Ergoswiss SL 13 Series User manual

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

1/27

Operating instruction –Spindle lifting system SL/SM 13xx with SCT iSMPS

It is essential to read this operating instruction thoroughly before commissioning the system.

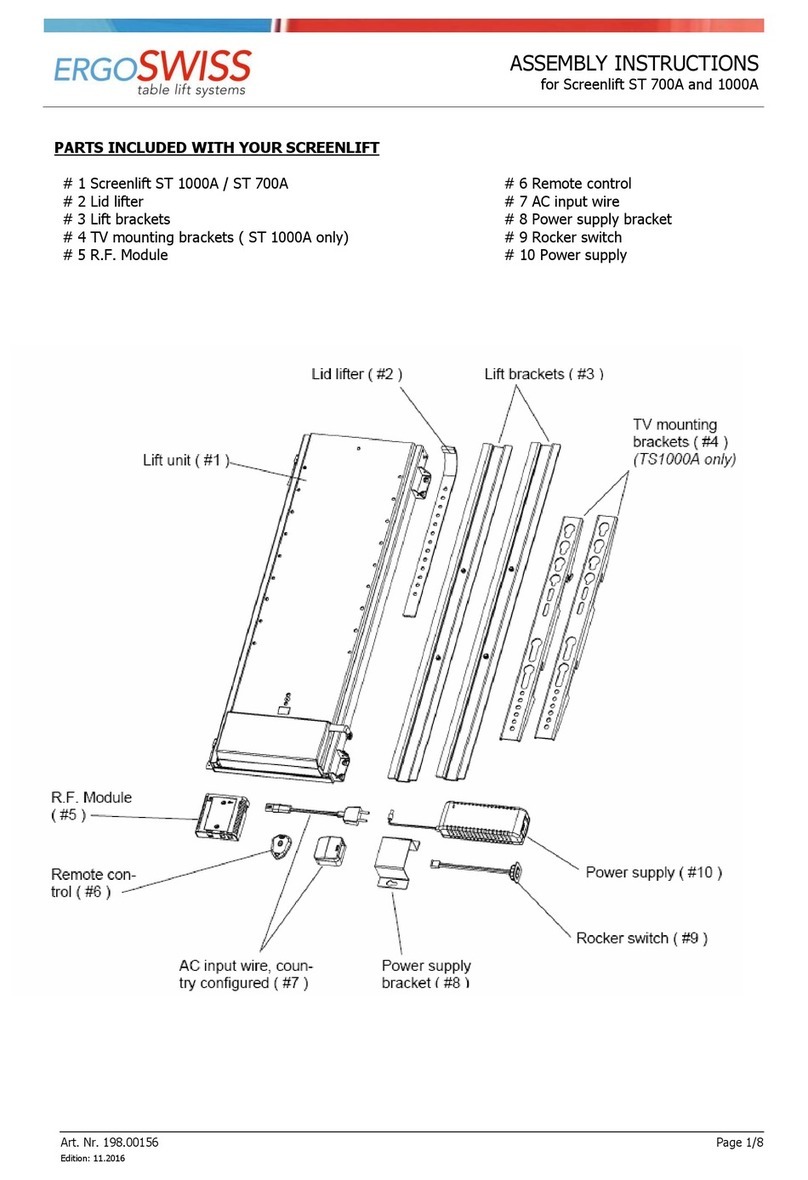

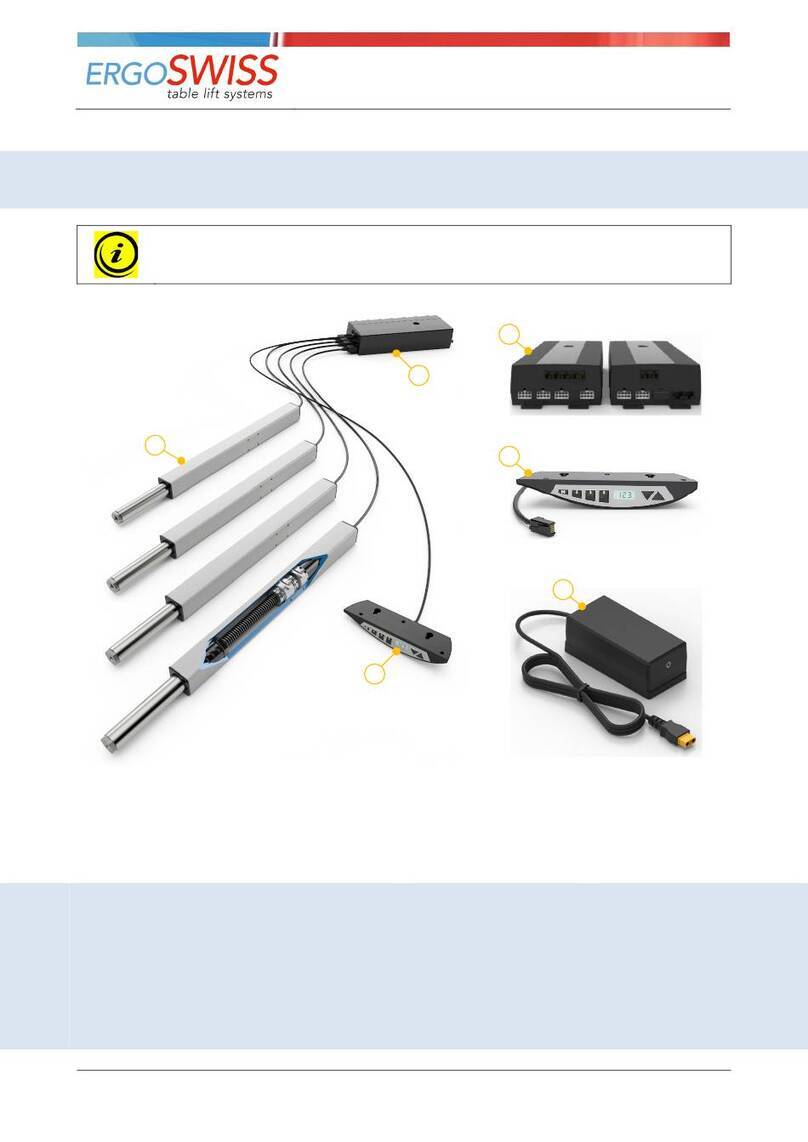

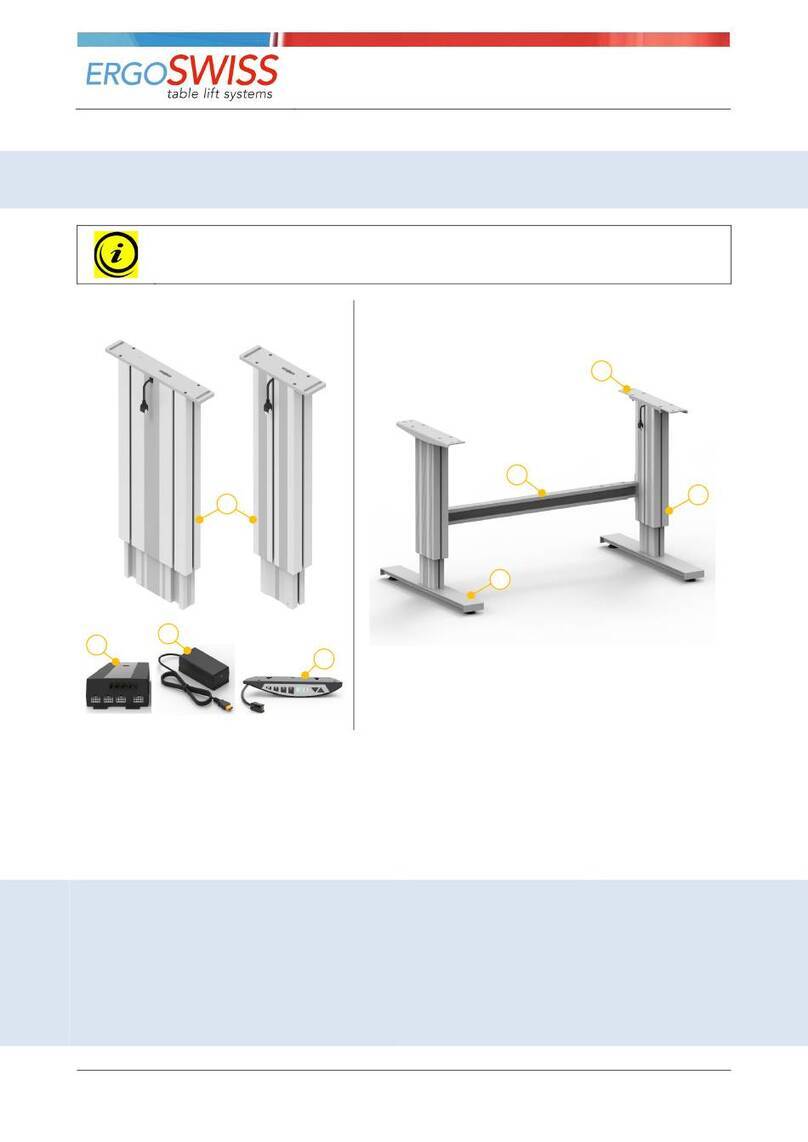

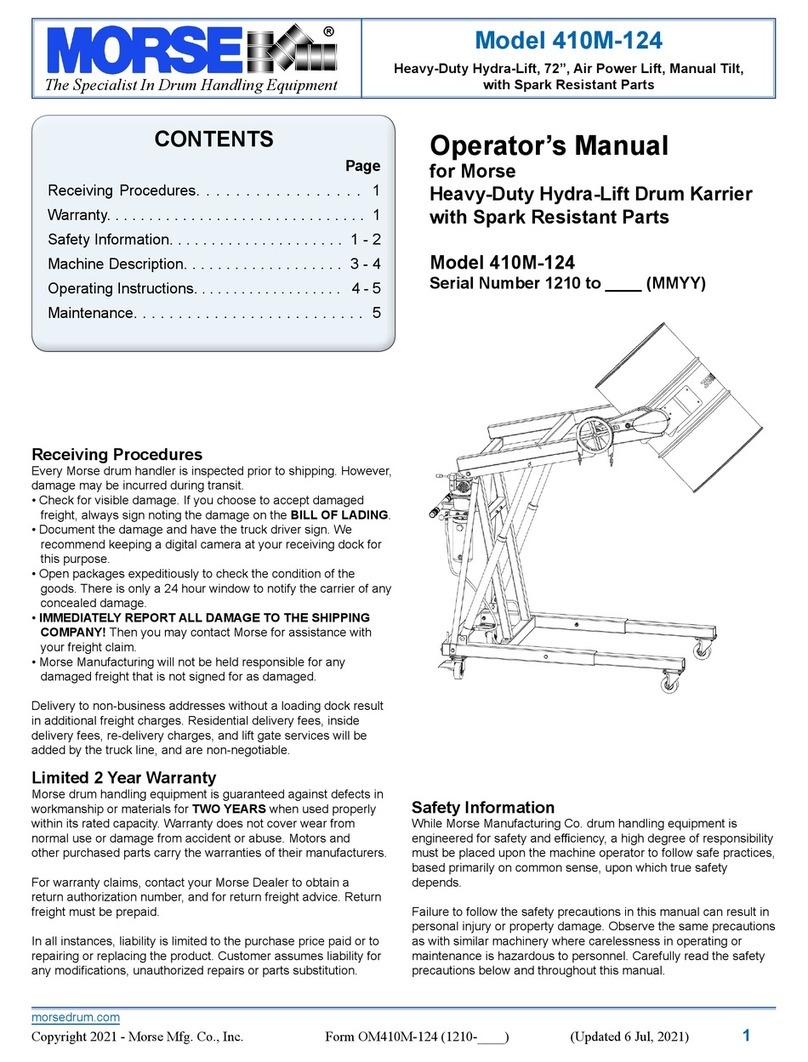

Spindle lifting column type SL 13xx

Spindle lifting column type SM 13xx

Control box SCT iSMPS

Manual control switch Up-Down or Memory

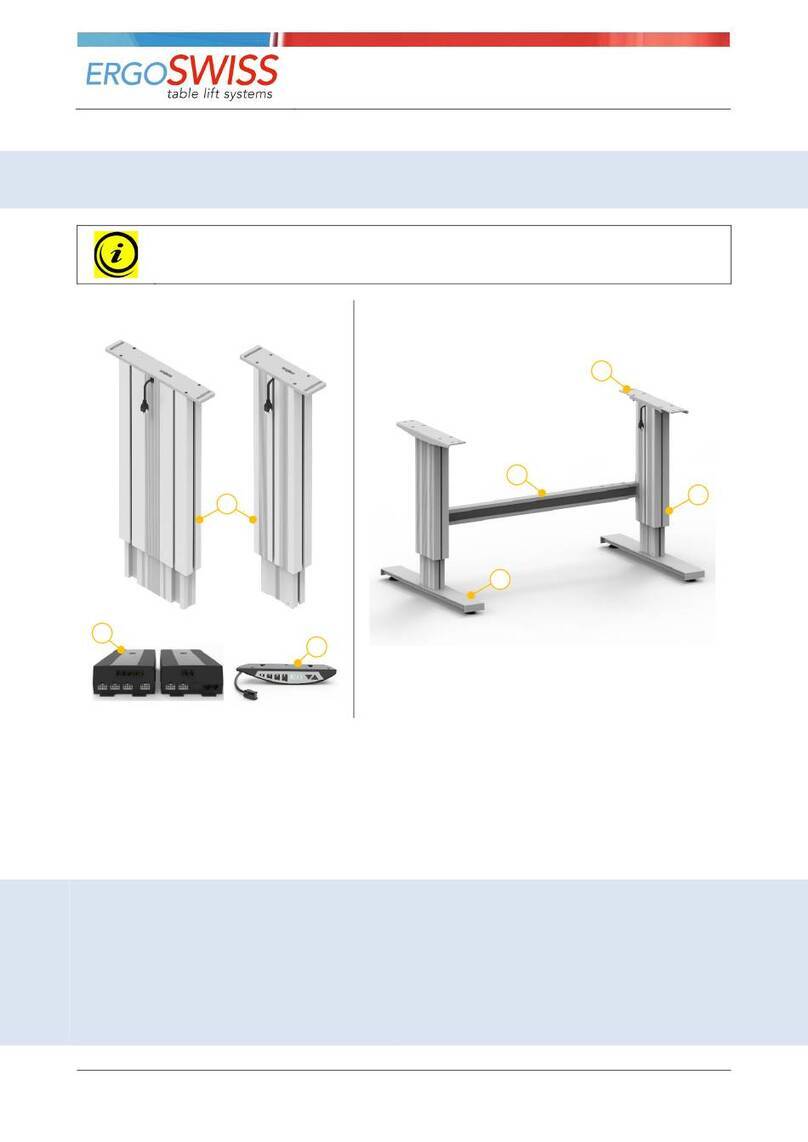

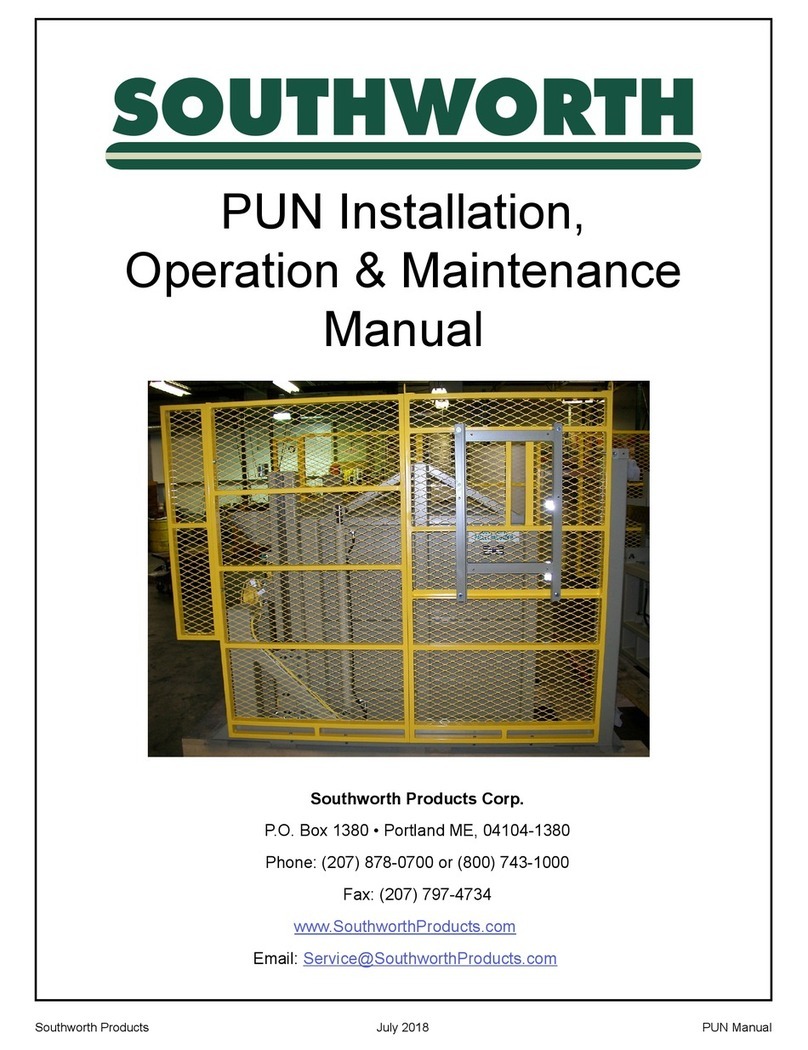

Example of a table frame with two lifting columns

Cross bar

Table feet

Errors and technical changes reserved.

Ergoswiss AG does not assume any liability for operat-

ing errors or using the products outside of the intended

purpose use.

At the time of delivery Ergoswiss AG will replace or re-

pair defect products within accordance with the warranty

provisions. In addition, Ergoswiss assumes no other lia-

bility.

For your questions and special custom demand

Ergoswiss AG will be at your disposal.

Ergoswiss AG

Nöllenstrasse 15

CH-9443 Widnau

Tel.: +41 (0) 71 727 06 70

Fax: +41 (0) 71 727 06 79

info@ergoswiss.com

www.ergoswiss.com

5

2

3

1

6

1

4

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

2/27

This operating instruction applies to:

Lifting system SL 13xx and SM 13xx with control box SCT iSMPS

Example.: Lifting system SL 2340 EU 12 (Item number: 901.41017)

Example.: Lifting system SM 4340 EU 12 (Item number: 902.41037)

Description

Standard version

SL

Lifting column type

SL

2340

Number of lifting columns

1, 2, 3, 4

2340

Spindle pitch in mm

3 mm

2340

Stroke length in cm

30 cm, 40 cm

EU

Power cable

EU, CH, US

12

11= Manual control switch Up-Down ; 12= Memory

11, 12

Frame SL 13xx and SM 13xx with control box SCT iSMPS

Example.: Frame SL-2 1340 960-1610 EU 12 (Item number: 901.51017)

Example.: Frame SM-2 1340 970-1620 EU 12 (Item number: 902.51017)

Description

Standard version

SL

Lifting column type

SL

-2

Number of lifting columns

1, 2, 3, 4

1340

Spindle pitch in mm

3 mm

1340

Stroke length in cm

30 cm, 40 cm

960-1610

Distance between lifting columns

Telescopic cross bar

EU

Power cable

EU, CH, US

12

11= Manual control switch Up-Down ; 12= Memory

11, 12

Other versions

Description

ESD

Electrostatic discharge from external profile via inner profile

s01-s99

Special version: adapter plate, table foot, fitting length, color, etc.

Notes on the operating instructions:

Lifting systems of Ergoswiss AG are intended for installation in a complete system and are classified in the

category of incomplete machines in accordance with the Machinery Directive 2006/42/EC. This manual con-

tains information on the commissioning, handling and safety of the lifting system and is intended for the re-

user and manufacturer of the entire system. The re-user of this lifting system is obliged to draw up an oper-

ating manual with all usage information and hazard warnings of the entire system.

The installation declaration is only valid for the Ergoswiss lifting system and not for the overall system cre-

ated by the re-user.

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

3/27

Table of content

1Safety requirements ...................................................................................................................................4

1.1 Explanations of the symbols and notes ...................................................................................................4

2System description .....................................................................................................................................5

2.1 General................................................................................................................................................ 5

2.2 Intended purpose use ...........................................................................................................................6

2.3 Target group and prior knowledge................................................................................................... 6

2.4 Performance characteristics ...................................................................................................................7

2.4.1 Lifting column SX 13xx .....................................................................................................................7

2.4.2 Control box SCT2 iSMPS and SCT4 iSMPS ...........................................................................................8

2.4.3 Manual control switch Up / Down and Memory....................................................................................8

2.4.4 System data .................................................................................................................................... 9

3Mounting instructions.............................................................................................................................. 10

3.1 Mounting instructions spindle column ................................................................................................... 10

3.2 Mounting the control box and connecting the cables .............................................................................. 12

3.3 Mounting the hand switch (cable remote control) .................................................................................. 13

3.3.1 Cable remote control SCT Memory T6 .............................................................................................. 13

3.3.2 Cable remote control SCT up-down.................................................................................................. 13

4Initial operation ....................................................................................................................................... 14

4.1 Duty cycle monitoring (ED).................................................................................................................. 14

5Operation with the hand switch type Memory........................................................................................ 15

5.1 Up / Down ......................................................................................................................................... 15

5.2 Saving and approaching a memory position .......................................................................................... 15

5.3 Limit the stroke length ........................................................................................................................ 16

5.3.1 Limit lower end position - Container-Stop ......................................................................................... 16

5.3.2 Limit upper end position - Shelf-Stop ............................................................................................... 16

5.4 Locking the movement (child protection) .............................................................................................. 17

5.5 Changing the measurement unit mm / inch........................................................................................... 17

5.6 Setting the shown height on the display ............................................................................................... 17

5.7 Restore factory settings....................................................................................................................... 18

5.8 Reset / initialize the end positions ........................................................................................................ 19

5.9 Deactivating /activating the tilt sensor .................................................................................................. 20

6Operation with the hand switch type up-down ...................................................................................... 21

6.1 Up / Down ......................................................................................................................................... 21

6.2 Reset / initialize the end positions ........................................................................................................ 21

7Synchronize 2 control boxes.................................................................................................................... 22

7.1 Commissioning ................................................................................................................................... 22

8Safety strip............................................................................................................................................... 23

8.1 Commissioning ................................................................................................................................... 23

9Maintenance and disposal ....................................................................................................................... 24

9.1 Maintenance and cleaning ................................................................................................................... 24

9.2 Repairs and spare parts ...................................................................................................................... 24

9.3 Disassembly and disposal .................................................................................................................... 24

9.4 Electrical and Electronic Equipment Act................................................................................................. 24

10 Error codes and trouble shooting ............................................................................................................ 25

10.1 Error codes on the display ................................................................................................................... 25

10.2 Trouble shooting ................................................................................................................................ 26

11 Declaration of Incorporation ................................................................................................................... 27

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

4/27

1Safety requirements

The safety instructions must be observed! If the system is operated improperly or not according to the in-

tended purpose, dangers for persons and objects can arise!

Before installing and operating the lifting system, this manual must be read and understood. The instructions

must be kept in the immediate vicinity of the system for lookup.

1.1 Explanations of the symbols and notes

Please pay attention to the following explanations of the symbols and notes. They are classified according to

ISO 3864-2.

DANGER

Indicates an immediate threatening danger.

Non-compliance with this information can result in death or serious personal injuries

(invalidity).

WARNING

Indicates a possible dangerous situation.

Non-compliance with this information can result in death or serious personal injuries

(invalidity).

ATTENTION

Indicates a possible dangerous situation.

Non-compliance with this information can result in damage to property or light to medium

personal injuries.

NOTE

Indicates general notes, useful operator advice and operating recommendations which do

not affect safety and health of the user.

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

5/27

2System description

2.1 General

The basic functionality of a spindle lifting system SL/SM by Ergoswiss AG is the lifting and lowering of work

surfaces, machine parts, profile systems, etc.

An operative spindle lifting System SL/SM consists of a minimum of following components:

•Lifting column

•Control box

•Manual control switch (Up-Down or Memory)

•Power cable

The lifting column SL/SM consists of two colorless anodized aluminum profiles which are guided with plastic

guides. The inner profile is moved by an inline spindle drive. Up to 4 spindle lifting columns can be con-

nected to one control box SCT4 iSMPS and be operated synchronously.

The high-performance control box SCT4 iSMPS is equipped with two or four motor channels, which are ad-

justed synchronously by an encoder converter. Due to the optimised driving comfort, the end positions are

gently approached as low-speed zones up to the standstill. An integrated tilt sensor reacts to the system tip-

ping and can prevent potentially dangerous situations. Additional functions, such as the synchronisation of

two control boxes or the connection of safety strips (squeezing protection) can be used.

With the separately available manual control switch Memory the spindle system can be operated comforta-

bly, the work surface will be adjusted steplessly in its height. The current height of the work surface is con-

tinuously shown on the display (cm or inches). Up to three different memory positions can be stored and

approached individually. Errors that occur are also shown on the display.

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

6/27

2.2 Intended purpose use

Field of application

NO field of application

•Height adjustment of work surfaces

•Height adjustment of machine parts

•Height adjustment of profile systems

•… List not final

•Clamping device

•Press (or counter stop for press)

•Passenger transport

•Security component

•… List not final

The lifting system can be used if:

•it is located at enclosed spaces, dry and non-explosive environments.

•ambient temperature is between +10 °C and +40 °C.

•relative humidity range is between 30 % and 70 % (not condensed).

•there are no strong electromagnetic fields nearby.

The lifting system must not be:

•operated outside the performance data (tensile, pressure, bending torque)

•loaded with pulse or impact forces (e.g. displacing loads).

•designed for continuous operation (the duty cycle (On/Off) must not exceed 2/40).

•operated with inadmissible or unintended components

(e.g. different types of lifting column; Replacement of the controller (control software))

•operated with damaged components

•open or post-processed

•used by children under 8 years of age or persons with limited physical, sensory or mental abilities.

Unless they are supervised by a person responsible for their security or receive instructions by this

very person on how to use the device.

When installing and operating the lifting system, the intended purpose of the entire system must be adhered

to. Commissioning is prohibited until the entire plant complies with the provisions of EG Machinery Directives

2006/42/EG (Machinery Directive). For this purpose, it is essential to perform a risk analysis, so that possible

residual hazards can be reacted to (e.g. by constructive measures or by means of instructions in the operat-

ing instructions or/and by safety instructions on the system). In the event of improper use, the liability of

Ergoswiss AG as well as the general operating licence of the lifting system expires.

2.3 Target group and prior knowledge

Before installing and operating the lifting system, this operation instruction must be read and understood.

The user manual must be kept in the immediate vicinity of the system for a look-up.

This manual is intended for the following groups of people:

The manufacturer of the complete system, who integrates this lifting system into a complete system

and integrates this operating manual into the operating instructions of the entire system.

The commissioning personnel, who install the lifting system in a workstation, a machine, etc. and put it

into operation. Basic mechanical and electrotechnical knowledge is required during commissioning.

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

7/27

2.4 Performance characteristics

2.4.1 Lifting column SX 13xx

Lifting column SL 13xx

Lifting column SM 13xx

Cross-section

260 x 60 mm

(10.2” x 2.8”)

150 x 70 mm

(5.9” x 2.8”)

Standard stroke length

300, 400 mm

(12”, 16”)

Installation length

Stroke length + 230 mm

(9”)

Weight

SL 1330 = 10.8 kg

(23.8 lbs)

SL 1340 = 11.5 kg

(25.4 lbs)

SM 1330 = 7.5 kg

(16.5 lbs)

SM 1340 = 9.3 kg

(20.5 lbs)

Max. allowed pressure

load

3000 N (674 lbf)

Max. allowed tensile

load

FTensile stat. 500 N

(112 lbf)

; FTensile dyn. 50 N

(11 lbf)

Power consumption

Voltage

24 V

Lifting speed

Noise level

< 60 dBA

Protection class

(DIN EN 60529)

IP 30

Electrical connection

Molex MiniFit plug 8 Pin

Cable length 1800 mm (70.8”)

End switch

No (reading Encoder)

Tested product life

5000 cycles

with 400 mm

(16’’)

stroke length, 3000 N

(674 lbf)

pressure load, duty cycle 2/40

dyn. = during the lifting movement

Duty Cycle 2/40; operating max. 2 min, pause 40 min

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

8/27

Max. allowed bending moment - spindle column SL

Max. allowed bending moment - spindle column SM

Mbxstat.

1200 Nm

(885 lbf ft)

Mbystat.

450 Nm

(330 lbf ft)

Mbxdyn.

550 Nm

(405 lbf ft)

Mbydyn.

200 Nm

(147 lbf ft)

Mbxstat.

900 Nm

(652 lbf ft)

Mbystat.

350 Nm

(258 lbf ft)

Mbxdyn.

450 Nm

(330 lbf ft)

Mbydyn.

150 Nm

(110 lbf ft)

Mbx = force x stroke

Mby = force x stroke

Mbx = force x stroke

Mby = force x stroke

dyn. = during the lifting movement

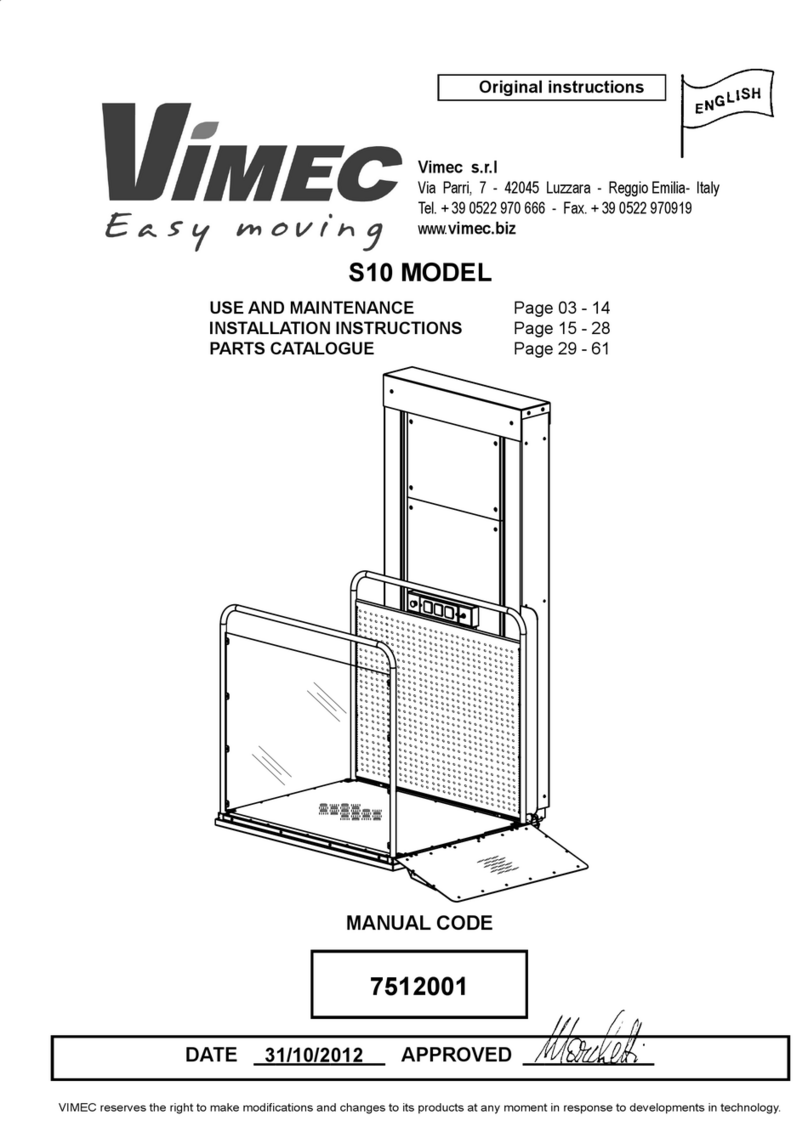

2.4.2 Control box SCT2 iSMPS and SCT4 iSMPS

Dimension (L, B, H)

309 x 120 x 55 mm

(12.2”x 4.7”x 2.2”)

Weight

1.1 kg

(2.4 lbs)

Supply voltage

EU: 207-254.4 V / 50 Hz / 4.5 A

US: 103.5–127.2 V / 60 Hz / 7.4 A

Primary standby power

< 0.6 W

Power

580 VA

Protection class (DIN EN 60529)

IP 20

Performance Level (DIN EN 13849-1)

PL b

2.4.3 Manual control switch Up / Down and Memory

Electrical connection

RJ-12 plug 6 Pin

Cable length 2000 mm

(78.7”)

Protection class (DIN EN 60529)

IP 30

Mbx

Mby

stroke

force

force

stroke

Mbx

stroke

force

stroke

force

Mby

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

9/27

2.4.4 System data

# spindle

column

Max. system

load

Stroke lenght

Column

Control box type

Lifting speed

Duty

cycle

[kg]

[lbs]

[mm]

[in]

Type

230 V

110 V

[On/Off]

1

300

660

300

12

1330

SCT2 iSMPS

SCT4 iSMPS

6 –8.5 mm/s

(0.24 –0.31 in/s)

(load

dependent)

2/40

400

16

1340

SCT2 iSMPS

SCT4 iSMPS

2

600

1320

300

12

1330

SCT2 iSMPS

SCT4 iSMPS

400

16

1340

SCT2 iSMPS

SCT4 iSMPS

3

750

1650

300

12

1330

SCT4 iSMPS

400

16

1340

SCT4 iSMPS

4

1000

2200

300

12

1330

SCT4 iSMPS

400

16

1340

SCT4 iSMPS

5

1100

2425

300

12

1330

2x SCT4 iSMPS

400

16

1340

2x SCT4 iSMPS

6

1200

2645

300

12

1330

2x SCT4 iSMPS

400

16

1340

2x SCT4 iSMPS

7

1300

2865

300

12

1330

2x SCT4 iSMPS

400

16

1340

2x SCT4 iSMPS

8

1500

3300

300

12

1330

2x SCT4 iSMPS

400

16

1340

2x SCT4 iSMPS

: spindle column SL or SM

: Duty cycle 2/40; operating max. 2 min, pause 40 min

NOTE

The lifting system can be subjected to uneven loads as long:

→the max. load on the lifting column (3000 N,

674 lbf

) is not exceeded,

→the max. bending torque of the lifting columns is not exceeded,

→the entire system is located on sufficient safe ground

→and the entire plant has been constructed in accordance with the provisions of the me-

chanical equilibrium. -> Conducting a risk analysis

ATTENTION

High pulse / impact forces due to the discontinuation of loads are not allowed.

(e.g. discontinuation of loads in feed with crane or forklift)

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

10/27

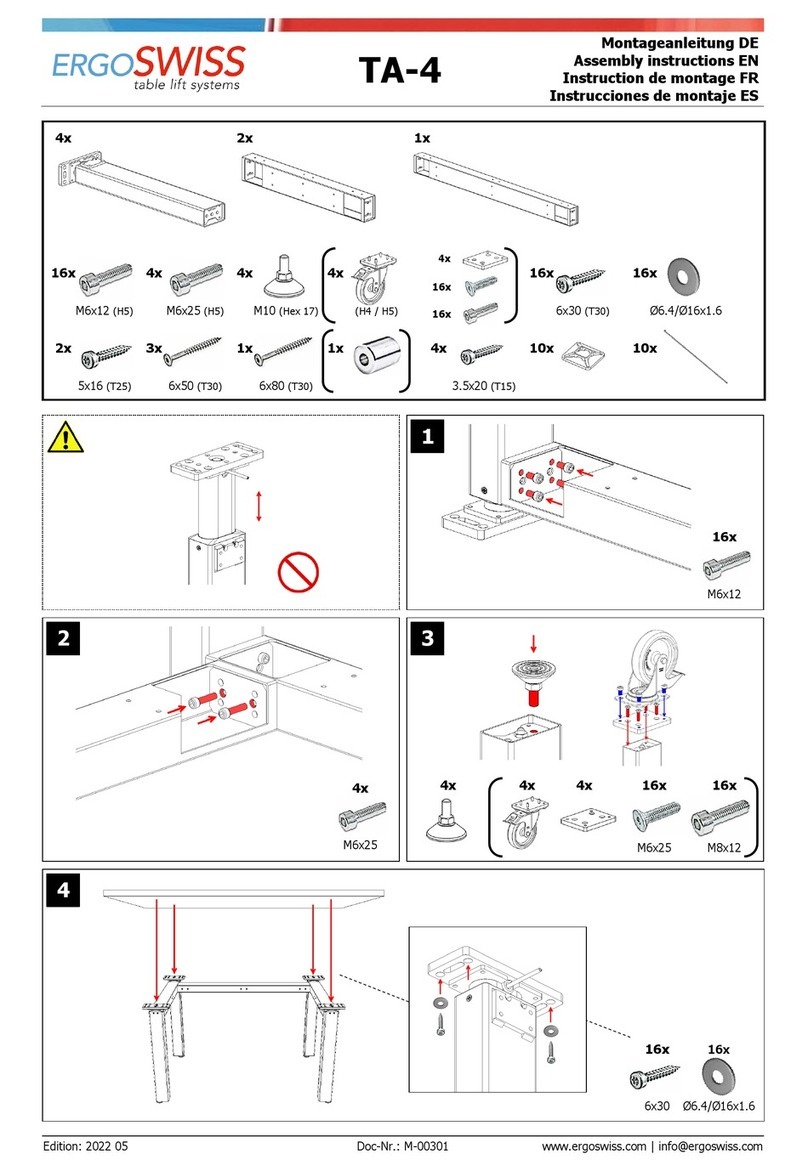

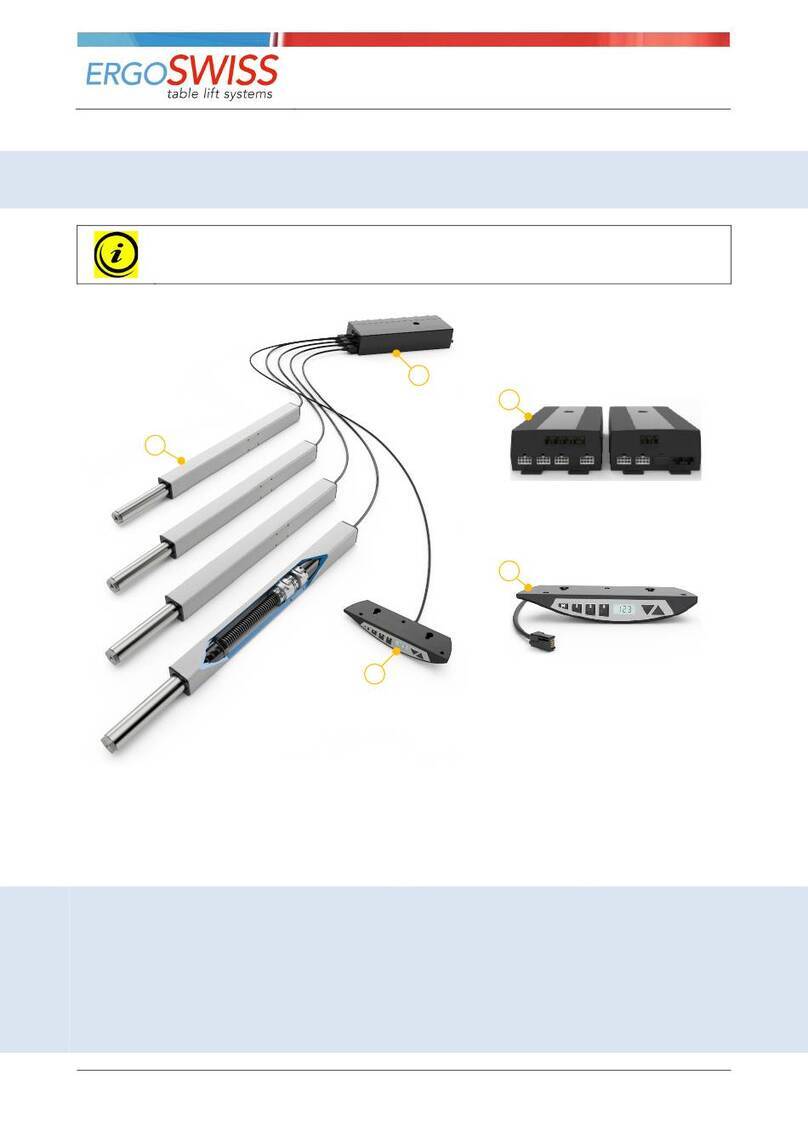

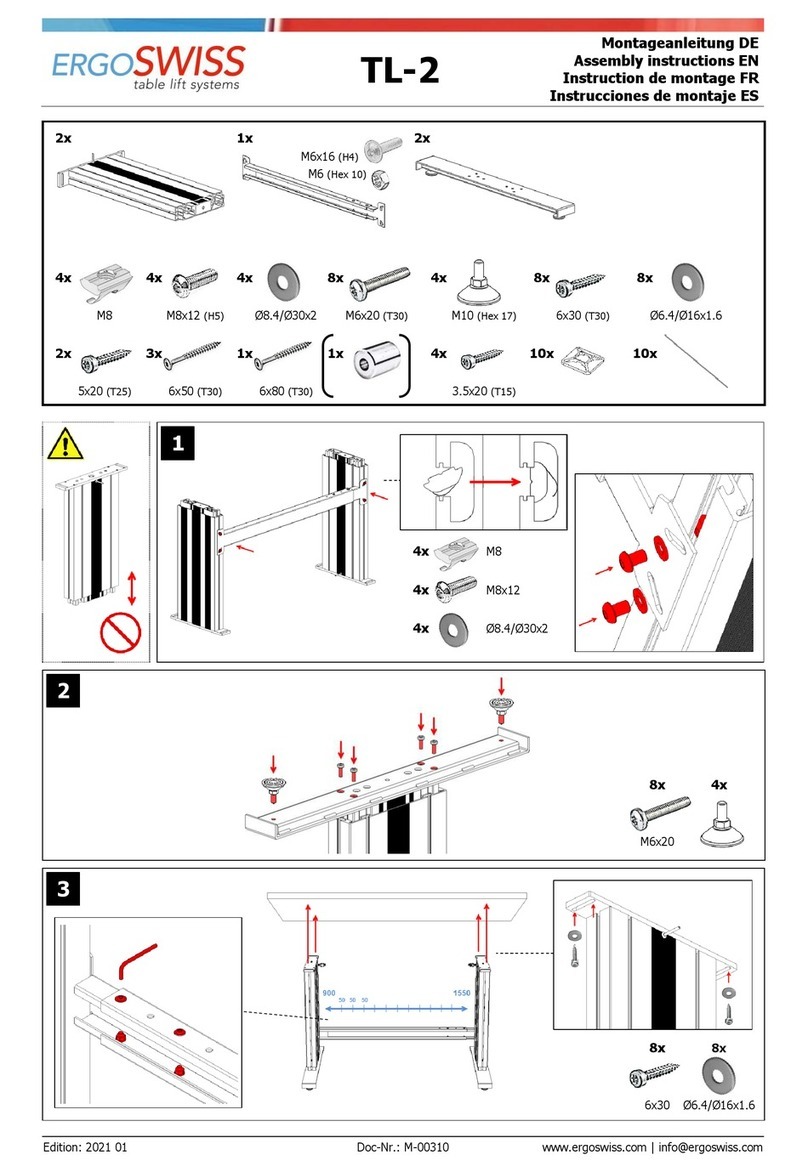

3Mounting instructions

3.1 Mounting instructions spindle column

NOTE

The lifting system must be mounted in such a way, that driving to the lowest position is pos-

sible at any time.

Otherwise, no initial operating and reset of the system can be carried out.

Fixing at the top

Adapter plate with long

hole (screw size M8)

Motor cable 1800 mm

(70.8”)

-can be extended up to 6000 mm

(236”)

.

(e.g. 4 motor extension cables of 1500 mm

(59”)

)

Attachment to T-slot (cross bar)

External profile with T-slots

Fixing bottom

Inner profile

4 x M6 x 20 self-tapping screw (included)

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

11/27

Lifting column type SL

Adapter plate (top)

2x long hole

➔For screw size M8

Inner profile (bottom)

8x Through hole

➔For screw size M6 (Ø5.3)

➔Torque max. 6 Nm

(4.4 lbf ft)

➔Screw-in depth

mind. 15 mm

(0.6”)

4x M6x20 self-tapping screw

included in the scope of delivery

Lifting column type SM

Adapter plate (top)

2x long hole

For screw size M8

Inner profile (bottom)

4x Through hole

➔For screw size M6

➔Torque max. 6 Nm

(4.4 lbf ft)

➔Screw-in depth

mind. 15 mm

(0.6”)

4x M6x20 self-tapping screw

included in the scope of delivery.

(drawing in mm)

(drawing in mm)

(drawing in mm)

(drawing in mm)

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

12/27

3.2 Mounting the control box and connecting the cables

ATTENTION

During mounting of the control box the power cable needs to be disconnected from

the mains!

NOTE

The control box has got an integrated tilting sensor as standard. To ensure smooth normal

operation, the controller must be fixed rigidly to the system before initial commissioning. (e.g.

below the tabletop)

Mounting the control box at the bottom of a tabletop:

1. Place the control box to the desired lo-

cation and mark the drill holes with a

pen

2. Pre-drill three holes (Ø 2.5 mm / 0.1”).

Be careful not to drill through the tab-

letop!

3. Fix the control box with three screws

torque max. 2 Nm

(1.5 lbf ft)

4. Connect the motor cables to the control box in the order from 1to 4.

(Automatic plug detection on all sockets)

5. Connect the hand switch to the control box ( )

6. Connect the power cable to the control box

7. Connect the power cable to the mains

Connection for safety strip

Connection for safety strip

Connection for manual control

Connection for sync cable

Motor socket 1

Motor socket 2

Motor socket 3

Motor socket 4

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

13/27

3.3 Mounting the hand switch (cable remote control)

NOTE

The cable of the cable remote control type Memory and up-down can be extended up to

3000 mm

(118’’)

-> (3x extension cable 124.00290)

3.3.1 Cable remote control SCT Memory T6

1. Position the hand switch at the desired location underneath

the tabletop. The control panel must overhang below the

work surface!

2. Fix the hand switch by using the mounting screws.

Be careful not to drill through the tabletop!

3.3.2 Cable remote control SCT up-down

1. Position the hand switch at the desired location underneath

the tabletop. The control panel must overhang below the

work surface!

2. Fix the hand switch by using the mounting screws.

Be careful not to drill through the tabletop!

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

14/27

4Initial operation

ATTENTION

Danger of squeezing during height adjustment

ATTENTION

The lowest block position must always be reachable.

The lifting element is not allowed to hit a stop before it reached its lowest block position.

Otherwise the reference will be stored at a wrong height. This would lead to a collision when

driving up to the mechanical block.

ATTENTION

The system can be fully loaded after the initial operation has been completed. During initial

operation, the lifting element can be loaded with a maximum of 150 kg

(330 lbs).

NOTE

During the initial operation, the lifting element drives with half the speed.

1. Keep the buttons and pressed simultaneously to drive to the under block position.

-> The system moves downwards at half speed.

-> Upward movement is disabled.

2. After reaching the block position, let go of the buttons and .

-> The control box will give a signal sound and the system will drive out a few millimeters.

-> After the drive out, control box will give another two signal sounds.

After reaching the block position, the lower and the upper position will be stored automatically. The initial

operation is completed.

(The lower position is 4 mm

(0.16’’)

higher than the block position. The upper position depends on the lifting

element type, resp. of the control box software.)

4.1 Duty cycle monitoring (ED)

The duty cycle monitoring checks for the operation/hold ratio. To avoid overheating of the system a duty

cycle of 2/40 (ON/OFF) should be maintained.

The maximum continuous operating time is 2 minutes. Afterwards a pause of at least 40 minutes needs to

be observed before the system can be operated again.

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

15/27

5Operation with the hand switch type Memory

5.1 Up / Down

This function is used for easy height adjustment of the system.

→Press the button or .

Keep the button pressed until the desired working height is reached.

5.2 Saving and approaching a memory position

With this function it is possible to memorise a certain position/height and approach it later by pushing one

button. With the three memory buttons up to three different positions can be stored and approached.

1. Drive to the desired position and press the button M3-times.

2. Press one of the buttons

1

2

3

within 5 s.

After saving there is a signal sound.

The memory position is now stored inside the pressed button.

To approach a stored memory position:

Keep one of the buttons

1

2

3

pressed until the desired working height is reached.

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

16/27

5.3 Limit the stroke length

These two features can be used to limit the stroke length of the lifting system (e.g. if a container is under

the table). The container stop position limits the lower end position, the shelf stop position the upper end

position.

5.3.1 Limit lower end position - Container-Stop

To define a Container-Stop position, proceed as follows:

1. Keep the buttons

1

2

and pressed simultaneously for 4 s.

-> The display shows «S01», while the S is blinking

2. Press the button or until «S05» is selected.

3. Confirm the selection «S05» with the button M.

-> The display stops blinking

4. Press the button or to drive to the desired Container-Stop position.

5. Confirm with the button M.

-> The display shows «S05»

6. Press the button

1

2

or

3

to leave the menu mode.

To delete a set Container-stop position, a new one has to be done with the same procedure.

5.3.2 Limit upper end position - Shelf-Stop

To define a Shelf-Stop position, proceed as follows:

1. Keep the buttons

1

2

and pressed simultaneously for 4 s.

-> The display shows «S01», while the S is blinking

2. Press the button or until «S04» is selected.

3. Confirm the selection «S04» with the button M.

-> The display stops blinking

4. Press the button or to drive to the desired Shelf-Stop position.

5. Confirm with the button M.

-> The display shows «S04»

6. Press the button

1

2

or

3

to leave the menu mode.

To delete a set Shelf-stop position, a new one has to be done with the same procedure.

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

17/27

5.4 Locking the movement (child protection)

By activating the locking function, the lifting systems can no longer move. Neither a movement with the up /

down arrows nor a move to a memory position is possible.

Activate:

→Press the buttons

1

2

3

simultaneously for 5 s.

A signal tone sounds. The system is locked. The code «E65» appears.

If any of the buttons on the hand switch is pressed, a signal tone sound and the

system will not move.

Deactivate:

→Press the buttons

1

2

3

simultaneously for 5 s.

A signal tone sounds. The system is not locked anymore and can be operated normally.

5.5 Changing the measurement unit mm / inch

1. Keep the buttons

1

2

and pressed simultaneously for 4 s.

-> The display shows «S01», while the S is blinking

2. Press the button or until «S07» is selected.

3. Confirm the selection «S07» with the button M.

-> The display blinks «cm» or «inch»

4. Press the button or to select the desired measurement unit.

5. Confirm with the button M.

6. Press the button

1

2

or

3

to leave the menu mode.

5.6 Setting the shown height on the display

1. Keep the buttons

1

2

and pressed simultaneously for 4 s.

-> The display shows «S01», while the S is blinking

2. Press the button or until «S06» is selected.

3. Confirm the selection «S06» with the button M.

-> The display shows the current height («cm» is blinking)

4. Measure the height of the table

5. Press the button or to select the measured height

6. Confirm with the button M

7. Press the button

1

2

or

3

to leave the menu mode.

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

18/27

5.7 Restore factory settings

ATTENTION

Before restoring the factory settings, it must be ensured that:

- the lifting element can retract completely.

- each lifting element is loaded with less than 150 kg

(330 lbs).

NOTE

When restoring the factory settings, the entire system is set up again. All settings such as

memory or Container-stop positions are lost.

1. If possible: Drive to lowest end position

-> This saves time because the system only drives with half speed when doing a reset.

2. If needed, the system can now be rewired

a. Remove the cable from the mains

b. Rewire the system:

More lifting columns, synchronization cables or safety strips can now be connected.

c. Connect the power cable to the mains.

3. Keep the buttons

1

2

and pressed simultaneously for 4 s.

-> The display shows «S01», while the S is blinking

4. Press the button or until «S00» is selected.

5. Confirm the selection «S00» with the button M.

-> A signal tone sounds

6. Press the button

1

2

or

3

to leave the menu mode.

-> The display shows «EdC»

7. Do an initial operation according to chapter 4.

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

19/27

5.8 Reset / initialize the end positions

ATTENTION

The lowest block position must always be reachable.

The lifting element is not allowed to hit a stop before it reached its lowest block position.

Otherwise the reference will be stored at a wrong height. This would lead to a collision when

driving up to the mechanical block.

ATTENTION

The system can be fully loaded after the initial operation has been completed. During initial

operation, the lifting element can be loaded with a maximum of 150 kg

(330 lbs).

NOTE

During a reset, the lifting element retracts completely and the end position (reference posi-

tion) of the lifting element is redefined.

NOTE

During the initial operation, the lifting element drives with half the speed.

1. If possible: Drive to lowest end position

-> This saves time because the system only drives with half speed when doing a reset.

2. Keep the buttons and pressed simultaneously to drive to the under block position.

-> The system moves downwards at half speed. Upward movement is disabled.

3. After reaching the block position, let go of the buttons and .

-> The control box will give a signal sound and the system will drive out a few millimeters.

-> After the drive out, control box will give another two signal sounds.

The reset is now completed.

Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

20/27

5.9 Deactivating /activating the tilt sensor

The control has an integrated tilt sensor, which is activated by default. The 0° inclination of the control is

initialized during initial operation or reset. If the inclination of the control exceeds 2.5° (e.g. inclined table),

the controller stops the lifting movement. After triggering the tilt sensor, the system can be released up-

wards. If this is not possible, a reset according to Chapter 5.8 must be performed.

ATTENTION

The tilt sensor is not a safety element!

There is still a risk of injury before the tilt sensor triggers.

NOTE

In addition to a collision, the inclination sensor can be triggered by different causes. There-

fore, the following should be observed:

1. Install control rigidly before initial commissioning or reset

→So that the inclination of 0° is properly initialized.

2. After the system is moved, the inclination sensor should be reinitialized

→reset according to chapter 5.8

3. For mobile applications (e.g. table on rollers),

the inclination sensor should be deactivated.

The tilt sensor is deactivated (or activated), when following commands are executed:

1. Keep the buttons

1

2

and pressed simultaneously for 4 s.

-> The display shows «S01», while the S is blinking

2. Press the button or until «S08» is selected.

3. Confirm the selection «S08» with the button M.

-> A signal tone sounds

4. Press the button

1

2

or

3

to leave the menu mode.

5. If the inclination sensor is activated, the message "Edd" appears.

For the new initialization of the tilt sensor, a reset according to chapter 5.8 must

now be performed.

Other manuals for SL 13 Series

1

This manual suits for next models

15

Table of contents

Other Ergoswiss Lifting System manuals

Ergoswiss

Ergoswiss SLA VD Series User manual

Ergoswiss

Ergoswiss SLA 13 Series User manual

Ergoswiss

Ergoswiss TL-2 User manual

Ergoswiss

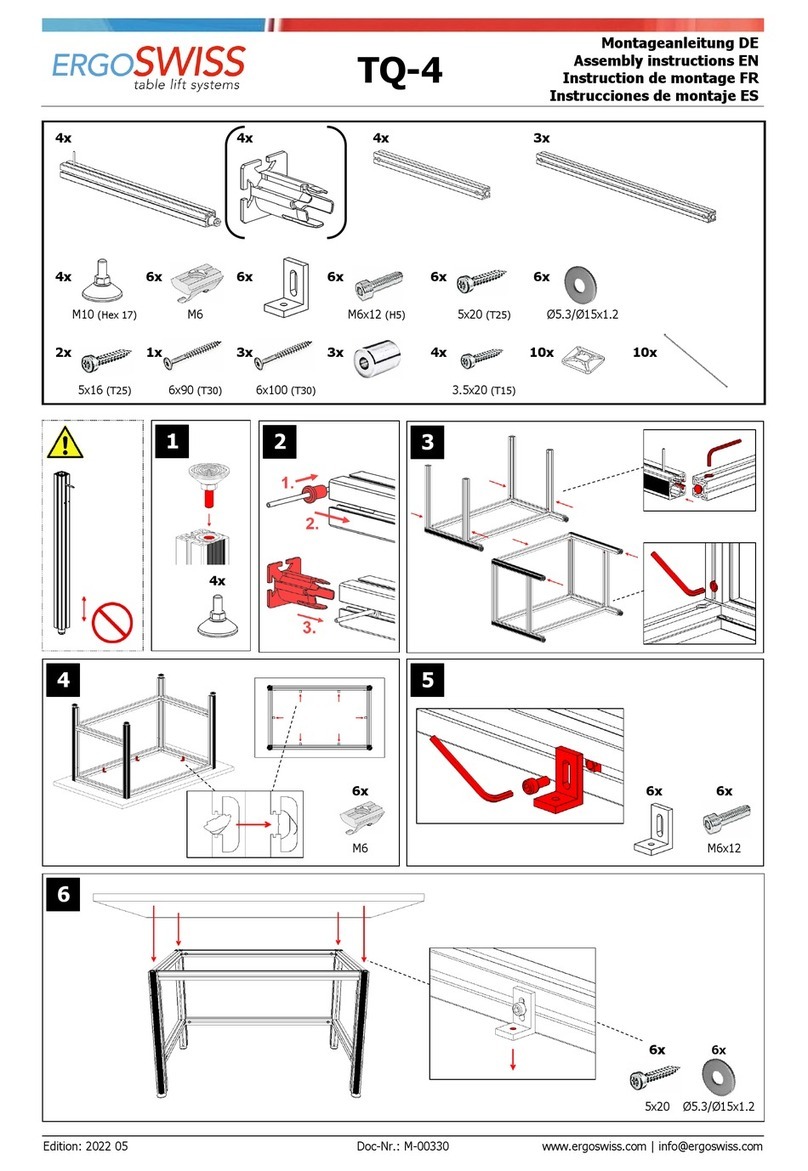

Ergoswiss TQ-4 User manual

Ergoswiss

Ergoswiss PA 2830 User manual

Ergoswiss

Ergoswiss SL compact User manual

Ergoswiss

Ergoswiss SLA User manual

Ergoswiss

Ergoswiss SL 14 Compact Series User manual

Ergoswiss

Ergoswiss FC 650 3.0 User manual

Ergoswiss

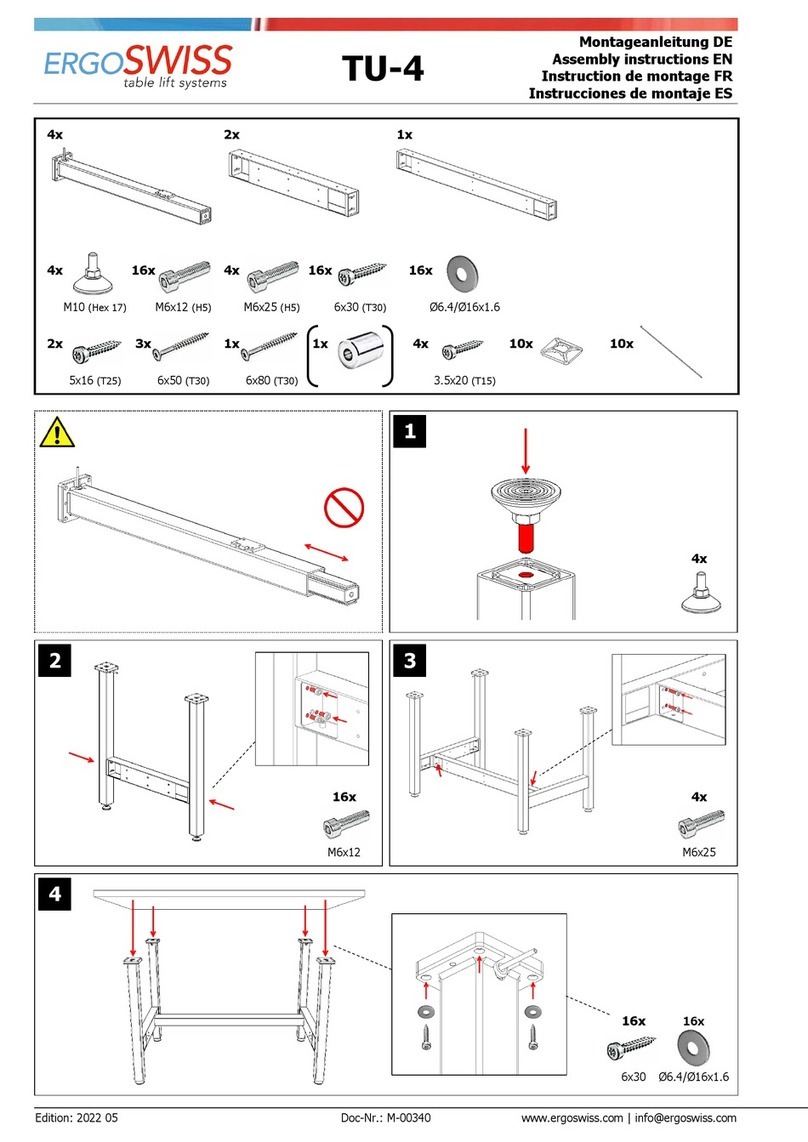

Ergoswiss TU-4 User manual