PNEUMATIC ACTUATORS

ASD SERIES

SPRING-DIAPHRAGM ROTARY ACTUATORS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

Operating Media

Air (max particle size µm), gas, water or mineral-based hydraulic fluid

Air Supply Pressure

Minimum operating pressure: bar ( psi)

Maximum operating pressure: bar ( psi)

Operating Temperature

Standard: -°C to °C (-°F to °F)

Low*: -°C to °C (-°F to °F)

High: -°C to °C (-°F to °F)

Travel Adjustment

+/- ° rotation adjustment at open or closed positions

Application

Suitable for both indoor and outdoor use

Lubrication

The actuator comes pre-lubricated; no additional lubrication is required except during maintenance activities.

*Standard Construction

4. OPERATING PRINCIPAL

Spring Stroke

Upon loss of pressure (air) on Port A, the stored energy in the

compressed springs forces the diaphragm retainer and connection

rod to move right and the crankshaft to rotate clock-wise. This

movement can be limited by using the adjustable close stop.

Field Reversible: Fail-closed and Fail-open operation is achieved

by inverting the actuator, as shown on page .

Air Stroke

Upon the supply of media (air) to Port A, the pressure forces the

diaphragm retainer and connection rod to move left, compressing

the springs and rotating the crankshaft counter clock-wise. This

movement can be limited by using the adjustable open stop.

Spring Stroke

Port A

Port A

Open stop

Open stop

Close stop

Close stop

Crankshaft

Crankshaft

Connecting rod

Connecting rod

Retainer

Retainer

Diaphragm

Diaphragm

Air Stroke

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

PNEUMATIC ACTUATORS

ASD SERIES

SPRING-DIAPHRAGM ROTARY ACTUATORS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

5. HANDLING

Lifting Straps

Lifting straps should be used to safely handle the actuator

as shown in the figure to the right. Approximate weights can

be found in the below table. Lifting straps should be in good

condition and of sufficient size and material to handle the load.

WARNING: Do not lift actuators using the 1/4" NPT in the

diaphragm cover.

Handling ASD Actuators

Actuator Series Approx Weight Kg (lbs)

ASD2 21 (46)

ASD3 33 (73)

ASD4 61 (134)

ASD5 107 (236)

ASD6 177 (390)

Eyebolts

Eyebolts are available in actuator sizes ASD, ASD and ASD to assist with proper lifting technique. The maximum weight load for the

eyebolts is . times the actuator weight. The eyebolts can only be used to lift the actuator itself.

WARNING: The eyebolts cannot be used for handling of an actuator and valve assembly. This could lead to damage or

personal injury.

For sizes ASD and ASD, the eyebolts are not available. Lifting straps should be used when handling the actuators.

6. VALVE AND ACCESSORY ASSEMBLY

The following should be noted prior to assembly to the valve:

• Verify that the position indicator on the actuator is assembled correctly for the desired failure mode, either spring-to-close or spring-

to-open. In the spring-to-close mode, the actuator will cycle clockwise to close upon loss of pressure. In the spring-to-open mode, the

actuator will cycle counterclockwise to open upon loss of pressure.

• If the actuator is not set up in the configuration desired, remove the hex head cap screws (), indicator plate (), indicator pointer (),

and remount them on the opposite mounting surface.

• Mount the actuator to the valve following ISO standards, the specific Valve Operating Manual, and the directions below:

- Check that the valve and actuator are in the same position (open or closed). Check the correct positioning (alignment) of all the

elements of the assembly, including the valve, connection piece, bracket, accessories and actuator.

- In spring-to-close mode, close the valve and then mount the actuator on the valve.

- In spring-to-open mode, open the valve, invert the actuator, and then mount the actuator on the valve.

- Fit the square of the valve directly into the square of the actuator.

- Ensure the actuator base is flat against the valve mounting flange and bolt together.

- Torque the mounting screws in a diagonal pattern to equalize loading. Ensure all position indicators are correctly adjusted and show

the correct positions.

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

PNEUMATIC ACTUATORS

ASD SERIES

SPRING-DIAPHRAGM ROTARY ACTUATORS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

Spring-to-Close

• Mount the accessories, such as a limit switch box or valve positioner, to the actuator following NAMUR (VDI/VDE ) standards. The

accessory can be directly mounted on the cover () of the actuator in spring-to-close mode. In spring-to-open mode, the accessory can

be directly mounted on the driver housing () of the actuator.

• Mount the NAMUR solenoid valve to the actuator following Namur (VDI/VDE ) standards for direct install on the diaphragm cover

(). A regulated air supply can be connected to the /" NPT fitting in the diaphragm cover ().

CAUTION: The maximum operating pressure is 100 psi (7 BAR).

Spring-to-Open Mount Namur Solenoid Valve

7. VALVE POSITION LIMIT ADJUSTMENT

CAUTION: The maximum rotation adjustment is ±5˚.

Adjust the travel stop screws () by releasing the hex jam nut (.) and turning. Stops can only be adjusted when driver arm () is off

the stop screw being adjusted. Be sure to re-tighten hex jam nut (.) after adjustment.

Driver arm () Driver arm ()

Open stop

screw

Close stop

screw

Close stop adjustment Open stop

screw

Close stop

screw

Close stop adjustment

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

PNEUMATIC ACTUATORS

ASD SERIES

SPRING-DIAPHRAGM ROTARY ACTUATORS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

8. DRIVE BUSH DISASSEMBLY AND ASSEMBLY

Using the removable drive bush (), drive styles can be quickly changed to the desired type by following the below steps:

, Remove the four socket head

screws from the drive bushing.

, Insert two of the socket head

screws into the tapped holes to

push out the drive bushing.

, Install new drive bushing.

9. MECHANICAL LOCKOUT

The actuator can be locked in the spring failure mode. Adjust the

set screw () by releasing the hex jam nut (.) and turning. The

actuator will be locked in any position from close to open.

Shown mechanically locked in the spring failure mode

10. GENERAL MAINTENANCE

Under normal operating conditions, the FNW Spring-Diaphragm Actuator requires only periodic checks to ensure proper adjustment.

Standard replacement items generally consist of bearings and diaphragms. These are numbered , , , and in the BOM.

NOTE: Keep the drive bushing in equilibrium when pushing it out. After installing a new drive bush, retighten the socket head bushing

screws ().

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

PNEUMATIC ACTUATORS

ASD SERIES

SPRING-DIAPHRAGM ROTARY ACTUATORS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

Replacing the Diaphragm

CAUTION: Ensure that pneumatic supply lines are properly bled and disconnected. All electrical connections should be safely isolated

and removed.

• While safely holding the diaphragm casing and spring housing together, back off the nuts () from the hex head screws (. and

.), until the nuts are flush with the hex head screw ends. Do not remove the nuts completely from the hex head screws.

If tension still exists on the hex head screws, then the spring package is not properly contained. Stop disassembly, retighten nuts and

return the actuator to FNW. If the spring package is intact, continue to remove the nuts (), spring-washers (), gaskets (), and

remove the hex head screws ().

• Lift off the diaphragm cover (). For ASD, ASD and ASD models, remove hex head cap screw (.) and retaining washer (.)

first. Remove the diaphragm ().

• Inspect the inside of the diaphragm cover (), the diaphragm retainer () and the spring housing () for any debris, rough spots, or

other issues that could damage the diaphragm.

• Place the new diaphragm () on the diaphragm retainer (). Do not pinch or stretch the diaphragm. For ASD, ASD and ASD

models, assemble the retainer washer (.) and retaining cap screw (.). Tighten to value shown in the torque requirements table on

page . Ensure that the spring housing () holes are aligned with diaphragm () holes. Place the diaphragm cover () on the spring

housing () such that all holes remain aligned across the spring housing, diaphragm, and cover.

• Insert hex head screws () into all holes. Caution: Do not force the hex head screws through the diaphragm. If necessary, realign all

holes across the spring housing, diaphragm, and cover. Install spring-washers (), gaskets () and nuts () on all screws and tighten.

Standard practice bolt pattern tightening methods should be used with the torque requirements from the table on page .

37.2 383523

20

39.1

21 22

37.137

39.2

WARNING:

DISASSEMBLY OF THE SPRING PACKAGE SHOULD NOT BE ATTEMPTED. SPECIAL EQUIPMENT IS REQUIRED.

DISASSEMBLY OF THE SPRING PACKAGE MAY RESULT IN SERIOUS PERSONAL INJURY. IF MAINTENANCE IS REQUIRED,

SHIP THE ENTIRE ACTUATOR TO FNW.

11. ACTUATOR DISASSEMBLY AND MAINTANENCE

CAUTION: When the actuator is a spring return unit, make sure that the actuator is in the failed position before disassembling

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

PNEUMATIC ACTUATORS

ASD SERIES

SPRING-DIAPHRAGM ROTARY ACTUATORS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

Remove the actuator from service following all standard safety procedures. Move to a clean well-lit area, following the handling

instructions in Section . Refer to the parts and materials list for identification.

• Remove the drive bushing () by removing the socket head screws (). Use the socket

head cap screws () to push out the drive bush () from the actuator. Repeat for NAMUR

Stem (). Be sure to keep the drive bushing in equilibrium when pushed-out.

• Remove the cover () by removing the socket cap screws (). If the cover cannot be

removed, tap it with a plastic hammer to break any adhesion between the body and cover

joint. Removing the spring housing () from the driver housing () is not always necessary.

However, if removal is required, the information in the Torque Requirements table on

page must be followed upon reassembly. Inspect and clean all components.

• Use air pressure to remove any spring preload by partially stroking the actuator. If the

diaphragm () is ruptured, replace as instructed in the previous section.

• To remove the socket shoulder screw () that holds the clevis () to the driver arm ():

Slowly increase air pressure until the driver arm () moves slightly off the stop screw ().

• Remove the socket shoulder screw (), per diagram B.

• Slowly relieve the air pressure in the actuator. The clevis () should be set against the spring

retainer () and positioned symmetrically about the slot in the spring housing per diagram C.

• Shut off and bleed the air pressure to zero. Disconnect the air lines.

• While safely holding the diaphragm casing and spring housing together, back off the nuts

() from the hex head screws (. and .) until the nuts are flush with the hex head screw

ends. Do not remove the nuts completely from the hex head screws. If tension still exists on

the hex head screws, then the spring package is not properly contained. Stop disassembly,

retighten nuts and return the actuator to FNW. If the spring package is intact, continue to

remove the nuts (), spring-washers (), gaskets (), and remove the hex head screws ().

• Lift off the diaphragm cover (). For models ASD, ASD and ASD, remove the hex

head cap screw (.) and retaining washer (.). Remove the diaphragm (). Inspect the

diaphragm for signs of wear, rupture or mechanical damage. Refer to Diagram D.

• Inspect the inside of the diaphragm cover (), the diaphragm retainer () and the spring

housing () for any debris, rough spots, or other issues that could damage the diaphragm.

• Lift the entire spring cartridge out of the unit. Do not attempt to disassemble the

spring cartridge.

5

6

7

8

19

26 30

2612

3717 24

P

37

37.1

38

37

.

1

37.2

Spring Cartridge

DIAGRAM A

5

6

7

8

19

26 30

2612

3717 24

P

37

37.1

38

37

.

1

37.2

Spring Cartridge

DIAGRAM B

5

6

7

8

19

26 30

2612

3717 24

P

37

37.1

38

37

.

1

37.2

Spring Cartridge

DIAGRAM C

5

6

7

8

19

26 30

2612

3717 24

P

37

37.1

38

37

.

1

37.2

Spring Cartridge

DIAGRAM D

5

6

7

8

19

26 30

2612

3717 24

P

37

37.1

38

37

.

1

37.2

Spring Cartridge

Spring cartridge of

ASD and ASD

5

6

7

8

19

26 30

2612

3717 24

P

37

37.1

38

37

.

1

37.2

Spring Cartridge

Spring cartridge of

ASD, ASD,ASD

Torque

TOOL LIST

Hex (Allen) wrench:

mm (ASD/ASD/ASD)

mm (ASD/ASD)

Flathead

screwdriver

Plastic faced mallet

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

PNEUMATIC ACTUATORS

ASD SERIES

SPRING-DIAPHRAGM ROTARY ACTUATORS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

12. ACTUATOR ASSEMBLY

CAUTION: To aid assembly, a commercial lubricant which is compatible with the gasket and diaphragm materials can be used.

• Press driver arm bearings () into the driver housing () and cover (). An arbor press should be used as best practice; however, a vise can

be used if care is taken not to damage the bearings or other components. Driver arm bearings should be pressed in until they are flush or

. inch (.mm) below the driver housing counterbore or the inside cover surface. Press clevis bearings () into the clevis ().

• Apply lubricant to inside of bearings for the driver arm only. Do not lubricate the clevis. Instead, lubricate the barrel of the shoulder

screw ().

• Place one thrust bearing () into the counterbore of the actuator drive housing (). Slide the second thrust bearing () onto the

trunnion of the driver arm (). Place the driver into the driver housing ().

• Lower the spring cartridge into the spring housing (). Ensure the spring package is not resting on the hex head cap screws () that

hold the spring housing and driver housing together. If the diaphragm retainer bearing () has separated from diaphragm retainer (),

hold in place while lowering spring cartridge into housing.

• Place the new diaphragm () on the diaphragm retainer () and attach. For ASD, ASD and

ASD models, assemble washer (.) and hex head cap screw (.). Torque to the value specified

in the below Torque Requirements table.

• Insert the hex head bolts (. and .) in all holes. Do not force the bolts through the diaphragm.

Install nuts () and tighten using standard bolt pattern tightening practice of tightening diametrically

opposite bolts in sequence. Torque to the value specified in the below Torque Requirements table.

• Connect a clean, regulated air supply to the pressure port () and slowly increase the air pressure

until the holes in the clevis () and driver arm () are aligned (refer to the Diagram C). If required, turn

the clevis a few degrees to align the holes.

CAUTION: Do not exceed the max recommended air pressure.

• Lubricate the threads of the shoulder screw (). Install it through the driver arm () and clevis (). Firmly hold the clevis with a wrench

or other appropriate tool while tightening the shoulder screw. Caution: An unsupported driver arm may tend to tip over. Tighten screws

per the below Torque Requirements table.

• Slowly release the air pressure. Assemble the cover () with the socket head screws (). Tighten screws per the below Torque

Requirements table.

• Install the drive bush () onto the driver arm (). Be sure that the cylindrical pins () are aligned with the cylindrical holes in the driver

bush (). Tap the bush with a plastic hammer to insert the bush into the correct position. Install the socket head bush screws () and

tighten uniformly using the standard practice of tightening diametrically opposite bolts in sequence. Tighten screws per the below

Torque Requirements table. Repeat process for the NAMUR stem ().

• Install the indicator pointer () and indicator plate (), if previously disassembled. Refer to the installation instructions for spring-to-close

and spring-to-open configuration.

2612

3717

P

1

2

3

5

4

6

7

8

9

10

11

12

13

14

15

16.1

16

17

17.1

1918

24

20

21

22 23 37

37.1

37.2 38 .193

(ASD2,ASD3)

(ASD4,ASD5,ASD6)

(ASD2,ASD3)

Spring Cartridge

Spring Cartridge

.293

Torque Requirements

Required Tightening Torques in ft-lbs (N-m) for various fasteners

ASD2 ASD3 ASD4 ASD5 ASD6

Nuts (20)for hex head screw assembly through diaphragm 24 (32)24 (32)24 (32)24 (32)24 (32)

Socket head cover screws (7)6 (8)6 (8)6 (8)15 (20)24 (32)

Socket head shoulder screws (24)55 (75)132 (179)132 (179)132 (179)132 (179)

Socket head bush screws (5)4 (6)5 (7)6 (8)11 (15)15 (20)

Hex head screws (36)between driver housing and spring housing 18 (24)30 (40)30 (40)55 (75)55 (75)

Hex head cap screws (37.1) for attaching the diaphragm to the retainer NA NA 10 (14) 17 (23) 17 (23)

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

PNEUMATIC ACTUATORS

ASD SERIES

SPRING-DIAPHRAGM ROTARY ACTUATORS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

13. PARTS AND MATERIAL LIST

No Part Name Qty Material Surface Treatment

ASD2/3 ASD4/5 ASD6

1Snap Ring 1 1 1 Stainless Steel 304

2Indicator Pointer 1 1 1 Stainless Steel 304

3 Hex Head Cap Screw 3 3 3 Stainless Steel 304

4Indicator Plate 1 1 1 Stainless Steel 304

5 Socket Head Bushing Screw 8 8 8 Stainless Steel 304

6NAMUR Drive Bushing 1 1 1 Carbon Steel Chemically Coated Nickel

7 Socket Head Cap Screw 6 6 6 Stainless Steel 304

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

PNEUMATIC ACTUATORS

ASD SERIES

SPRING-DIAPHRAGM ROTARY ACTUATORS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

No Part Name Qty Material Surface Treatment

ASD2/3 ASD4/5 ASD6

8Cover 1 1 1 Carbon Steel Polyester Powder Coated

9Driver Arm Bearing 2 2 2 Stainless Steel w/Acetal Lining

10 Thrust Bearing 222 Nylon

11 Cylindrical Pin 8 8 8 Carbon Steel

12 Driver Arm 1 1 1 Ductile Iron Chemically Coated Nickel

13 Driver Housing 111 Ductile Iron Polyester Powder Coated

14 Cylindrical Pin 2 2 2 Stainless Steel 304

15 Nameplate 1 1 1 Stainless Steel 304

16 Set Screw 1 1 1 Stainless Steel 304

16.1 Hex Jam Nut 1 1 1 Stainless Steel 304

17 Travel Stop Screw 2 2 2 Stainless Steel

17.1 Hex Jam Nut 2 2 2 Stainless Steel 304

18 Breather 1 1 1 Stainless Steel 316

19 Drive Bushing 1 1 1 Carbon Steel Chemically Coated Nickel

20 Lock Nut 12 12 24 Stainless Steel

21 Spring Washer 12 12 24 Stainless Steel

22 Gasket 24 24 48 Stainless Steel

23 Spring Housing 1 1 2 Carbon Steel Polyester Powder Coated

24 Shoulder Screw 1 1 2 Carbon Steel

25 Clevis Bearing 1 1 2 Stainless Steel w/Acetal Lining

26 Clevis 1 1 2 Carbon Steel

27 Hex Jam Nut 1 1 2 Stainless Steel 304

28 Actuator Rod 1 1 2 Carbon Steel

29 Hex Jam Nut 1 1 2 Carbon Steel

30 Spring Retainer 1 1 2 Carbon Steel Polyester Powder Coated

31/32 Compression Springs 1 1 2 55 Mn Spring Steel Polishing Capacitance Coated

33 Spring Retainer Plate 1 Carbon Steel Polyester Powder Coated

34 Diaphragm Retainer Bearing 112 POM

34.1 Diaphragm Retainer Bearing Pin 12 UHMWPE

35 Diaphragm Retainer 1 1 2 Carbon Steel Polyester Powder Coating

36 Hex Head Cap Screw 4 4 8 Carbon Steel

37 Diaphragm (Optional)1 1 2 NBR/Nylon 66 Fabric Blend (-25°C – 70°C)

37 Diaphragm* 1 1 2 LNBR/Nylon 66 Fabric Blend (-40°C – 70°C)

37 Diaphragm (Optional)112EPDM4/Polyester Fabric Blend (-29°C – 170°C)

37 Diaphragm (Optional)112Viton/NOMEX Fabric Blend (-15°C – 200°C)

37.1 Retainer Washer NA 1 2 Stainless Steel

37.2 Hex Head Cap Screw NA 1 2 Stainless Steel

38 Diaphragm Cover 1 1 1 Carbon Steel Polyester Powder Coated

39.1 Hex Head Cap Screw (Long)2 2 4 Stainless Steel 304

39.2 Hex Head Cap Screw (Short)10 10 20 Stainless Steel 304

*Standard Construction

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

PNEUMATIC ACTUATORS

ASD SERIES

SPRING-DIAPHRAGM ROTARY ACTUATORS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

14. LIMITED WARRANTY

Warranty

Subject to the limitations expressed herein, Seller warrants that products manufactured by Seller shall be free from defects in design,

material and workmanship under normal use for a period of one year from installation but in no case shall the warranty period extend

longer than eighteen months from the date of sale. This warranty is void for any damage caused by misuse, abuse, neglect, acts of God,

or improper installation. For the purpose of this section, “Normal Use” means in strict accordance with the installation, operation and

maintenance manual. The warranty for all other products is provided by the original equipment manufacturer.

Claim Process and Remedies

Seller shall repair or replace, at its option, any non-conforming or otherwise defective product, upon receipt of notice from Buyer

during the Manufacturer’s warranty period at no additional charge. SELLER HEREBY DISCLAIMS ALL OTHER EXPRESSED OR IMPLIED

WARRANTIES, INCLUDING, WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS OR FITNESS FOR

A PARTICULAR PURPOSE.

In order to file a claim under the terms of this Warranty, a claimant must promptly notify FNW that a product may be defective within

days of the suspected failure or defect via the telephone number, mail or website listed below and may be required to submit proof of

purchase and/or photographs.

• Telephone: ---

• Mailing Address:

Lakefront Commons, Newport News, VA

• Website: fnw.com

All products alleged to be defective must be sent to FNW for inspection and testing for determination of the cause of the alleged defect

or failure.

Limitation of Liability

UNDER NO CIRCUMSTANCES SHALL EITHER PARTY BE LIABLE TO THE OTHER FOR INCIDENTAL, PUNITIVE, SPECIAL OR

CONSEQUENTIAL DAMAGES OF ANY KIND. BUYER HEREBY ACKNOWLEDGES AND AGREES THAT UNDER NO CIRCUMSTANCES,

AND IN NO EVENT, SHALL SELLER’S LIABILITY, IF ANY, EXCEED THE NET SALES PRICE OF THE DEFECTIVE PRODUCT(S)

PURCHASED DURING THE PREVIOUS CONTRACT YEAR.

Labor Allowance

Seller makes NO ADDITIONAL ALLOWANCE FOR THE LABOR OR EXPENSE OF REPAIRING OR REPLACING DEFECTIVE PRODUCTS

OR WORKMANSHIP OR DAMAGE RESULTING FROM THE SAME.

Recommendations by Seller

Seller may assist Buyer in selection decisions by providing information regarding products that it manufactures and those manufactured

by others. However, Buyer acknowledges that Buyer ultimately chooses the product’s suitability for its particular use, as normally

signified by the signature of Buyer’s technical representative. Any recommendations made by Seller concerning the use, design,

application or operation of the products shall not be construed as representations or warranties, expressed or implied. Failure by Seller

to make recommendations or give advice to Buyer shall not impose any liability upon Seller.

Excused Performance

Seller will make a good faith effort to complete delivery of the products as indicated by Seller in writing, but Seller assumes no responsibility

or liability and will accept no back charge for loss or damage due to delay or inability to deliver, caused by acts of God, war, labor difficulties,

accidents, inability to obtain materials, delays of carriers, contractors or suppliers or any other causes of any kind whatever beyond the

control of Seller. Under no circumstances shall Seller be liable for any special, consequential, incidental, or indirect damages, losses, or

expense (whether or not based on negligence) arising directly or indirectly from delays or failure to give notice of delay.

This manual suits for next models

5

Table of contents

Other FNW Controllers manuals

Popular Controllers manuals by other brands

TiSUN

TiSUN SIMPLEX user guide

Behringer

Behringer CP3A-O quick start guide

Tech Controllers

Tech Controllers EU-391 zPID user manual

Johnson Controls

Johnson Controls CK721-A Factory Field Upgrade

Physik Instrumente

Physik Instrumente C-863 Mercury user manual

AB Quality

AB Quality SD3000 PLUS installation instructions

Deep Sea Electronics Plc

Deep Sea Electronics Plc 8620 Installation instructions and instructions for use

Honeywell

Honeywell Alerton ACM installation instructions

Sven

Sven Neo R 600 Operation manual

Comparato

Comparato DIAMANT CLIMA installation manual

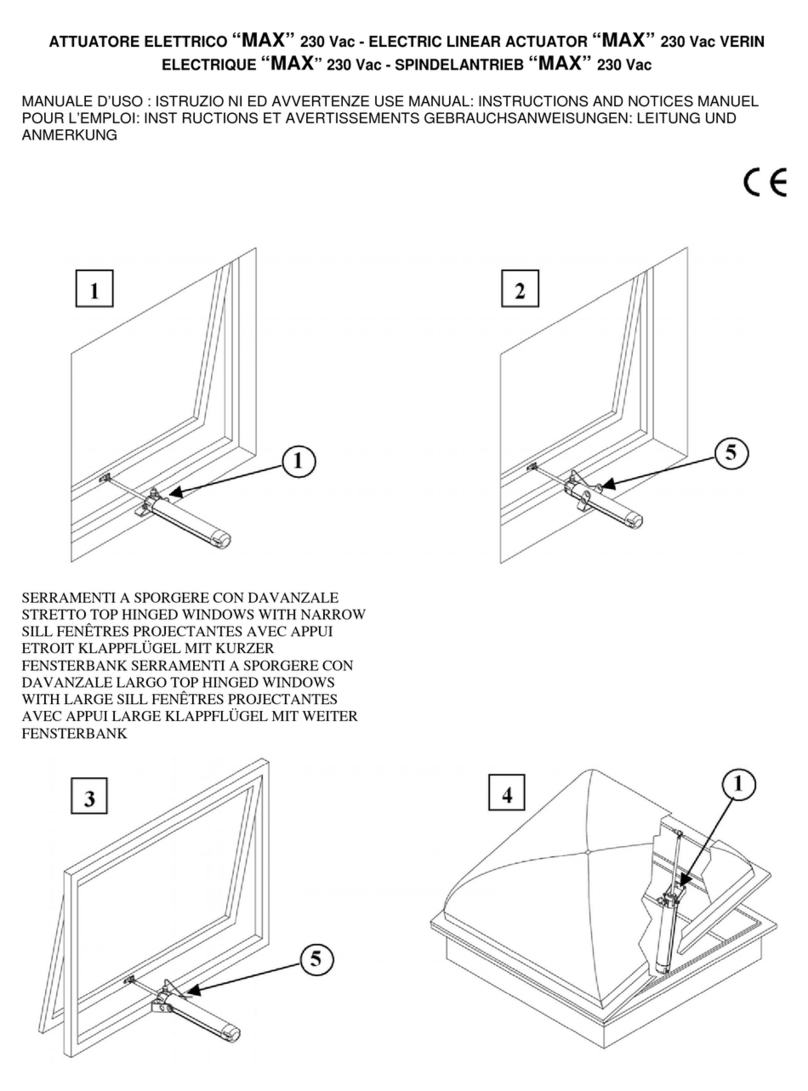

SMOLKA

SMOLKA MAX manual

Rockwell Automation

Rockwell Automation Allen-Bradley OneGear user manual