FOOTAGE C200 User manual

C200

1/2" - 2" Remote Squeeze Off Tool

OWNERS

MANUAL

ECN 1813 C200 (1/2 TO 2 in.) EXTENDED REACH

SQUEEZE OFF TOOL FOR PE PIPE Page 2 of 7

DO NOT OPERATE THIS TOOL UNLESS THESE INSTRUCTIONS HAVE BEEN CAREFULLY

READ AND UNDERSTOOD

Preliminary Assembly:

To connect the C615-A115 static grounding kit, mount the grounding tool lead to the head with the

¼” hardware supplied (see attached). Clean all connections prior to assembly. If not using a ratchet

to power the drive screw by the top hex, insert the “T” handle into the cross hole in the top of the

power screw and thread the bolt into the end to secure it. Do not use extension on the “T”

handle. The tool as supplied by the manufacturer has sufficient leverage to perform the task it was

designed for.

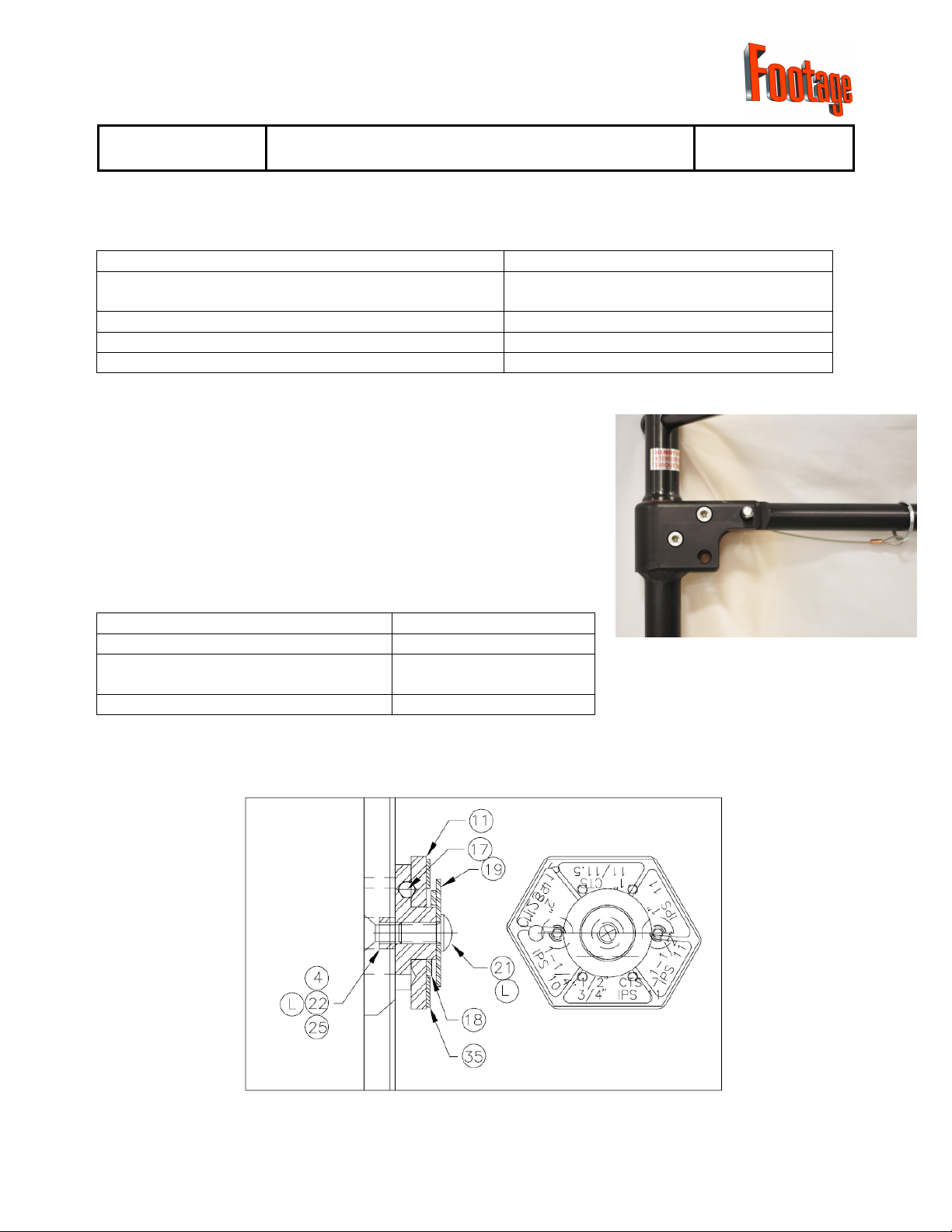

Operating Instructions: A) Installation on Pipe

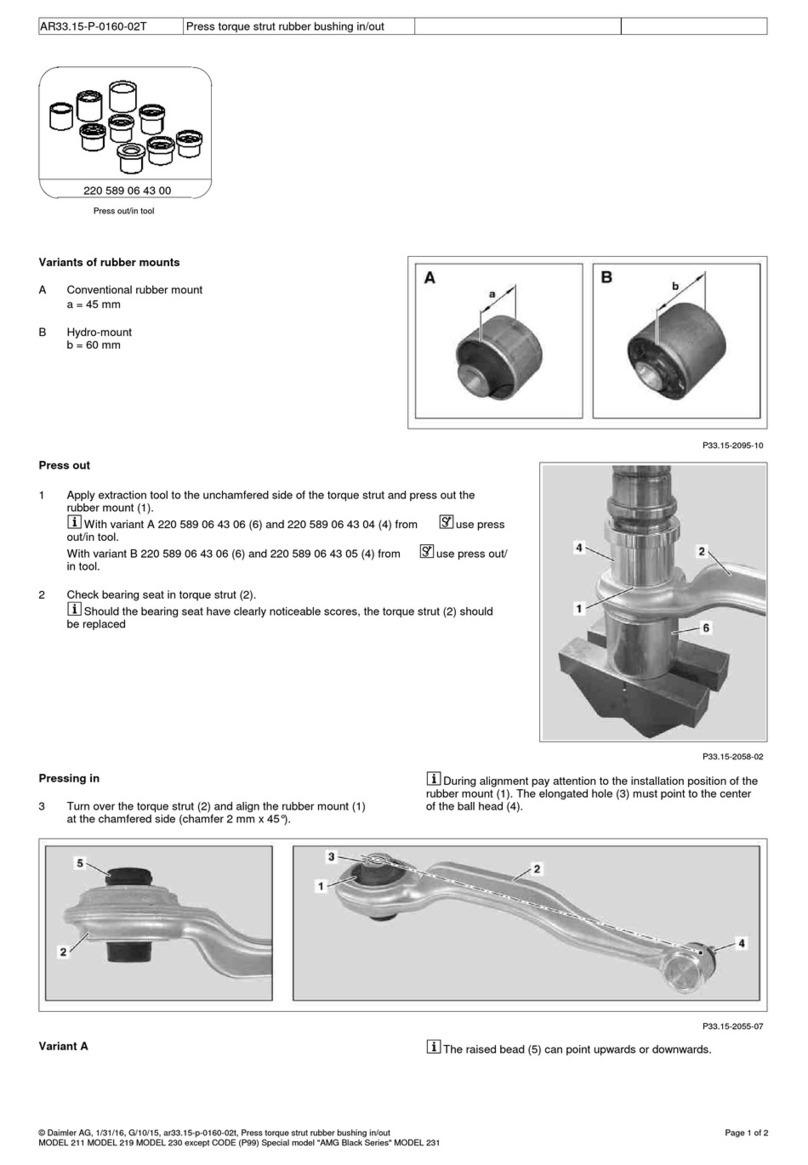

1) Inspect tool to ensure that it is clean and free from

any debris that may hinder proper operation. The

head and gauge plate assembly must be clean,

free of dirt and debris to function properly. Open

folding handle and secure with attached pin as

shown at left. (figure 1)

2) When using the optional grounding spike C615-

A115 fully install the grounding spike in firm ground

near the tool. Moist soil is required. Soak the

area that the grounding spike will be inserted into if

necessary.

Fi

g

ure 1

3) Grasping the Aluminum handle with one hand,

turn the steel “T” handle with the other hand

counterclockwise to fully open the squeeze jaws. Do

not attempt to over open the jaws as this may damage

the tool. Inspect the 2 centering springs. They should

now be under tension.

4) Set the gauge plate stop on the side of the unit

to the proper pipe size and SDR setting required. The

gauge plate assembly may be stiff, it will be easier to

set if the gauge plate is pulled out slightly from body

of tool while turning it. If the detent action is not

positive, the gauge plate mechanism requires

cleaning and/or service. Position the arrow on the

gauge plate setting so that it faces the bronze barrel

nut as shown at right. (Figure 2)

Figure 2

ECN 1813 C200 (1/2 TO 2 in.) EXTENDED REACH

SQUEEZE OFF TOOL FOR PE PIPE Page 3 of 7

Figure 4

Figure 3 Fi

g

ure 5

5) Place the head of the tool on the pipe such that the pipe runs between the squeeze jaws. Note

that the aluminum handle is parallel to the pipe as shown in figure 3. Place the tool centrally on

the pipe using the centering springs to assist in location as shown in figure 4. As a rough guide

note that the inside edge of the pipe is in approximate alignment with the side of the tool body

as shown in figure 5. Make sure that the pipe stays in contact with both centering springs.

B) Squeezing the Pipe

1) Advance the squeeze bar by turning the drive screw clockwise until the lower jaw starts to touch

the pipe. During the “squeeze-off” operation keep tool at right angles to the pipe.

2) The rate of squeeze is very important in minimizing the damage to the pipe walls. Advance the

squeeze no faster than 2” per minute. Increase this time in colder weather below 32°F (0°C).

Consult your local utility as to their specific procedure for this operation. As the pipe is

ECN 1813 C200 (1/2 TO 2 in.) EXTENDED REACH

SQUEEZE OFF TOOL FOR PE PIPE Page 4 of 7

squeezed the centering springs will relax and fold out of the

way of the pipe. (Figure 6)

3) Continue slowly squeezing until the gauge plate stops come

in contact with the bronze barrel nut. (See Figure 6) DO NOT

CONTINUE SQUEEZING ONCE THE GAUGE STOPS

HAVE BEEN REACHED OR TOOL DAMAGE MAY

RESULT. Keep in mind; it may not be necessary to

squeeze the pipe all the way to the gauge stops to obtain

satisfactory flow control. NEVER USE EXTENSIONS ON

THE “T” HANDLE OR RATCHET TO GET MORE

SQUEEZE, AS TOOL DAMAGE MAY RESULT.

C) Releasing the Pipe

1) To avoid any damage to the plastic pipe, it is critical that a

slow release rate be achieved. A release rate of ½” (12.5 mm)

per minute is recommended. This time allows for the controlled rebound of the plastic,

decreasing the chances of slow crack propagation. Below 32°F (0°C), the release rate should

be slower. Consult your local utility as to their specific procedure for this operation.

2) Unscrew the powerscrew slowly, not exceeding the release rate. Continue to open the tool at

this rate until it can be removed from the pipe.

3) WARNING: Do not continue to unscrew the tool past the point that the barrel

nut comes in contact with the bottom of the cut-out in the tool head side plate,

or damage may result.

D) Re-rounding of Pipe

1) This tool can not be used for re-rounding pipe due to the length of the handle. It should also be

noted that PE pipe rebounds on it’s own to its near original shape very well. Squeeze points on

the pipe are typically marked in some fashion for future reference. Consult your local utility as

to their specific procedure for this operation.

E) WARNING

1) Do not exceed the recommended squeeze and release rates. Temperatures below

32°F (0°C) will require slower squeeze and release rates. Release is more critical

than squeeze; thus slower rates are required.

WARNING

2) When performing a squeeze, stay at least 3 pipe diameters away from fittings, fusion

areas and previously squeezed areas.

WARNING

3) To ensure the removal of any static electric charge buildup, ensure the grounding

system is properly planted in the soil. Your tool can easily be fitted with a grounding

spike if not so equipped. Contact your FOOTAGE TOOLS dealer for installation

instructions and parts.

Figure 6

Important Notice

If you experience difficulty obtaining flow control when

squeezing HDPE pipe, we recommend you perform a

double squeeze and vent to atmosphere.

Please consult your local Utility for their specific

operating procedure.

ECN 1813 C200 (1/2 TO 2 in.) EXTENDED REACH

SQUEEZE OFF TOOL FOR PE PIPE Page 5 of 7

F) Maintenance

Ensure the tool is in good operating order by routinely inspecting the following points prior to use:

Inspect the centering springs for damage. Replace as needed

Inspect the gauge plate assembly for positive

detent action Clean, repair or replace parts as needed

Inspect the grounding spike connections. Replace as needed

Inspect the tool for free operation. Clean, repair or replace parts as needed

Inspect the squeeze jaws for surface damage. Replace as needed

G) Service

Partially disassemble the tool by removing the screw indicated in

figure 7. This will allow the power screw to be unthreaded from

the barrel nut and lifted out from the top of the tool. The barrel nut

is then pulled out from the side of the tool body. This in turn will

free the active jaw for removal from the tool head. Should your

tool require more extensive service work please refer to the

attached drawing in the next section (H) for assembly instructions

and parts information.

Inspect the power screw for dirt. Clean and lubricate.

Inspect the tool head cavity for dirt. Clean as needed

Inspect the power screw thread for

damage. Repair or replace as

needed

Inspect the barrel nut for damage. Replace as needed

Figure 7

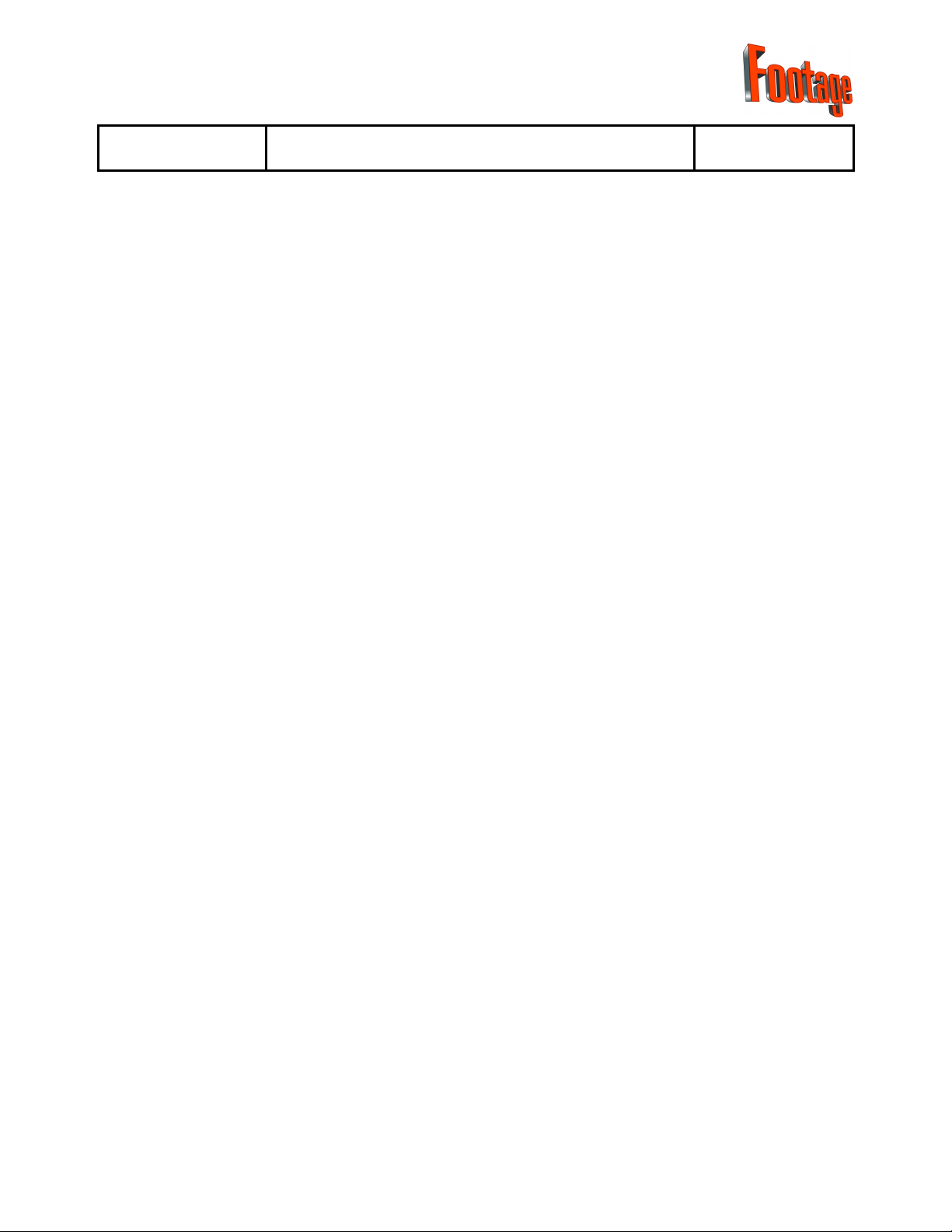

Detail of Gauge Plate Assembly and Installation

DETAIL A

SCALE .5

1

1

2

2

3

3

4

4

A A

B B

C C

D D

SHEET 1 OF 1

DRAWN

CHECKED

QA

MFG

APPROVED

nguyenj

nguyenj 7/7/2009

DWG NO

C200-A2

TITLE

SIZE

C

SCALE

REV

D

A

Parts List ITEM

DESCRIPTION

PART NUMBER

QTY 36LABEL - OWNERS MANUALLABEL-009135GAUGE PLATE LABELC125-14134FOOTAGE TOOLS LABEL - NEWLABEL-012

133LABEL, DO NOT USE EXTENSIONLABEL-001

132BOX FOR C200BOX-C200131STOPPERC200-21130GOURND SPIKE ASMC615-A115

129

BUSHING, FLANGED 1"

99-178-16-2008

128

FHCS 10-24 X 1/2

99-110-01-9008227

FHCS 3/8-16 X 3/4

99-110-00-0612926SHOULDER BOLT 3/8 X1 1/499-114-01-0512225CHROME BALL99-157-00-0006

124SPRING WASHER W-385C200-25123BHCS 10-32 X 199-105-01-9004422BHCS 1/4-20 X 1/299-104-01-0408

121

HHCS 7/16 X 3/4

99-100-00-0706

120END WASHERC110-17119TORQUE BAR ASMC105-42118DOWEL PIN 3/8 X 1 3/499-165-00-2428

417

SHSS 1/4-20 X 1

99-150-S0-0416

116

ROLL PIN 1/8 X 1/2

99-163-00-0808115

WASHER1/4 (FASTENAL #33207)

99-145-00-0041114

KEY RING 1.5" O.DC200-22

113HITCH PIN & LANYARDC200-19

112GRIP WORKS #GP-6C200-23111GAUGE PLATEC125-12110SPRING, SPEC #E0240-034-2500C200-2029WEAR RINGC200-15

18BOTTOM JAWC200-1217BARREL NUTC200-1616

HANDLE BAR

C200-09

15

TOP JAWC200-06

14GAUGE PLATE HUBC200-1413SIDE PLATEC200-0212POWER TUBE WELDMENTC200-W02

11

POWER SCREW WELDMENTC200-W01

1

15

25

16

3

28

3

27 34

13

14

19

6

12

1

33

18

5

23

10

87

9

2

2

1

2

17

21

20

26

22

11

4

29

30

31

FOOTAGE TOOLS INC.

C200-A1 ASSEMBLY DWG

2" REM. SQUEEZE OFF TOOL

NTS

REMOVE ALL SHARP CORNERS

UNLESS SPECIFIED OTHERWISE

35

24

36

ECN 1813 C200 (1/2 TO 2 in.) EXTENDED REACH

SQUEEZE OFF TOOL FOR PE PIPE Page 7 of 7

I) Footage Tools Limited Warranty

FOOTAGE TOOLS INC, hereinafter sometimes referred to as “Manufacturer” warrants each

new industrial product of its own manufacture to be free from defects in material and workmanship,

under normal use and service for one full year after delivery to the end user. Warranty is void

unless warranty registration card is completed in full and returned to FOOTAGE TOOLS INC

within thirty days from the date of purchase. This warranty and any possible liability of

FOOTAGE TOOLS INC hereunder are in lieu of all other warranties, expressed, implied, or

statutory, including, but not limited to, any warranties of merchantability or fitness for a particular

purpose.

The parties agree that the Buyers SOLE AND EXCLUSIVE REMEDY against Manufacturer,

whether in contract or arising out of warranties, representations, instructions, or defects shall be for

the replacement or repair of defective parts as provided herein. In no event shall Manufacturers

liability exceed the purchase price of the product. The Buyer agrees that no other remedy

(including, but not limited to, in incidental or consequential loss) shall be available to him. If during

the warranty period, any product becomes defective by reason of material or workmanship and

Buyer immediately notifies Manufacturer of such defect, Manufacturer shall, at its option, supply a

replacement part or request return of the product to its plant in Toronto, Canada. No parts shall be

returned without prior written authorization and a return goods authorization number from

Manufacturer, and this Warranty does not obligate the Manufacturer to bear any transportation

charges in connection with the repair or replacement of defective parts. The Manufacturer will not

accept any charges for labour and/or parts incidental to the removal or remounting of parts repaired

or replaced under this Warranty.

This Warranty shall not apply to any part or product which shall have been installed or

operated in a manner not recommended by FOOTAGE TOOLS INC, nor to any part or product

which shall have been neglected, or used in any way which, in the manufacturers opinion,

adversely affects its performance; nor negligence of proper maintenance or other negligence, fire,

or other accident: nor if the unit has been altered or repaired outside of a FOOTAGE TOOLS INC

authorized dealership in a manner of which, in the sole judgement of FOOTAGE TOOLS INC

affects its performance stability or reliability: nor to any product in which parts not manufactured or

approved by FOOTAGE TOOLS INC have been used, nor to normal maintenance services or

replacement of normal service items. Equipment and accessories not of our manufacture are

warranted only to the extent of the original Manufacturers Warranty and subject to their allowance

to us, if found to be defective by them.

The original purchaser, user is responsible for “downtime” expenses and all business costs

and losses resulting from a warrantable failure. FOOTAGE TOOLS INC specifically disclaims any

responsibility for any damages of any kind or description, whether to property or person, in any way

connected with or arising out of the use of FOOTAGE TOOLS INC products.

Tool Registration Card

Warranty registration

now available online.

Please visit

www.footagetools.com

and click on

‘warranty registration’.

Model:

S/N:

IMPORTANT NOTICE

IMPORTANT NOTICE

Vaughan, Ontario

54 Audia Crt. Unit #1

Toll Free: 1-888-737-3668

www.footagetools.com

Table of contents

Other FOOTAGE Tools manuals