3 4

Vacuum Packaging & Food Safety

The vacuum packaging process extends

the life of foods by removing most of the

air from sealed zipper bags and containers,

thereby reducing oxidation, which affects

nutritional value, flavour and overall quality.

Removing air can also inhibit growth of

micro-organisms, which can cause problems

under certain conditions:

Mould – Easily identified by its fuzzy

characteristic. Mould cannot

grow in a low oxygen environment;

therefore vacuum packaging can

slow the growth of mould.

Yeast – Results in fermentation, which can

be identified by smell and taste.

Yeast needs water, sugar and a

moderate temperature to grow. It

can also survive with or without

air. Slowing the growth of yeast

requires refrigeration, while freezing

stops it completely.

Bacteria – Results in an unpleasant

odour, discoloration and/or

soft or slimy texture. Under the

right conditions, Clostridium

botulinum (the organism that

causes Botulism) can grow

without air and sometimes

cannot be detected by smell or

taste. Although it is extremely

rare, it can be very dangerous.

To preserve foods safely, it is critical that

you maintain low temperatures.

It is important to note that vacuum

packaging is NOT a substitute for canning

and it cannot reverse the deterioration of

foods. It can only slow down the changes

in quality. It is difficult to predict how

long foods will retain their top-quality

flavour, appearance or texture because

it depends on the age and condition of

the food on the day it was vacuumed

packaged.

Food Safety Warning

Use fresh, perishable foods soon after

purchase. Even under proper storage

conditions, foods lose freshness and

nutritive value if they are stored too long.

Food Preparation Tips

Hard Cheeses:

To keep cheese fresh, vacuum package it

after each use.

IMPORTANT: Soft cheeses should never

be vacuum packaged.

Baked Goods:

To vacuum package soft or airy baked

goods, we recommend using a FoodSaver®

Container so they will hold their shape.

Accessories

Get the most out of your FoodSaver®

appliance with easy-to-use FoodSaver®

Bags, Containers and Accessories.

FoodSaver®accessories are available

through the consumer service number as

listed on the back page of this user guide.

Charging Your Handheld Vacuum

Appliance: Before using the appliance

for the first time please charge it for at least

24 hours. Failure to do so will reduce the

product’s battery life. The charge Indicator

Light remains illuminated when the appliance

is plugged in.

IMPORTANT: Should liquid be collected in

the reservoir, stop vacuuming and clean it

frequently for smooth operation.

Sealing FoodSaver®

Vacuum Zipper Bag

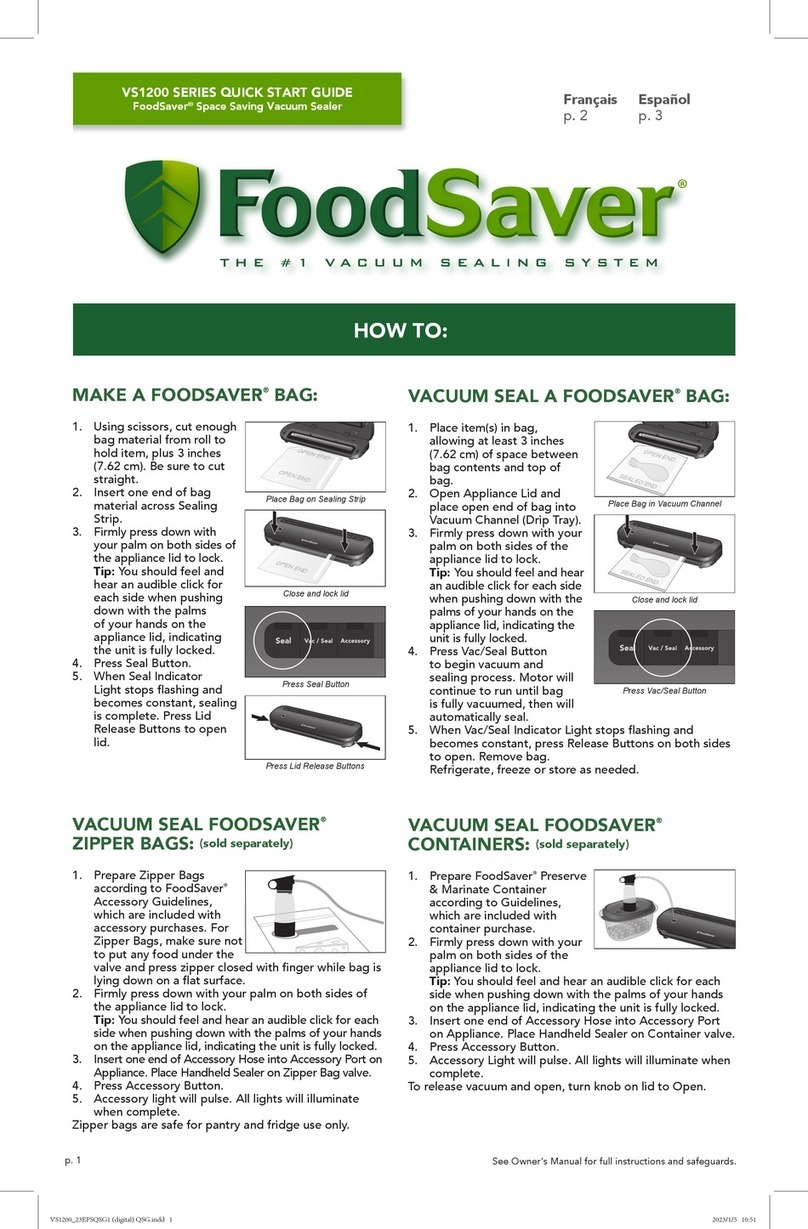

Step 1: Fill and Seal Bag

Place food in FoodSaver®Vacuum Zipper

Bag. Lay the Zipper Bag flat with the grey

circle facing upwards press zipper firmly to

start seal. Slide fingers across the zipper to

close the bag.

Step 2: Remove Air from Bag

Press FoodSaver®Vacuum Sealer over the

grey circle on the bag and gently press the

Green “Start” button.

Step 3: Refrigerate

Place the bag with food into the refrigerator

or pantry.

*Bags are not intended for liquids.

Sealing FoodSaver®

Containers (not included)

Step 1: Fill and Close

With FoodSaver®Container on a flat surface

– Place food in Container. Set lid on top and

apply pressure with both hands to snap

into place to prepare for vacuum sealing.

Step 2: Attach FoodSaver®Container

Adapter to bottom of Vacuum Nozzle by

pushing into bottom as shown.

Step 3: Evacuate Air

With the container adapter attached, place

the vacuum nozzle tip over the grey valve on

container lid. Press “Start” Button on unit

and evacuate for 10 seconds. The Container

is now ready to be stored. Look for the

dimple at the centre of the grey valve – it

tells you that air has been removed from

the container.

Step 4: Release Vacuum

To release the vacuum in the Container,

simply release the Vacuum Valve/Air Release

Flap by gently lifting the tab.

Guidelines for vacuum packaging Instructions

FSFRSH0050-073_13ECM2.indd 3-4 1/18/13 10:11 AM