Fohrenbach HT102 User manual

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page :2/16/

CONTENTS

1.INTRODUCTION...........................................................................................................3

1.1.HandToolFunction....................................................................................................3

1.2.PhysicalDescription...................................................................................................3

1.3.Principlesof Operation...............................................................................................3

1.4.Specifications.............................................................................................................4

2.OPERATION.................................................................................................................5

2.1.Operating Procedures................................................................................................5

2.2.TerminalInspection....................................................................................................6

3.TROUBLESHOOTING..................................................................................................8

4.PARTSREPLACEMENTPROCEDURES....................................................................9

4.1.AnvilReplacement...................................................................................................9

4.2.Wireand Insulation BarrelCrimpersand TonkerReplacement

(see Figure13)..........................................................................................................11

5.ADJUSTMENTPROCEDURES....................................................................................12

5.1.CrimpHeightAdjustment...........................................................................................12

6.PARTS..........................................................................................................................14

6.1.SpareParts...............................................................................................................14

6.2.PartsOrderingInformation.......................................................................................14

6.3.Hand ToolRepairPolicy............................................................................................14

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page :3/16/

1. INTRODUCTION

1.1Hand Tool Function

The HT-0102isamanuallyoperated handtooldesigned forcrimpingloosepiece(individual)

Crimp-to-WireMalePinterminalstowiresizesof22-32 AWG.

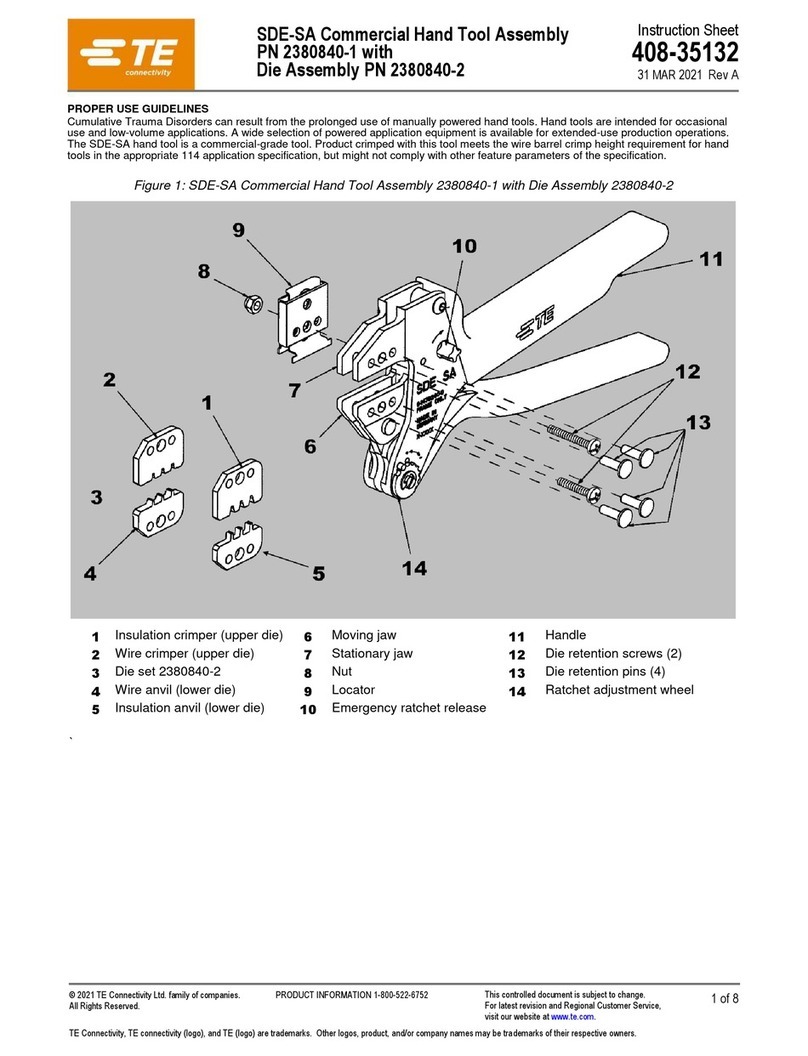

1.2Physical Description

The majorcomponentsthatmakeupthe HT-0102areidentifiedinFigure1. Theseincludea

frame,lever,tooling,toolingholdersand aterminalholder.The heartofthe handtoolisthe

tooling.Thetooling performsthecrimpingoperationand isdivided intotop and bottom

componentgroups.The topgroupconsistsofthosepartswhichremainstationarywiththe

frame.Thebottomgroup containsthosepartsthatmovewiththelever.TheHT-0102 is

equipped withtooling forcrimping twodifferentrangesofwire sizes.Theseareidentified as

"A"and"B"on aplateaffixed tothehand toolframe.The .A.sidetooling isfor crimping

terminalstowiresizesrangingfrom28-32 AWG.The "B"sidetoolingisusedforwiresizes

from22-26 AWG.

1.3Principles ofOperation

The leverattachestothe lowertoolingandprovidesthemechanicaladvantagetogenerate

thenecessarycrimpingpressure.Asthe leverisclosed,aratchetmechanismengagesto

prevent theleverfromopening untilthe crimpingcycleiscomplete.

Whenthe leverispulled closed,the lowertoolingandterminalarepushed upagainstthe

uppertooling.Thecrimpisformed betweenthe wireandinsulation barrelanvilsandthe wire

and insulationcrimpers.

Onceclosed,theratchetreleasesand allowsaspringtopullthe lever open

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page :4/16/

1.4Specifications

Whencrimping the MalePintowires,thefollowing parametersmustbemet.

-WireLengthRequirements:

•Minimum.................19-05mm(0.75in.)

•Maximum................AsRequired

-InsulationDiametersofWires:

•"A"Side(28-32 AWG)

LatchHousingand DiscreteApplications.............................0.81-1.37 mm

(0.032-0.054in.)Dia.

•B"Side (22-26 AWG)

LatchHousingand DiscreteApplications..............................0.96-1.52 mm

(0.038-0.060in.)Dia.

-StripLengthofInsulation:

LatchHousingand DiscreteApplications..............................3.81-4.32mm

(0.150-0.170in.)

-WireBarrelCrimpHeight:

•SingleWire (28-32 AWG)OrDoubleWires(30-32AWG).....0.61-0.66 mm

(0.024-0.026in.)

•SingleWire (22-26 AWG)OrDoubleWires(26-28AWG)....0.76-0.81 mm

(0.030-0.032in.)

-InsulationBarrelCrimpHeight:

•"A"Side(28-32 AWG)LatchHousingandDiscreteApplications1.75mm

(0.069in.)Max.Dia.

•B"Side (22-26 AWG)LatchHousingand DiscreteApplications1.75mm

(0.069in.)Max.Dia.

-MalePinTerminals:

•LoosePiece...........................................................................22-32 AWG

NOTE

Loosepieceterminalshavedifferent partnumbersthan reeledterminals

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page :5/16/

CAUTION

Ifthe terminaland the toolingare notcompatible,damage tothe toolingcouldresult. Ifyou

wishtouseaterminalwithapartnumberotherthan the one thatwasorderedforthe HT-

0102check withyourdistributortobesurethatthe newterminalnumberiscompatiblewith

yourhandtool.

2. OPERATION

2.1Operating Procedures

WARNING

To preventhand injury,keepfingersfrombetweentheupperand lowertoolingand

from betweentheleverandhandlewhenclosing handtool.

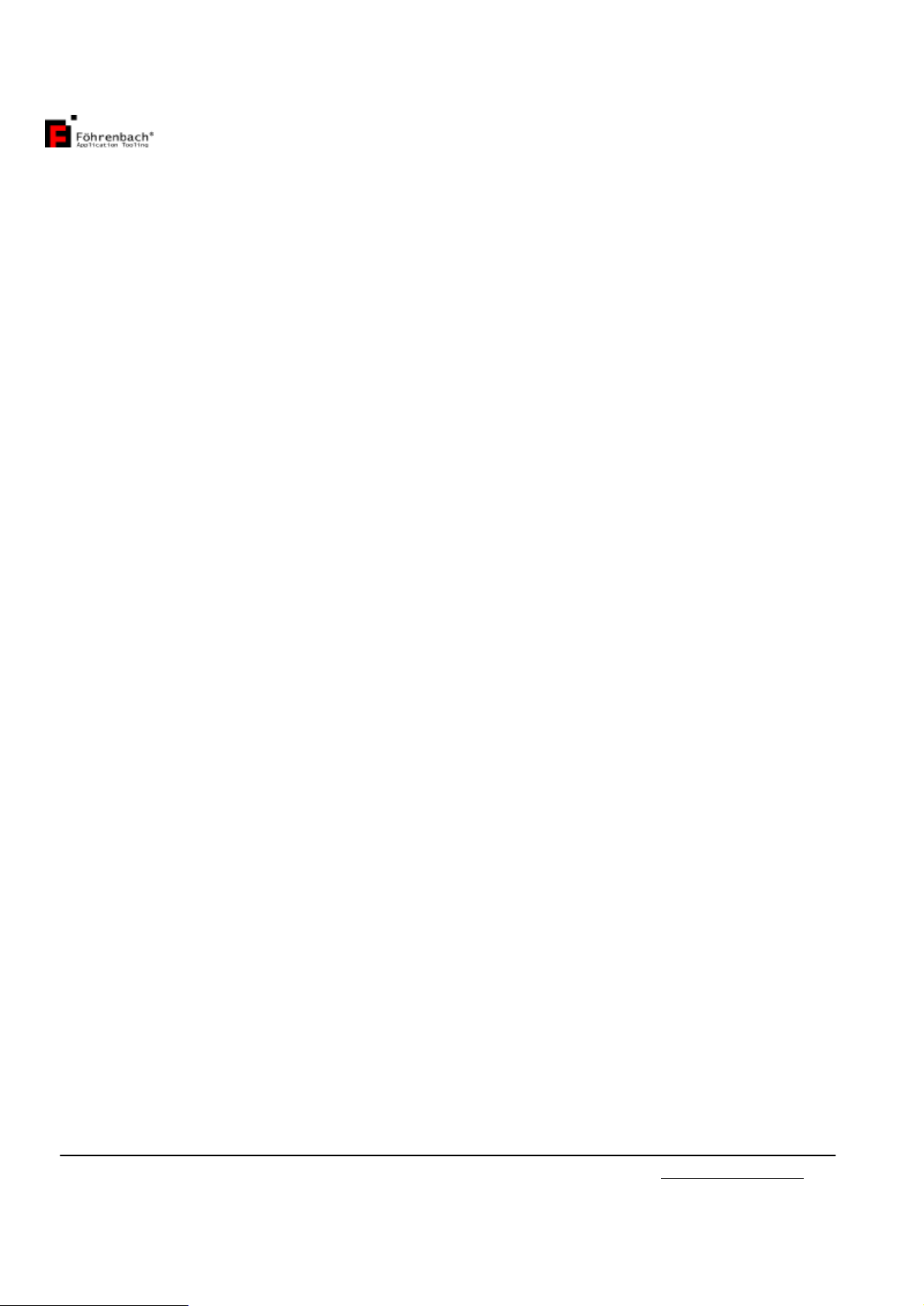

1.Holdthe handtoolsothatthe leverisontheleft. Withyour indexfinger,pushandhold

theterminalholder initsforwardposition (seeFigure 2).

NOTE

Wheninsertingaterminalintotheterminalholderyouwillnoticeaslightdrag(interference)

on the terminal.Thedrag iscaused bythe spring ballplunger (see Figure13itemno.21)

applyingdownwardpressureonthe pinendoftheterminal.

Thisdownward pressure helpstoorientandholdtheterminalinthe terminalholder until

crimped.

2.Insertthe pinend of the terminal, with“U” shaped barrels

up,intotheterminalholderandagainstthe pinshoulder.

Whileholding theterminalagainstthe shoulder,release

theterminalholder.Thisensuresthatthe terminal

remainsinthe properposition whilemovingoverthe

anvil.

Figure2. PositioningTerminalfor

Crimping

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page :6/16/

3.Whilegraspingthe leverand the handleportion of theframe,insert awiresothattheend

oftheinsulationiscentered between thewirebarrelandthe insulationbarrelofthe

terminal(seeFigure 3).Analternatemethod istopositionthe endoftheinsulation

againstthetonker(seeFigure13,itemno.2)whichprotrudesfrombetween thecrimpers

(3 &4).Then closethe handtoollever completely.Thiswillcrimptheterminaltothe

wire(s).

4.Releasethe levertoopen the handtoolandremovethecrimped terminalbylightlypulling

straightout on thewire.

CAUTION

Thecrimpheightforthishandtoolwas factoryadjusted.Anychangestothiscrimp

heightadjustmentcouldcause adefectivecrimpor damagetothetooling.

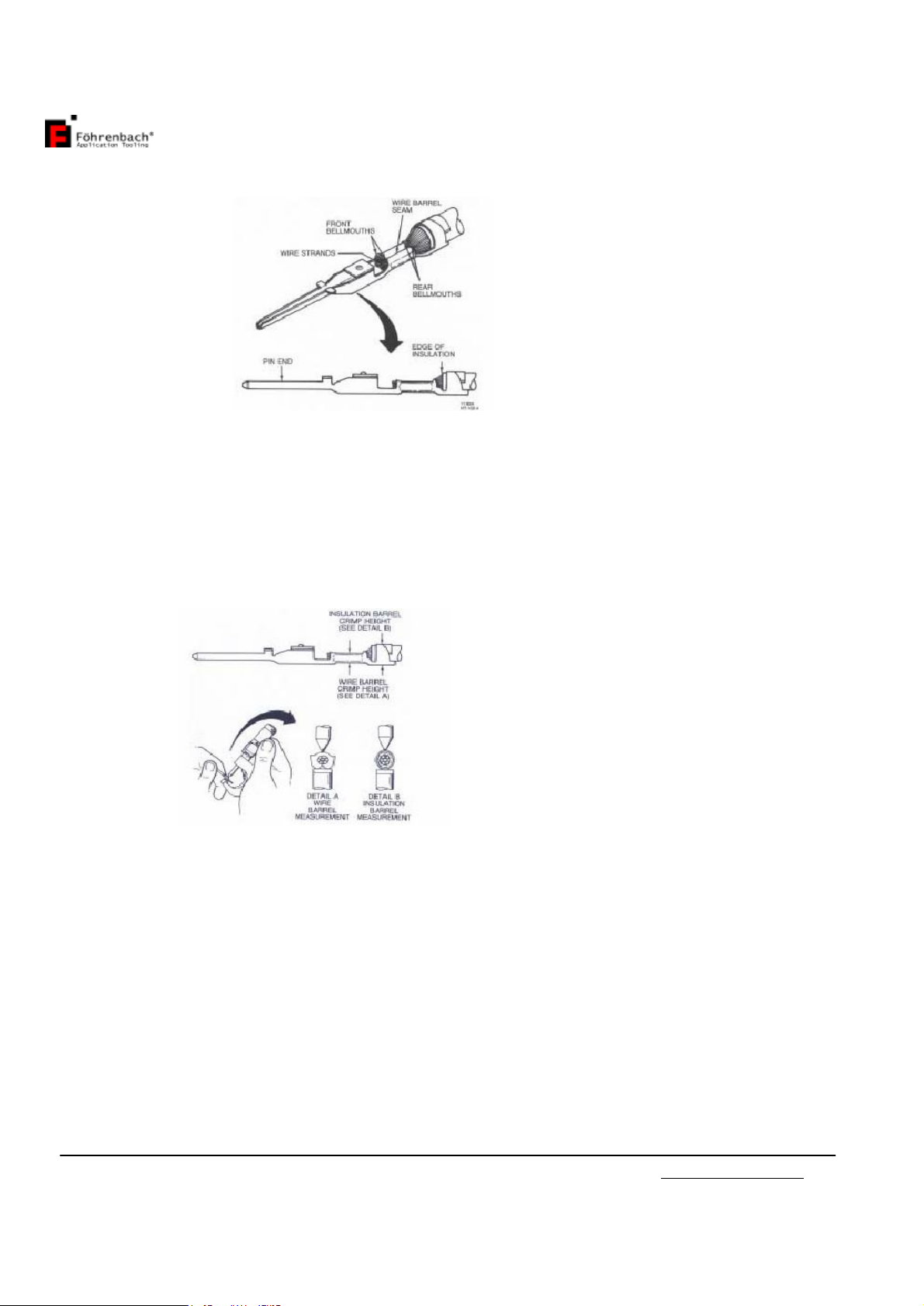

2.2Terminal Inspection

The crimped terminalshouldbe inspected toensurethatthe toolingiscorrectlyaligned and

thatthe wire wascorrectlyinserted. Makethefollowing visualchecks(seeFigure4).

NOTE

Ifinspection ofthe crimped terminalrevealsanydefects,the terminalhasnotbeenproperly

crimpedand shouldbe discarded.

•Checkthatall wirestrandswerecrimpedwithinthewirebarrel.

•Checkthatthe end ofthewireinsulationliesbetween theinsulationand the wirebarrel.

•Checkthatthe bellmouth(s)wereformed correctly.

•Checkthatthe wirebarrelseamiseven andtightlyclosed.

Figure3.Crimping TerminaltoWire

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page :7/16/

Next,obtainacrimpheightmicrometer andmeasurethe areasoftheterminalshownin

Figure5.Ifthecrimpheightsdo notmeetthespecificationslistedinSection1,Paragraph

2.4,refertoSection5forproper adjustmentprocedures.

Figure4. Correctly CrimpedTerminal

Figure5.MeasuringCrimpHeightof

Terminal

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page :8/16/

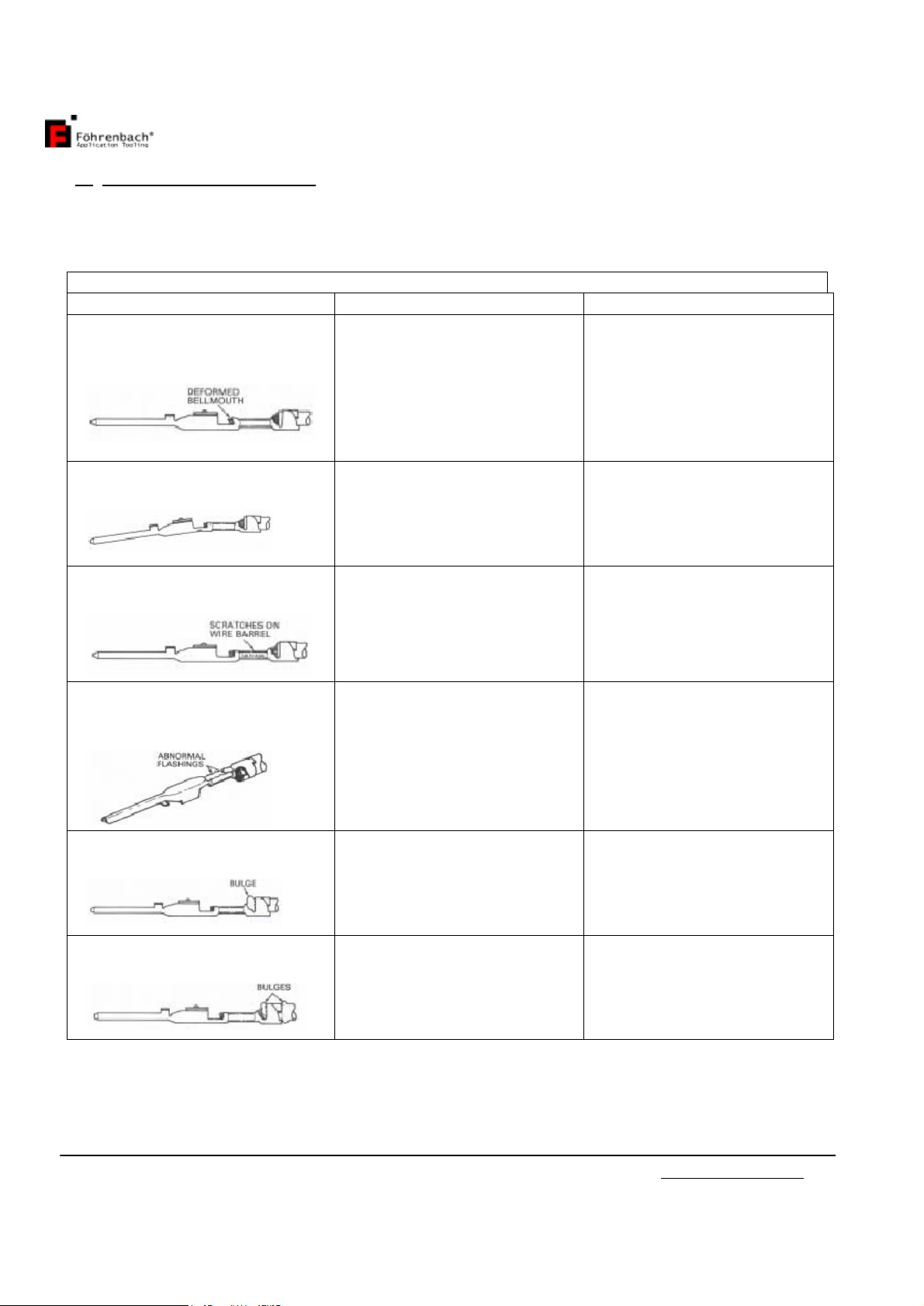

3. TROUBLESHOOTING

The troubleshootinginformationprovided inthefollowing chartwillhelpisolateandidentify

crimping problems.

TroubleshootingChart, MalePinTerminal

PROBLEM POSSIBLECAUSE CORRECTIVE ACTION

Bellmouth(s)isdeformedor

improperlypositionedonwire

barrel.

Terminalisnot properly

positionedincrimpingarea.

Insertterminalsoits

shoulder isagainstthe

terminalholder.

Reposition guidepinsuntil

proper bellmouth(s)is

achieved.

Pinendofterminalisbent

down

Terminalissticking inwire

barrelcrimper.

Tooling isbroken or

cracked.

Replacewirebarrelcrimper

asdescribed inSectionIV,

paragraph B.

The sidesofthe terminalswire

barrelarescored orscratched.

Wirebarrelcrimperis

defective. Replacewirebarrelcrimper

asdescribed inSectionIV

paragraph B.

Flashingsformed on the

bottomof thewirebarrelare

unequalor abnormal.

Anvilisworn orbroken Replaceanvilasdescribed

inSection IV,paragraphA.

Insulationbulgesbetween wire

and insulationbarrels.

Wirestriplengthisincorrect,

orwirewasinserted toofar

intothe terminal.

RefertoSection I,

ParagraphD(specifications)

forstriplengthrequirements.

Insulationbulgesaround

insulationbarrel

Wireorinsulationdiameter

isincorrect for the terminal

beingused.

Refertosection I,paragraph

D(specifications)forcorrect

insulationdiameter

requirements.

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page :9/16/

4. PARTSREPLACEMENTPROCEDURES

4.1AnvilReplacement

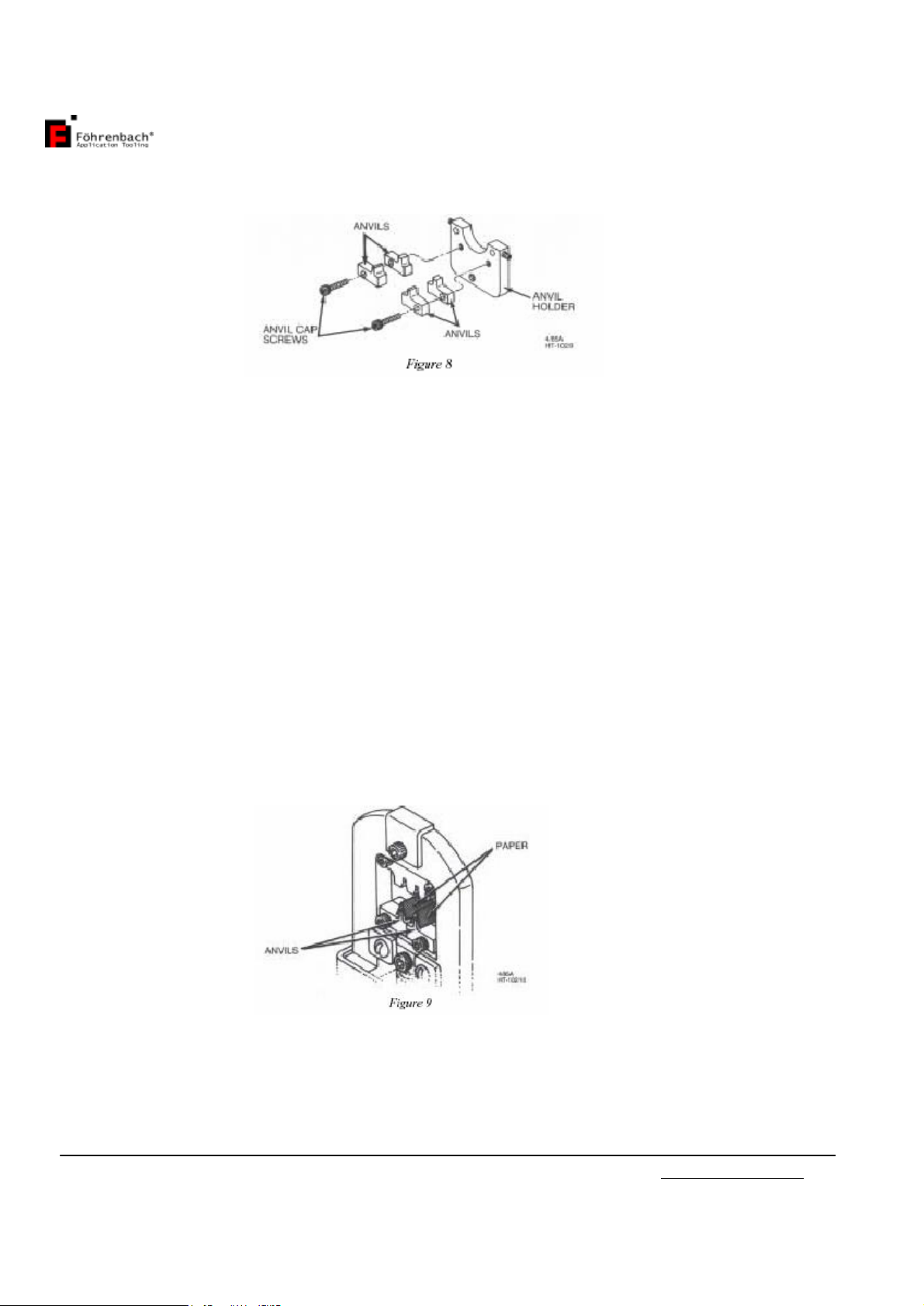

Replaceanvilswhen theyshowexcessivewear orbecomecrackedorchipped.

Removal

1.Removethe capscrewsecuringthe anvilholderassemblytothe handtool(see Figure 6)

and thenremovethe anvilholderassembly.

2.Loosen the twosetscrewsintheanvil holder andremovetheterminalholder (seeFigure

7).

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page: 10 / 16/

3.Removethe capscrewand defectiveanvil(s)fromtheanvilholder(seeFigure 8).

Installation

NOTE

Whenreplacing theanvils,be sure thatthe partnumberforthenewanvil(s)isthe sameas

theone being replaced.

1.Looselyinstallthe newanvilstothe anvilholderwiththeattaching capscrew(SeeFigure

8).

2.Reinstall theanvilholderontothehand tooland tighten the attaching cap screw.

CAUTION

Topreventtheanvilsfrombeingdamaged during alignment, placeapieceofpaper over

theanvils.

3.Cutouttwostripsofpaper.Then foldthestripsinhalfandplacethemover the anvils(see

Figure9).

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page: 11 / 16/

4.Slowlyclosethehandtoollevercompletely.Thiswillalign the anvilstothecrimpers.Then

tightentheanvilcapscrewand releasethe lever.Next,removethepaper fromtheanvils.

5.Reinstall the terminalholdertothe anvilholder.Makesurethattheflatson theend of the

terminalholderguidepinsfacethesetscrewsintheanvilholder.Thentightenthe anvil

holderset screws.

6.Crimpaterminaltothepropersizewire.Then inspecttheterminalasdescribedinsection

II,paragraph B.

4.2WireandInsulation Barrel Crimpersand TonkerReplacement(seeFigure13)

Removal

1.Loosen,butdonotremoveatthistime,the twocap screws(7)that securethe crimpersto

thecrimperholder(1).

2.Removethe capscrew(9)fromthe crimperholder(1).

Then removethe spring retainer(8) and the crimperholder(1)withcrimpersattached.

3.Removethe twotonkersprings(5)andthetwospringguides(6) fromthehand tool

frame.Thiscan be accomplishedbytilting thehandtooldown.

4.Removethe twocap screws(7)thatsecure thecrimperstothe crimperholder(1).

5.Removethe crimpers(3and4)andtonkers(2) fromthe crimper holder(1).

6.Removethe damaged crimper(s)(3)or(4).The topcrimperisthe wire barrelcrimper

(4).

Installation

NOTE

When replacing tooling,alwaysbe sure thatthe partnumberofthe newpartisthe same

numberthatison theoldpartthat wasremoved

7.Placethe insulationcrimper(3)ontotheflatsideofthecrimperholder(1).Placethe wire

barrelcrimper(4) ontheinsulation crimper(3) andlooselyinstallthetwoattaching cap

screws.

8.Inserttonkers(2),withthetoptabsfacing outwards,intothe slotsbetween thewireand

insulationcrimpers.

9.Placeand holdthecrimperassemblyintothehand toolwithcrimper holder (1)onthe

sameside asthe anvil holder (11).

Makesurethatthe tonkers(2)go intothe holesinthetop ofthehandtoolframe.

10.Placespring guides(6) intothe holesintopofthe handtoolframe,theninsertthesprings

(5)intothe holessothatthespringsslipoverthebodyof thespringguides.

11.Placespring retainer(8)overtonkersprings(5).Makesure springsare compressed,then

looselyattachthespring retainer (8)andthe crimperholder(1)tothe handtoolwiththe

attaching capscrew(9).

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page: 12 / 16/

12.Toalignthe tooling, closehandtoolcompletelyandholdit init.sclosedposition. Tighten

thetwocapscrews(7)tosecurethecrimperstotheirholder.Thentighten thecap screw

(9),whichsecuresthe crimperholdertothe handtoolframe.

13.Crimpaterminaltoaproper-sizewire andinspecttheterminalasdescribed inSectionII,

paragraph B.

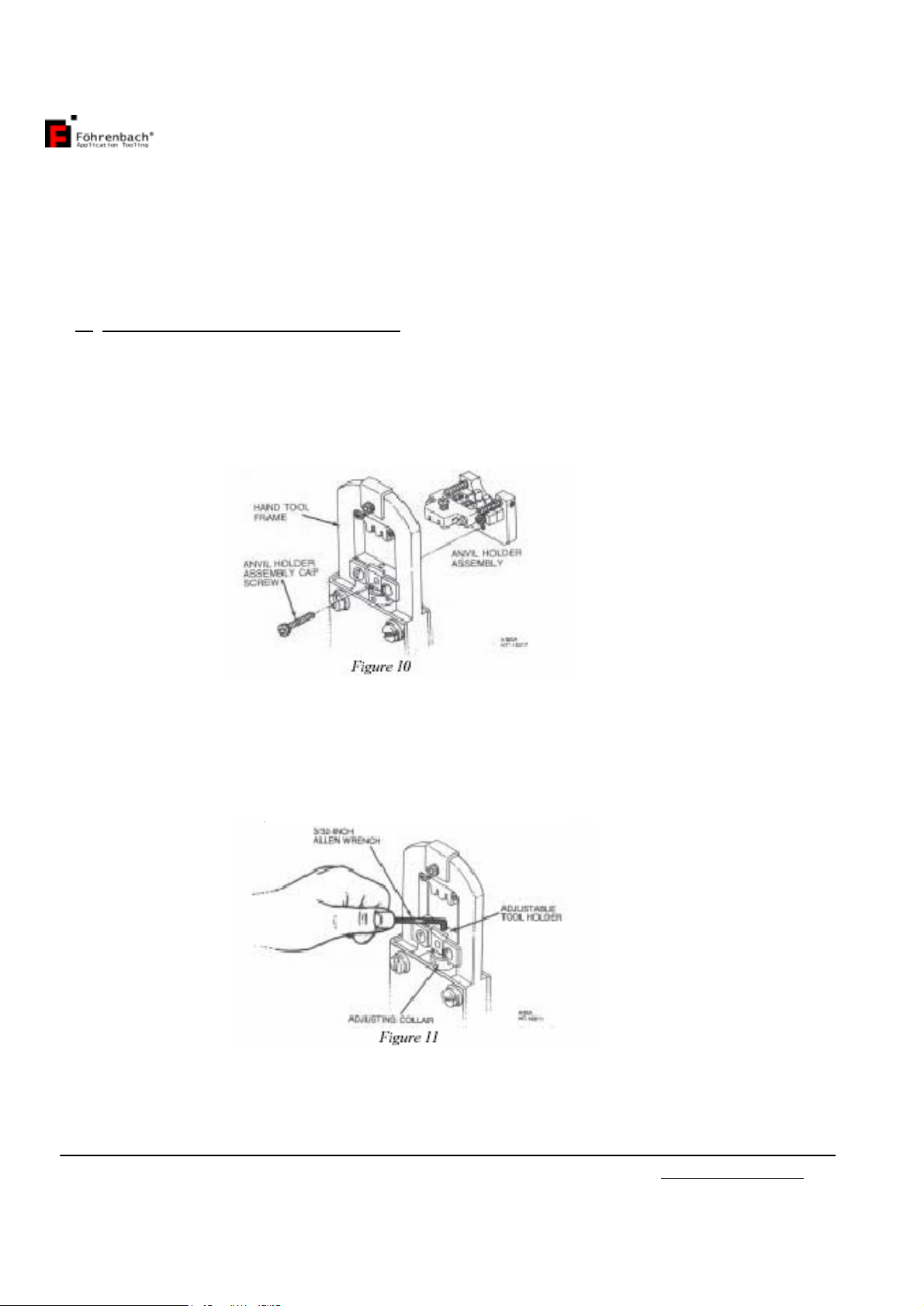

5. ADJUSTMENTPROCEDURES

5.1CrimpHeightAdjustment

1.Removethe capscrewsecuring theanvilholder assemblytothe handtool(seeFigure

10).Then

removetheanvilholderassembly.

2.Inserta3/32-inchAllen wrenchintotheholeinthe adjustabletoolholderandintothe

sockethead

setscrew(seeFigure11).Turn the setscrew¼turncounterclockwisetounlockthe

adjusting collar.

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page: 13 / 16/

3.Closethehandtoollever oneclicktogainaccesstothe holesinthe sideofthe adjusting

collar.Next,insertapinapproximately1/16-inchindiameter,intooneoftheholesinthe

collar(see Figure12).Then rotatethecollarabout5degreescounterclockwiseto

increasecrimpheightor clockwisetodecreasecrimpheight.

4.Reinstalltheanvil holder assemblyontothe handtooland tighten theattaching cap

screw.

5.Crimpaterminaltothe propersizewireandcheckthe wirebarrelcrimpheightofthe

crimpedterminal.Ifcrimpheightisnotasspecified,removethe anvil holderassembly

and turn theadjustingcollar anadditional5degrees.Thenreinstall theanvilholder

assemblyand againcheck the crimpheight.Continueadjustingthe crimpheightinthis

manneruntilthe propercrimpheightisachieved.

6.Removethe anvil holderassemblyandtightenthesetscrewclockwiseintheadjustable

toolholder. Then reinstallthe anvilholderassemblyand tightenthe attaching cap

screw.

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page: 14 / 16/

6. PARTS

6.1SpareParts

ThesearepartsthatFöhrenbachApplicationTooling considerspracticalforthe usertostock

forreplacement. Recommended sparepartsfor thehand toolare specified inboldtypeinthe

partslistforFigure 13.

6.2Parts OrderingInformation

Toobtainreplacementparts,contactFöhrenbachApplication Tooling.

6.3HandToolRepairPolicy

FöhrenbachApplication Tooling chargesastandardratetorepairanyhandtoolnotunder

warranty.FöhrenbachApplication Tooling willrepairthe handtooland returnit toyou bythe

fastestmeanspossible.

Instruction manualHT102www.foehrenbach.be

Date: August2007Documentrev. : 4Page: 15 / 16/

PartsList forFigure 13,HT-0102 HandToolParts

Index

no. PartNo. Description Quantity

1A-857-5 CRIMPERHOLDER 1

2* 104964-1 TONKER 2

3* 108175-1 INSULATIONBARRELCRIMPER22-32 GAUGE

WIRE 1

4* 108176-1 WIREBARRELCRIMPER22-32GAUGEWIRE 1

5A-1153 TONKERSPRING 2

6A-1155 GUIDESPRING 2

7915305-224 SHCS, 4-40 NFX .. LONG 8

8104963-1 SPRINGRETAINER 1

9915305-205 SHCS, 6-40 NFX ½. LONG 2

10 915305-559 SHSS(SETSCREW)2-56NC X 1/8.LONG 2

11 102466-1 ANVILHOLDER 1

12* 108178-1 INSULATIONBARRELANVIL,SIDE“A”, 28-32

GWIRE 1

13* 108178-2 INSULATIONBARRELANVIL,SIDE“B”, 22-26

GWIRE 1

14* 108177-1 WIREBARRELANVIL,SIDE“A”,28-32GWIRE 1

15* 108177-2 WIREBARRELANVIL,SIDE“B”,22-26GWIRE 1

16 102470-1 TERMINALHOLDERSPRING,0.65.LONG 2

17 147070-1 TERMINALHOLDER 1

18 900066-001 O-RING,0.070. I.D.,01-004 2

19 102468-2 GUIDEPIN 2

20 144547-001 GUIDERAIL 2

21 147071-1 TERMINALCLAMP 1

22 147072-1 QUILL PUNCH 1

23 102470-2 PUNCH SPRING,0.300.LONG 1

24 150564-1 COLLAR.NYLON_,PRESS-FIT, 0.0625. I.D. 1

*RecommendedSpareParts

This manual suits for next models

1

Table of contents

Other Fohrenbach Crimping Tools manuals

Popular Crimping Tools manuals by other brands

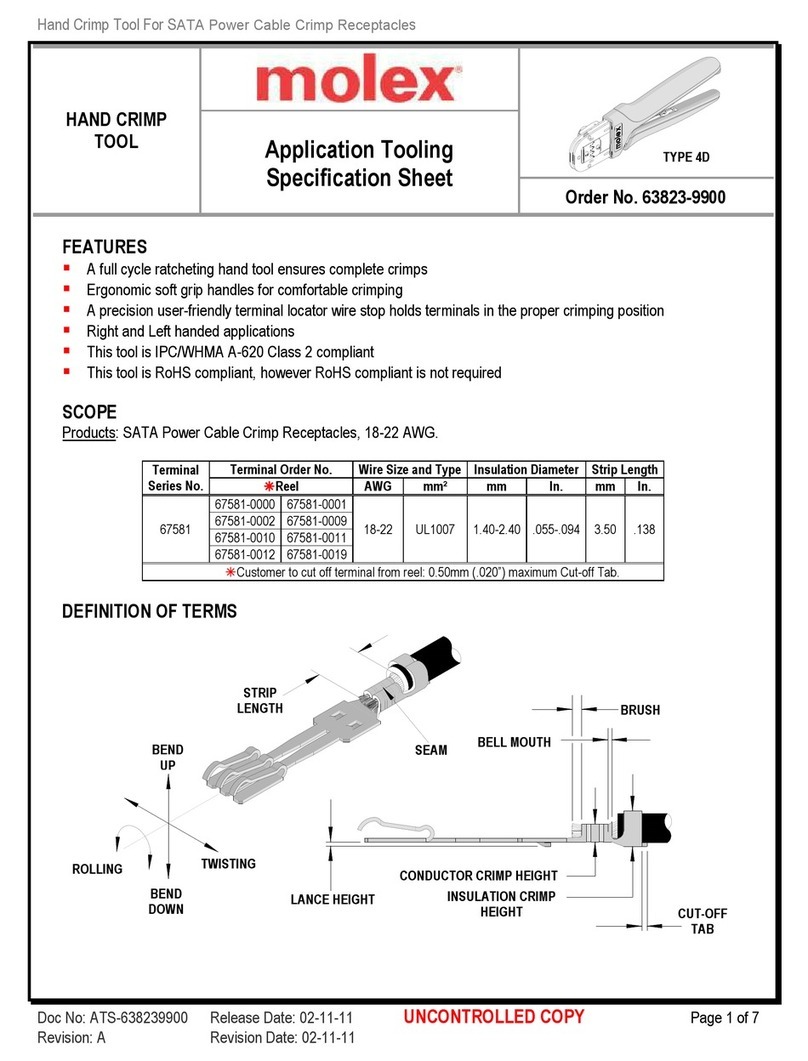

molex

molex 207129 Series manual

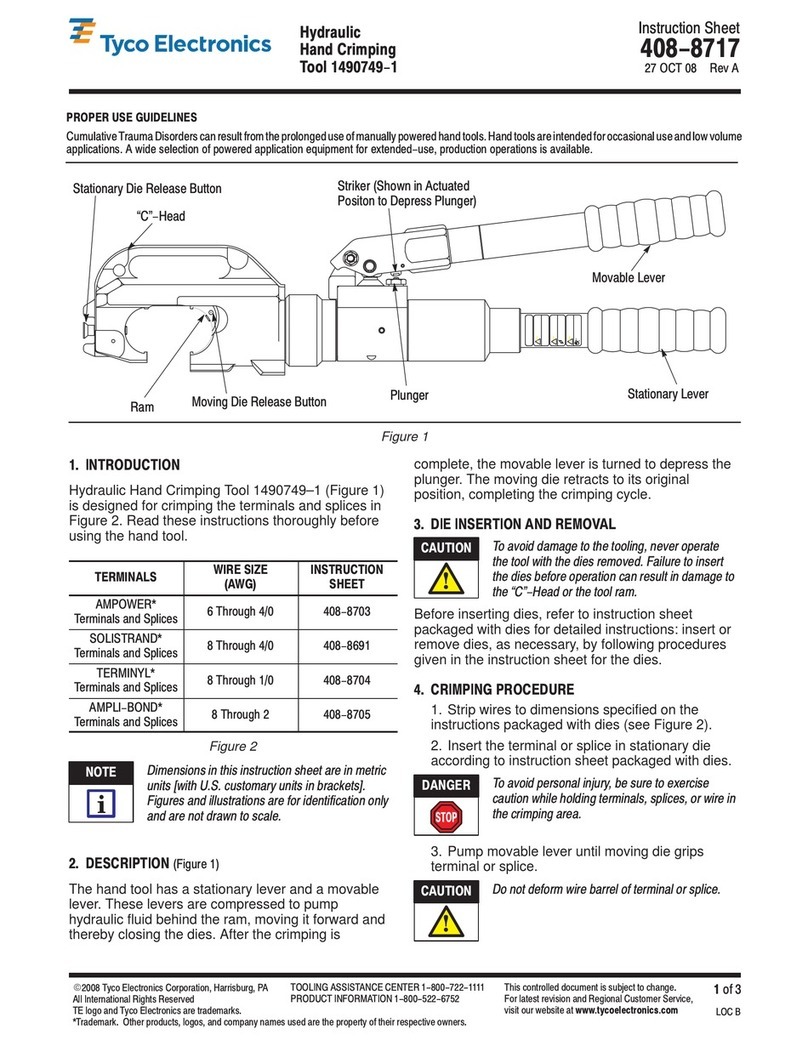

Tyco Electronics

Tyco Electronics 1490749-1 instruction sheet

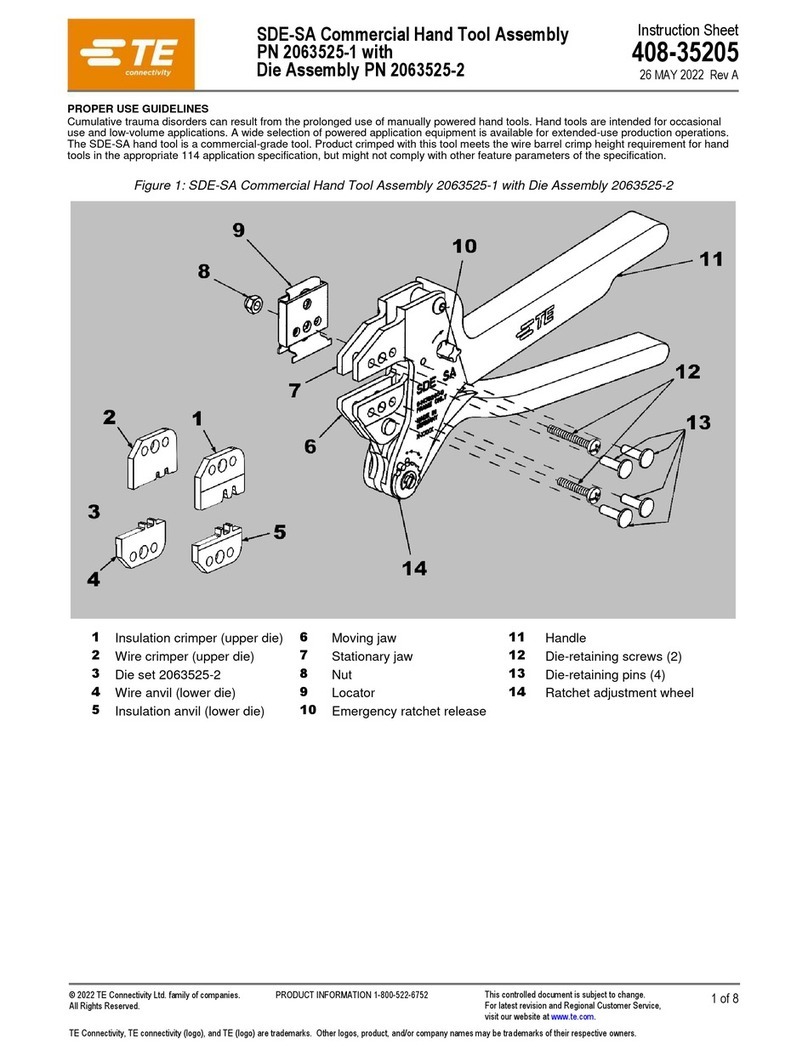

TE Connectivity

TE Connectivity 2063525-1 instruction sheet

Milwaukee

Milwaukee M18 HCCT109/42 Original instructions

BARTON TOOLS

BARTON TOOLS EC300 instruction manual

Rothenberger

Rothenberger ROFLARE REVOLVER Instructions for use