AT-AFIFG Air Crimp Tool Head

Doc. No: ATS-640054300 Release Da e: 10-01-03 UNCONTROLLED COPY Page 2 of 6

Revision: B Revision Da e: 05-05-04

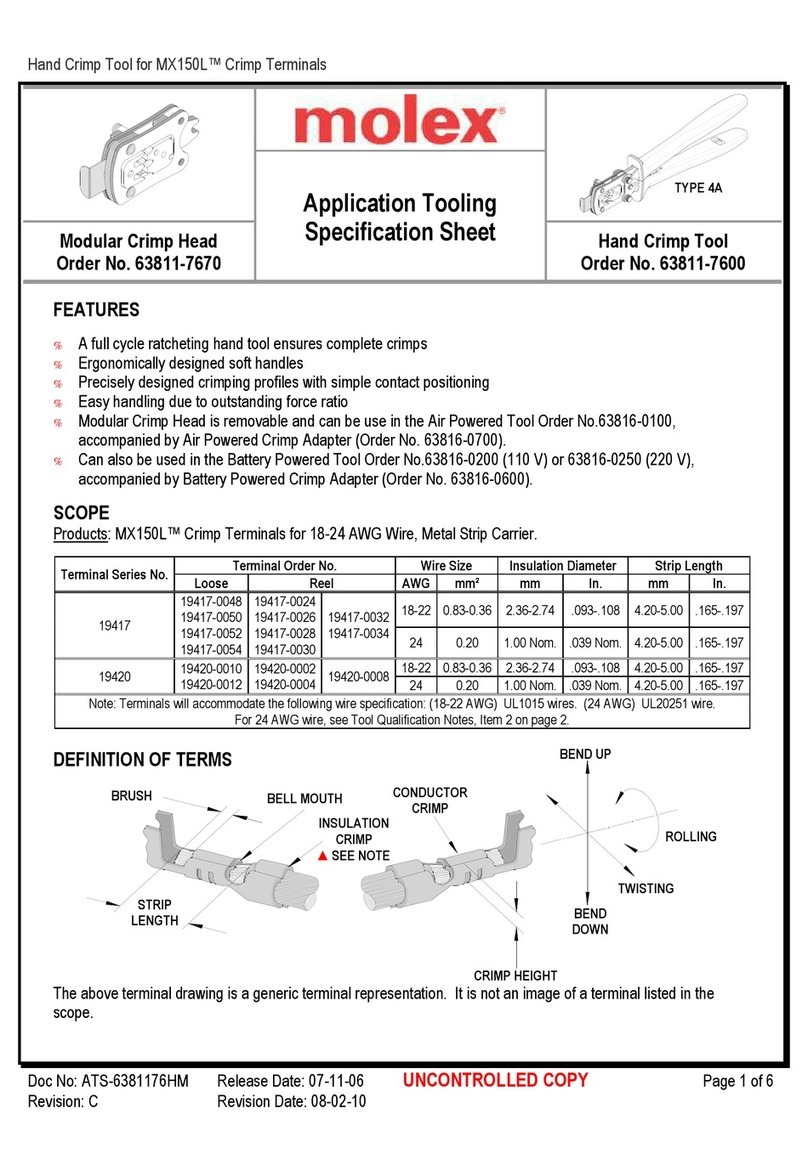

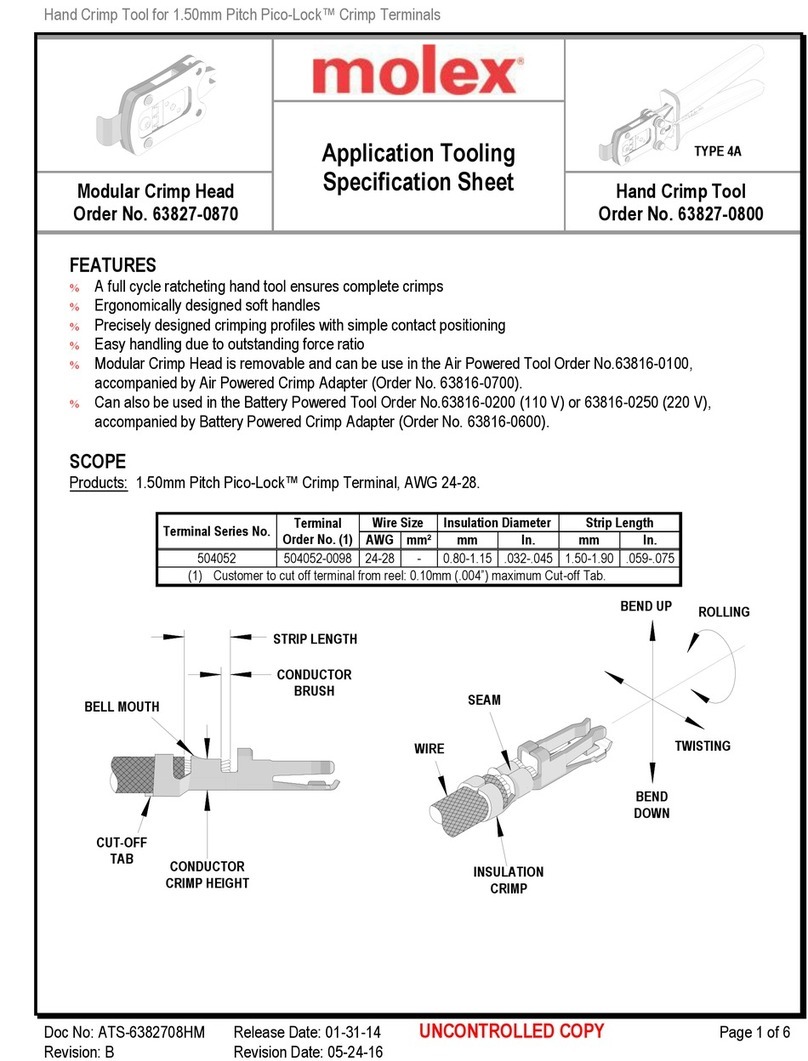

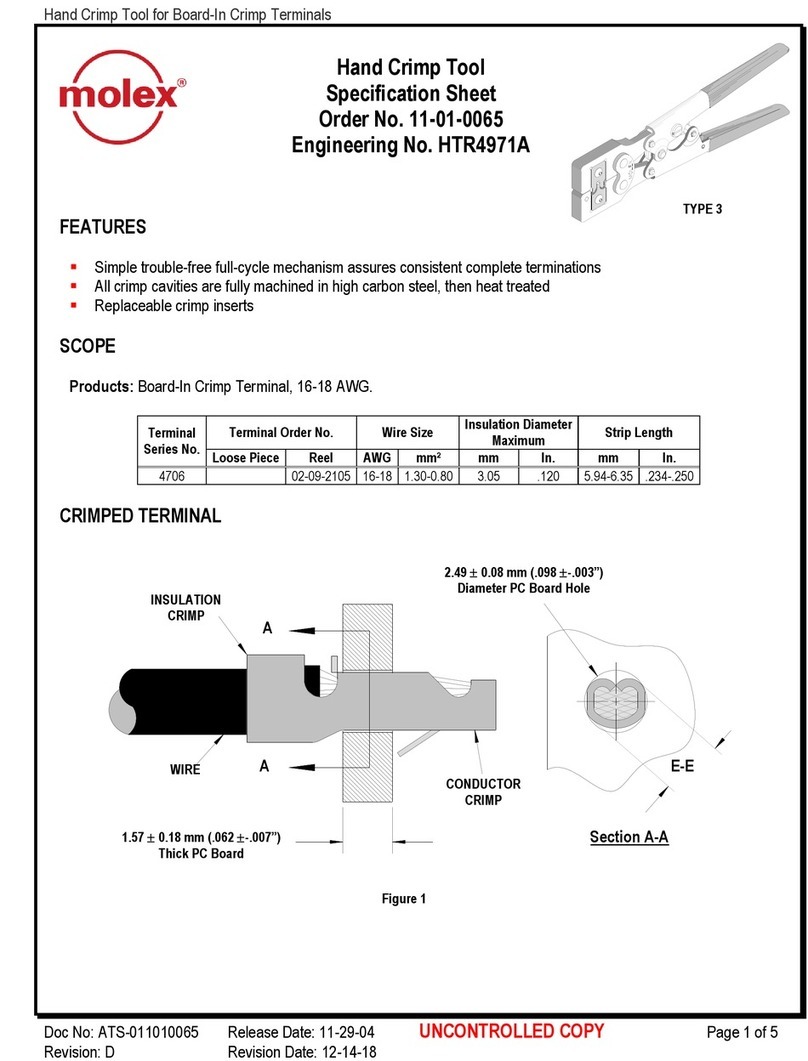

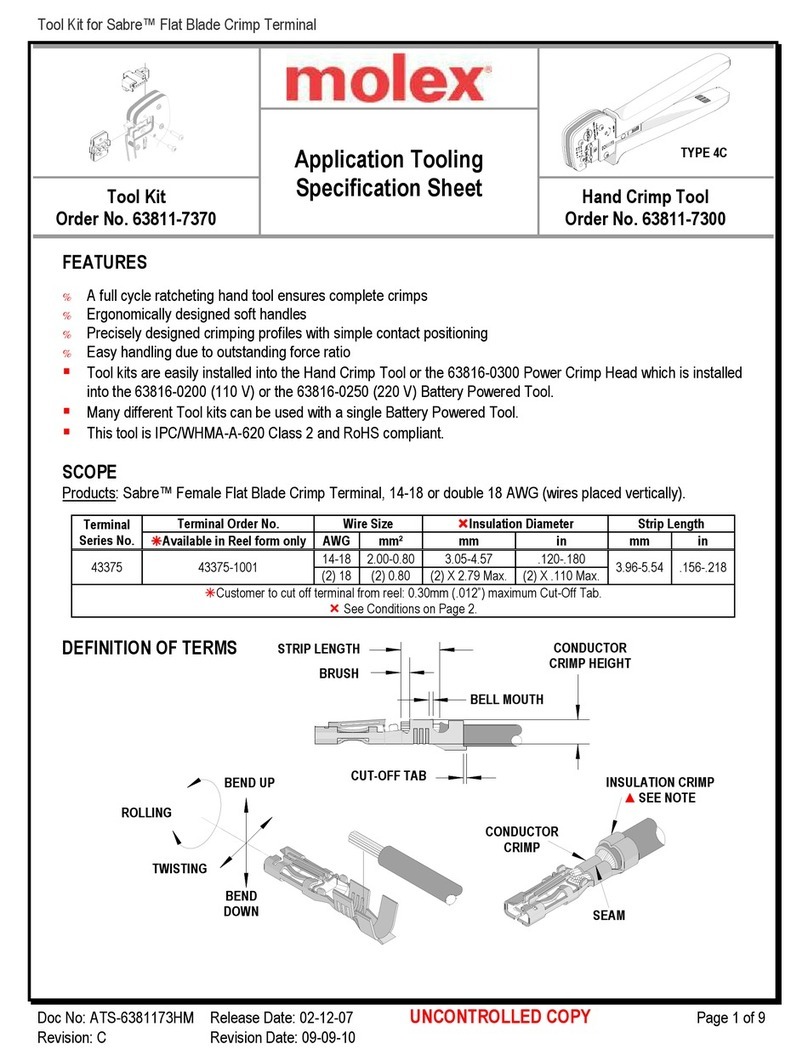

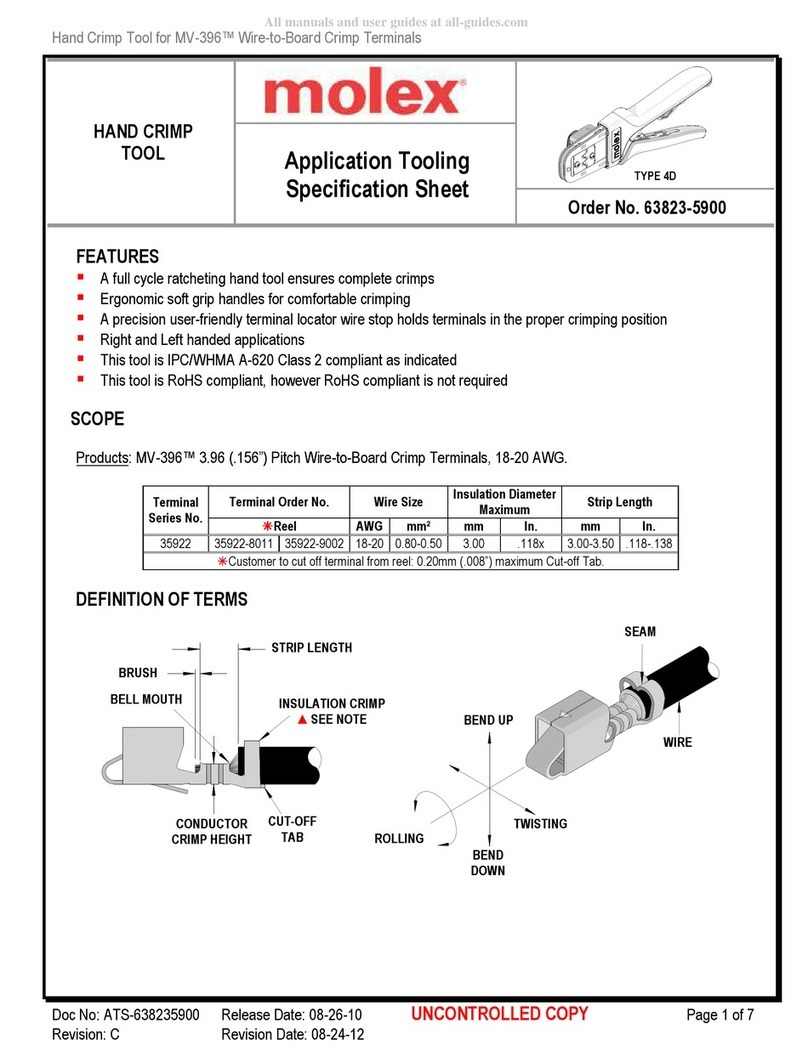

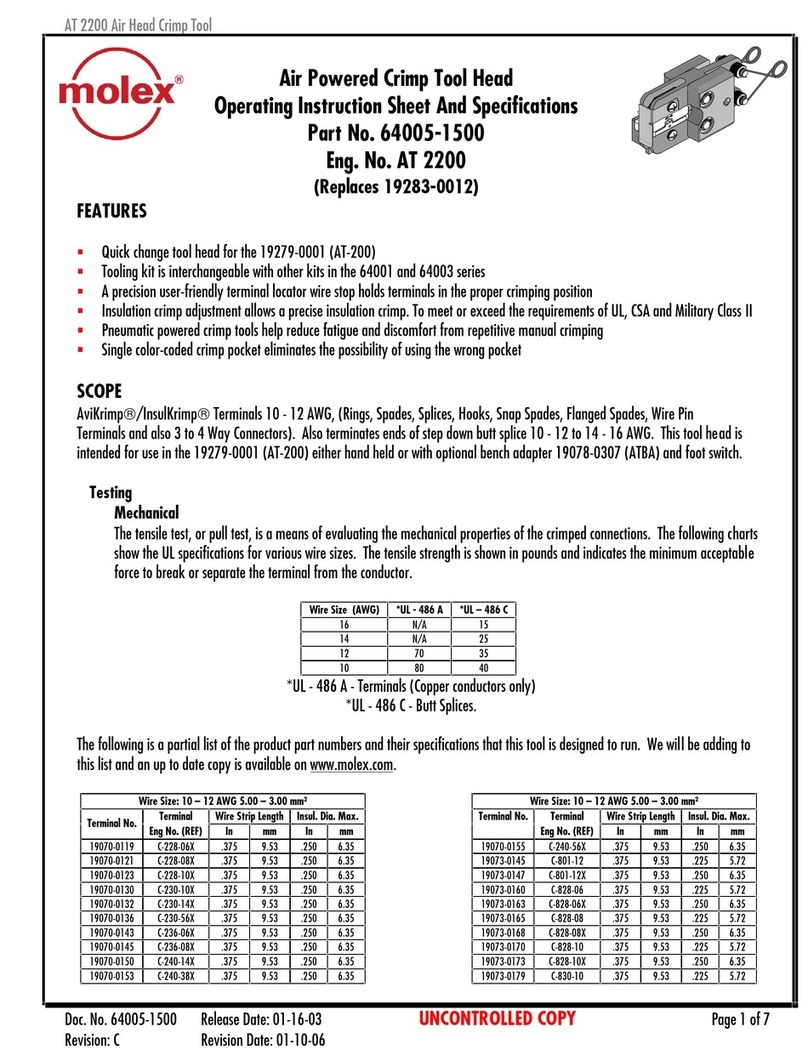

TERMINAL

HIELD

WIRE

CONDUCTOR ANVIL

WIRE

PUNCH

OF TERMINAL

LOCATOR

NUT

BARREL

OPERATION

Refer o he ins ruc ion manual for he 19279-0001 (AT-200) for

moun ing his crimp ool head.

Caution: Never opera e his ool wi hou he supplied safe y shield

in place. Never place fingers in he ooling nes s.

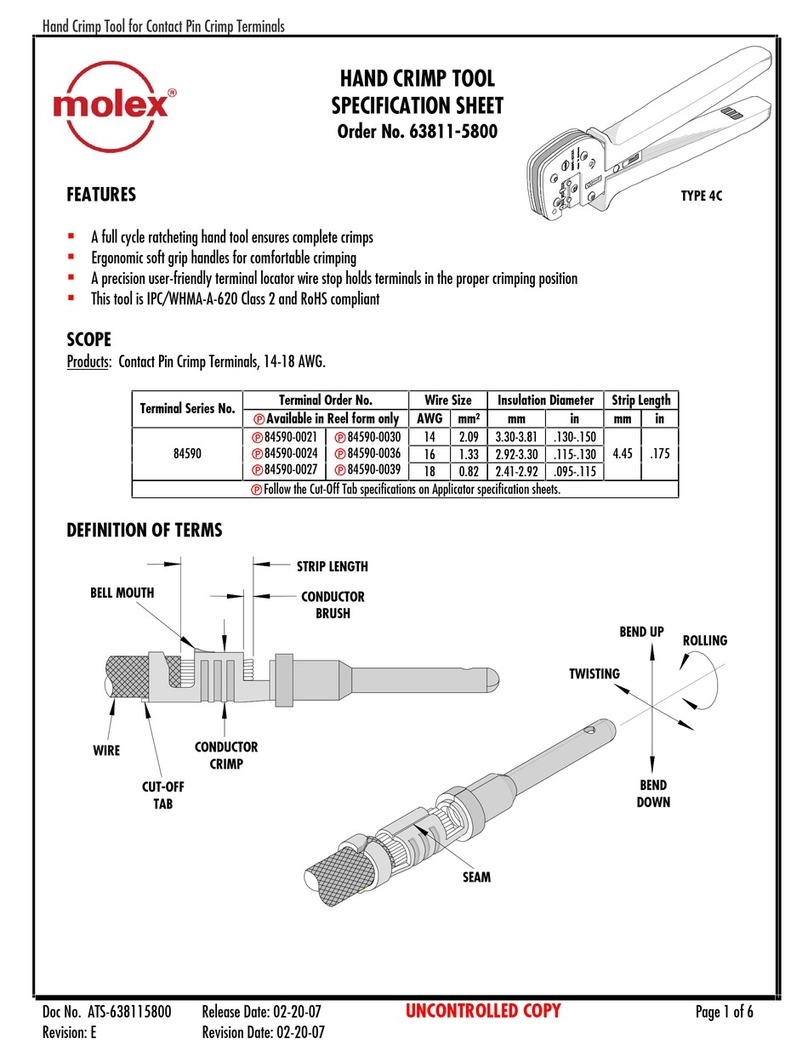

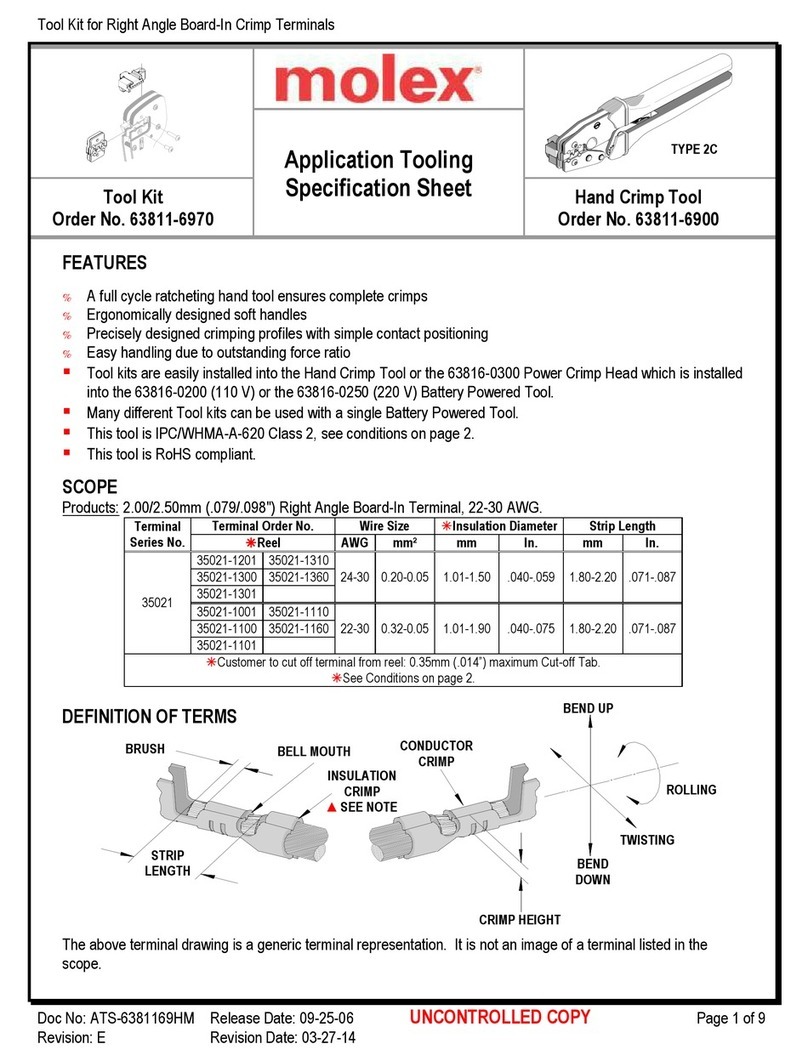

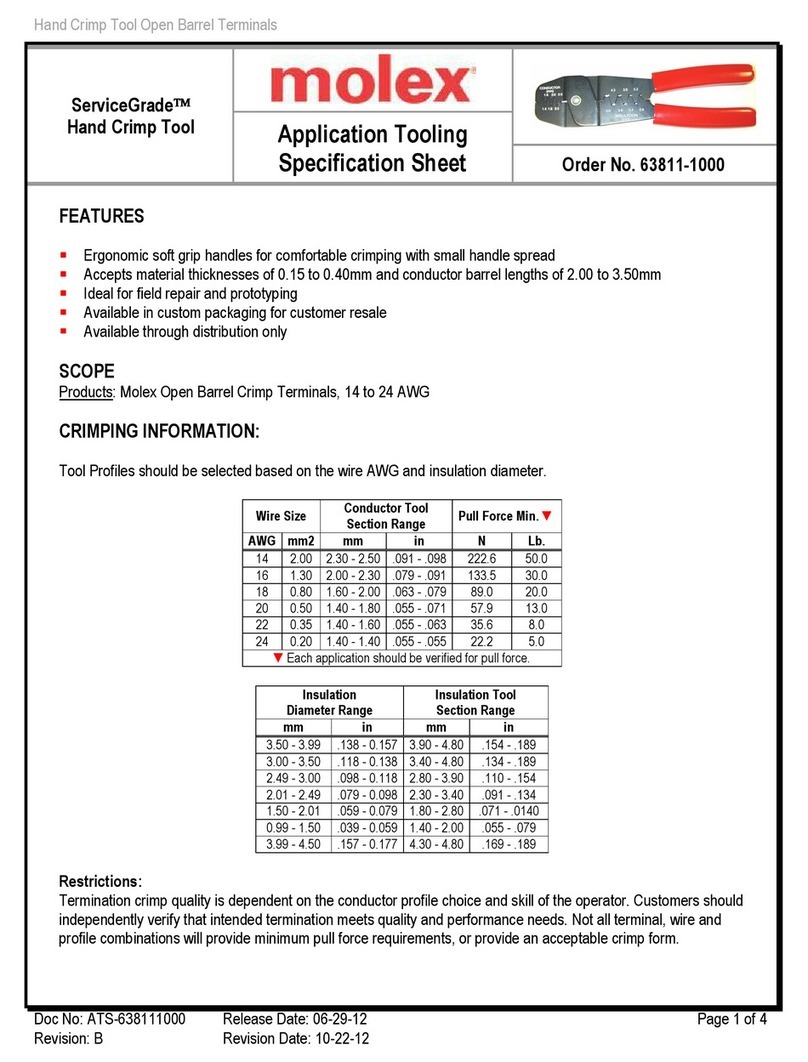

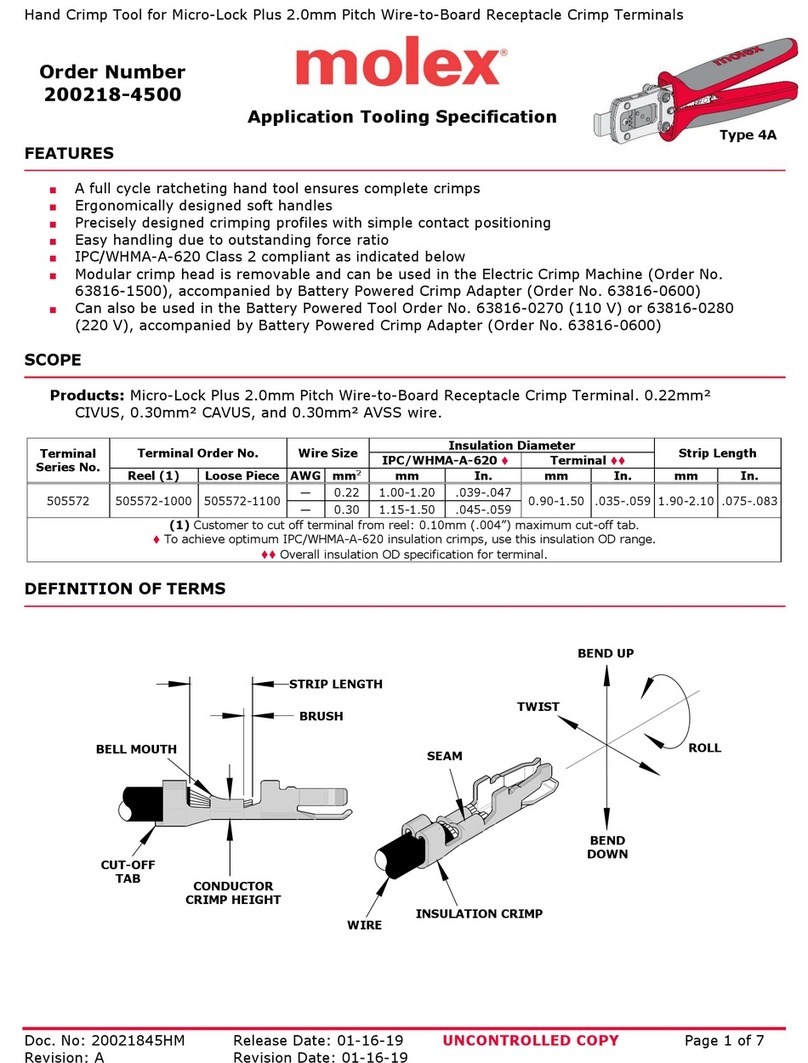

Crimping Terminals

1. Inser he wire in o he erminal. Inser he erminal wi h he

barrel in o he color-coded nes and he square edge of he flag

facing ou for 14-16 AWG and in for 18-22 AWG. Make sure he

back of he flag erminal is agains he loca or. See Figure 1. If

erminal is no flush agains he loca or loosen he M4 wing nu

and adjus he loca or up or down so ha he fla edge of he erminal is flush agains he wall of he loca or.

Tigh en he M4 wing nu . See Figure 2.

2. Par ially close he ool o hold he erminal in

place.

3. Push on wire o assure i is s ill fully sea ed

in he erminal. Cycle he ool.

4. Remove he crimped erminal. Inspec for

proper crimp loca ion, and check for

insula ion closure. Loca or is adjus able up

and down o keep erminals s raigh af er

crimping.

5. If he insula ion par of he crimp needs o

be adjus ed, firs disconnec air source and

loosen he M4 screw on he bo om ool jaw,

hen inser a 3/32” hex wrench (supplied)

in o he bo om of he lower die. See Figure 3. A clockwise (CW) ro a ion decreases insula ion crimp while

a coun er-clockwise (CCW) ro a ion increases insula ion crimp. Af er adjus ing, re igh en he M4 screw.

Reconnec air source.

Maintenance

I is recommended ha each opera or of he ool be

made aware of, and responsible for, he following

main enance s eps:

1. Remove dus , mois ure and o her con aminan s

wi h a clean brush, or sof , lin -free clo h.

2. Do no use any abrasive ma erials ha could

damage he ool.

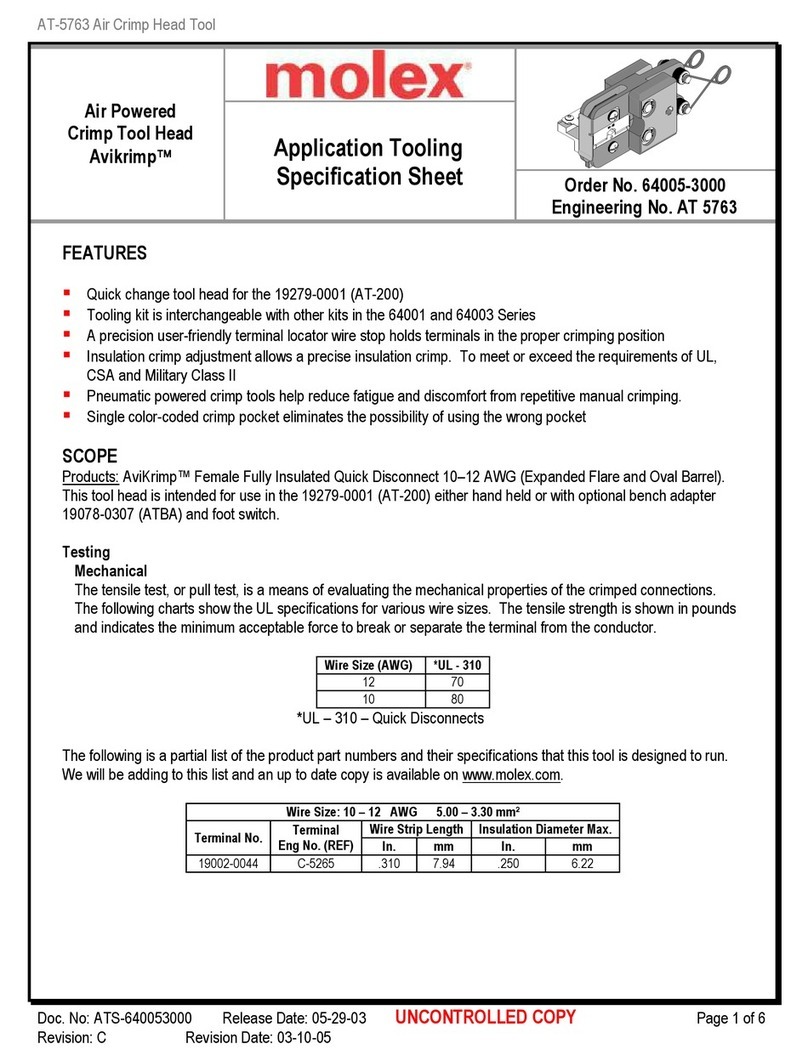

3. Make cer ain all pins; pivo poin s and bearing surfaces are pro ec ed wi h a hin coa of high quali y

machine oil. Do no oil excessively. This ool was engineered for durabili y, bu like any fine piece of

equipmen , i needs cleaning and lubrica ion for a maximum service life of rouble-free crimping. Use a ligh

oil, such as 30 weigh au omo ive oil a he oil poin s shown in Figure 3, every 5,000 crimps or mon hly will

significan ly enhance he ool life and ensure a s able calibra ion.

(BOTH IDE ) LIGHT OIL

(EVERY 3 MONTH

OR 5,000 CRIMP )

M4 CREW

WRENCH