TRANZSPORTER TP250 User manual

404-344-0000 • www.tiedown.com

605 Stonehill Drive SW, Atlanta, GA 30336

www.tranzsporter.com

Carriage Assembly Instructions

TP250

(Pages 1-4)

TP400

(Pages 5-8)

Instruction Sheet #08290 Rev. 11-23-20

E1563

Congratulations

You’ve purchased a roofing hoist manufactured by TIE DOWN ENGINEERING. All of hoist products are easy to

assembly and is solidly built in USA and tested to ensure years of service.

Before You Begin

We’ve included this easy to use instruction sheet to ensure quick, easy assembly of your carriage

platform. Be sure to read the instructions (a time saver in the long run). Identify all parts and hardware.

Questions?

We’re here to help, just call 800-241-1806. For faster service, have your model and serial number

ready when calling.

Read this manual before using this product.

Failure to follow the instructions and safety precautions in this manual can result in serious

injury or death. Keep this manual in a safe location for future reference.

WARNING: This product can expose you to

chemicals including Nickel, which is known to

the State of California to cause cancer. For more

information go to: www.P65Warnings.ca.gov

Page 2 of 8

TP250 Carriage Parts Description List

TP250 Carriage Assembly Instructions

Carriage Base

Carriage Base

Carriage Base

Plywood Brackets

Platform Base

Platform Base

Platform Base

Back/Flap

Platform Back/Flap

Platform

Back/Flap

Platform Back/Flap,

Pivot Tab Holes

Description Qty.

Platform Back Flap 1

Platform Base 1

Carriage Base 1

Support Struts w/Pins 2

Plywood Brackets w/Pins 2

5/16”-18 x 2” Bolt 4

5/16” Nyloc Nuts 4

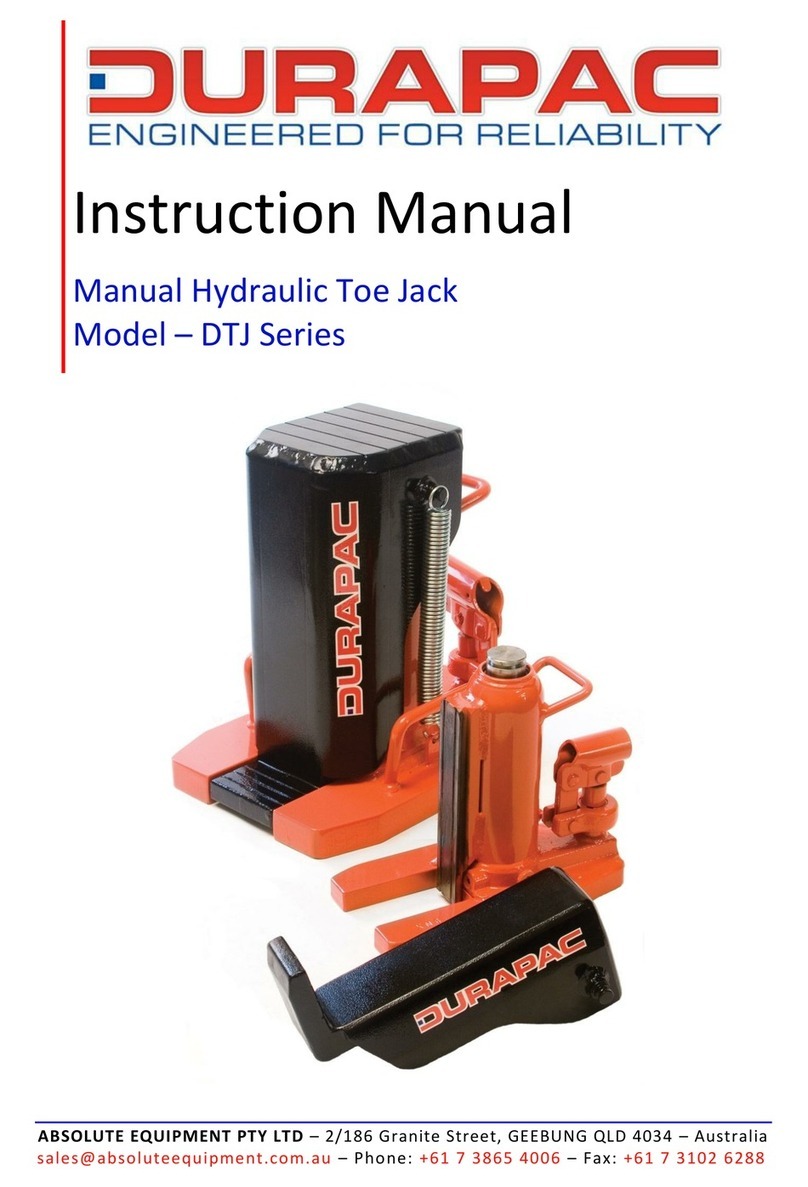

Step #1

Place the Carriage Base (wheels upward)

and Platform Base (Smooth flat top upward)

on a hard flat surface. Place both bases back to

back so the pivot tab holes align with each other.

Position the Platform Back/Flap at a 90˚ angle.

The Back/Flap should have the smooth flat

surface facing the smooth flat surface of

the platform base. Align the pivot tabs/holes with

Back/Flap/Carriage/Platform. The Back/Flap will

overlap both carriage and platform base tabs.

Step #2

Insert 5/16” x 2” Bolt through all three

tab holes (Back/Flap, Carriage and Platform

bases). Tighten nylock nut with the bolt; not

so tight as to prevent free movement.

Repeat #1 and #2 for opposite side.

Support Struts

(TP400 on page 5)

(TP400 on page 5)

404-344-0000 • tiedown.com

605 Stonehill Drive SW, Atlanta, GA 30336

Page 3 of 8

TP250 Carriage Assembly Instructions

Carriage Base

Insert Safety Pins

from the inside

of the carriage

Support Strut

Beveled End

Beveled End

Support Slots

Round End

Platform

Base

Platform Back/Flap

Platform

Back/Flap

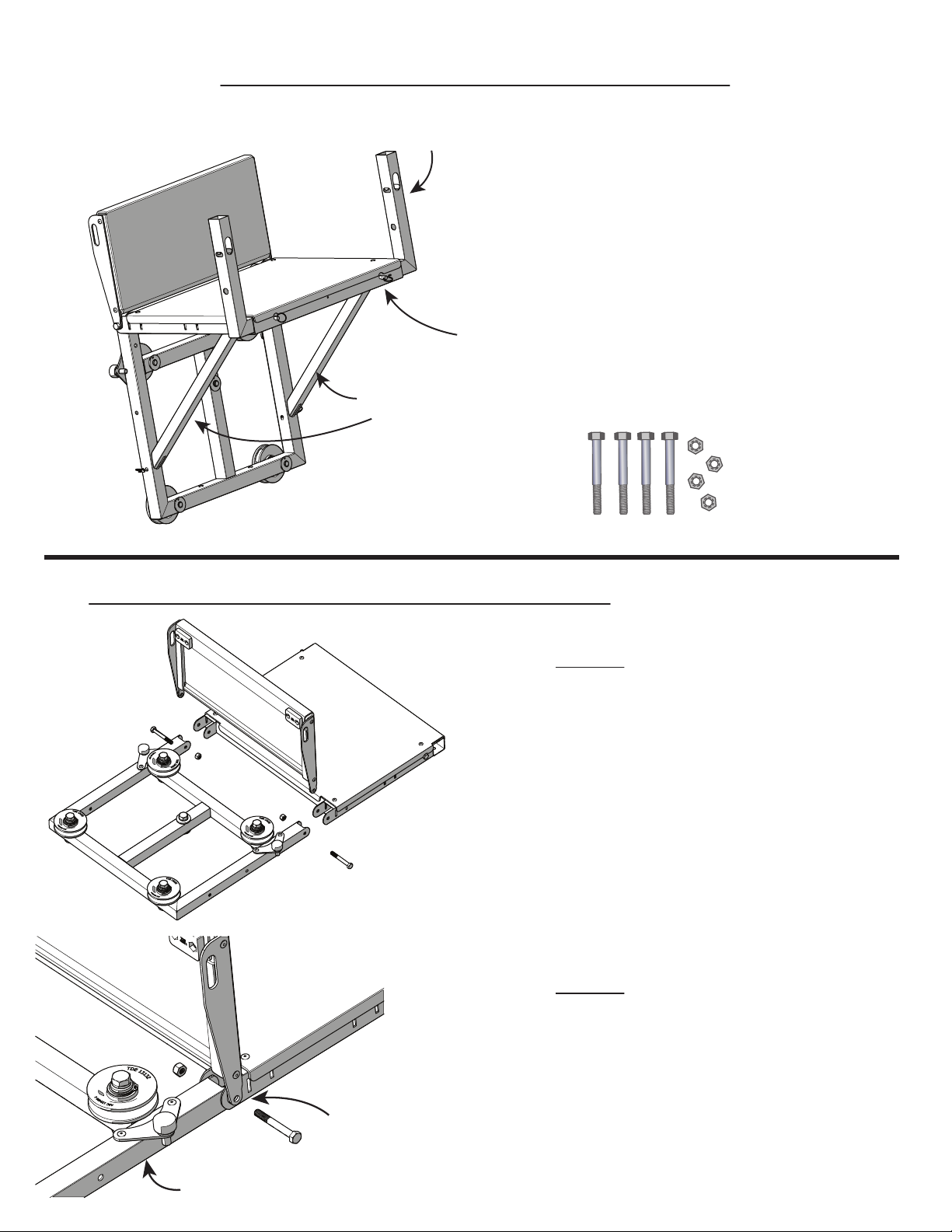

Step #3

Lift up one side of the carriage 90˚

and let it rest on its side.

Place the round end of the

support strut in the platform

(underside) base, align with

mounting holes.

The support strut must be

positioned with the beveled

end as shown right.

Insert 5/16”x 2” Bolt through

base and strut. Tighten nylock

nut with the bolt.

Important: Do not over-tighten

nylock nut so tight as to

prevent free movement.

Flip the carriage assembly 180˚.

Repeat for second support strut.

Step #4

Flip the carriage on its side with the

carriage base - wheels down and the

back/flap on flat ground.

With both hands, hold the beveled end

each of the support struts. Slide the

struts upward while holding the strut

and the carriage base with your

hands. Insert the beveled end strut

into the slots on the carriage base.

Step #5

From the inside of the carriage base

insert safety pins for both support

struts (labels indicate pin location).

Page 4 of 8

TP250 Carriage Assembly Instructions

Plywood Brackets

Safety Pins

Step #6

Insert the plywood brackets into slots

on the front of the Platform base.

If you plan to use the plywood

brackets insert the short end into

the slots with the long end 90˚ up.

Insert safety pins on each bracket.

When not in use or during transport

turn the plywood brackets down 90˚

and insert safety pins on both sides.

Step #7

You have completely assembled the TP250

Carriage unit.

Please proceed to the TP250 Operations Manual

for further instructions.

When not in use or during transport

turn the plywood brackets down 90˚

and insert safety pins on both sides.

404-344-0000 • tiedown.com

605 Stonehill Drive SW, Atlanta, GA 30336

404-344-0000 • tiedown.com

605 Stonehill Drive SW, Atlanta, GA 30336

www.tranzsporter.com

Carriage

Assembly

Instructions

TP400

Congratulations

You’ve purchased a roofing hoist manufactured by TIE DOWN ENGINEERING. All of hoist products are easy to

assembly and is solidly built in USA and tested to ensure years of service.

Before You Begin

We’ve included this easy to use instruction sheet to ensure quick, easy assembly of your carriage

platform. Be sure to read the instructions (a time saver in the long run). Identify all parts and hardware.

Questions?

We’re here to help, just call 800-241-1806. For faster service, have your model and serial number

ready when calling.

Page 5 of 8

Read this manual before using this product.

Failure to follow the instructions and safety precautions in this manual can result in serious

injury or death. Keep this manual in a safe location for future reference.

WARNING: This product can expose you to

chemicals including Nickel, which is known to

the State of California to cause cancer. For more

information go to: www.P65Warnings.ca.gov

TP400 Carriage Parts Description List

TP400 Carriage Assembly Instructions

Carriage Base

Carriage Base

Carriage Base

Lift This

Side

Support

Strut

Platform

Base

Platform Base

Platform Base

Platform Back/Flap

Platform base/Carriage, Pivot

Tab Holes

Pivot

Tab Holes

Description Qty.

Platform Back Flap 1

Platform Base 1

Carriage Base 1

Support Struts w/Pins 2

Plywood Brackets w/Pins 2

5/16”-18 x 2” Bolt 2

5/16”-18 x 1” Bolt 2

5/16” Nyloc Nuts 4

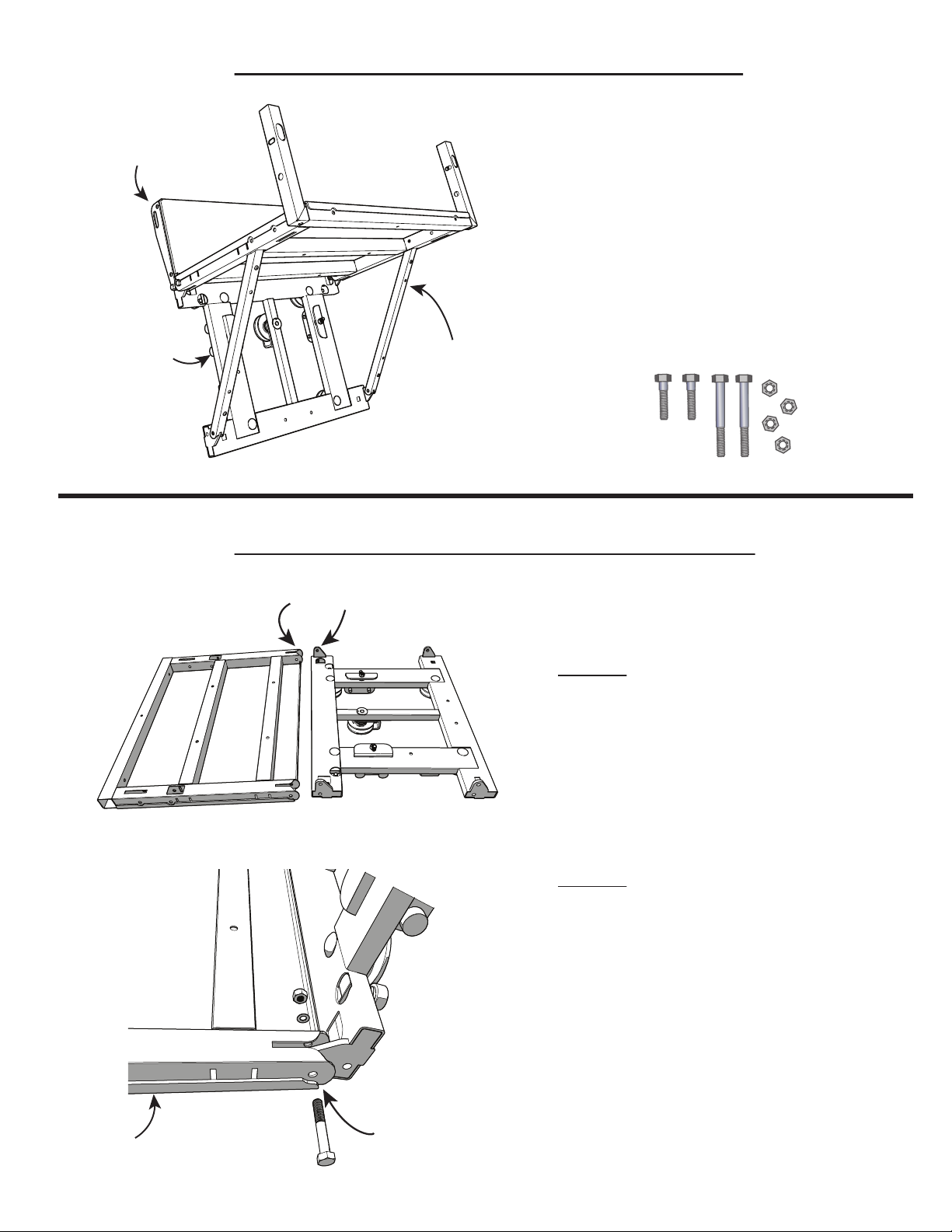

Step #1

Place the Carriage Base (wheels down)

and Platform Base (Smooth flat top down)

on a hard flat surface. Lift carriage base on

one end (shown left) so the pivot tab holes

align with each other.

Step #2

Insert 5/16” x 2” Bolt through platform and

carriage base tab holes Tighten nyloc nut with

the bolt; not so tight as to prevent free movement.

Repeat opposite side.

Page 6 of 8

TP400 Carriage Assembly Instructions

Support

Strut

Safety Pin

Safety Pin

Platform

Base

Platform Back/Flap

Tab Holes

Carriage Base

Step #3

Flip the carriage base over so that it lays

flat on top of the carriage base

Align the platform back/flap tap holes

with the carriage holes.

Insert 5/16”x 1” bolt through back/flap

tap holes and carriage base, Tighten nylock nut

with the bolt. Do not over-tighten nyloc nut so

tight as to prevent free movement.

Repeat for the other side.

Step #4

Fold the platform back/flap down,

lift the carriage base up 90 degrees

to both back/flap and platform base.

Position support strut with tab over the

carriage base tab as shown.

Insert safety pin. Insert safety pin

between the platform base and strut

as shown right.

Repeat for the other side.

Platform

Back Flap

Page 7 of 8

Carriage Base

404-344-0000 • tiedown.com

605 Stonehill Drive SW, Atlanta, GA 30336

TP400 Carriage Assembly Instructions

Step #6

You have completely assembled the TP400

Carriage unit.

Please proceed to the TP400 Operations Manual

for further instructions.

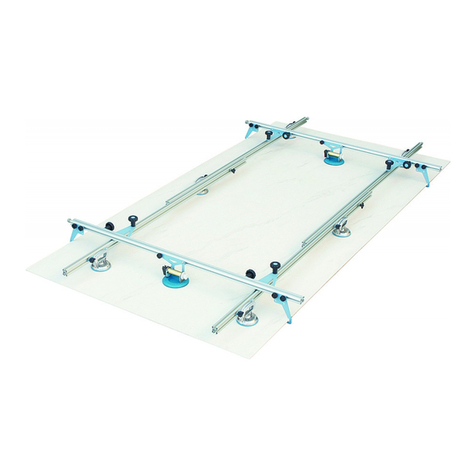

Plywood Brackets

Safety Pins

Plywood brackets used when

handling panel goods.

Plywood brackets in position for

transport or storage.

Step #5

Flip the completed base over. Insert the plywood brackets into slots on the front of the Platform base.

If you plan to use the plywood brackets insert the short end into the slots with the long end 90˚ up.

Insert safety pins on each bracket.

When not in use or during transport turn the plywood

brackets down 90˚ and insert safety pins on both sides.

Page 8 of 8

Safety Products Division

www.tiedown.com

Atlanta, Georgia 30336

800-241-1806 • 404-344-0000

ISO 9001:2015 Certification

Intellectual property of TIE DOWN Inc. ©2018 TIE DOWN, Inc.

Instruction #08290 (E1563 Rev. 11/23/20)

Other manuals for TP250

3

This manual suits for next models

1

Other TRANZSPORTER Lifting System manuals

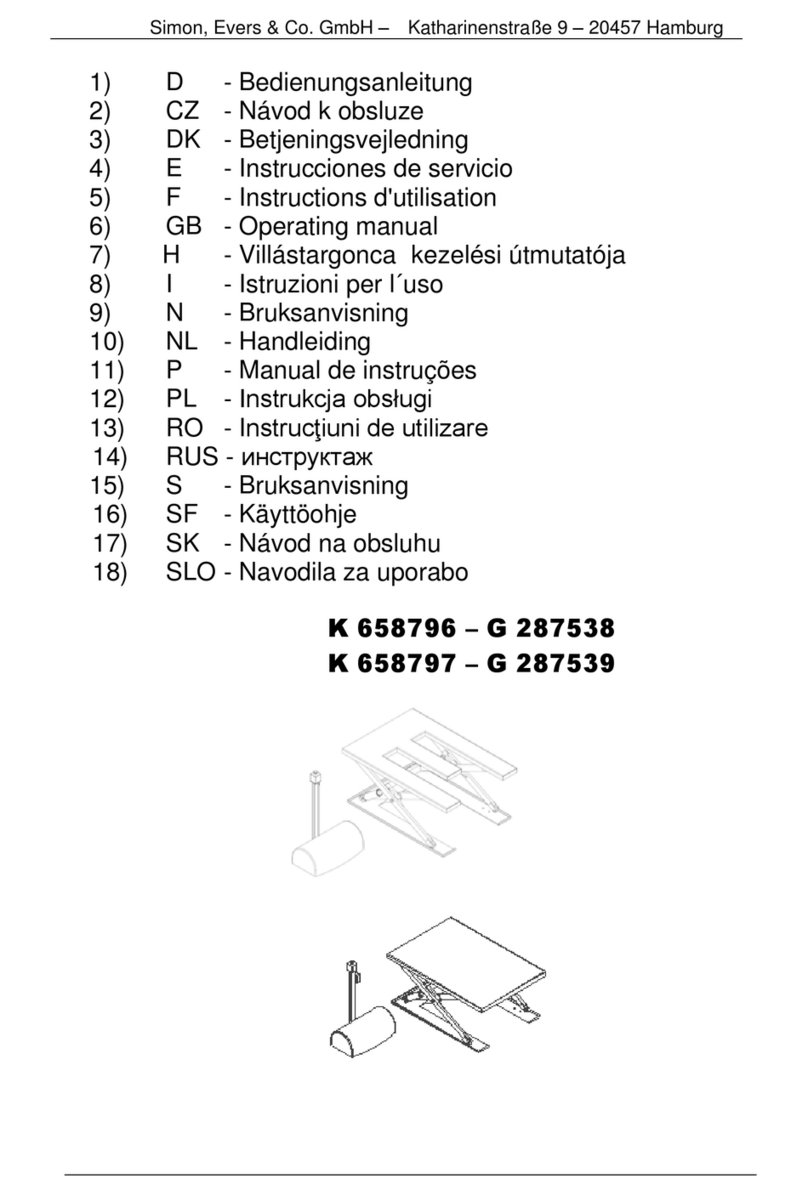

Popular Lifting System manuals by other brands

Aqua Creek Products

Aqua Creek Products Power EZ F-03PEZ manual

Ravaglioli

Ravaglioli RAV4300 Translation of the original instructions

Simon, Evers & Co

Simon, Evers & Co HTF-E operating manual

LoadSurfer

LoadSurfer XTN 540-1150 instructions

Braun

Braun UVL Series Operator's manual

Braun

Braun Under-Vehicle Lift NUVL603C Service manual