FOG 444 9160 User manual

E 219 GB (991 9709)

Edition 1 : 01/2007

Installation - Operation

Maintenance - Spare Parts

Servicebook

2-POST VEHICLE LIFT

444 9160 (3 T)

444 9180 (3 T)

442 9020 (3.5T)

English

444 9160 / 444 9180 / 442 9020

E 219 GB - Issue 1

2

Issue

F.F.B. reserves the right to modify the information contained in this manual at any time (non-contractual

document).

Despite the greatest care with which this document has been prepared, F.F.B. cannot be held

responsible, and may not be sued for any error or omission which may have crept into this publication.

All the updates of this manual are displayed below. The latest issues or additional copies of this manual

are available from F.F.B. S.A. Rue du Pré Neuf. 58440 Myennes FRANCE.

Minor changes are indicated by a thick line next to the modified text.

ISSUE PUBLICATION TEXT/ILLUSTRATIONMODIFIED

Number 1 01/2007 First issue.

444 9160 / 444 9180 / 442 9020

3

E 219 GB - Issue 1

Table of contents

TABLE OF CONTENTS

Description: Page:

1. Application range and appropriate use 4

2. SafetyInstructions 5

General Safety Instructions / Owner’s Responsibility 5

Basic Safety Measures during Normal Operation, Maintenance and Repair 6

ElectricalWork 6

Protection of the Environment 6

Practical Safety Instructions and Signs 7

General Safety Instructions for Vehicle Lifts 8

General Vehicle Lift Safety Instructions 9

Remaining Risks 10

3. ProductDescription 11

4. Technical Data 12

Datasheet 12

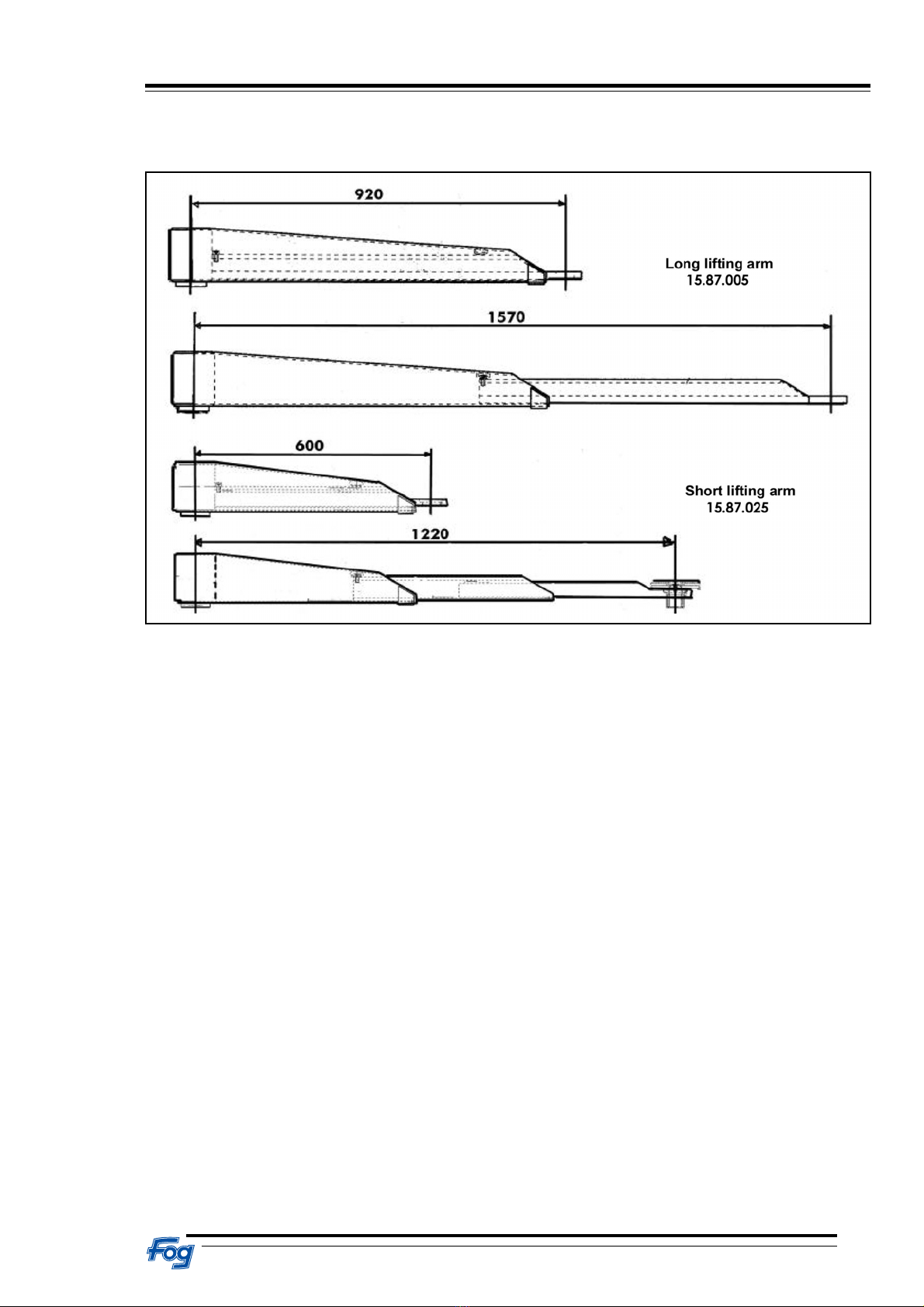

Lifting arms 16

5. Transport-Storage-Unpacking-Scope of Delivery 18

Informations in case of damages in transit 18

Notification of damages in transport 19

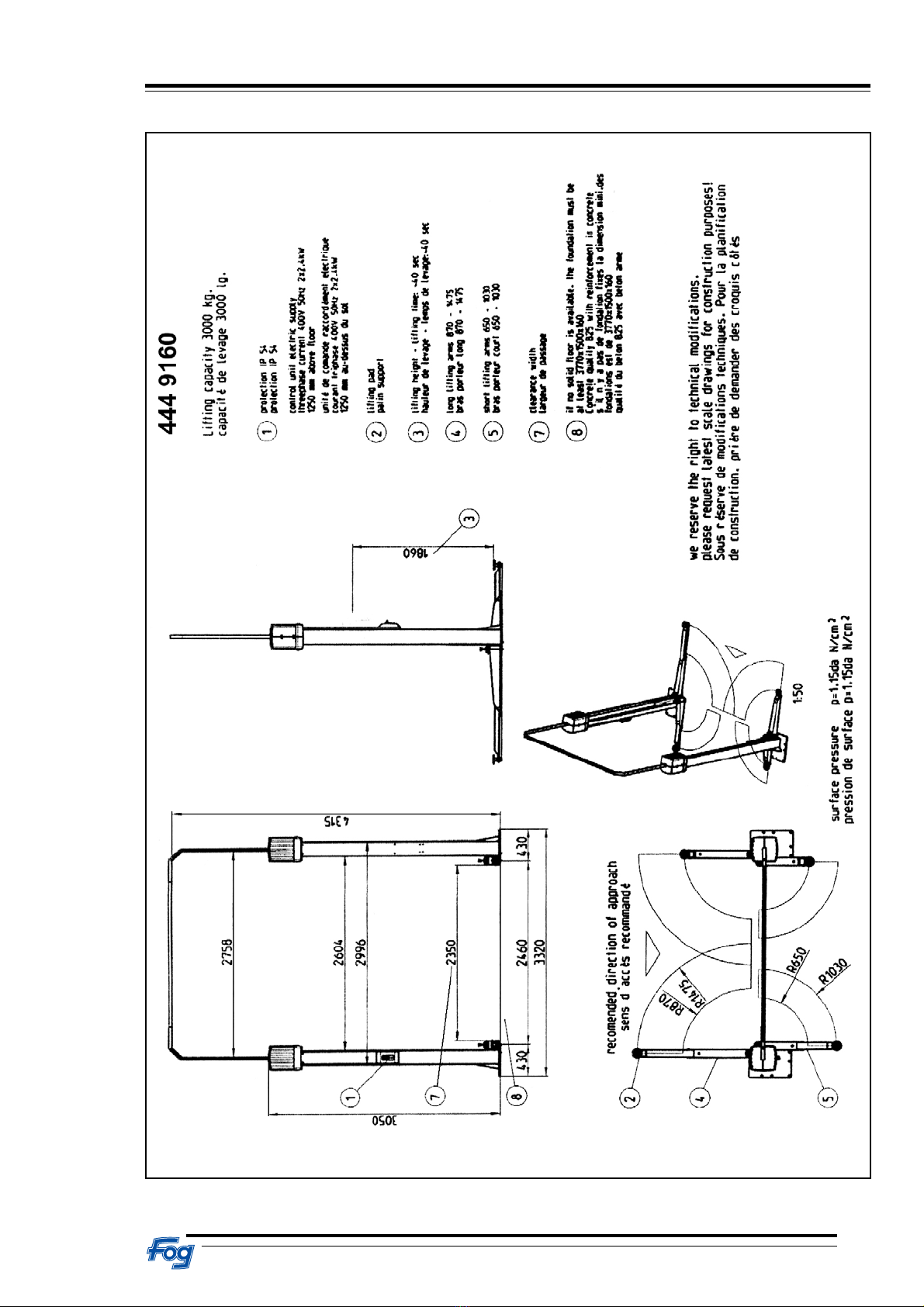

6. Foundation Plan and Power Supply (Customer) 20

Construction of foundation 21

Electrical connections, Air plug 22

Wiring in the concrete 23

7. Assembly and Installation 24

Area layout 24

Dowelling of the columns 24

Mounting of the lifting arms 27

Electricalconnections 28

Control platform 29

Adjustment of control platform 30

Mounting of housing 31

8. Handling and Conduct during Operation 32

Description of operating elements 32

Initial operation 33

9. Fault finding / problem solving 34

Emergency lowering at power failure 35

Emergency lowering with the service plug 35

Operating instructions – control of new vehicle lifts 36

10. Monitoring of Safety Devices 39

Carrying nut break protection 39

Carrying nut wear and tear test 39

Obstacle detection 39

11. Maintenance 40

12. Spare parts supply 41

13. Electrical diagrams 42

14. Spare parts 45

15. Service book 61

Guarantee 69

444 9160 / 444 9180 / 442 9020

E 219 GB - Issue 1

4

1. Application range and appropriate use

The 2-Post lift has been tested for functionality and longevity. It is most economical and safe. It is up to you to

make use of these advantages.

This is best achieved through correct handling, good maintenance and good care of the lift. Please read the

operating instructions carefully. It contains all necessary data and shows how easy it is to keep your lift in

good working order.

The lift is designed to lift motorised vehicles; it is not meant to transport persons. If the

lift is used in car body shops, i.e. in rooms where solvents are used, please be aware of

the danger of explosion. The standard engine is not protected against explosions.

The lift is exclusively designed for lifting passenger cars or vehicles where the total

weight is not above the maximum permitted carrying capacity of the lift and where

stipulated acceptance points lie within the acceptance area of the lift.

Your lift has been furnished with a safety device which guarantees safe operation when handled in

accordance with the instructions.

During installation and operation please pay attention to the functioning of the safety device and check this

after each fault incident.

Please make sure that a function test is carried out after each fault incident.

Your vehicle should only be maintained and repaired by manufacturer trained specialists who possess the

relevant certificate.

Only original spare parts should be used.

If other spare parts are used, the CE-conformity will be null and void.

According to the regulations about the operation of vehicle lifts, lifting gear must be subjected to a safety test

by an expert after one year at the latest.

This test must be entered into the test report book.

Please note, that only manufacturer trained specialists who are certified by the manufacturer as lift experts

can test your lift and confirm its good functioning.

Customer responsibilities

1. A site complying with the specifications in chapter 6 must be provided.

2. Ensure access to a protected electrical supply complying with CE regulations, and use a qualified

electrician to connect the lift to the electrical supply and check the safety of the electrical circuits.

3. Use fixing bolts of an appropriate length. See Assembly and Installation Chapter.

4. Any person assisting the installing technician must be familiar with the handling and health and safety

regulations.

5. An initial inspection must be carried out before commissioning the lift to comply with current legislation

(static and dynamic tests).

6. Means for marking out the danger zone must be provided.

7. Ensure that only competent persons operate and service the lift.

8. Keep this manual for the lift’s entire service life.

444 9160 / 444 9180 / 442 9020

5

E 219 GB - Issue 1

2. Safety Instructions

GENERAL SAFETY INSTRUCTIONS

Owner’s Responsibility:

The vehicle lift is constructed and built to legal standard and further technical specifications. It therefore

corresponds to current technology and gua rantees the highest degree of safety in operation.

Please note, that the machine is only safe in action when all necessary measures have been met. It is the

responsibility of the vehicle lift owner to plan and check that the regulations are adhered to..

The owner is responsible for the following safety aspects:

•The vehicle lift must only be used for its intended purpose.

•The vehicle lift must be kept in good functioning condition and especially the safety equipment

must be checked regularly to ensure that they are functioning reliably.

•Operating, maintenance and repair staff must be supplied with the necessary protective gear

and it is essential that this is worn.

•The operating instructions must be kept in a legible condition and must be available where the

machine is used.

•Only qualified and authorised personnel should operate, maintain and repair the machine.

•The personnel must be regularly informed about relevant industrial safety and environmental

issues and must know the operating instructions and the safety regulations contained therein.

•Any safety labels and warnings attached to the vehicle lift must not be re moved and must be

legible.

444 9160 / 444 9180 / 442 9020

E 219 GB - Issue 1

6

Basic Safety Measures during Normal Operation:

The vehicle lift may only be operated by authorised personnel who have received

specialist training who know the operating instructions and are able to adhere to them.

Before switching on the lift, the following must be checked and ensured:

•Only authorised persons may be present in the working area of the lift.

•It must be ensured that nobody can be injured when the lift is set in motion.

•Before each use, the lift must be checked for visible damages and it must be ensured that

it is only operated in good condition.

•Faults must immediately be reported to the responsible member of staff.

•Before starting to operate the machine it must be checked and secured that all safety

equipment is in good functioning order.

Inspection and maintenance intervals stipulated in the operating instructions must be

observed.

Basic Safety Measures during Maintenance and Repair:

Before maintenance or repair work is carried out, the working area of the lift must

be made inaccessible for unauthorised persons. A sign should show clearly that

maintenance or repair work is in progress!

Before maintenance or repair work is carried out, unplug the power supply or, if this is

not possible, switch off at the mains and secure it with a padlock. The key to this padlock

should be kept by the person who carries out the maintenance or repair work. If heavy

machine parts are to be exchanged, the load bearing equipment and buffer should be

in good condition.

Any lubricating, cooling or cleaning agents which might endanger the environment,

should be disposed of properly.

Electrical Work:

Repair work on the electrical system of the lift should only be carried out by a qualified

electrician.

Electrical installations should be checked regularly.

Loose connections should be tightened.

Damaged leads / cables must be exchanged immediately.

Keep housing of electrical installations closed at all times. Access is only per mitted

to authorised persons in charge of the key / tools.

Housing of electrical installations must never be cleaned with a hose pipe.

Protection of the Environment:

During all work with and on the vehicle lift the statutory regulations regarding the

avoidance of waste and proper waste disposal must be adhered to.

In particular during installation, repair and maintenance work, water contaminating

materials must not be allowed to seep into the soil or into the sewage system. These

include: - Grease and oils - Oils for hydraulic systems

- Cooling agents - Detergents containing solvents

Such materials must be kept, transported and collected in suitable containers and

disposed of.

444 9160 / 444 9180 / 442 9020

7

E 219 GB - Issue 1

Practical Safety Instructions and Signs:

The following operating instructions contain practical safety directions in order to draw attention to any

unavoidable risks which might occur while the vehicle lift is in operation. Such remaining risks en danger:

•people

•products

•the environment

The signs used in the operating instructions are there mainly to draw attention to the safety directions.

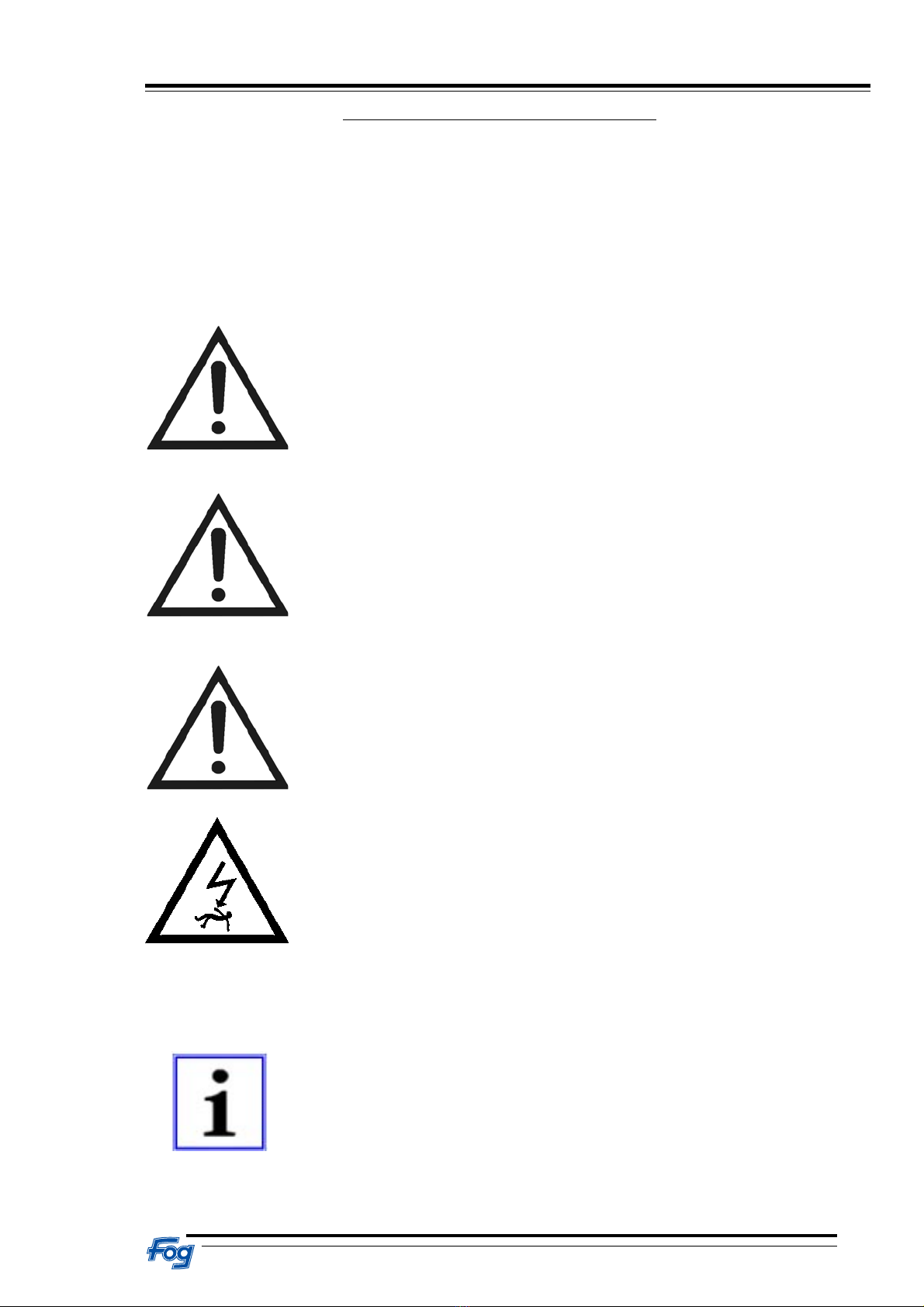

Danger - The sign points to danger for persons (fatal accidents or injuries)

Caution - This sign points to danger for machines, materials and the environment.

Danger – general sign

This sign is a reminder that the power supply to the housing must be switched off

and locked so that it is secured against accidental switching on.

The most important aim of the safety directions is to prevent injury to people.

The applied sign cannot replace the text of the safety directions. The text must always be read in full.

This sign does not relate to safety but gives information which should lead to a

better understanding of the machine proceses.

Danger

Caution

Information

444 9160 / 444 9180 / 442 9020

E 219 GB - Issue 1

8

General Safety Instructions for Vehicle Lifts:

The vehicle lift must only be used for lifting vehicles in accordance with the technical data.

Only trained personnel may operate the system.

Safety devices must not be replaced.

Necessary repair work may only be carried out by instructed customer service personnel.

Unauthorised alterations of the equipment render any liability by the manufacturer for any

resulting damages invalid.

Work on electrical installations may only be carried out by electricians.

The vehicle lift must not be operated in environments liable to explosions.

444 9160 / 444 9180 / 442 9020

9

E 219 GB - Issue 1

General Vehicle Lift Safety Instructions:

An uneven distribution of load on the front and back pick-up platforms should not exceed the listed

ratio of the types: 444 9160 and 444 9180 at a capacity of 3000 kg

3 to 2

442 9020 at a capacity of 3500 kg

2 to 1

The vehicle must always rest on all 4 supporting pads.

The vehicle must be picked up at the points stipulated by the manufacturer.

The vehicle and the lift must be observed during all vertical movements.

While the lift is operated, the danger area must be kept free. Travelling on or climingup on the

lift is not permitted. Persons under the age of 18 must not operate the lift.

The safety devices must not be changed in their position or function.

Repairs should only be carried out by authorised specialists.

The statutory accident prevention rules must be adhered to.

No work must be carried out on the vehicle during vertical movements.

The nominal load shown on the lift must not be exceed.

After a brief lifting of the vehicle it should be checked that all lifting arms are securely bolted.

If necessary, the vehicle should be lowered again and by a slight oscillating movement of the

lifting arm the bolt should slip into place.

During assembly and dismantling of vehicle units the eccentricity of the centre of gravity must

be taken into account.

Take care when vehicles are loaded! (other total weight and weight displacement)

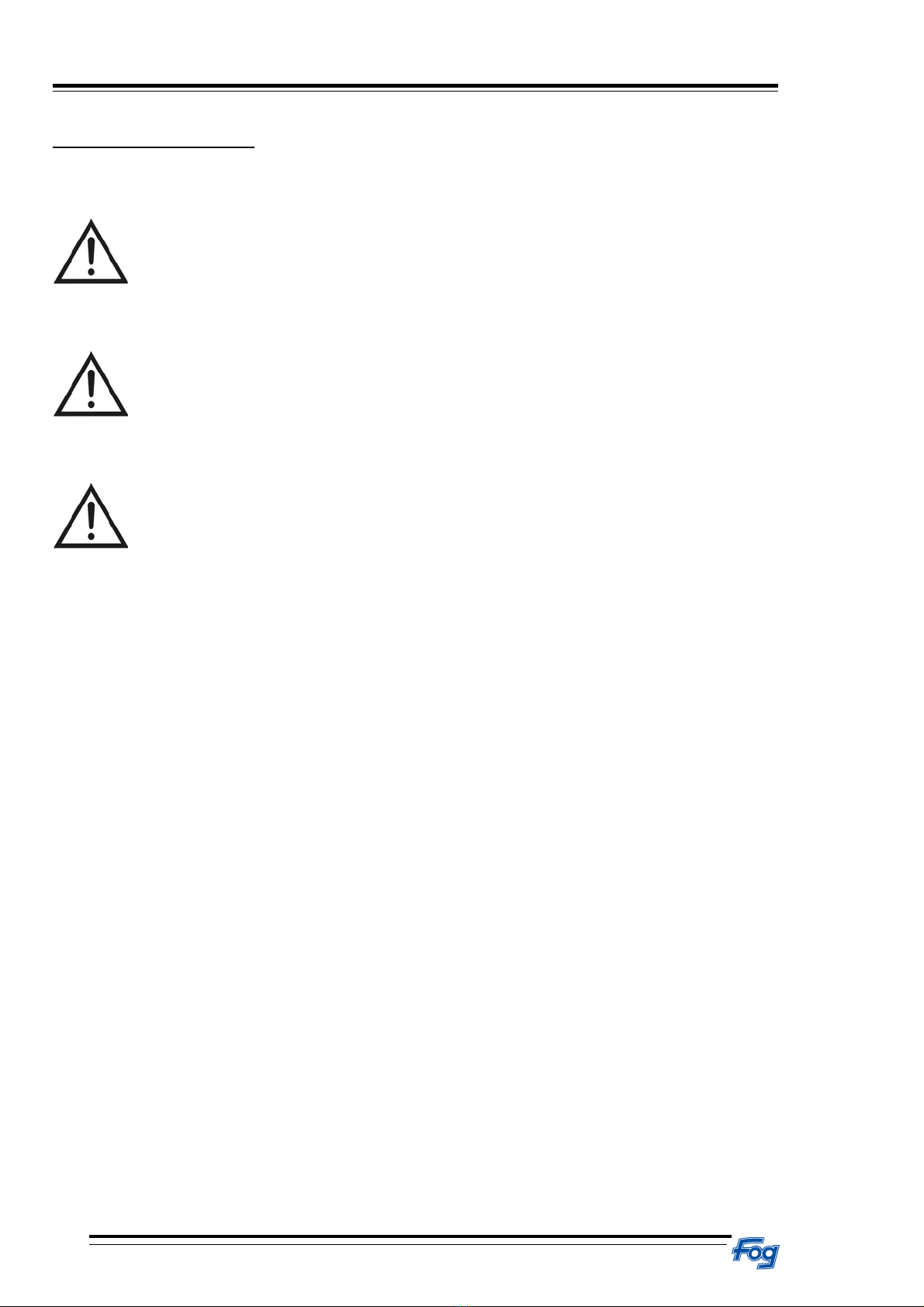

If the safety instructions are not observed there is a

danger of injury!

Danger

444 9160 / 444 9180 / 442 9020

E 219 GB - Issue 1

10

Remaining Risks:

During vertical movements of the lift, no person is permitted to stand underneath a vehicle on

the lift or in the danger area. If this prohibition is not adhered to, there may be the danger of

injury. The operator must be expressly instructed to activate the up and down switch only if no

person is standing in the danger area.

The foot protection corresponds to statutory regulations, but this does not exclude all

imaginable possibilities of injury, but only those which are probable according to experience.

The operator must be instructed to activate the up and down switch only if no person is

standing in the danger area. Before each use, the protective device of the lift must be

checked for its perfect functionality.

If a vehicle has been mounted onto the lift according to instructions, there will be no danger of

accidents. If, however, the vehicle has not been mounted according to instructions, there is the

danger of injury. Special care must be taken with loaded vehicles or in cases of eccentricity of

centre of gravity through mounting or dismantling of heavy parts. The operator must be

instructed to check the mounting of the vehicle onto the lift before work commences.

444 9160 / 444 9180 / 442 9020

11

E 219 GB - Issue 1

3. Product Description

This lift consists mainly of two equal lift columns which are driven by an electric motor: the control column

with integrated base plate and the auxiliary column with an integrated base plate. There is no

mechanical connection between the lift columns. Each of the columns contains lifting spindles and a lifting

carriage with the load accepting devices.

The two electrical motors drive the lifting spindles by means of a sturdy and low-noise ribbed V-belt.

Integrated thermo-sensors in the motor coil winder act as an overload monitor.

The spindles house the various types of nuts: - supporting nuts with safety nuts - which are connected with the

two lifting carriages and, depending on the direction of the drive, carry out the up or down movements. The

two lifting carriages are guided by four gliding pieces in each column. The spindle supporting nut system

with carriages are maintenance free for one year if used as repair lift.

The necessary synchronisation of the carriage is guaranteed by an electronic synchronisation monitor. In the

event that the two carriages are not in parallel (for example, due to one-sided load, insufficient lubrication,

etc.) the synchronisation monitor will adjust the deviation within a distance of approx. 10 mm. This is done

by stopping the advanced carriage until the carriage which is lagging behind is at the same level again.

This process can be observed during a lifting action, possibly several times.

The drive is activated depending on the input by means of a key pad on the control panel; it is switched

on via an analogue path measuring counter in the upper and lower end position. After releasing the key

pad these return to “0” position automatically and the movement of the lift is stopped in each position of

the load uptake device.

The lift is fitted with safety devices, for example, the supporting nut break safety device which will transfer the

load to a free running safety nut in the case of a worn thread. During this process a mechanical safety system

is activated which will switch off the lift via the analogue path measuring counter and prevent a restart.

There is also the oscillating arm arrest which locks the lifting arms in their oscillating movement after a

lifting distance from the base position of approximately 100 mm in order to avoid that the supported

vehicle slips of the load bearing de vice.

The foot protection is activated via the analogue path measuring counter which stops the lowering of the

load automatically in the danger area (120 mm above the platform base). By pressing the key pad

“SENKEN” (down) again, the load carrier can be brought back into base position. This down-action in

the danger area will activate a warning signal tone.

The thermo-sensor in the drive motors causes the motors to switch off when they are too hot and after a

cooling-off time (of approx. 10-15 minutes) indicates that the lift can be used again.

An arch, which can be simply assembled, is placed above the control column to the auxiliary column, ,

serving as a safety channel for electrical cables (power supply, monitoring and control cables).

The lifting arms are, depending on the type, constructed resembling a single or double telescope which

can be adjusted to the required working length. The long single telescopic lifting arms in direction “up” at

the back and the short single or double telescopic lifting arms “up” in the front. This ensures that the doors

are free on both sides.

The vehicle to be raised is to be placed in such a way that the front door hinges are in the area of the lift

columns, so that a large door opening angle is created

The aim should be to direct the motor side of the vehicle towards the short oscillating arms (centre of

gravity of the vehicle should be at the centre of the lift if possible).

444 9160 / 444 9180 / 442 9020

E 219 GB - Issue 1

12

4. Technical Data

We reserve the right to alter the construction.

444 9160 444 9180 442 9020

Lifting arms: With short 2-part lifting arms

min: 650 mm

max: 1030 mm

................................

And long 2-part lifting arms

min: 870 mm

max: 1475 mm

With short 3-part lifting arms

min: 550 mm

max: 1070 mm

................................

And long 2-part lifting arms

min: 870 mm

max: 1475 mm

With short 3-part lifting arms

min: 600 mm

max: 1220 mm

................................

And long 2-part lifting arms

min: 920 mm

max: 1570 mm

Lifting arm

Locking device:

Automatic locking of lifting

arms

Automatic locking of lifting

arms

Automatic locking of lifting

arms

Supporting pads: Rotary plate d = 120 mm

Intake height:

min: 80 mm

max: 110 mm

Rotary plate d = 120 mm

Intake height:

min: 80 mm

max: 110 mm

Rotary plate d = 120 mm

Intake height:

min: 80 mm

max: 110 mm

Spindle lifting nut

system:

Electronic monitoring with

analogue counter

1 year maintenance free

Electronic monitoring with

analogue counter

1 year maintenance free

Electronic monitoring with

analogue counter

1 year maintenance free

Operating panel: 1 key pad on steering

column

1 key pad on steering

column,

1 additional key pad

2 sockets 230V,

1 air supply on auxiliary

column

1 key pad on steering

column,

1 additional key pad

2 sockets (1 socket

Switzerland) 230V, 1 air

supply on auxiliary column

Drive:

Power:

Connection value:

Fuse protection:

2 alternating current motors

2x2,4 KW

400V AC 50 Hz

3x20 A

2 alternating current motors

2x2,4 KW

400V AC 50 Hz

3x20 A

2 alternating current motors

2x3 KW

400V AC 50 Hz

3x25 A

Carrying

capacity:

1860 mm 1860 mm 1860 mm

Lifting time: 40sec 40sec 40sec

Weight:

Capacity: 3.000 kg 3.000 kg 3.500 kg

ED-operation: S3 S3 S3

Sound pressure

level:

70 dB(A) 70 dB(A) 70 dB(A)

444 9160 / 444 9180 / 442 9020

13

E 219 GB - Issue 1

444 9160 / 444 9180 / 442 9020

E 219 GB - Issue 1

14

444 9160 / 444 9180 / 442 9020

15

E 219 GB - Issue 1

444 9160 / 444 9180 / 442 9020

E 219 GB - Issue 1

16

Lifting arms for type 444 9160

Long lifting arm

15.87.001

Short lifting arm

15.87.020

Lifting arms for type 444 9180

Long lifting arm

15.87.001

Short lifting arm

15.87.023

444 9160 / 444 9180 / 442 9020

17

E 219 GB - Issue 1

Lifting arms for type 442 9020

444 9160 / 444 9180 / 442 9020

E 219 GB - Issue 1

18

5. Transport-Storage-Unpacking-Scope of Delivery

Transport and Storage:

The packed lift should only be lifted at the appropriate points.

Gripping the lift from below with a fork lift truck can lead to costly repairs.

The lift should not be stored outside.

The lift should be unpacked only one time arrived on its place of installation.

Unpacking

When the lift and the accompanying packages are unpacked, damages in transit should be noted and the

forwarding agent as well as F.F.B. should be informed immediately (see enclosed notification form).

The individual parts must be laid out in such a way that nothing can be lost when the packing material is

disposed of.

Despatch List

1x column complete control side

1x column complete opposite side

2x protective cap

2x lifting arm long complete

2x lifting arm short complete

1x U-profile for cross connection

1x box of accessories

IMPORTANT INFORMATION!

for our lift end customers in case of

DAMAGES IN TRANSIT

Delivery

Please check the goods immediately after arrival in the presence of the forwarding agent.

Should the goods show damages in transit, the forwarding agent must no be given a blank receipt.

If necessary, note the damage on the haulage documents.

Claim for damages

In order to ensure a quick and unproblematic handling of the damage, each damage in transit must be

reported to the F.F.B.-service partner immediately after the damage has been noticed.

The notification can be made by telephone, in writing or by fax / e-mail and must contain the following:

No. of assignment on the F.F.B.-delivery note and date of delivery

Type of lift and serial number

Exact description of the damage

(If necessary, use the back side of this information sheet).

Rectifying damages and settlement

The company F.F.B. can only deal with transport damages if a damage claim, as de scribed above,

has been made.

REPAIRS OR DELIVERIES OF SPARE PARTS AS WELL AS THE FINANCIAL SETTLEMENT

OF TRANSPORT DAMAGES ARE HANDLED BY YOUR F.F.B. SERVICE PARTNER.

444 9160 / 444 9180 / 442 9020

19

E 219 GB - Issue 1

NOTIFICATION OF DAMAGES IN TRANSPORT

On the lift Type: ______________________________________________________

Serial no.: ______________________________________________________

Delivered with Delivery note no.: ______________________________________________________

By Company: ______________________________________________________

Date: ______________________________________________________

The following damage was noticed On delivery

During unpacking

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

(accurate description of the damage)

The packing was Damaged

Not damaged

Place/date Customer

444 9160 / 444 9180 / 442 9020

E 219 GB - Issue 1

20

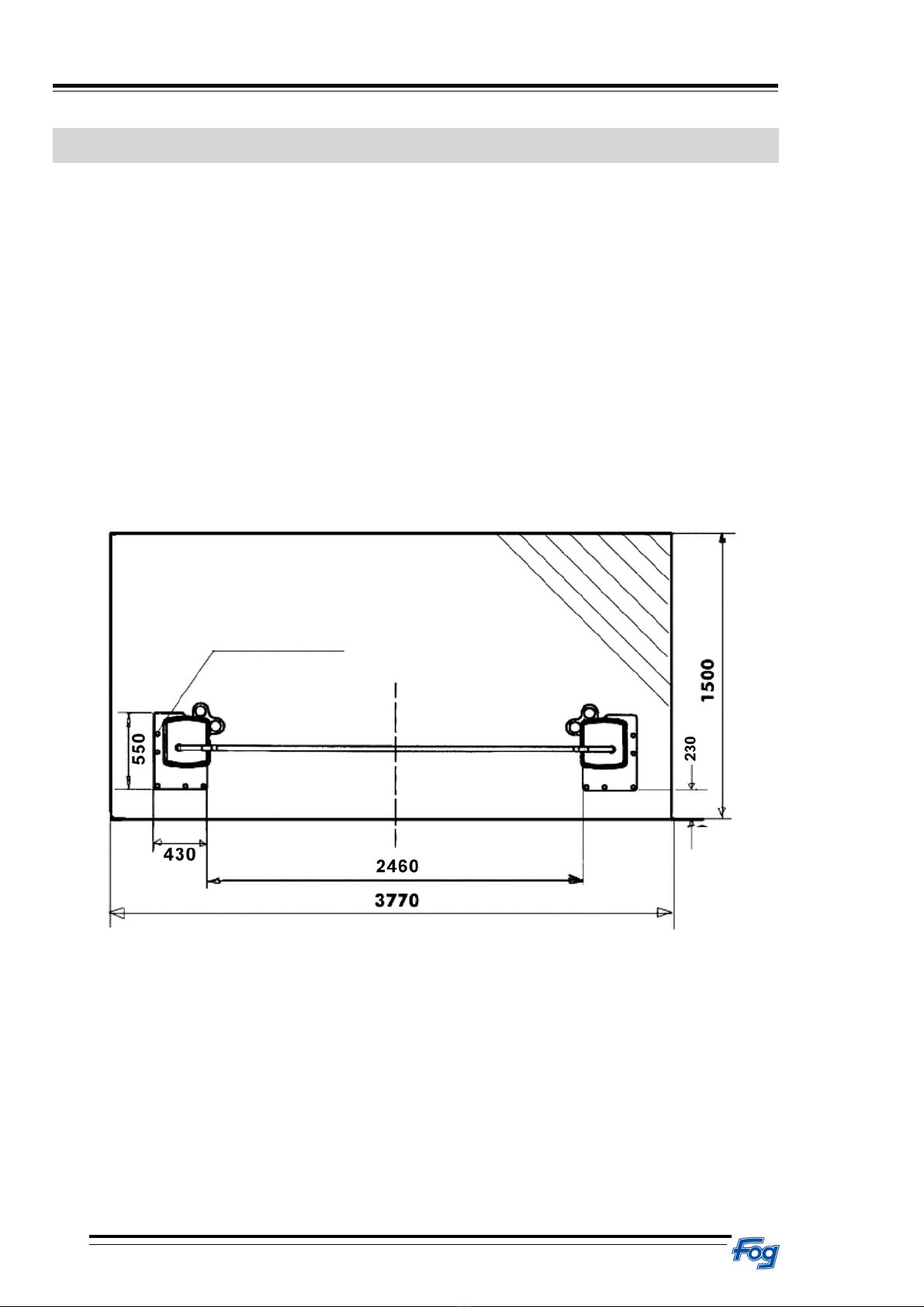

6.FoundationPlanandPowerSupply(Customer)

Minimumrequirementrelatingtothebase:

The surface of the base must be level on all lifts. The foundation must comply with the general building

regulations (DIN 1054). For lifts which are installed outdoors, the foundation must be frost resistant. If the

lift is not to be installed on solid ground, an engineer engaged in statical calculations must examine each

case individually. The lifts are anchored with dowels.

If no adequatel fixed foundation with the necessary concrete texture class is

available, then a foundation with the minimum size of 3770x1500x250 mm

of the concrete quality B25 with reinforcement must be created.

Surface pressing: p=1.15 daN/cm2 for Type 444 9160 / 444 9180

p=1.34 daN/cm2 for Type 442 9020

Drillholesfor

dowels

This manual suits for next models

2

Table of contents

Other FOG Lifting System manuals

Popular Lifting System manuals by other brands

Bishamon

Bishamon LV50WE Operation and service manual

Aqua Creek Products

Aqua Creek Products F-802SC2 quick start guide

Pro-Lift

Pro-Lift T-5350B Operating instructions & parts manual

MSA

MSA XTIRPA Instruction and safety manual

ABACO MACHINES

ABACO MACHINES ASB056M3 Operation manual

MAHA

MAHA HL CS Series operating instructions

Vestil

Vestil EHU-2 instruction manual

Blitz

Blitz MRG25-4 Operation & maintenance manual

EDER

EDER Power Climber 130 operating instructions

PLATFORM BASKET

PLATFORM BASKET SPIDER 18.90 PRO Use & maintenance manual

Sinoboom

Sinoboom AB16EJ Plus Maintenance manual

TRANZSPORTER

TRANZSPORTER TP250 Assembly instructions