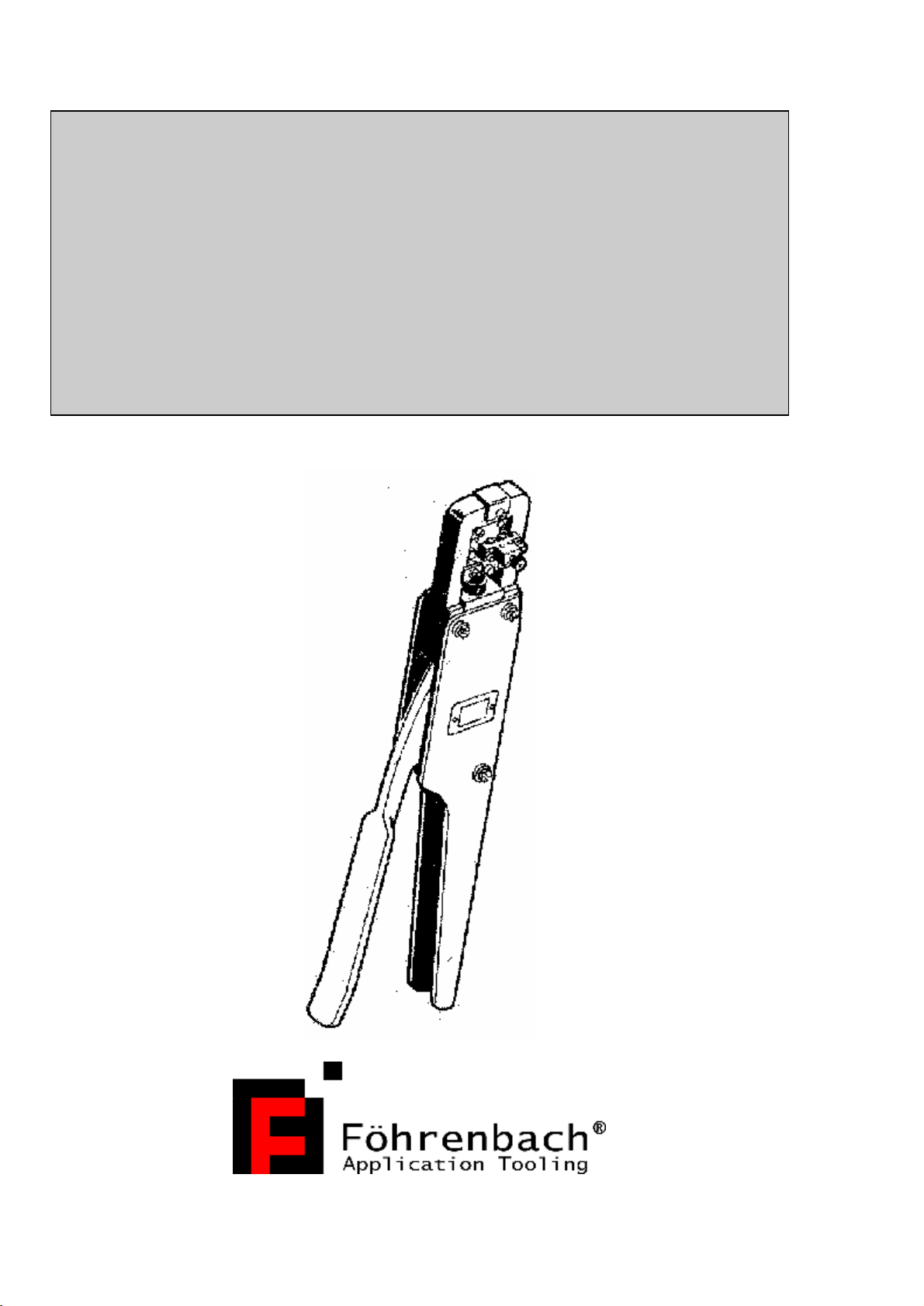

Fohrenbach HT95 User manual

HT95

HandpistolminiPV

AWG 22-32

User’sGuide

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 2/ 15

CONTENTS

1.Introduction..........................................................................................................3

1.1Hand toolfunction................................................................................................3

1.2Physicaldescription.............................................................................................3

1.3Principlesof operation..........................................................................................3

1.4Specifications.......................................................................................................4

2.Operation.............................................................................................................5

2.1Operatingprocedures..........................................................................................5

2.2Terminalinspection..............................................................................................6

3.Troubleshooting...................................................................................................8

4.Partsreplacement procedure...............................................................................9

4.1Anvilreplacement.................................................................................................9

4.2Wireand insulation barrelcrimpersand tonkerreplacement...............................10

4.3Holdingpinreplacement......................................................................................11

5.Crimpheight adjustment......................................................................................12

6.Parts.....................................................................................................................14

6.1Spareparts...........................................................................................................14

6.2Partsordering information....................................................................................14

6.3Hand toolrepairpolicy.........................................................................................14

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 3/ 15

1. INTRODUCTION

1.1.HandTool Function

The HT-95isamanuallyoperated handtooldesignedforcrimping loosepiece

(individual)MiniPV™terminalstovarioussizesof wire.

1.2.Physical Description

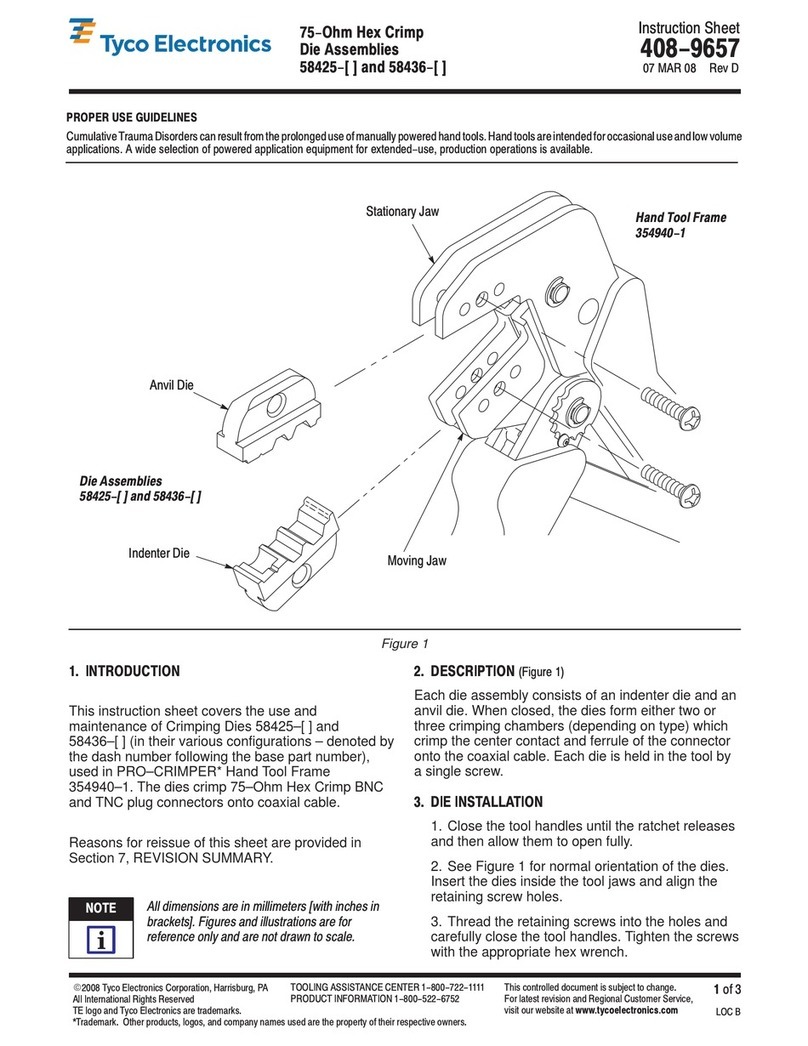

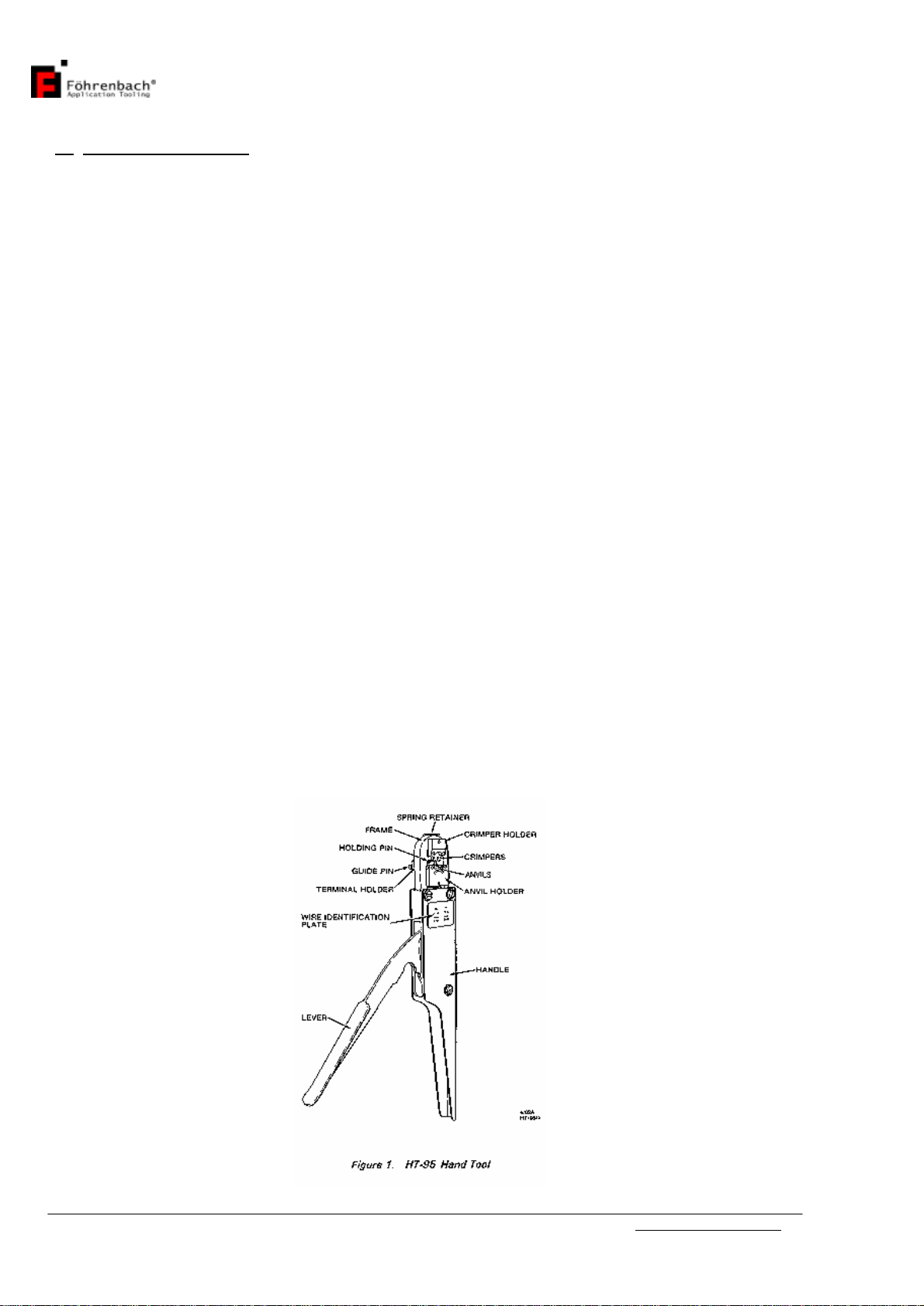

The majorcomponentswhichmakeup the HT-95 areidentified infigure1.These

includeaframe,lever,toolingand tooling holders,and terminalholding pins.Theheart

of the hand toolisthe tooling. The tooling performsthe crimping operation and isdivided

intotopand bottomcomponentgroups.Thetop group consistsofthosepartswhich

remainstationarywiththe frame.The bottomgroup containsthosepartswhichmove

withthe lever.TheHT-95 isequipped withtoolingforcrimpingtwodifferentrangesof

wiresizes.Theseareidentified as"A"and "B"on aplateaffixed tothe hand toolframe.

The "A"side toolingisforcrimping terminalstowiresizesrangingfrom28-32 AWG. The

"B"sidetooling isused forwiresizesfrom22-26 AWG.

1.3.Principles ofOperation

The leverattachestothe lowertooling andprovidesthe mechanicaladvantage to

generatethenecessarycrimping pressure.Asthe leverisclosed,aratchetmechanism

engagestoprevent theleverfromopeninguntilthecrimping cycleiscomplete.

When theleverispulledclosed,the lowertooling andterminalarepushed up against

the uppertooling.The crimpisformed between the wireand insulation barrelanvilsand

the wireandinsulationcrimpers.

Onceclosed, the ratchetreleasesand allowsaspring topulltheleveropen.

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 4/ 15

1.4.Specifications

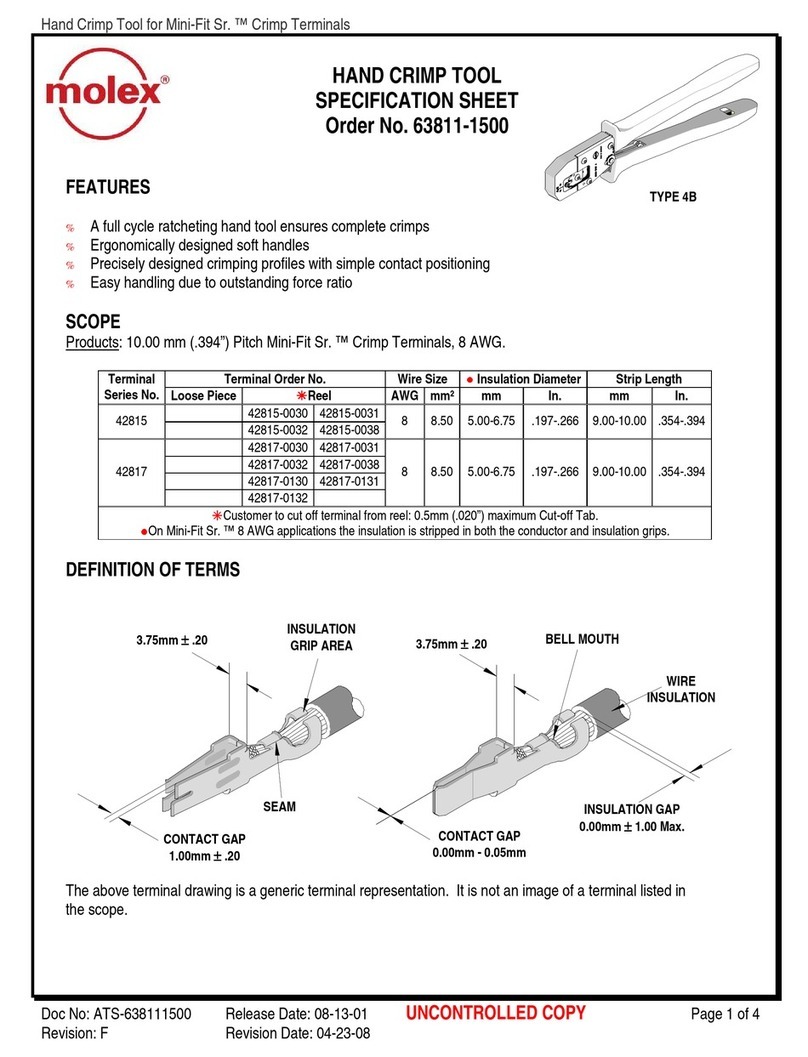

Whencrimping the MiniPV™towires, thefollowing parametersmust be met.

WireLengthRequirements:

•Minimum...................19.05 mm(0.75 in.)

•Maximum..................AsRequired

Insulation DiametersofWires:

•"A"Side(28-32AWG)..0.71-1.37mm

(0.028-0.054in.)Dia.

•"B"Side(22-26AWG)..0.91-1.52mm

(0.036-0.060in.)Dia.

Striplengthof Insulation:

•Discreteand latch

HousingApplications.3.81-4.31 mm

(0.150-0.170in.)

•Rod Housing............3.30-3.81 mm

Applications...............(0.130-0.150in.)

WireBarrelCrimpHeight: (ForAllApplications)

•SingleWire22-26AWGor

TwoWires26-28 AWG0.81-0.86 mm

(0.032-0.034in.)

•SingleWire28-32AWGor

TwoWires30-32 AWG0.66-0.71 mm

(0.026-0.028in.)

Insulation BarrelCrimpHeight:

•DiscreteApplication.2.84 mm(0.112 in.)Max.

•LatchandRod Housing

Applications...............1.75 mm(0.069 in.)Max.

MiniPV™Receptacles:

•loosePiece22-32AWG

NOTE

Loosepieceterminalshavedifferent part numbersthanreeled terminals.

CAUTION

If theterminaland the toolingarenotcompatible,damage tothe toolingcouldresult.If

you wishtouseaterminalwithapartnumberotherthan the one thatwasordered for

the HT95,check withyourdistributororFöhrenbachApplicationTooling NVtobe sure

that the newterminalnumberiscompatiblewithyourhand tool.

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 5/ 15

2. OPERATION

2.1OperatingProcedures

WARNING

To preventhandinjury,keepfingersfrombetweentheupperandlowertooling

andfrombetweentheleverandhandlewhenclosinghandtool.

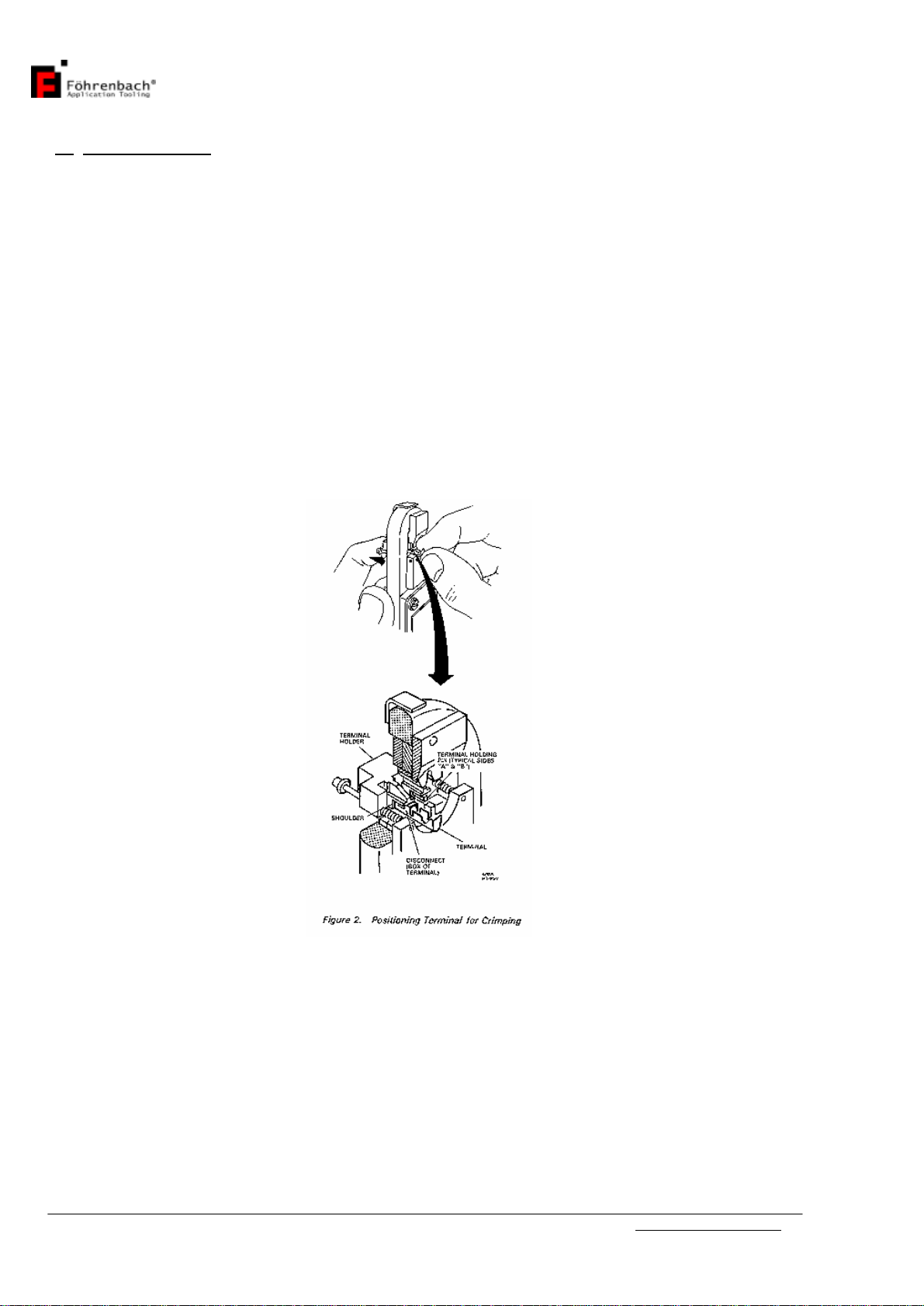

1.Holdthehandtoolsothatthe leverison theleft. Withyourindexfinger,pushand

holdthe terminalholderinitsforwardposition.(See figure2.)

2.Insertthe disconnect(box)portion ofthe terminal,with"U"shaped barrelsup,onto

the holding pinand againstthe pinshoulder.Whileholdingthe terminalagainstthe

shoulder,releasetheterminalholder.Thisensuresthattheterminalremainsin

properposition whilemoving overthe anvil.

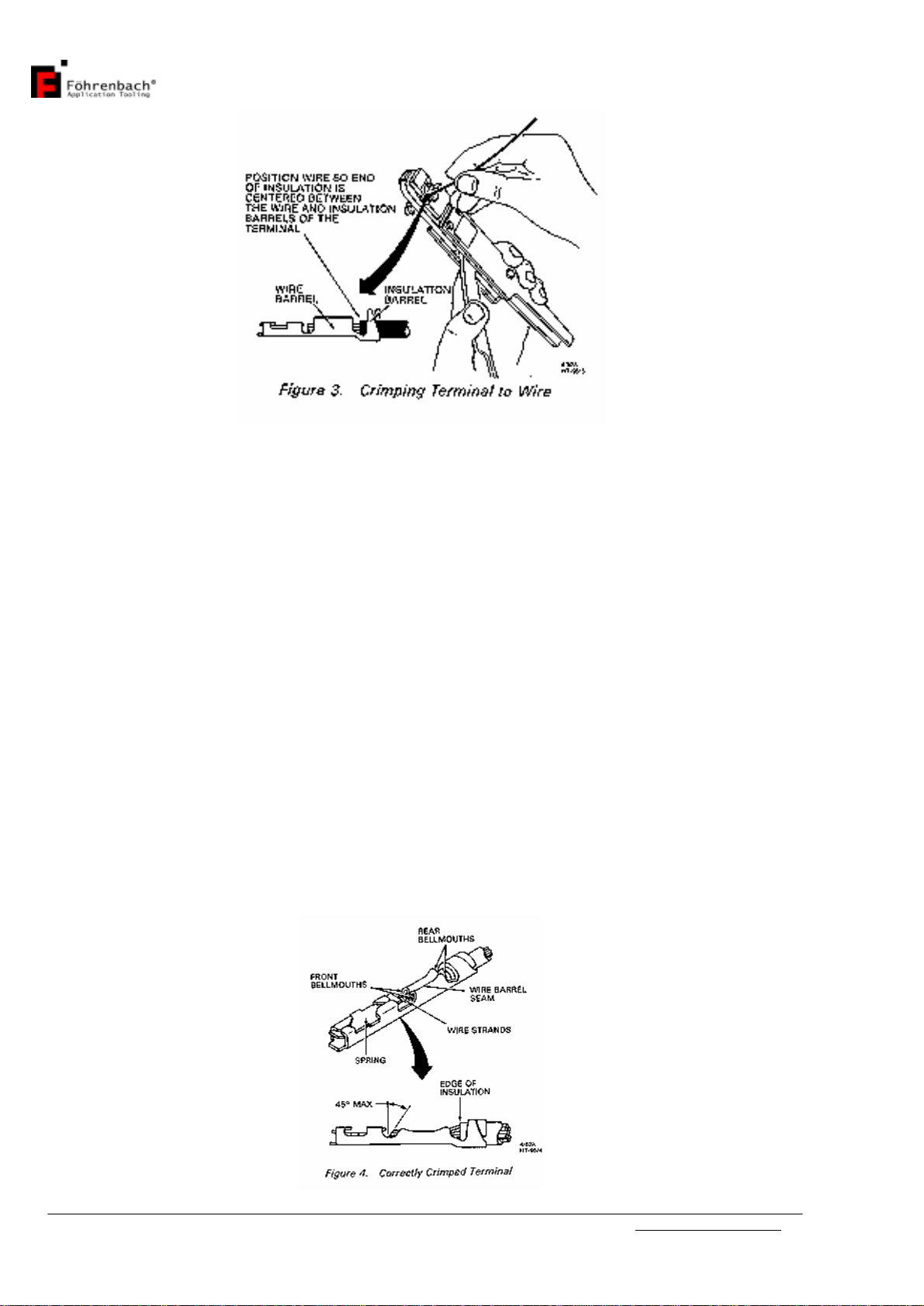

3.Whilegrasping the leverandthe handleportionof the frame, insert awiresothatthe

end of theinsulationiscentered between the wirebarreland the insulation barrelof

the terminal(seefigure3),then closethe handtoollevercompletely. Thiswillcrimp

the terminaltothe wire(s).

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 6/ 15

4.Releasethe levertoopen the hand tooland removethe crimped terminalfromthe

holding pinbylightlypulling straight out onthewire.

CAUTION

The crimpheightforthishand toolwasfactoryadjusted.Anyrandomchangestothis

adjustment couldcauseadefectivecrimpordamage tothe tooling.

2.2Terminal Inspection

The crimped terminalshouldbe inspectedtoensurethatthetoolingiscorrectlyaligned

and thatthe wirewascorrectlyinserted. Makethe following visualchecks (see figure4).

NOTE

If inspection ofthe crimped terminalrevealsanydefects,theterminalhasnotbeen

properlycrimped and shouldbediscarded,

-Check that allwirestrandswerecrimped withinthe wirebarrel.

-Check that theend of the wireinsulation liesbetween the insulation and wirebarrel.

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 7/ 15

-Check that thebellmouth(s)wereformed correctly.

-Check thatthespringwasnotdislodgedfromthe disconnect(box)portion ofthe

terminal.

-Check thatthe endsofthe wirestrandsforman anglenotexceeding approximately

45°.

-Check that thewirebarrelseamiseven andtightlyclosed.

Next, obtainacrimpheightmicrometerand measurethe areasofthe terminalshownin

figure5.If thecrimpheightsdo notmeetthe specificationslisted inSection I, paragraph

D, refertoSection Vforproperadjustment procedures.

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 8/ 15

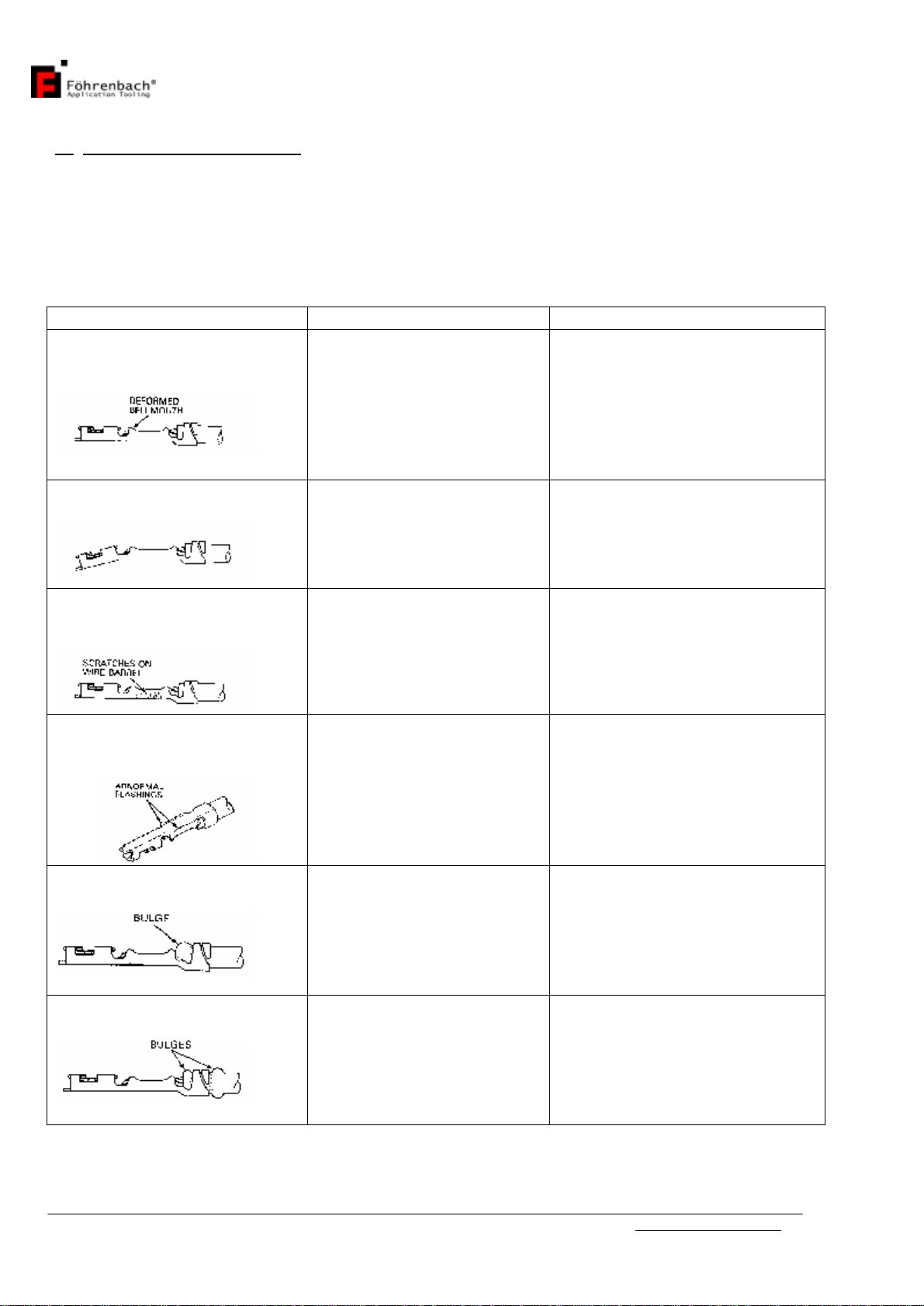

3. TROUBLESHOOTING

The troubleshooting information provided inthe following chartwillhelpisolateand

identifycrimping problems.

TroubleshootingChart,PV™ReceptaclesHT-95

PROBLEM POSSIBLECAUSE CORRECTIVE ACTION

1. Bellmouth(s)isdeformed

orimproperlypositionedon

wirebarrel.

Terminalisnot properly

positioned incrimping

area.

Loosen thetwo2-56 setscrews

on the sideof theanvilholder

and reposition guide pinsuntil

properbellmouth(s)is

achieved.

2. Disconnect(box)portionof

terminalisbent down.

Terminalissticking inwire

barrelcrimper.

Tooling isbroken or

cracked.

Replacewirebarrelcrimperas

described inSection 2,para-

graph 2.

3. The sidesof the terminals

wirebarrelarescoredor

scratched.

Wirebarrelcrimperis

defective.

Replacewirebarrelcrimperas

described inSection 4,para-

graph 2.

4. Flashingsformed on the

bottomof the wirebarrelare

unequalorabnormal.

Anviliswornorbroken.

Replaceanvilasdescribedin

Section 4, paragraph 1.

5. Insulationbulgesbetween

wireand insulation barrels.

Wireisinsertedtoo farinto

terminal.

Position the endof the

insulation sothatitliesmidway

between the endsof the wire

barreland theinsulationbarrel.

6. Insulationbulgesaround

insulation barrel.

Wiresizeorinsulation

diameterisincorrect for

the terminalbeingused.

RefertoSection1, paragraph

4(specifications)forcorrect

insulation diameter

requirements.

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 9/ 15

4. PARTSREPLACEMENTPROCEDURE

4.1Anvil Replacement(see figure6)

NOTE

Replaceanvilswhen theyshowexcessivewearorarecracked orchipped.

4.1.1.Removal

Whenremoving the anvil,the terminalholder(10)and guidepins(15)mustalsobe

removed.Priortoremoval,notethe position ofthe guidepinsinthe anvilholder,sothat

theycanbepositioned astheywerebeforeremoval:the flatontheguidepinsmustface

the setscrews(12)intheanvilholder(4).

1.Loosen the two2-56setscrews(12)intheanvilholder(4)and removeterminal

holderassembly(10).

2.Remove4-40 capscrew(9)fromthe damagedanvil(s)(5)and (7), or(6)and(8).

3.Removedamaged anvil.

4.1.2.Installation

NOTE

When replacingtooling,be surethatthepartnumberofthe partbeing replaced isthe

sameasthe numberof the partthat wasremoved.

1.Looselyinstallthenewanvil(s)tothe anvilholder(4)withthe4-40cap screw(9).

2.Closehandtoolcompletely;thisalignsanvil tothe crimper.Tighten the 4-40 cap

screw(9), and releasethe lever.

3.Re-installterminalholder(10)tothe anvil holder(4)and tightenthe two2-56

setscrews(12).

4.Crimpaterminaltoaproper-sized wire,andinspecttheterminalasdescribed in

Section II, paragraph B.

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 10 /15

4.2.WireandInsulationBarrel CrimpersandJonkerReplacement

(see figure6)

4.2.1.Removal

1.Loosen butdonotremoveatthistime,the two4-40 cap screws(9)thatsecurethe

crimperstothe crimperholder(1).

2.Removethe 6-40 cap screw(13)fromthe crimperholder(1).Then removethe

spring retainer(21)and the crimperholder(1)withcrimpersattached.

3.Removethe twotonkersprings(19)andthetwospringguides(20)fromthe hand

toolframe. Thiscan beaccomplished bytiltingthe hand tooldown.

4.Removethe two4-40 cap screws(9)thatsecurethe crimperstothe crimperholder

(1).

5.Removethe crimpers(2and 3)and tonkers(18)fromthe crimperholder.6.Remove

the damaged crimper(s)(2or3).The top crimperisthe wirebarrelcrimper(3).

4.2.2.Installation

NOTE

When replacing tooling,always be surethatthe partnumberon the part(s)being

replaced isthe sameasthe numberof the part that wasremoved.

1.Placetheinsulationcrimper(2)ontotheflatside ofthecrimperholder(1).Placethe

wirebarrelcrimper(3)on theinsulation crimper(2)and installtwo4-40capscrews

(9)andlooselytighten.

2.Inserttonkers(18),withthe top tabsfacing outward,intotheslotsbetween the wire

and insulationcrimpers.

3.Placeand holdthe crimperassemblyintothe hand toolon thesameside asthe anvil

holder(4).Makesurethatthe tonkers(18)gointotheholesinthetopofthehand

toolframe.

4.Placespringguides(20)intothe holesinthe top ofthe handtoolframe,then insert

the springs(19)intothe holessothatthe springsslipoverthe shoulderofthe spring

guides.

5.Placespring retainer(21)overtonkersprings(19).Makesurespringsarefully

compressed, then looselyattachthe spring retainer(21)and the crimperholder(1)to

the handtoolwitha6-40cap screw(13).

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 11 /15

6.Toalignthe tooling,closehand toolcompletelyandholditinitsclosedposition.

Tighten the two4-40 cap screws(9)tosecurethe crimperstotheirholder.Then

tighten the 6-40 cap screw(13),whichsecuresthe crimperholdertothe handtool

frame.

7.Crimpaterminaltoaproper-sized wire,andinspecttheterminalasdescribed in

Section II, paragraph B.

4.3.HoldingPinReplacement(see figure6)

NOTE

Whenholding pins(14)becomebent, itisnecessarytoreplacethem.

4.3.1.Removal

NOTE

Whenremoving the holding pin,the terminalholder(10)and guide pins(15)mustalso

be removed.Priortoremoval.notethe positionofthe guide pins(15)intheanvilholder,

sothattheycan be repositioned astheywerebeforeremoval:the flaton the guide pin

must facethe setscrew(12)inthe anvilholder(4).

1.Loosen thetwo2-56 setscrews(12)intheanvilholder(4). Thenremovethe terminal

holderassemblywhichincludesthe terminalholder(10),guide pins(15),"0" rings

(16),holding springs(17),and holding pins(14)attached.

2.Removethe twoholding springs(17)and the guidepins(15)fromthe terminal

holder.

3.Loosen the two2-56 setscrews(12)inthetop ofthe terminalholder(10)which

securetheholdingpins(14).

4.Usingneedle-nosepliers,removebothholdingpins(14)bypullingstraightoutfrom

terminalholder(10). Discardthe damaged holdingpints).

4.3.2.Installation

CAUTION

Overtightening the two2-56 setscrews(12)inthe top ofthe terminalholder(10)can

flatten theholding pins(14), making themextremelydifficult toremove.

1.Install twonewholding pins(14)(0.025 in.squareBergPin™material0.430 in. long)

intoterminalholder(10)untilpinsareflushwiththe extended supports.Besurethat

aflatsideofeachpinisatrightanglestothetwo2-56 setscrewholeson topofthe

terminalholder(10).

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 12 /15

2.Lightlytighten the two2-56 setscrews(12)intothe terminalholder(10)tosecurethe

holding pins(14).

3.Re-installthe twoguidespins(15), "0" rings(16), andthe twoholding springs(17).

4.Re-installthe terminalholder(10)tothe anvilholder(4),and tighten the two2-56

setscrews(12)inthe anvilholder(4)ontotheflatsof the guide pins(15).

5.Crimpaterminaltoaproper-sized wire,andinspecttheterminalasdescribed in

Section II, paragraph B.

5. CRIMPHEIGHTADJUSTMENT(seefigure6)

1.Loosen thetwo2-56 setscrews(12)inthe anvilholder(4).Removeterminalholder

assemblywhichincludesthe terminalholder(10),guide pins(15),"O"rings(16),

holding springs(17), and holdingpins(14)attached.

2.Removethe 6-40 cap screw(13)whichsecuresthe anvil holder(4)tothe adjustable

toolholder(11). Removethe anvilholderwithanvilsattached.

3.Inserta3/32-inchAllenwrenchintothe holeintheadjustabletoolholder(11)and

intothe socket headsetscrew. Turnscrewtothe right 1/4turntounlock theadjusting

collar.

4.Inserttheturned-downend ofthe3/32-inchAllen wrench(suppliedwithhandtool)or

apinapproximately1/16-inchindiameterintoone ofthe fourholesinthe adjusting

collar.Rotatetheadjustingcollarabout5degreestothe righttoincreasethecrimp

height by0.002 inch, ortothe left todecreasecrimpheight by0.002 inch.

5.Re-installanvilholder(4)withanvilsand looselytighten the 6-40 cap screw(13).

6.Closehandtoolcompletelysothattheanvilsalignthemselvestothecrimpers. While

inthe closedposition,tighten thecap screw(13)tolock anvilsintoposition.Open

the handtool.

7.Re-installterminalholderassemblytothe anvilholder(4)and tighten the two2-56

setscrews(12)against theflatsonthe guide pins(15).

8.Crimpaterminaltoawireand recheck the wirebarrelcrimpheight.

a.If crimpheightmeetsspecifications,removeterminalholderassemblyandanvil

holder(4),then lock the adjusting collarbytightening thesetscrewinthe adjustable

toolholder(11).Reinstallterminalholderassemblyand anvilholderasdescribed in

steps5through 7above.

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 13 /15

b.If crimpheight doesnot meet specifications, closethehand toolone click (sothat the

adjusting collarisvisible)and rotatethe adjusting collarasdescribed instep 4.When

correctcrimpheightisattained,lock theadjustingcollarbytighteningthe setscrewin

the adjustabletoolholder(11).Reinstallterminalholderassemblyandanvilholder

asdescribed insteps5through 7above.

PartsListforFigure6. HT-95HandTool Parts

Index

No. Part No Description OtyPer

1 A-857 -5 Crimperholder 1

2* 104958-1Insulation barrelcrimper, 22-26 and 28-32 gauge wire

1

3* 104959-1Wirebarrelcrimper, 22-26 and 28-32 gaugewire 1

4 102466-1Anvilholder 1

5* 104914-A

Insulation barrelanvil, 28-32 gauge wire 1

6* 104914-B

Insulation barrelanvil, 22-26 awgwire 1

7* 104960-A

Wirebarrelanvil, 28-32 gauge wire 1

8* 104960-B

Wirebarrelanvil, 22-26 gauge Wire 1

9 Screw, cap, socket Hd, 4-40 NFx0.37 in. Ig. 4

10 104961-1Terminalholder 1

11 A-856-1 Toolholder, adjustable

12 Setscrew, socket Hd. 2-56NFx0.12 in. Ig. 4

13 Screw, cap, socket Hd. 6-40 NFx0.50 in. Ig 2

14* 104756-1Holdingpin, (0.025"sq. Bergpin™material0.430" Ig.) 2

15 102468-1Guidepin 2

16 "O"ring,01-004 2

17 102470-1Holdingspring 2

18 104964-1Tanker 2

19 A-1153 Springtanker 2

20 A-11 55 Springguide2

21 104963-1Springretainer 1

*Recommended SpareParts

Instruction manualHT95www.foehrenbach.be

Date: August 2007 Documentrev. : 3Page : 14 /15

6. PARTS

6.1SpareParts

ThesearepartswhichF.A.Tooling NVconsiderspracticalforthe usertostock for

replacement. Recommended sparepartsforthe hand toolarespecified inboldtype in

the partslistforfigure6.

6.2PartsOrderingInformation

Toobtainreplacementparts,contactF.A.ToolingNV,Krijgsbaan 128,2640 Mortsel,

Belgium.Provide the description ofthe part, partnumber(ifspecified),quantitydesired,

and alsothehandtoolmodelandserialnumber.

6.3. HandTool RepairPolicy

The repaircostisaccording toexpenses.

Table of contents

Other Fohrenbach Crimping Tools manuals

Popular Crimping Tools manuals by other brands

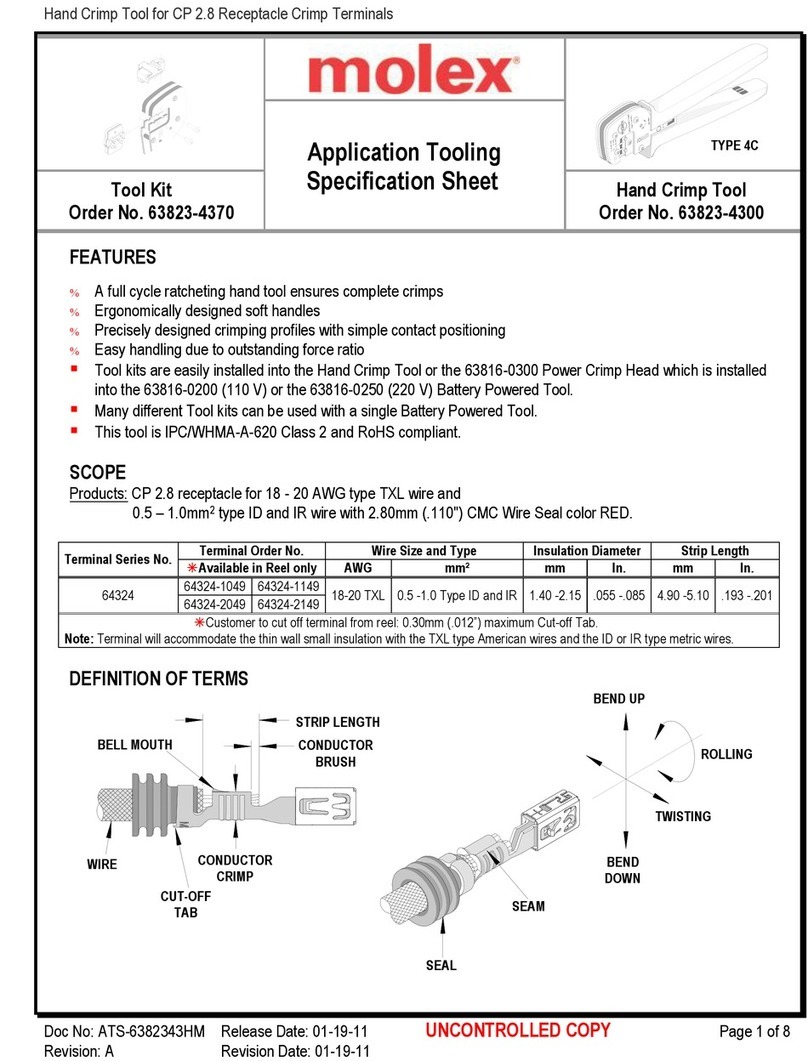

molex

molex 207129 Series Specification sheet

Emerson

Emerson Klauke EK 120IDCFM Assembly instructions

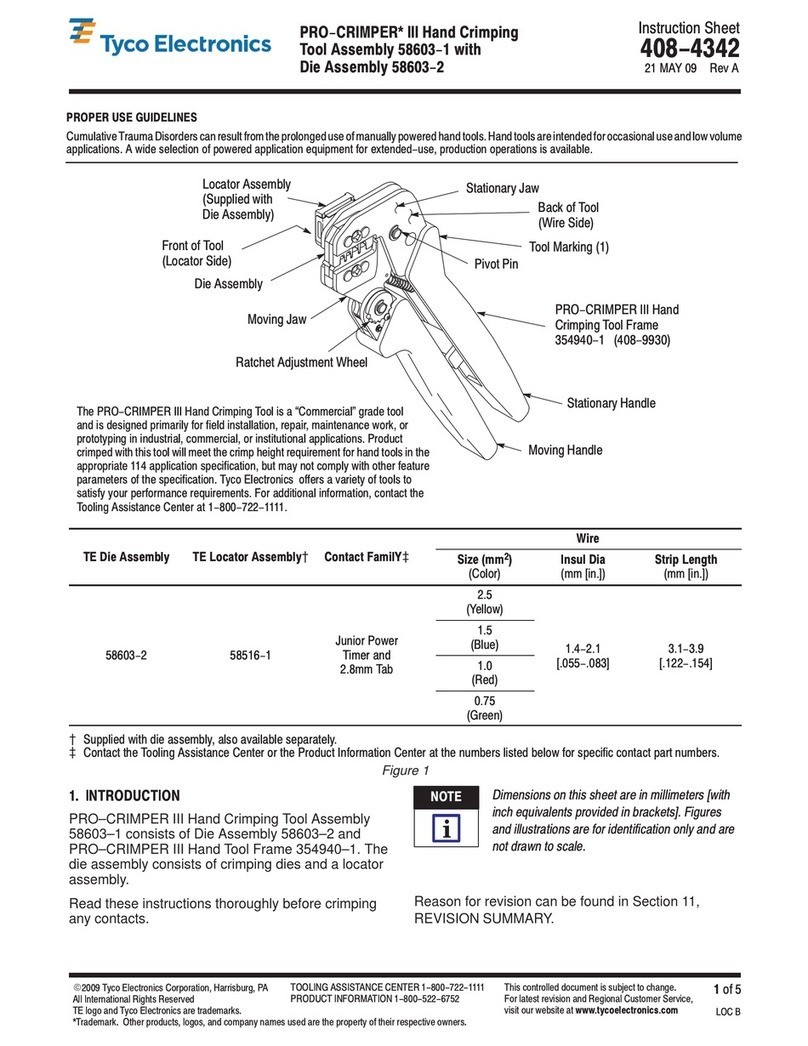

Tyco Electronics

Tyco Electronics PRO-CRIMPER III 58603-1 instruction sheet

PRECISETOOL

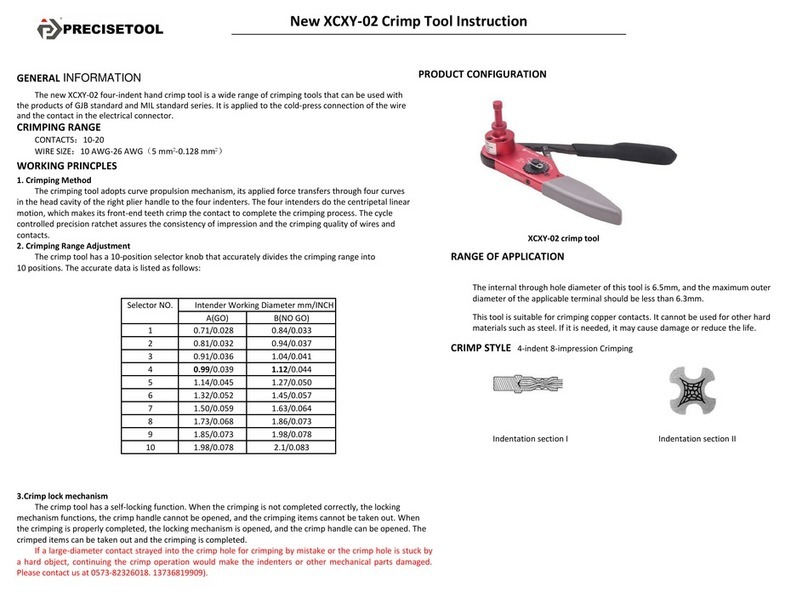

PRECISETOOL XCXY-02 instructions

Hubbell

Hubbell BURNDY PATRIOT 81K2 Series SAFETY OPERATING & MAINTENANCE INSTRUCTIONS

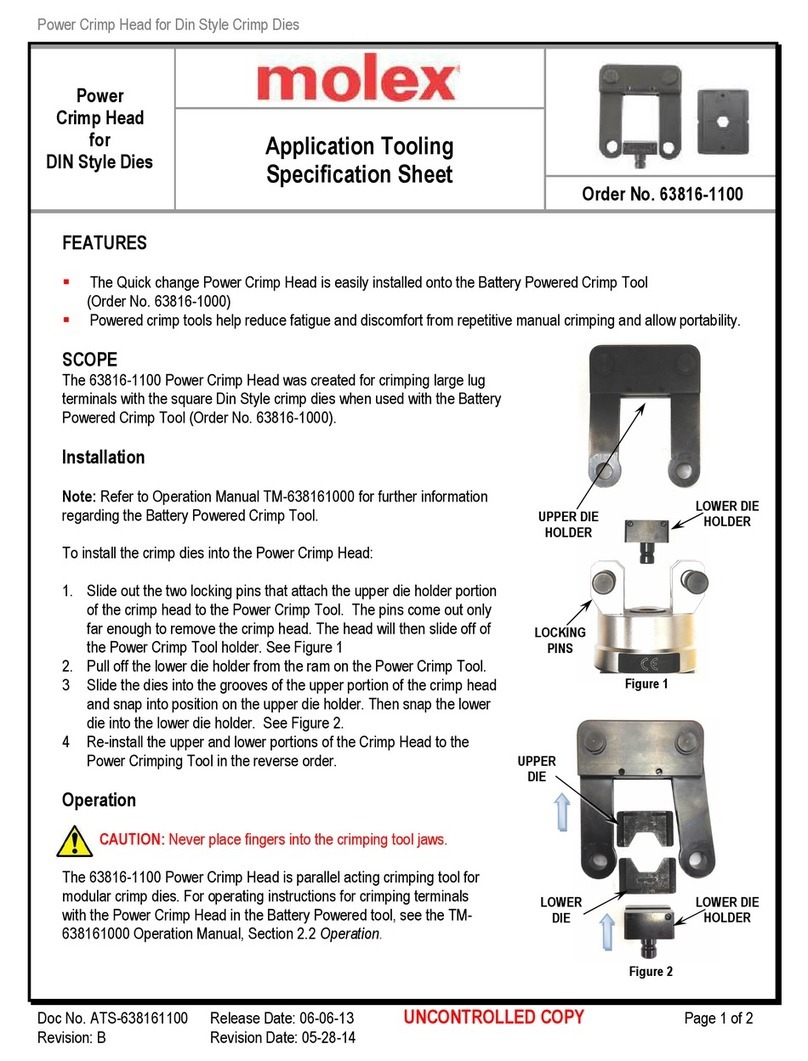

molex

molex 63816-1100 quick start guide