30260 R0 3

WESTFIELD GRAIN AUGERS

MK 100/130 PLUS X91’ - 111’

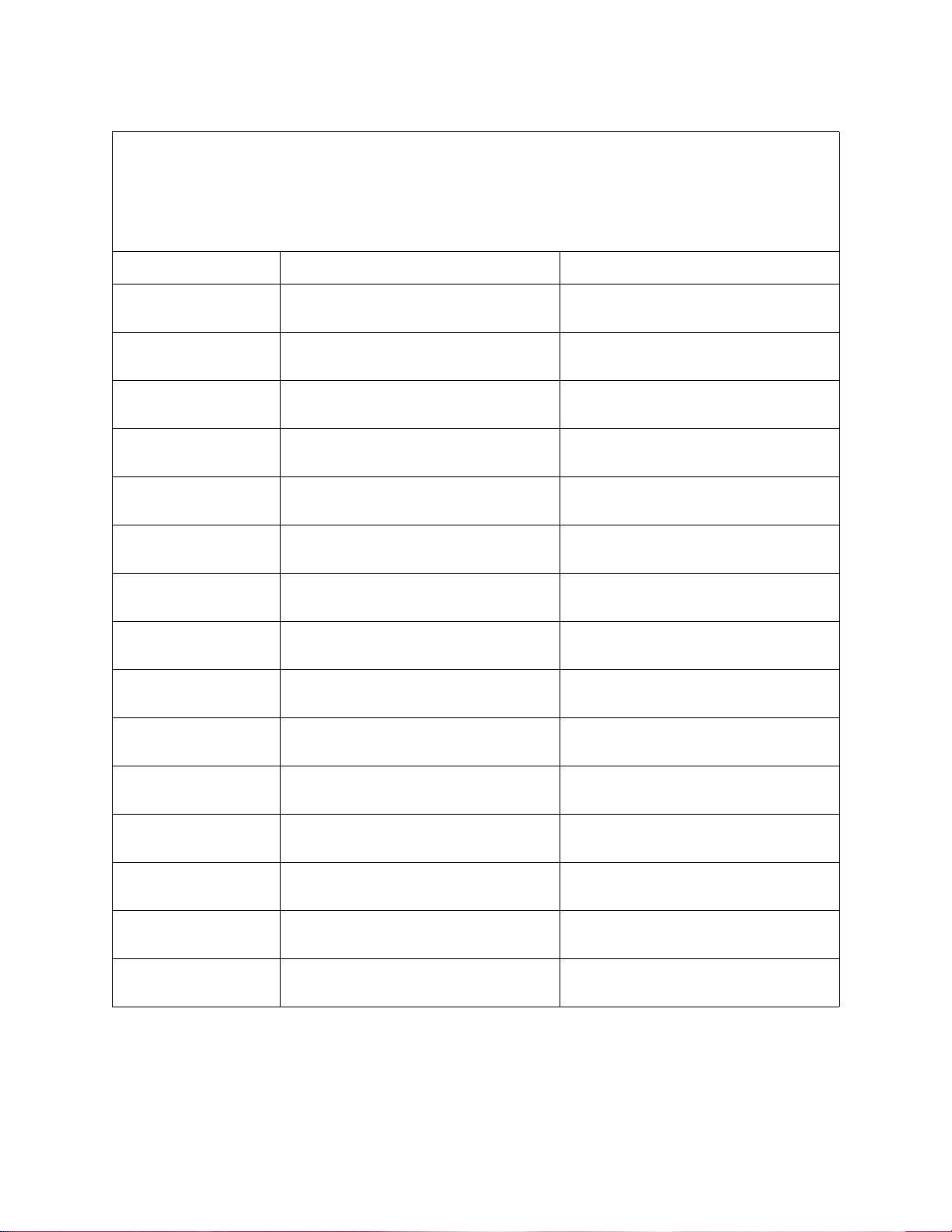

TABLE OF CONTENTS

1. Introduction .......................................................................................................................... 5

2. Safety First............................................................................................................................ 7

2.1. General Safety ......................................................................................................... 8

2.2. Assembly Safety....................................................................................................... 9

2.3. Operation Safety ...................................................................................................... 9

2.4. PTO Safety............................................................................................................. 10

2.5. Hydraulic Safety..................................................................................................... 11

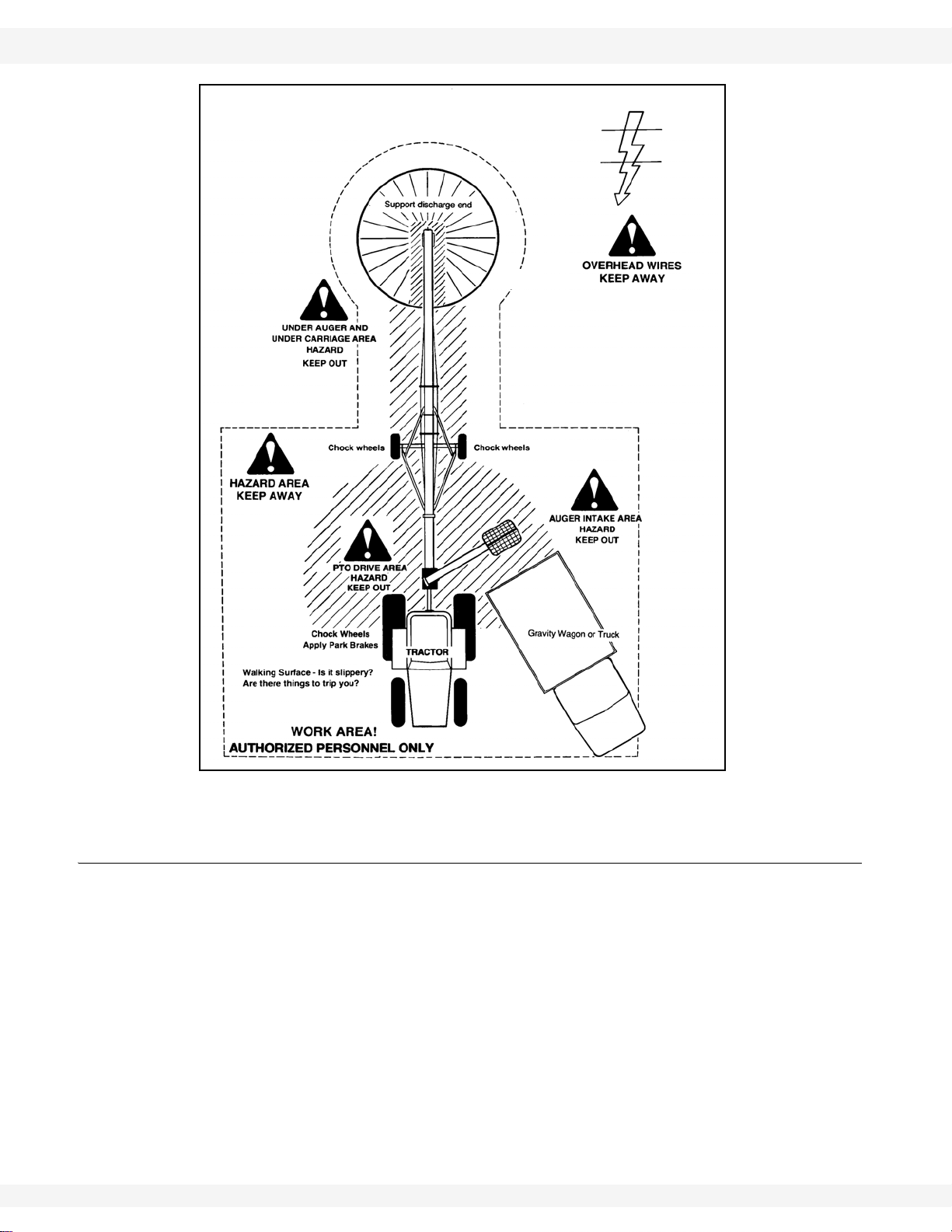

2.6. Transport & Placement Safety ............................................................................... 12

2.7. Maintenance Safety................................................................................................ 13

2.8. Safety Decal Locations........................................................................................... 13

2.8.1. Decal Installation...................................................................................... 13

2.8.2. Decal Locations........................................................................................ 13

3. Assembly ............................................................................................................................ 17

3.1. Tubes & Flighting ................................................................................................... 17

3.2. Track Shoe, Trackstop, & Lift-Assist Arm............................................................... 19

3.3. Tow Bar.................................................................................................................. 19

3.4. Boot........................................................................................................................ 20

3.5. Discharge Spout and Thrust Adjuster .................................................................... 22

3.6. Truss ...................................................................................................................... 22

3.6.1. Cable Trussing ......................................................................................... 24

3.7. Transport Undercarriage ........................................................................................ 27

3.8. Lift Cables .............................................................................................................. 30

3.9. Hydraulic Hoses..................................................................................................... 31

3.10. PTO (CV) Driveline............................................................................................... 33

3.11. Standard Intake Hopper....................................................................................... 33

3.12. Optional Low Profile Hopper ................................................................................ 36

3.13. Hitch Jack............................................................................................................. 38

3.14. Hopper Lift Arm / Winch....................................................................................... 39

3.15. Auger-to-Tractor Hookup...................................................................................... 40

3.15.1. PTO Driveline / Drawbar......................................................................... 40

3.15.2. Hydraulic Hose Couplers........................................................................ 42

3.16. Plastic Manual Holder .......................................................................................... 42

4. Transport & Placement...................................................................................................... 43

4.1. Transport Procedure .............................................................................................. 43

4.2. Placement Procedure............................................................................................. 44