Page 2-2 0040501008 2217 - Translated original instructions -

Operating and installation instructions

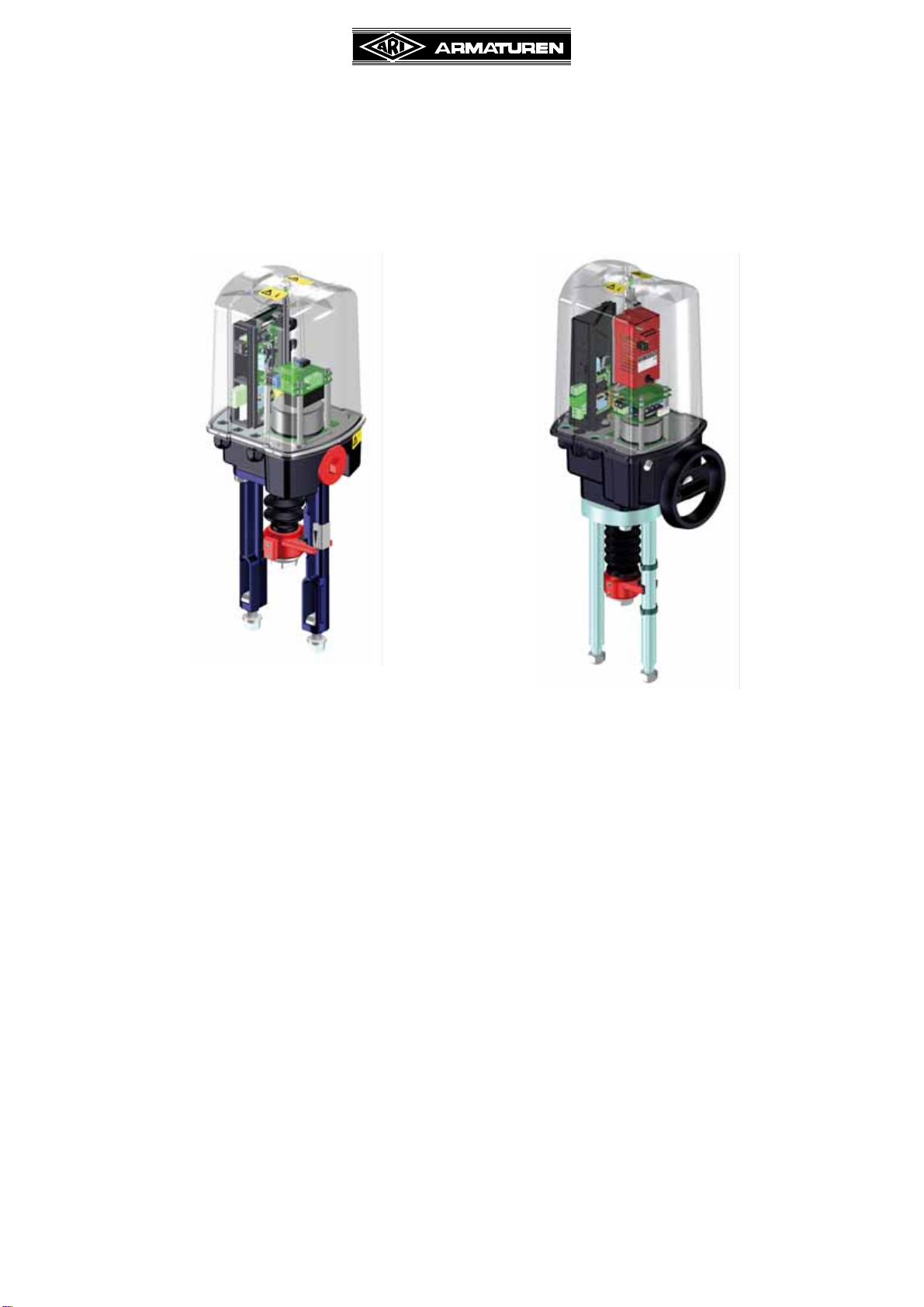

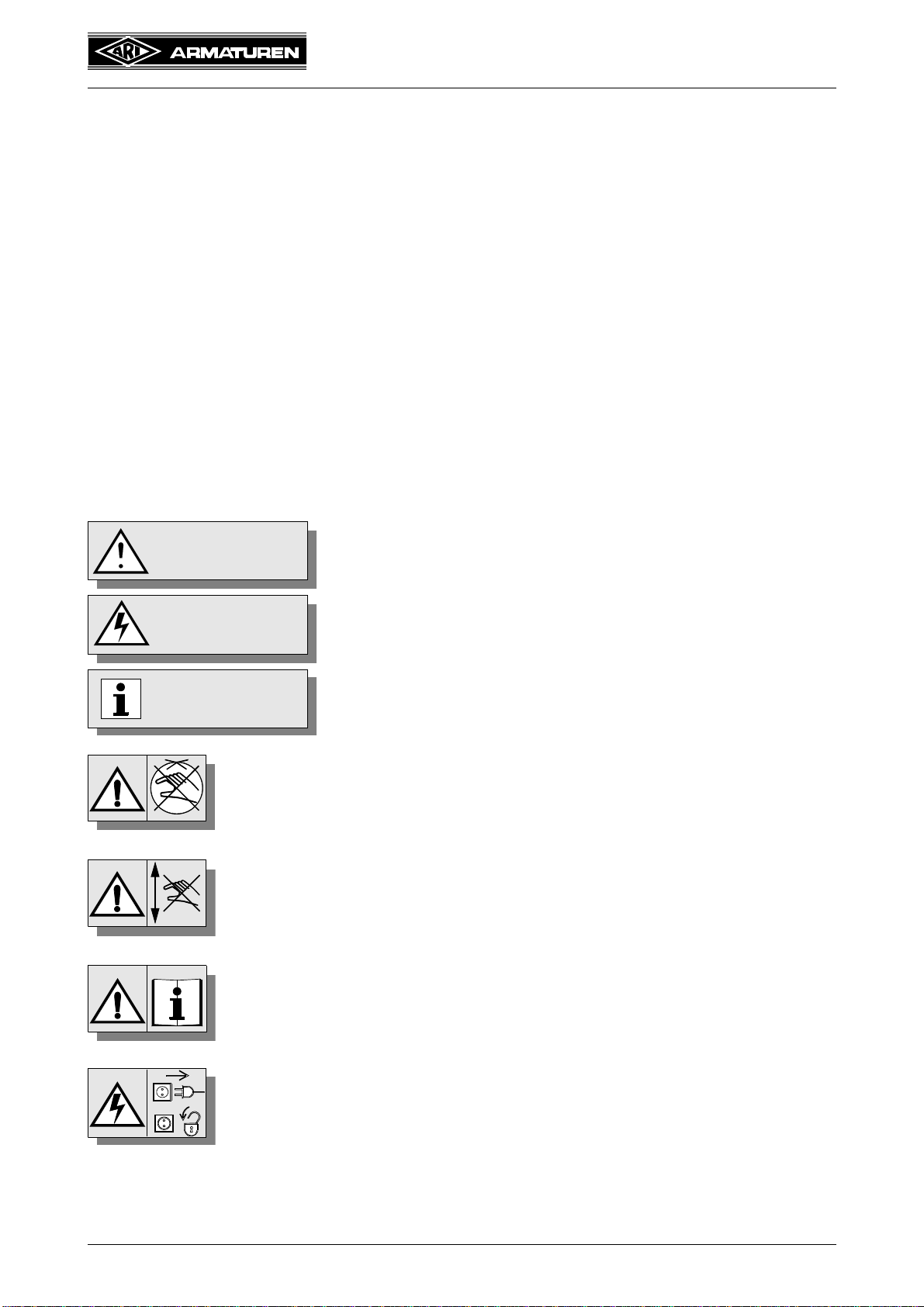

Electric thrust actuator ARI-PREMIO® 2,2 - 25kN

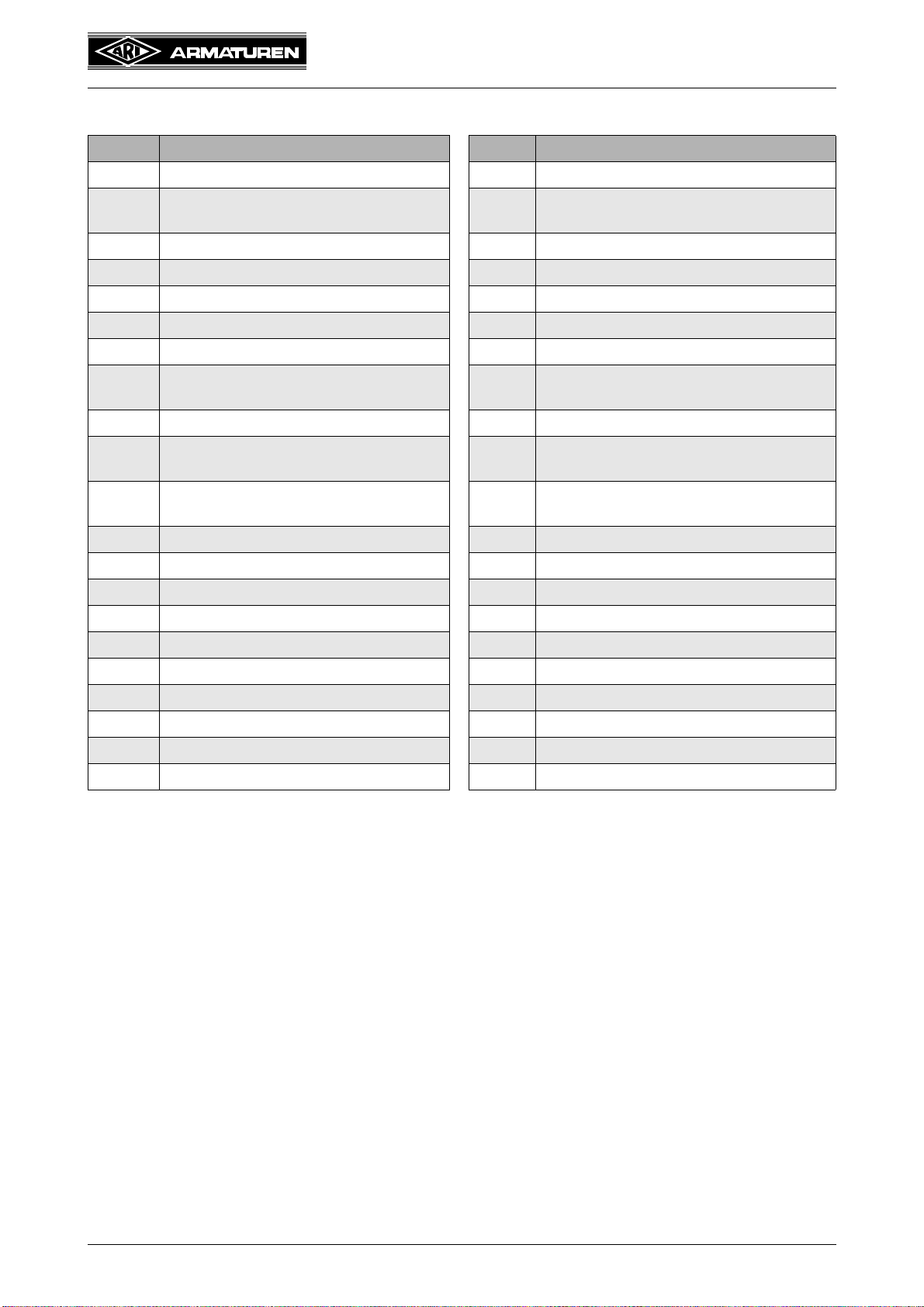

4.5 Accessories..............................................................................................................................................2-11

4.6 Dimensions ............................................................................................................................................. 2-13

5.0 Installation ..................................................................................................................................................... 2-14

5.1 General installation data ......................................................................................................................... 2-14

5.2 Manual operation .................................................................................................................................... 2-15

5.3 Mounting to valves .................................................................................................................................. 2-16

5.4 Electrical connection ............................................................................................................................... 2-17

5.4.1 Connection..................................................................................................................................... 2-17

5.4.2 Wiring diagram............................................................................................................................... 2-18

5.4.2.1 Standard ...........................................................................................................................................2-18

5.4.2.2 dTRON 316.......................................................................................................................................2-19

5.4.2.3 Accessories ......................................................................................................................................2-20

5.5 Installation and setting of options............................................................................................................ 2-21

5.5.1 Trip slide and setting S3 ............................................................................................................... 2-21

5.5.1.1 Installation.........................................................................................................................................2-22

5.5.1.2 Setting...............................................................................................................................................2-22

5.5.2 Additional travel switches and setting............................................................................................ 2-23

5.5.2.1 Method of functioning .......................................................................................................................2-24

5.5.2.2 Setting...............................................................................................................................................2-24

5.5.3 Potentiometers............................................................................................................................... 2-25

5.5.3.1 Method of functioning .......................................................................................................................2-25

5.5.3.2 Installation.........................................................................................................................................2-26

5.5.3.3 Setting...............................................................................................................................................2-26

5.5.4 Error-proof potentiometer for single-channel, error-proof position feedback ................................. 2-27

5.5.4.1 Method of functioning .......................................................................................................................2-28

5.5.4.2 Setting...............................................................................................................................................2-28

5.5.5 Heating .......................................................................................................................................... 2-29

5.5.5.1 Method of functioning .......................................................................................................................2-29

5.5.5.2 Installation.........................................................................................................................................2-29

5.5.6 Electronic position indicator RI21 / Electronic position controller ES11 ......................................... 2-30

5.5.6.1 Installation of one electronic ............................................................................................................2-30

5.5.6.2 Installation of two electronics............................................................................................................2-31

5.5.6.3 Electronic position indicator RI21 .....................................................................................................2-32

5.5.6.4 Electronic position controller ES11 ...................................................................................................2-32

5.5.7 Integrated processcontroller dTRON 316 ...................................................................................... 2-32

5.5.7.1 Method of functioning .......................................................................................................................2-32

5.5.7.2 Installation.........................................................................................................................................2-32

5.5.7.3 Setting...............................................................................................................................................2-33

6.0 Putting the actuator into operation .............................................................................................................. 2-34

7.0 Care and maintenance................................................................................................................................... 2-34

8.0 Troubleshooting............................................................................................................................................. 2-34

9.0 Troubleshooting table ................................................................................................................................... 2-35

10.0 Dismantlement of thrust actuator............................................................................................................... 2-36

11.0 Warranty / Guarantee................................................................................................................................... 2-37

12.0 Translated Declaration of Incorporation and Conformity ........................................................................ 2-38