FoamPRO 2527-0142 User manual

INSTALLATI N AND

PERATI N MANUAL

Advanced Feature Controller

Model 2527-0142

Form 803

4/09

All quality FoamPro products are ruggedly designed, accurately machined, carefully assembled, thoroughly inspected

and tested. In order to maintain the high quality of your unit, and to keep it in a ready condition, it is important to follow the

instructions on care and operation. Proper use and good preventive maintenance will lengthen the life of your unit.

ALWAYS INCLUDE THE UNIT SERIAL NU BER IN CORRESPONDENCE.

Unit

Serial

Number

FoamPro • 375 Fifth Avenue NW • New Brighton, MN 55112 USA • (651) 766-6300 • FAX (651) 766-6614

2

Installation and peration Manual

9. CAUTI N: Do not attempt to operate the

system at or above a temperature of 160oF

[71oC].

10. CAUTI N: Be sure that the electrical source of

power for the 2001, 2002, 2002HP, 2024 and

3000 series units are 12 or 24 volt, all with

negative-ground DC. The systems require a

minimum current rating as listed in the

appropriate OIP for that model.

11. CAUTI N: Periodically inspect the pump and

the system components. Perform routine

preventive maintenance as required. Failure to

perform routine maintenance may damage the

pump. See the maintenance section of this

manual for recommended maintenance

procedures and intervals between maintenance

work.

12. CAUTI N: Read and understand the “Operating

Instructions” section before attempting to

operate the unit.

13. CAUTI N: Always disconnect the ground straps

and control cables from the Digital Display

Control odule or other FoamPro equipment

before electric arc welding at any point on the

apparatus. Failure to do so will result in a power

surge through the unit that could cause

irreparable damage to the display or other

system components.

14. CAUTI N: The cables shipped with each

FoamPro unit are tested at the factory.

Improper handling and forcing connections can

damage these cables which could result in other

system damage.

1. Do not pump at pressures higher than the

maximum recommended pressure (400 psi [28

BAR]).

2. Do not permanently remove or alter any

guarding devices or attempt to operate the

system when these guards are temporarily

removed.

3. Always disconnect the power source before

attempting to service any part of the pump.

Note this system contains a capacitor which will

hold a charge for a time after power is

disconnected. Take care to dissipate this

charge by connecting a 12 or 24 volt test lamp

from the pump base to the positive main power

terminal.

4. Release all pressure within the system before

servicing any of its components.

5. Drain all concentrate and water from the

discharge system before servicing any of its

component parts.

6. Check all hoses for weak or worn conditions

after each use. Ensure that all connections and

fittings are tight and secure.

7. From the foam pump outlet to the injector fitting,

use only pipe, hose, and fittings that are rated at

or above the maximum pressure (400 psi [28

BAR] minimum for 2001, 2002, 2024 and 3000

series systems, and 600 psi [41 BAR] for

2002HP) rating that the water pump system

operates.

8. Any electrical system has the potential to cause

sparks during service. Be sure to eliminate

explosive or hazardous environments during

service/repair.

1Safety Please read all of the following safety precautions and follow

carefully. They are important to the prevention of personal

injury or damage to the equipment.

3

Installation and peration Manual

AFC

FULL TIME REM TE START/ST P

FEATURE

This feature was changed from a programmable

feature to a full-time feature. When using the

Remote Start/Stop module with the FoamPro 2000

or 3000 system, the Concentrate anagement

System (C S) can be operated at the same time.

The Remote Start/Stop module will operate and

install in the same manner as before, but it will not

be a programmable feature. The FoamPro AFC will

automatically recognize that this feature is being

used when the 4-pin cable is attached to the

receptacle on the back of the controller.

FULL TIME C NCENTRATE

MANAGEMENT SYSTEM FEATURE

This feature was changed from a programmable

feature to a full-time feature. The C S module can

now be used concurrently with the Remote

Start/Stop feature without changing or setting the

defaults manually. When a C S module is installed

to the FoamPro AFC, it will automatically recognize

that this feature is being used. The interface wiring

has changed for this feature and is described in this

manual. The C S operation, set-up and calibration

will remain the same as with the standard FoamPro

system controller. When using this feature, you will

need to purchase the 2520-0091 C S interface

cable.

The FoamPro Advanced Feature Digital Display

Control odule (AFC) is designed to add specific

options to the functionality of your 2000 or 3000

Series FoamPro System. Basic installation, setup,

calibration and operation are all the same as the

standard controller (Reference Forms 829, 836, 860,

903 and 904). The basic operation of the controller

remains the same as the standard controller with the

following added features:

AUT MATIC “ N” FEATURE

This programmable feature allows the

operator to remotely power up the 2000 or 3000

FoamPro system directly into the “ON” mode. In this

mode, when power is supplied to the system, the

system is powered and ready for operation without

pressing the red “ON” button. There is an

approximate 5-second delay before system

operations will begin, which allows the system to run

the self diagnostics programming. When water flow

is present, the system will start to operate

automatically. The “ON” button, when depressed,

will turn the system on and off the same as the

standard controller.

An example of when this feature would be used is

when the operator always requires foam operations

from the initial setup of equipment. The system may

be powered up along with the engagement of the

apparatus pump PTO. This would allow the

FoamPro system to be active and running with the

first water flow to the discharge from the initial

engagement without adding extra operation

procedures for the engineer.

Another example of this type of operation would be

in conjunction with the engagement of the

compressor in a CAF system.

2Introduction & peration

4

Installation and peration Manual

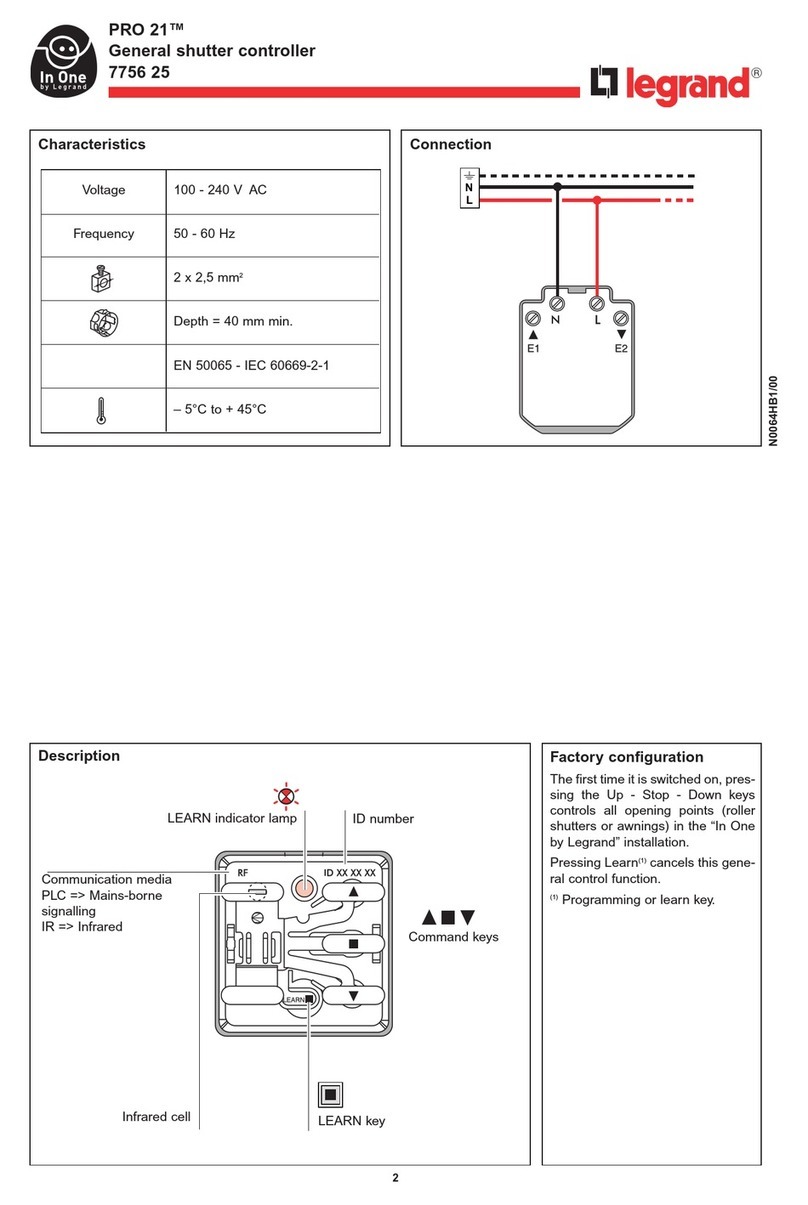

Figure 1. AFC Display

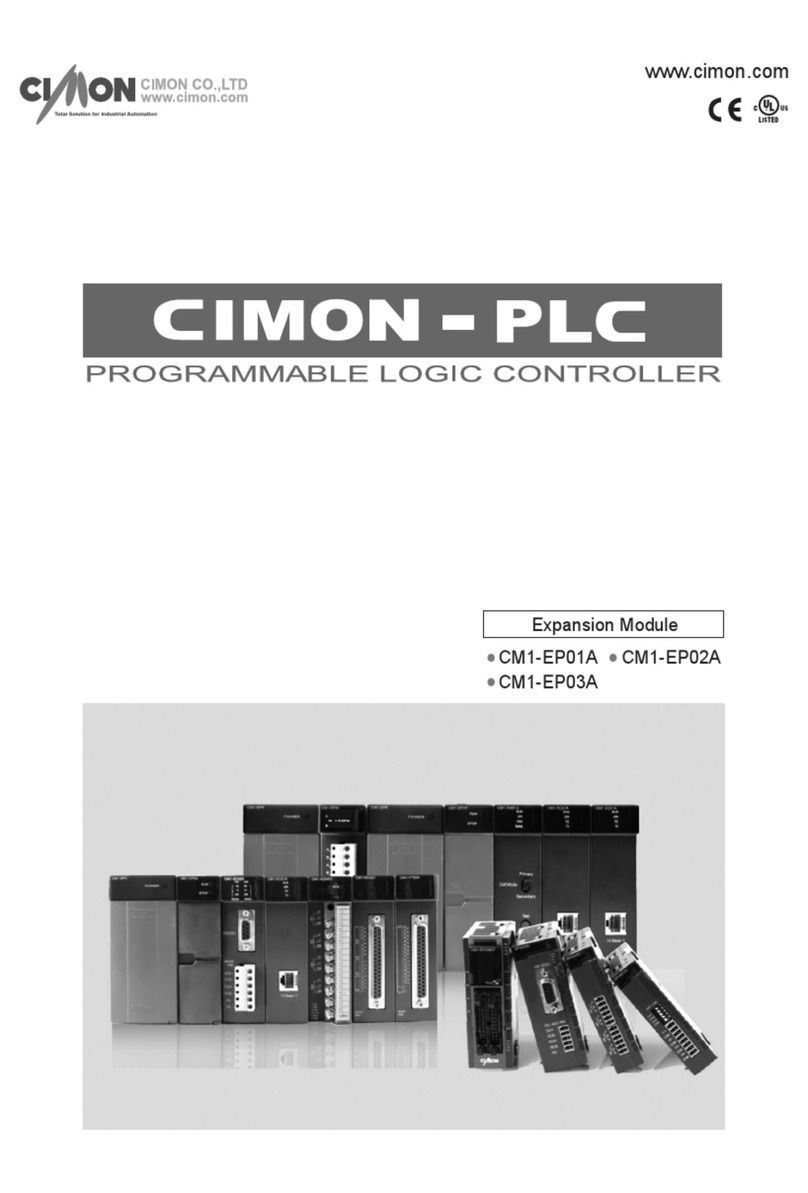

Figure 2. Solid State Contactor Installation

n/ ff Button

Down Button

Internal Calibration

Switch Internal Diagnostic

Switch

Flowmeter or

MultiFlo Connector

(3 Pin)

Control

Connector

(5 Pin)

CMS

Connector

(6 Pin)

Up Button

Remote Start/Stop

Connector (4 Pin)

Select Button

Engage Switch

pen - ff

Closed - n

Ground

Battery

Ground

Solid State Contactor

2510-0043

+ Power to

FoamPro Unit

5

Installation and peration Manual

AFC

Installation procedures for the FoamPro system and

the AFC are identical to those of the standard

controller with the exceptions that follow.

AUT MATIC “ N” FEATURE

Installation for the AFC, when using the Auto “ON”

feature, is the same as for the standard system

controller. The system must be installed as shown in

the appropriate operator’s manual (Ref. Forms 829,

836, 860 or 903) except for the main power lead to

the system itself. The main power lead will be

switched remotely via a solenoid or a separate high

load master switch. This lead must still originate

from the battery or battery master disconnect switch.

A solenoid or secondary high-load solenoid switch

may be installed in this power line to turn on and off

power to the system.

The usage of the FoamPro Solid State Contactor

(SSC) is recommended to help protect the FoamPro

system from excessive voltage surges that can take

place in fire apparatus systems. The solid state

contactor also has a higher life expectancy than

mechanical relay options used for this application.

The SSC allows the operator to easily power the

system up and to shut it down with the use of a

simple switch. The following diagram depicts the

installation of this accessory (see figure 2 on page

4).

The FoamPro AFC is factory defaulted to the

automatic “ON” mode. To use the normal operating

mode, the default must be reset to the AUTO OFF

mode. This is done by following the procedure as

listed:

1. Remove the cover screws for setup and

diagnostics modes (see figure 1 on page 4).

2. Enter the set-up mode by pressing the internal

switch button on the left side of the controller.

3. Enter default set mode by pressing the internal

switch on the right side of the controller.

4. The display will flash “CONF” and “AS.ON”

alternately.

5. Press the DOWN button once. The display will

now flash “CONF” and “AS.OFF” alternately.

6. Press the setup internal switch on the left side of

the controller once. This places you into the

normal operational mode.

7. Replace both cover screws and O-ring seals.

CAUTI N: When exiting the setup mode and

defaulting to the auto on mode, the system will

be turned on upon exit.

To reset the default to the AUTO ON mode of

operation, follow the preceding procedure except

press the UP button once.

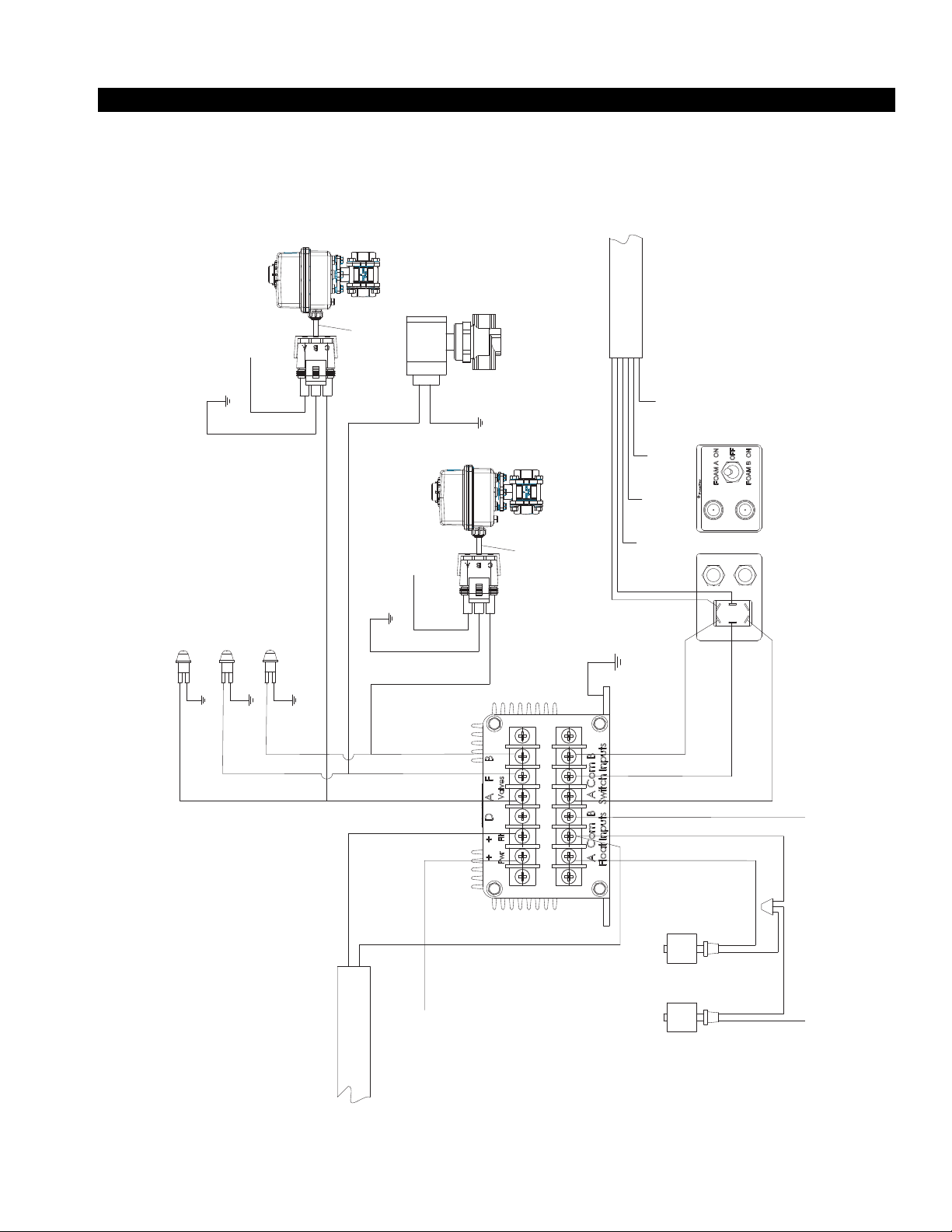

C NCENTRATE MANAGEMENT

SYSTEM FEATURE

Installation for the AFC, when using the C S

feature, is the same as for the standard system

controller. The system must be installed as shown in

the appropriate operator’s manual, except for the

interface between the controller and the C S

connections. Please reference the main operator’s

manual (Form 828 or 887) that came with your C S

for the general installation notes and procedures.

Revised wiring diagrams are shown (see fig. 3 or 4)

that reflect the wiring changes for the manual and

electronic C S systems. NOTE: The only changes

to the wiring are to the interface connections

between the controller and the C S.

3Installation & Setup

6

Installation and peration Manual

Figure 3

Manual Dual-Tank Electrical Hookup for AFC

“B” Switches

“B” Tank Float

Brown

Blue

Grey

Blue

Pink

White

Black

(Separate and Seal Ends)

Brown

“A” Tank Float

“A” Switch

Terminal Block Located

on Bottom of Valve Bracket

CAUTI N: Prevent system

short circuits by stripping only

1/4 inch of insulation from

wire ends when making

connections.

Cable to Lower

6 Pin Port of

Display

P/N 2520-0091

Tank Sensor Cable

Connect to otor Driver

P/N 2520-0042

7

Installation and peration Manual

AFC

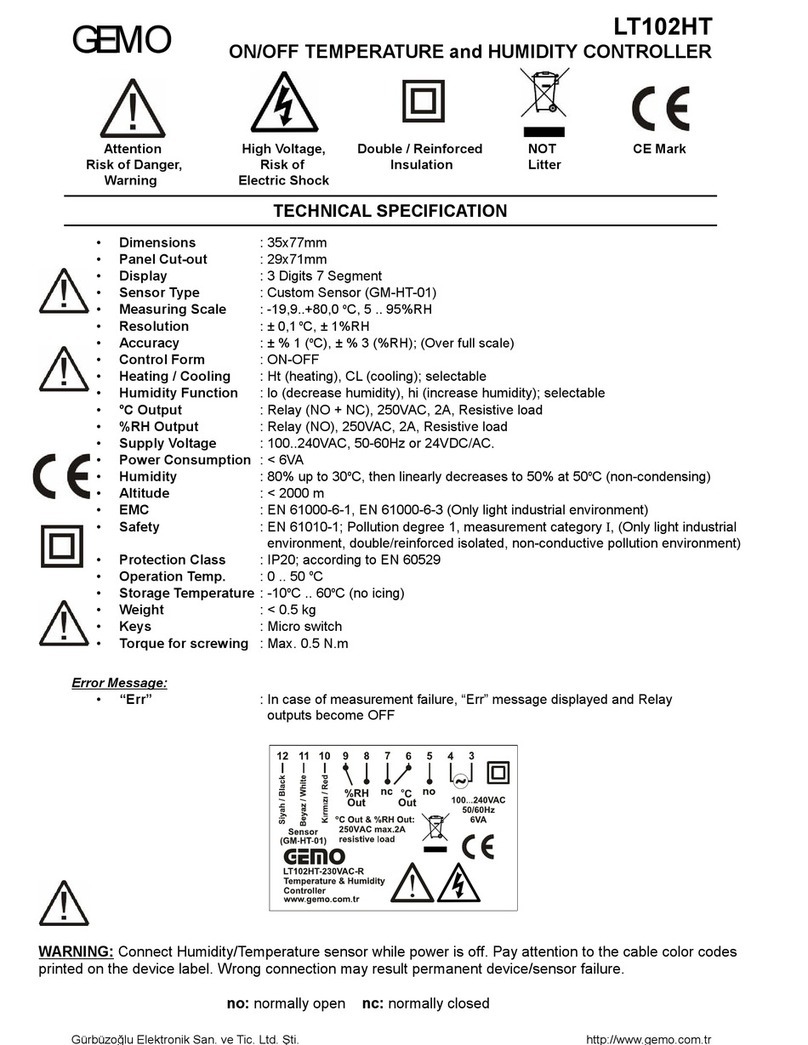

GND

GND

GND

TAN K A INDICATOR LIGHT

FLUSH INDICATOR LIGHT

TAN K B INDICATOR LIGHT

GND

+ 12 OR 24 VDC

POWER SOURCE

GND

+ 12 OR 24 VDC

POWER SOURCE

GND

TAN K B

LEVEL SWITCH

TAN K A

LEVEL SWITCH

TAN K SENSOR CABLE

TO MOTOR DRIVER

BROWN

BLUE

+12VOR24V

POWER SOURCE

BROWN

GREY PINK WHITE BLACK BLUE CABLE TO LOWER 6 PIN

PORT OF DISPLAY

2520-0091

B

COM

A

GND

FLUSH VALVE

TAN K B VALVE

TAN K A VALVE

CAUTION:

PREVENT SYSTEM SHORT CIRCUITS BY

STRIPPING ONLY 1/4-INCH OF INSULATION

FROM WIRE ENDS WHEN MAKING

CONNECTIONS TO THE CONTROL

MODULE AND SOLENOID CONTROLS

PIN A RED

PIN B BLACK

PIN C WHITE

PIN A RED

PIN B BLACK

PIN C WHITE

Figure 4

Electronic Concentrate Management System

Electrical Hookup for AFC

Installation and peration Manual

FoamPro warrants to the original purchaser, each new pump, system or other product of its own manufacture, for a period of one year from the

date of shipment from the factory, to be free from defects in material and workmanship under normal use and service. “Normal use and service”

means not in excess of recommended maximum speeds, pressures, and temperatures, or handling fluids not compatible with components

materials, as noted in applicable FoamPro product catalogs, technical literature, and instructions. This warranty shall not apply to any pump,

system or other product which shall have been repaired or altered to adversely affect the performance or reliability of the pump, system or other

product.

Neither this warranty nor any implied warranty apply to damage or harm caused by any or all of the following: (1) Freight damage; (2) Freezing

damage; (3) Damage caused by parts and/or accessories or components not obtained from or approved by FoamPro; (4) ANY CONSEQUENTIAL

OR INCIDENTAL DA AGES, OTHER THAN INJURY TO THE PERSON, ARISING FRO THE USE OF ANY PU P OR OTHER PRODUCT

ANUFACTURED BY FOA PRO EXCEPT in states that do not allow the exclusion or limitation of incidental or consequential damages; (5)

Damage due to misapplication and/or misuse; (6) Normal wear of moving parts or components affected by moving parts.

The liability of FoamPro under the foregoing warranty is limited to the repair or replacement at FoamPro’s option without charge for labor or

materials of any parts upon return of the entire pump, system or other product or of the particular part to the FoamPro factory within the warranty

period, at the sole expense of the purchaser, which part shall upon examination appear to FoamPro’s satisfaction to have been defective in

material and workmanship.

The liability of FoamPro under any theory of recovery (except any express warranty where the remedy is set forth in the above paragraph) for loss,

harm or damage, shall be limited to the lesser of the actual loss, harm or damage or the purchase price of the involved pump, system or other

product when sold by FoamPro to its customer.

FoamPro expressly warrants its pumps and other products as above stated. THERE ARE NO OTHER EXPRESS WARRANTIES. ANY I PLIED

WARRANTIES, INCLUDING I PLIED WARRANTY OF ERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE, ARE LI ITED

IN DURATION TO ONE YEAR FRO THE DATE OF PURCHASE BY THE ORIGINAL PURCHASER EXCEPT in states that do not allow time

limitations on implied warranties. THERE IS NO I PLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR ERCHANTABILITY

WHEN THIS PRODUCT IS PUT TO RENTAL USE.

No person including any dealer or representative of FoamPro is authorized to make any representation or warranty concerning FoamPro products

on behalf of FoamPro, or to assume for FoamPro the obligations contained in this warranty. FoamPro reserves the right to make changes in

design and other changes and improvements upon its products without imposing any obligations upon itself to install the same, upon its existing

products then in process or manufacture.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

IMP RTANT N TICE

It is imperative to package all FoamPro components properly, before shipment (with Return Goods Authorization attached) back to FoamPro. The

FoamPro contains electronic components that may receive damage from improper shipping procedures! All FoamPro components shipped back to

FoamPro will pass through Quality Control Inspection, and will be photographed after the box is opened. Any shipping damage, such as superficial

scratches, nicks, etc., to the unit makes it unusable (even after the internal warranty problem is repaired) and thus must be refinished to “like-new”

condition during the warranty process.You are responsible for any physical damage occurring to FoamPro components at your facility and during

shipment back to FoamPro.

Package the FoamPro, complete with all the recommended parts the Customer Service representative requires (i.e., Digital Display control with all

premolded wire cables etc.) in its original carton with the Styrofoam and other packaging materials, as it was received at your facility.

FoamPro appreciates your attention in this matter, as we feel it will help us to serve you in a better fashion, while keeping the cost of the FoamPro

product competitive. Thank you.

4Warranty

375 Fifth Avenue NW •New Brighton, Minnesota 55112 USA

Phone: (651) 766-6300 •800-533-9511 •Fax: (651) 766-6614

foampro@pentair.com •www.foampro.com

Table of contents

Other FoamPRO Controllers manuals

Popular Controllers manuals by other brands

Sentera Controls

Sentera Controls HPSPX-2 Mounting and operating instructions

Daikin

Daikin BRC7E530W installation manual

Gemo

Gemo LT102HT quick start guide

jbc

jbc QSC-A manual

CitrinSolar

CitrinSolar CS 2.5 Mounting and operating instructions

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-R C Series Programming manual