Fohrenbach HT119 User manual

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page :2/15/

CONTENTS

1.INTRODUCTION...............................................................................................................3

1.1.HandToolFunction........................................................................................................3

1.2.PhysicalDescription.......................................................................................................3

1.3.Principlesof Operation...................................................................................................3

1.4.Specifications.................................................................................................................4

2.OPERATION.....................................................................................................................5

2.1.Operating Procedures....................................................................................................5

2.2.TerminalInspection........................................................................................................6

3.TROUBLESHOOTING......................................................................................................8

4.PARTSREPLACEMENTPROCEDURES........................................................................9

4.1.AnvilReplacement.......................................................................................................9

4.2.Wireand Insulation BarrelCrimpersand TonkerReplacement

(see Figure13)..............................................................................................................11

5.ADJUSTMENTPROCEDURES........................................................................................12

5.1.CrimpHeightAdjustment...............................................................................................12

6.PARTS..............................................................................................................................13

6.1.SpareParts...................................................................................................................13

6.2.PartsOrderingInformation...........................................................................................13

6.3.Hand ToolRepairPolicy................................................................................................13

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page :3/15/

1. INTRODUCTION

1.1Hand Tool Function

The HT-0119 isamanuallyoperatedhandtooldesignedforcrimping loosepiece(individual)

Crimp-to-WireMalePinterminalstowiresizesof22-26 AWG.

1.2Physical Description

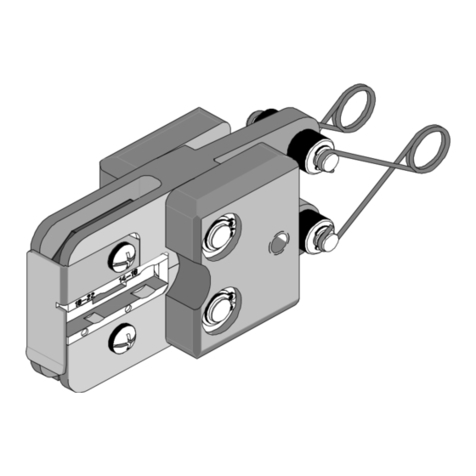

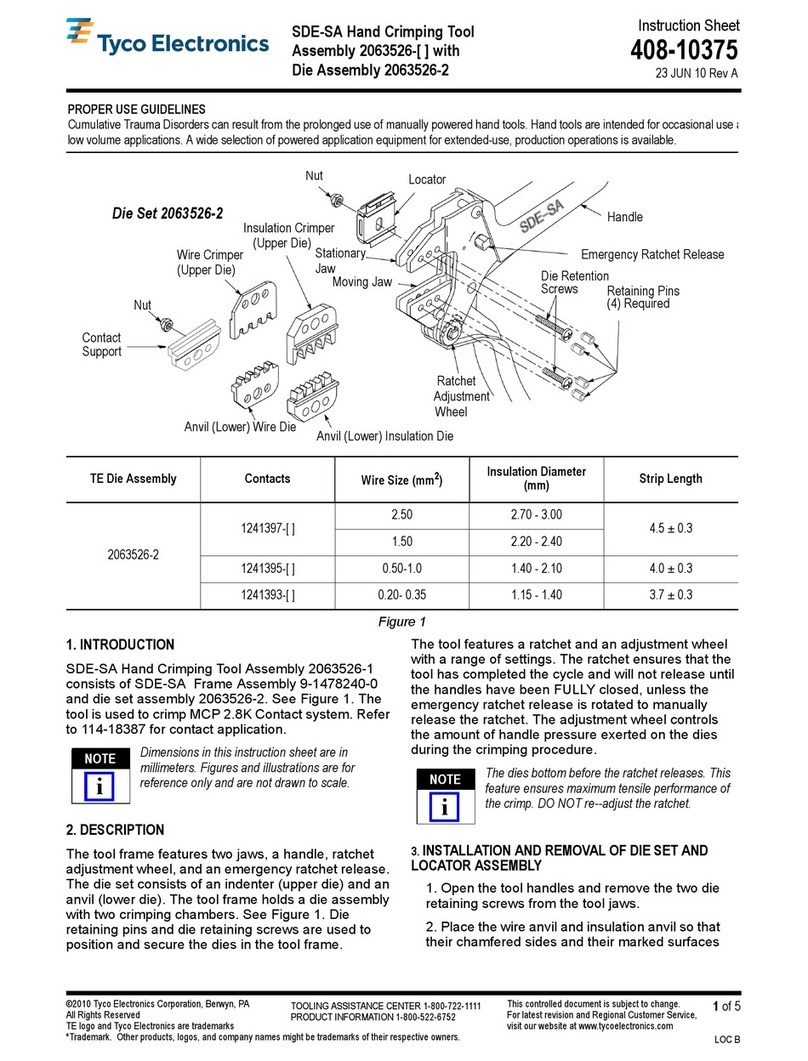

The major componentsthatmakeup theHT-0119are identified inFigure1.Theseinclude a

frame,lever,tooling,toolingholdersandaterminalholder.The heartofthehand toolisthe

tooling.The toolingperformsthe crimpingoperationand isdividedintotopandbottom

componentgroups.Thetop group consistsofthosepartswhichremainstationarywiththe

frame.Thebottomgroupcontainsthosepartsthatmovewiththelever.The HT-0119is

equipped with2crimpingplaces.Bothsidesareusedforwiresizesfrom22-26 AWG.

1.3Principles ofOperation

The leverattachestothelowertoolingandprovidesthe mechanicaladvantage togeneratethe

necessarycrimpingpressure.Astheleverisclosed,aratchetmechanismengagestoprevent

thelever fromopeninguntil thecrimpingcycleiscomplete.

When thelever ispulledclosed, thelowertooling andterminalarepushed upagainst theupper

tooling.The crimpisformed betweenthe wireandinsulationbarrelanvilsand thewire and

insulationcrimpers.

Onceclosed,theratchetreleasesand allowsaspringtopullthe lever open

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page :4/15/

1.4Specifications

Whencrimping the MalePintowires,thefollowing parametersmustbemet.

-WireLengthRequirements:

•Minimum.................19-05mm(0.75in.)

•Maximum................AsRequired

-InsulationDiametersofWires:

LatchHousingand DiscreteApplications..............................0.96-1.52 mm

(0.038-0.060in.)Dia.

-StripLengthofInsulation:

LatchHousingand DiscreteApplications..............................3.81-4.32mm

(0.150-0.170in.)

-WireBarrelCrimpHeight:

•SingleWire (22-26 AWG).....................................................0.76-0.81 mm

(0.030-0.032in.)

-InsulationBarrelCrimpHeight:

•(22-26AWG)LatchHousing andDiscreteApplications........1.75mm

(0.069in.)Max.Dia.

NOTE

Loosepieceterminalshavedifferent partnumbersthan reeledterminals

CAUTION

If theterminalandthetooling arenot compatible,damage tothetoolingcouldresult.Ifyou wish

touseaterminalwithapartnumberother thanthe onethatwasorderedfortheHT-0119check

withyourdistributortobe surethat the newterminalnumberiscompatiblewithyourhandtool.

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page :5/15/

2. OPERATION

2.1Operating Procedures

WARNING

To preventhand injury,keepfingersfrombetweentheupperandlowertooling andfrom

betweentheleverandhandlewhenclosinghandtool.

1.Holdthe hand toolsothattheleverisonthe left.Withyourindexfinger,pushand holdthe

terminalholderinitsforwardposition(seeFigure2).

NOTE

Wheninsertingaterminalintotheterminalholderyouwillnoticeaslightdrag(interference)on

theterminal.The dragiscaused bythespring ballplunger(seeFigure13itemno.21)

applyingdownwardpressureonthe pinendofthe terminal.

Thisdownwardpressurehelpstoorientandholdtheterminalintheterminalholderuntil

crimped.

2.Insertthepinendofthe terminal,with“U” shaped barrels

up,intotheterminalholderandagainstthepinshoulder.

Whileholdingtheterminalagainsttheshoulder,release

theterminalholder. Thisensuresthat theterminalremains

inthe properposition whilemovingovertheanvil.

3.Whilegraspingthelever and thehandleportion ofthe

frame,insertawiresothattheendofthe insulation is

centered betweenthe wirebarrelandtheinsulationbarrel

oftheterminal(see Figure3).Analternatemethodisto

position theend oftheinsulation againstthetonker(see

Figure13,itemno.2)whichprotrudesfrombetween the

crimpers(3&4).Then closethehand toollever

completely.Thiswill crimpthe terminaltothe wire(s).

Figure2. PositioningTerminalfor

Crimping

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page :6/15/

4.Releasethe levertoopenthehand tooland removethe crimped terminalbylightlypulling

straightout on thewire.

CAUTION

Thecrimpheightforthishandtoolwasfactoryadjusted.Anychangestothiscrimp

heightadjustmentcouldcause adefectivecrimpor damagetothetooling.

2.2Terminal Inspection

The crimped terminalshouldbeinspected toensure that thetoolingiscorrectlyaligned andthat

thewirewascorrectlyinserted.Makethefollowingvisualchecks (see Figure4).

NOTE

Ifinspectionofthe crimpedterminalrevealsanydefects,the terminalhasnotbeenproperly

crimpedand shouldbe discarded.

Figure3.Crimping TerminaltoWire

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page :7/15/

•Checkthatall wirestrandswerecrimpedwithinthewirebarrel.

•Checkthatthe end ofthewireinsulationliesbetweentheinsulationand the wirebarrel.

•Checkthatthe bellmouth(s)wereformed correctly.

•Checkthatthe wirebarrelseamiseven andtightlyclosed.

Next,obtainacrimpheightmicrometerand measuretheareasofthe terminalshowninFigure

5.IfthecrimpheightsdonotmeetthespecificationslistedinSection 1,Paragraph 2.4,refer to

Section 5forproperadjustment procedures.

Figure4.Correctly CrimpedTerminal

Figure5.MeasuringCrimpHeightof

Terminal

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page :8/15/

3. TROUBLESHOOTING

The troubleshootinginformationprovided inthefollowing chartwillhelpisolateandidentify

crimping problems.

TroubleshootingChart, MalePinTerminal

PROBLEM POSSIBLECAUSE CORRECTIVE ACTION

Bellmouth(s)isdeformed or

improperlypositioned on wire

barrel.

Terminalisnot properly

positionedincrimpingarea.

Insertterminalsoitsshoulder

isagainst theterminalholder.

Reposition guidepinsuntil

properbellmouth(s)is

achieved.

Pinendofterminalisbent

down

Terminalissticking inwire

barrelcrimper.

Tooling isbrokenorcracked.

Replacewirebarrelcrimper

asdescribedinSectionIV,

paragraphB.

The sidesofthe terminalswire

barrelarescored orscratched.

Wirebarrelcrimperis

defective. Replacewirebarrelcrimper

asdescribedinSectionIV

paragraphB.

Flashingsformed on the

bottomof thewirebarrelare

unequalor abnormal.

Anvilisworn orbroken Replaceanvilasdescribed in

Section IV, paragraphA.

Insulationbulgesbetween wire

and insulationbarrels.

Wirestriplengthisincorrect,

orwire wasinserted too far

intothe terminal.

Refer toSectionI, Paragraph

D(specifications)forstrip

lengthrequirements.

Insulationbulgesaround

insulationbarrel

Wireorinsulationdiameter is

incorrectforthe terminal

beingused.

Refer tosection I,paragraph

D(specifications)forcorrect

insulation diameter

requirements.

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page :9/15/

4. PARTSREPLACEMENTPROCEDURES

4.1AnvilReplacement

Replaceanvilswhen theyshowexcessivewear orbecomecrackedorchipped.

Removal

1.Removethe capscrew securingtheanvil holder assemblytothe handtool(seeFigure 6)

and thenremovethe anvilholderassembly.

2.Loosen the twosetscrewsintheanvil holder andremovetheterminalholder(seeFigure 7).

3.Removethe capscrewand defectiveanvil(s)fromtheanvilholder (seeFigure 8).

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page: 10 / 15/

Installation

NOTE

When replacing theanvils,besurethatthepartnumberforthenewanvil(s)isthesameasthe

one beingreplaced.

1.Looselyinstallthe newanvilstothe anvil holder withtheattachingcap screw(See Figure

8).

2.Reinstall theanvilholderontothehand tooland tighten the attaching cap screw.

CAUTION

Topreventtheanvilsfrombeing damagedduringalignment,placeapieceofpaperover

theanvils.

3.Cutouttwostripsofpaper.Thenfoldthestripsinhalfand placethemovertheanvils(see

Figure9).

4.Slowlyclosethehand toollevercompletely.Thiswillalignthe anvilstothe crimpers.Then

tightentheanvilcapscrewand releasethe lever.Next, removethepaper fromtheanvils.

5.Reinstall the terminalholdertotheanvil holder.Makesurethattheflatsontheendofthe

terminalholderguidepinsfacethesetscrewsinthe anvilholder.Then tightentheanvil

holderset screws.

6.Crimpaterminaltotheproper sizewire.Theninspectthe terminalasdescribed insectionII,

paragraph B.

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page: 11 / 15/

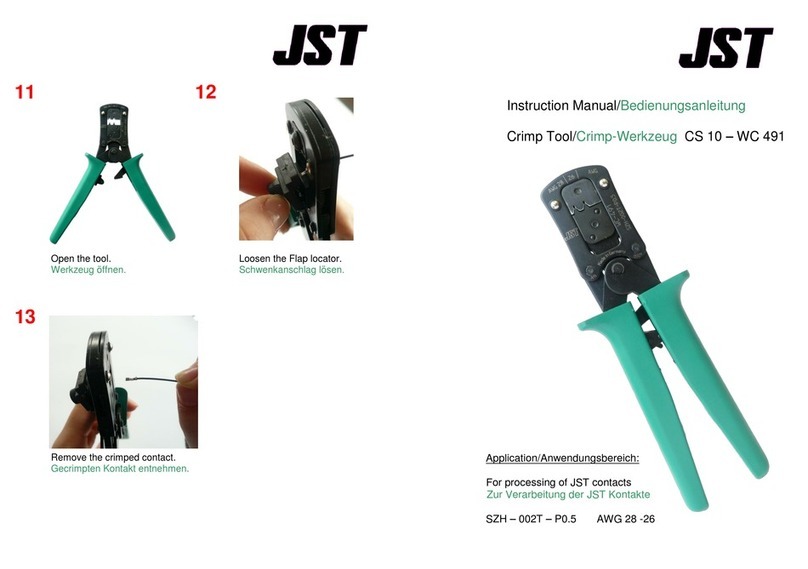

4.2WireandInsulation Barrel Crimpersand TonkerReplacement(seeFigure13)

Removal

1.Loosen,butdonotremoveatthistime,the twocap screws(7)thatsecurethecrimpersto

thecrimperholder(1).

2.Removethe capscrew(9)fromthe crimperholder(1).

Then removethe spring retainer(8) and the crimperholder(1)withcrimpersattached.

3.Removethe twotonkersprings(5)andthetwospring guides(6) fromthehandtoolframe.

Thiscan beaccomplished bytiltingthehand tooldown.

4.Removethe twocap screws(7)thatsecure thecrimperstothe crimperholder(1).

5.Removethe crimpers(3and4)andtonkers(2) fromthe crimper holder(1).

6.Removethe damaged crimper(s)(3) or(4). The topcrimper isthewirebarrelcrimper (4).

Installation

NOTE

When replacing tooling,always be sure thatthe partnumberofthenewpartisthesame

numberthatison theoldpartthat wasremoved

7.Placetheinsulationcrimper(3) ontotheflatsideofthe crimperholder (1).Placethewire

barrelcrimper(4)onthe insulationcrimper(3)andlooselyinstallthetwoattachingcap

screws.

8.Inserttonkers(2),withthe toptabsfacingoutwards,intothe slotsbetween thewireand

insulationcrimpers.

9.Placeandholdthecrimper assemblyintothe hand toolwithcrimperholder(1)onthesame

side asthe anvilholder(11).

Makesurethatthe tonkers(2)go intothe holesinthetop ofthehandtoolframe.

10.Placespringguides(6)intotheholesintop ofthe handtoolframe,theninsertthesprings

(5)intothe holessothatthespringsslipoverthebodyof thespringguides.

11.Placespringretainer(8)overtonkersprings(5).Makesure springsarecompressed,then

looselyattachthespring retainer(8)and the crimperholder(1) tothe handtoolwiththe

attaching capscrew(9).

12.Toalignthetooling, closehand toolcompletelyand holditinit.sclosed position. Tighten the

twocapscrews(7)tosecurethe crimperstotheirholder.Thentightenthecap screw(9),

whichsecuresthecrimperholder tothehandtoolframe.

13.Crimpaterminaltoaproper-sizewire andinspecttheterminalasdescribedinSectionII,

paragraph B.

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page: 12 / 15/

5. ADJUSTMENTPROCEDURES

5.1CrimpHeightAdjustment

1. Removethe capscrewsecuring the anvilholderassemblytothe handtool(seeFigure10).

Then removethe anvil holder assembly.

2. Inserta3/32-inchAllenwrenchintothe holeintheadjustabletoolholderandintothe socket

headsetscrew(see Figure11). Turnthe setscrew¼turncounterclockwisetounlockthe

adjusting collar.

3. Closethehand toolleveroneclick togainaccesstotheholesintheside oftheadjusting

collar.Next,insertapinapproximately1/16-inchindiameter,intoone oftheholesinthe

collar(seeFigure12).Then rotatethe collarabout 5degreescounterclockwisetoincrease

crimpheightorclockwisetodecreasecrimpheight.

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page: 13 / 15/

4. Reinstall the anvilholderassemblyontothehand tooland tightenthe attaching cap screw.

5. Crimpaterminaltothepropersizewireand checkthewire barrelcrimpheightofthe

crimpedterminal.If crimpheightisnotasspecified,removetheanvilholderassemblyand

turntheadjustingcollar anadditional5degrees.Thenreinstall theanvilholderassembly

and againcheckthe crimpheight.Continueadjustingthecrimpheightinthismanneruntil

theproper crimpheightisachieved.

6. Removethe anvil holderassemblyandtightenthesetscrewclockwiseintheadjustabletool

holder.Then reinstallthe anvilholder assemblyandtighten the attachingcap screw.

6. PARTS

6.1SpareParts

Theseare partsthatFöhrenbachApplication Tooling considerspracticalfortheusertostockfor

replacement. Recommended sparepartsforthe handtoolarespecified inboldtypeintheparts

list forFigure13.

6.2Parts OrderingInformation

Toobtainreplacementparts,contactFöhrenbachApplication Tooling.

6.3HandToolRepairPolicy

FöhrenbachApplicationToolingchargesastandard ratetorepairanyhand toolnotunder

warranty.FöhrenbachApplicationToolingwillrepairthehandtoolandreturnittoyou bythe

fastestmeanspossible.

Instruction manualHT119www.foehrenbach.be

Date: August2007Documentrev. : 4Page: 14 / 15/

PartsListforFigure 13, HT-0119 Hand ToolParts

Index

no. PartNo. Description Quantity

1A-857-5 CRIMPERHOLDER 1

2* 104964-1 TONKER 2

3* 415601-001 INSULATIONBARRELCRIMPER22-26

GAUGEWIRE 1

4* 415602-001 WIRE BARRELCRIMPER22-26 GAUGEWIRE 1

5A-1153 TONKERSPRING 2

6A-1155 GUIDE SPRING 2

7915305-224 SHCS, 4-40NFX ..LONG 8

8104963-1 SPRINGRETAINER 1

9915305-205 SHCS, 6-40NFX ½.LONG 2

10 915305-559 SHSS(SETSCREW)2-56NC X1/8.LONG 2

11 102466-1 ANVILHOLDER 1

13* 108178-002 INSULATIONBARRELANVIL,22-26 GWIRE 1

15* 108177-002 WIRE BARRELANVIL,22-26GWIRE 1

16 102470-1 TERMINALHOLDERSPRING,0.65. LONG 2

17 147070-1 TERMINALHOLDER 1

18 900066-001 O-RING,0.070.I.D.,01-004 2

19 102468-2 GUIDE PIN 2

20 144547-001 GUIDE RAIL 2

21 147071-1 TERMINALCLAMP 1

22 147072-1 QUILL PUNCH 1

23 102470-2 PUNCH SPRING,0.300.LONG 1

24 150564-1 COLLAR.NYLON_,PRESS-FIT,0.0625.I.D. 1

*RecommendedSpareParts

Table of contents

Other Fohrenbach Crimping Tools manuals

Popular Crimping Tools manuals by other brands

Burndy

Burndy PATRIOT 444S Series SAFETY OPERATING & MAINTENANCE INSTRUCTIONS

Textron

Textron Klauke ERB0818-L instruction manual

Panduit

Panduit CT-920 Series instruction manual

TE Connectivity

TE Connectivity 68321-1 instruction sheet

Tyco Electronics

Tyco Electronics SDE-SA 2063526 Series instruction sheet

Cembre

Cembre HT61 Operation and maintenance manual