FOOTAGE C16000 User manual

C1600

DO NOT OPERATE THIS TOOL UNLESS THESE INSTRUCTIONS HAVE BEEN

CAREFULLY READ AND UNDERSTOOD

BLEEDING OF THE HYDRAULIC SYSTEM

HYDRAULIC PUMP OIL LEVEL

This Footage Tools’ Hydraulic Squeeze Off Tool is sold in one configuration; fine

controlled release. This fine controlled unit has a needle valve with a built-in orifice in

the high-pressure pump line.

The tool is powered by an air operated, hydraulic pump which is a single speed pump

that gives the high pressures needed to squeeze large diameter pipe. Requiring 60 to

120 psi air supply pressure to operate, this pump is safer than an electrically operated

pump in the potentially explosive atmosphere near a gas main. The pump is equipped

with an air filter/regulator/lubricator to ensure it will operate properly. Ensure the

filter/regulator/lubricator is in good operating condition and filled with air tools oil.

The pump contains a 3-position control valve. Pushing the control valve lever clockwise

will allow oil to be pumped through the needle valve and to effect the squeezing

operation of the tool. Similarly, pulling the control valve lever fully counter-clockwise will

allow oil to be pumped to release (open) the tool. The neutral position (center) -

pump will stop building pressure, while holding existing pressure in the hose.

Cleanliness is critical while checking and refilling oil. Use a funnel with a

filter. Do not allow any dirt to enter the reservoir.

2) If motion of the tool seems jerky, bleeding air from the system may be necessary. To

accomplish this, join the two hoses together, eliminating the tool as shown in the photo.

A bypass valve, set at 10,000 PSI, is built into the

pump to prevent over-pressurization.

PRELIMINARY ASSEMBLY:

1) Ensure the pump is filled with good quality, ISO 32

weight, hydraulic oil. To check or refill, connect the

pump to the tool, retract the cylinder, and release

system pressure. (Failure to follow this instruction may

result in overfilling the reservoir – this could result in

the fill cap venting excessive oil and creating a spill.)

With the pump level and resting horizontally on the

base, remove cap and fill up to 1-1/2" from top and

recap.

Ensure the reservoir oil is topped up. Fully

open needle valve by turning knob counter

clockwise. Place the pump control valve to

"squeeze" and pump for 2 minutes. Place

the pump control valve to "Release" and

pump for 1 minute. Return the valve to the

"Neutral" position. Disconnect the hoses

and assemble them to the tool.

Cycle the tool fully open, to fully closed, a few times. Repeat if necessary. Ensure

the reservoir is topped up again, having the tool in the closed position.

ECN1638A C1600 SQUEEZE OFF TOOL FOR PE PIPE Page 2 of 9

WARNING:

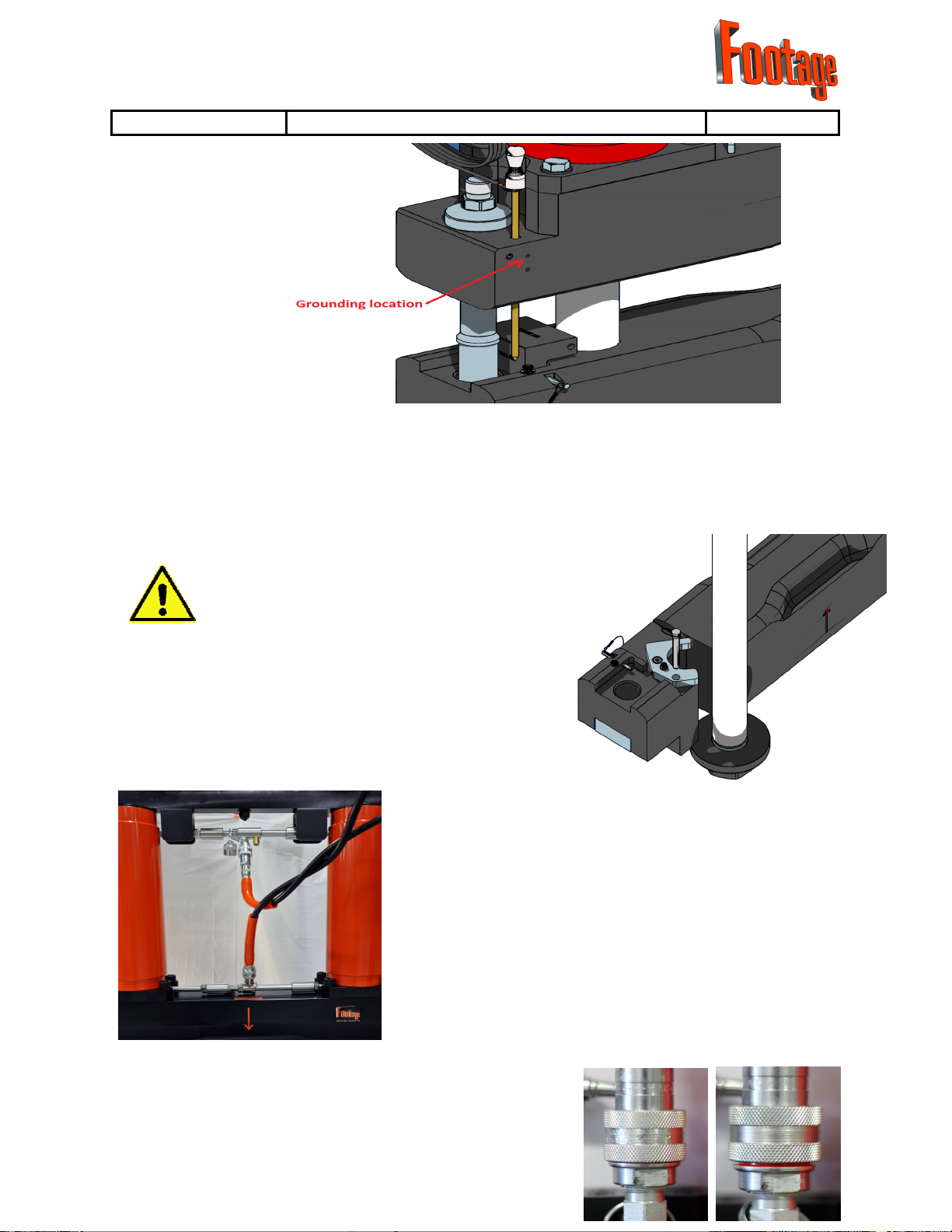

2) Inspect the tool to ensure that it is

clean and free from any dirt that may

hinder proper operation. Pay particular attention

to the locking mechanism on the lower bar where

the side shaft engages. It is critical that bar is

clean and free of debris. Clean if necessary.

Ensure the hydraulic couplings are clean and connect

the two hoses from the pump to the squeeze off tool.

Once the tool is fully open, do not continue to

pump. Continuing to pump will cause hydraulic oil to

be vented from the relief valve to prevent tool

damage.

LOCKING DEVICE & SLOT

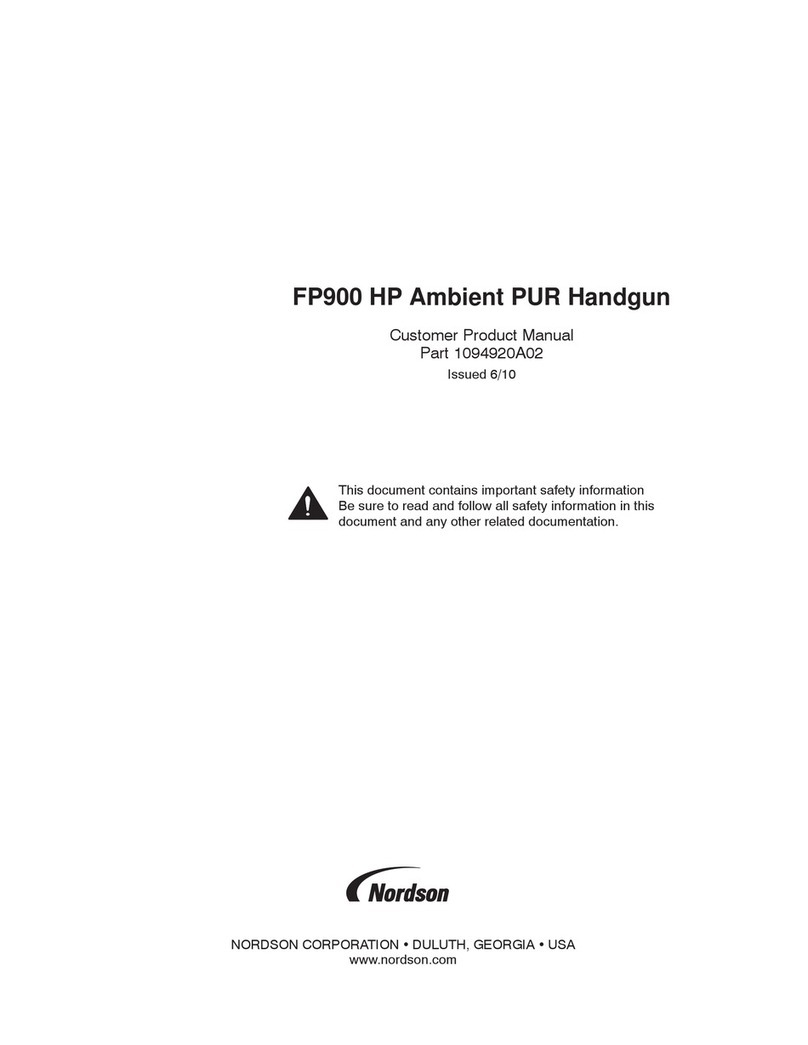

LOCATION OF GROUNDING SPIKE

ATTACHMENT OF HYDRAULIC

COUPLINGS

To Eliminate any possibility of accidental

disconnection, the threaded collar must be

fully threaded on, to enable pressure to reach

the tool - tighten fittings until you can no

longer see ORANGE paint on the inside collar.

Correct

Incorrect

Notice the hoses

have a male and female end attached to them

that fit with mating parts on the squeeze off tool,

so the hoses cannot be connected incorrectly.

4) Open the tool by placing the pump control

valve in the release position. Caution: Ensure

the needle valve is fully open. Pump until the

squeeze bars are sufficiently open to allow the

pipe to be inserted.

OPERATING INSTRUCTIONS:

INSTALLATION ON PIPE

1) Fully install the grounding spike in firm soil near the tool and work area. Moist soil is

required to ensure good contact to ground. Soak the area if necessary where the spike

will be inserted. This is critical as this grounding system should remove any static electric

charge that is created when the flow of gas is cut-off during the squeeze operation,

thereby reducing the chances of sparks being created.

ECN1638A C1600 SQUEEZE OFF TOOL FOR PE PIPE Page 3 of 9

3) Close

the tool with

the pump

until the

bars start to

touch the

pipe.

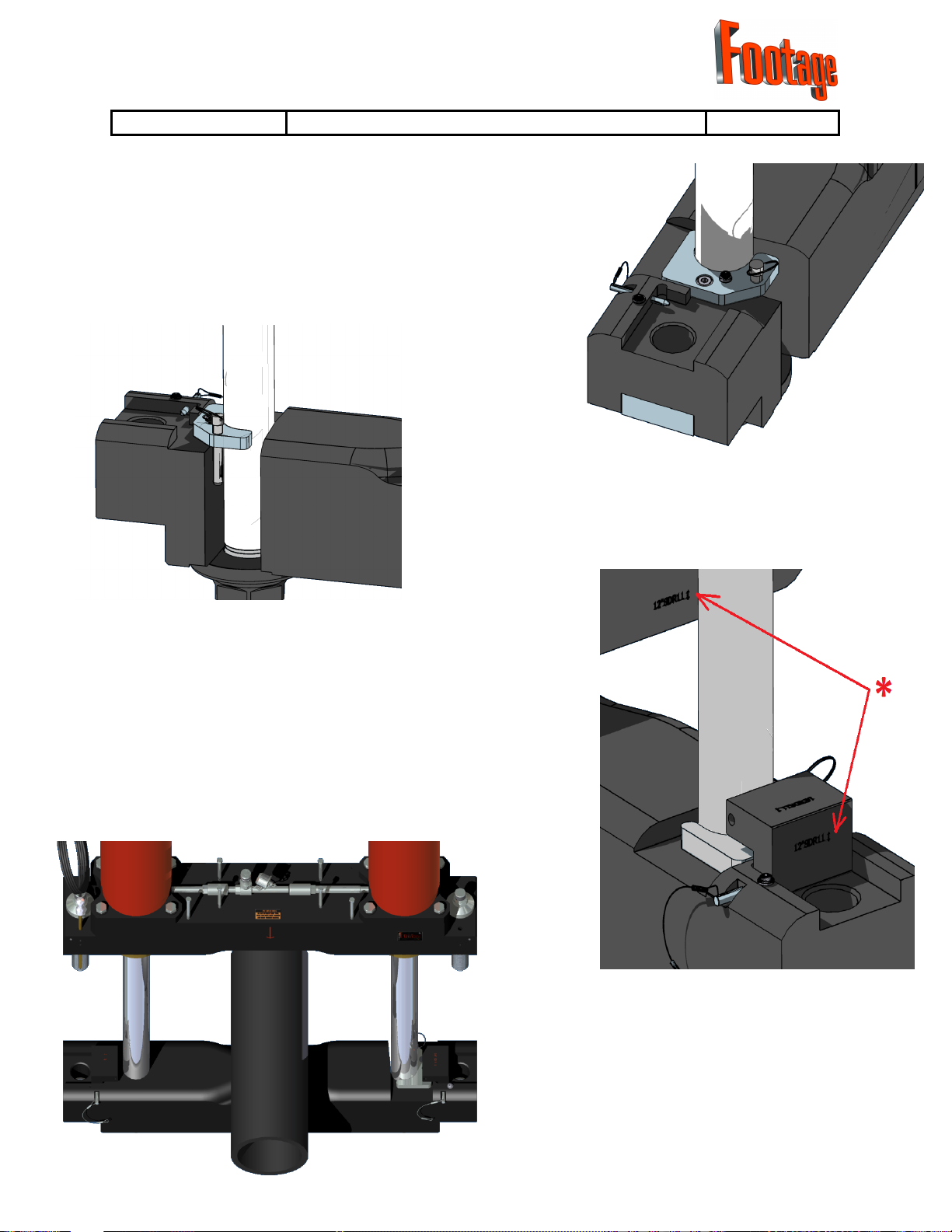

Position the tool centrally on the pipe. The

squeeze bars must be at right angles to the

pipe. The arrow on the top bar indicates the

central position. If this is not done,

satisfactory flow control may not be

achieved.

LOWER BAR IN CLOSED POSITION

LIFT LOCKING PLUNGER

POSITION TOOL CENTRALLY ON PIPE

5) Lift the locking pin and swing the bottom bar out

and place the squeeze off tool over the pipe.

Swing back the bottom bar and lock into position over

the rod nuts on the cylinder rods by inserting back the

locking pin. Full engagement is critical or tool

damage may result. The operator should visually

check to ensure that the pin has engaged in the

slot of the bar so that the locking plate will hold

the lower bar in

the closed

position.

There should not

be any gap between the side shaft and the lower

bar. This is important so that the tool cannot open

accidentally and ensure that there is equal load

on both sides. Failure to comply with this step may

result in tool damage.

SQUEEZING THE PIPE

1) Set the block stops on each side of the unit to the

proper pipe size and SDR setting. (Ensure both

sides are identical or tool damage may result.)

The arrows on the vertical face of stop blocks indicate the

pipe size to be squeezed for that position.

2) Close the needle valve and move the control lever on

the pump to the squeeze position.

BLOCK STOPS

ECN1638A C1600 SQUEEZE OFF TOOL FOR PE PIPE Page 4 of 9

WARNING:

LOCK-DOWN BOLTS

This hydraulic squeeze off tool

ENGAGEMENT OF LOCK-DOWN BOLTS

ECN1638A C1600 SQUEEZE OFF TOOL FOR PE PIPE Page 5 of 9

4) The rate of squeeze is very important in preventing pipe damage. Do not exceed 2"

per minute squeeze rate. The pump does not exceed the prescribed 2” per minute

squeeze rate. Consult your local utility for their specific recommendations regarding the

prescribed squeeze rate.

5) Continue slowly squeezing until the upper bar comes in contact with the block stops.

Slower rates should be used below 32°F (0°C).

Keep in mind it may not be necessary to squeeze the pipe all the way to the gauge

stops to obtain satisfactory flow control.

CAUTION:

6) Because of the size and power of this tool (522,000 Lb force), it is important to

stop squeezing when the gauge plates reach the contact plate (on the upper bar),

otherwise tool damage may result.

features a steel lock down bolt at each end

of the upper bar, to allow the tool to be

locked on a squeeze and the hydraulics

detached or in the event that hydraulic

pressure is lost with a minimum loss of

flow control. To engage, screw the bolts

into the bottom bar. The bolts need only

be tightened by hand, not with a wrench.

They are not intended to assist in

squeezing the pipe. The squeeze off tool

has more than enough power available to

satisfactorily squeeze the pipe. Start threading the bolts into the bottom bars as

the squeeze nears completion (approx. 1" before reaching the stops) to assist with

alignment into the steel nuts in the bottom bar. Thread the bolts as the tool

continues to squeeze the pipe. Once the tool has reached the stops on both sides,

the lock-down bolts should be completely threaded until the hex end is flush with

the top bar.

7) If the hydraulic pressure needs to be released, first cycle the control lever from

squeeze to release position twice and stop it in neutral. Now the hoses and pump can be

disconnected from the tool and removed from working area.

WARNING:

3) Ensure the needle valve is fully closed.Move the pump control valve

handle from "squeeze" to "release". As this is done, the tool will start to open

immediately. Should the operator want to stop the release, return the pump

control valve handle to the squeeze position. The orifice in the needle valve controls the

release rate. As the pipe opens, the pressure in the tool will decrease and the release

rate will slow down. Once the pipe is sufficiently relaxed and the tool does not open any

further, the operator can then fully open the needle valve to raise the bars more rapidly

for a complete release. By opening the needle valve early, a large amount of oil will

enter into the pump and cause it to overflow, which may result in seal damage to

the pump. Having the pump control valve handle to the release position, start to pump.

Continue to open the tool until it can be removed from the pipe. Once the tool is fully

open, do not continue to pump. Continuing to pump will cause hydraulic oil to be

vented from the relief valve to prevent tool damage.

4) To remove the tool from the pipe let the upper bar rest against the pipe. Pull up

the locking pin then rotate the bottom bar clear of the pipe. The tool may now be lifted

clear of the pipe. Be aware that the balance of the tool will shift because of the

change in position of the lower bar.

5) If re-rounding of pipe is not to be performed, the grounding spike may now be

removed and the tool can be repacked into its shipping container, in the open position.

RE-ROUNDING THE PIPE, IF REQUIRED

Once the tool is fully open reposition the tool 90°from the original squeeze on the top of

the peaks of the squeeze. Squeeze the pipe back to its original shape as outlined in

“Installation on Pipe” and “Squeezing the Pipe” detailed above. Consult your local utility

for their specific recommendations regarding this procedure. The grounding spike may

now be removed and the tool can be repacked into its shipping container, in the

closed position.

ECN1638A C1600 SQUEEZE OFF TOOL FOR PE PIPE Page 6 of 9

RELEASING THE PIPE

1) Unscrew the lock-down bolts located at each end of the clamping bars. It will be

necessary to place the pump control valve into the "squeeze" mode and apply more

pressure to the tool to relieve the upward strain on the bolts created by the pipe trying to

bounce back.

2) To avoid any damage to the pipe it is critical that a slow release rate be achieved. A

release rate of 1/2 inche per minute is recommended. This time allows for the PE pipe

to "flow" minimizing the chances of pipe damage. Below 32°F (0°C), the release rate

should be slower. Consult your local utility for their specific recommendations regarding

their prescribed release rate.

SAFETY PRECAUTIONS

WARNING:

Do not exceed the 2" per minute squeeze and the ½" per minute release

rates. Temperatures below 32°F (0°C) require slower squeezes and

releases. Releases are more critical than squeezes; thus slower rates are

required. Consult your local utility regarding their specific recommendations for this

procedure.

WARNING:

WARNING:

Ensure the grounding system is properly planted in moist soil to reduce

chances of sparking.

WARNING:

Keep away from any high-pressure hydraulic leaks. A high-pressure jet of oil

can cause serious injury. Repair immediately.

MAINTENANCE

This section contains maintenance instructions for the tool. Do not attempt any

maintenance which you do not fully understand, nor that you cannot perform accurately

and safely with the tools and equipment available to you. If you encounter a problem that

you do not understand or cannot solve, contact your Footage Tools dealer. (Note that

item 11 is pre-calibrated at the factory for proper operation of the tool and it

should NOT be tightened.)

(Ensure the tool is in good operating order by routinely checking the following:)

whichever is greater from fittings, fusions or previously squeezed pipe.

Inspect the pump fluid level (See Preliminary Assembly) Top up as needed

Inspect the cylinder rods for damage. Replace if needed

Inspect the tool, pump, valves and hoses for oil leakage. Tighten, repair or replace as required

Inspect the squeeze bars for damage. Replace if needed

Inspect the lock-down bolts for damage. Replace if needed

Inspect the Stop Blocks for dirt. Clean as needed.

Inspect cylinder rods for dirt. Clean as needed.

SPECIFICATIONS

GENERAL C1600

Max Pipe Diameter: 16”

Weight: 1300lbs

Operating Pressure (max): 10,000 psig

ACCESSORIES

Grounding Spike Kit 10 foot heavy duty C615HD-B110

Accessory Kit (pump, 20’ hoses, needle valve w 0.009” orifice, C812S-AK1

10,000 psi gauge, air filter/regulator/lubricator)

ECN1638A C1600 SQUEEZE OFF TOOL FOR PE PIPE Page 7 of 9

When performing a squeeze,stay a minimum of 12" or 3 times pipe diameter,

Important Notice

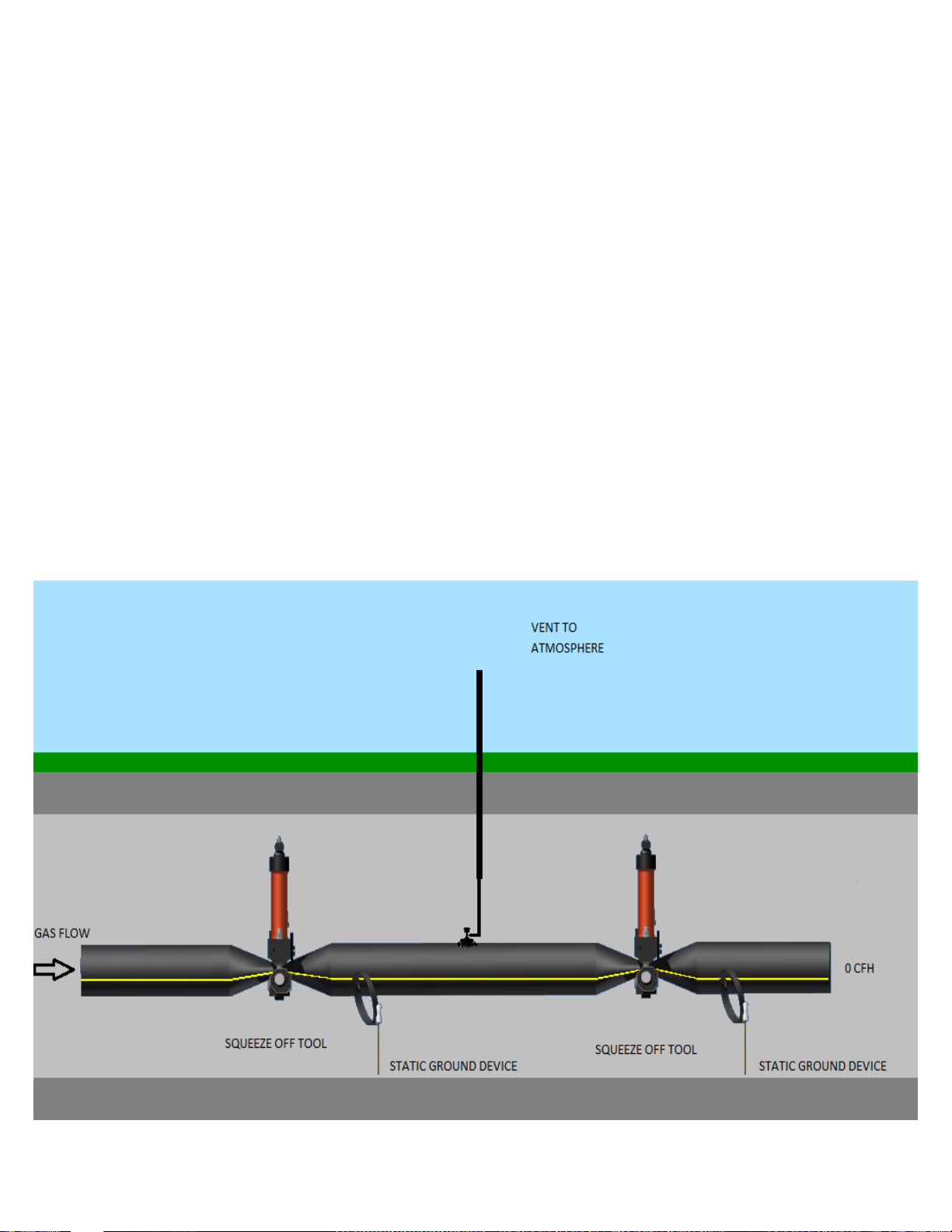

If you experience difficulty obtaining flow control when

squeezing HDPE pipe, we recommend you perform a

double squeeze and vent to atmosphere.

Please consult your local Utility for their specific

operating procedure.

1

1

2

2

3

3

4

4

A A

B B

C C

D D

SHEET 1 OF 2

DRAWN

CHECKED

QA

MFG

APPROVED

User

J. NGUYEN

N. NEAG

4/2/2019

4/3/2019

DWG NO

C1600-A1

TITLE

SIZE

C

SCALE

REV

-

Parts List ITEM

DESCRIPTION

PART NUMBER

QTY 57

PLUNGER, 1/4-20 X 0.56" LG99-155-00-0409256

NIPPLE, 3/8MNPT X 3/8MNPT

99-200-00-0606

155GROUND KIT, 10FT HEAVY DUTYC615-B110154

WASHER, LOCK 1/4"99-140-00-0004

153HHCS, 1/4-20 X 1/2"LG99-100-00-0404

152O-Ring, BUNA # 11699-490-00-0116251

BACK UP RING FOR O'RING #116

C1200-51250WASHER, FLAT, 5/1699-141-00-0005349

LANYARD

C36S-39

148WARNING LABEL - GAUGE STOPSLABEL-028147WEIGHT LABEL - C1600LABEL-027146

HHCS, 3/8-16 X 4.5"LG99-100-00-0636845

RATCHET WRENCH 1/2" DRIVE

C1200-45

144

SHIPPING SKID (NOT SHOWN)

C1600-BASE143

SHIPPING COVER (NOT SHOWN)

C1600-BOX142BHCS, 5/16-18 X 5/8" LG99-104-00-0510341

WARNING LABEL - OWNERS MANUALLABEL-008

140METAL DUST CAP FOR FEMALE CONNECTIOND-31-300C139METAL DUST CAP FOR FEMALE CONNECTIOND-30-300C138PRESSURE RELIEF VALVEC648-50

137FOOTAGE TOOLS INC. DECALLABEL-011

136

1.5 SOCKET (1/2 DRIVE)

C1200-46135HYDRUALIC MANIFOLD, LOW PRESSUREC1200-52134HYDRUALIC MANIFOLD, HIGH PRESSUREC1200-49

133FEMALE, HYDRUALIC CONNECTOR, THREADEDD-30-300

132MALE, HYDRUALIC CONNECTOR, THREADEDD-31-300131

WASHER, 3/4" - BLACK ZINC

C1200-50830HHCS, 3/4-10UNC X 3"LG99-100-00-1224829HYDRUALIC MANIFOLD, LONGC1600-30228HYDRUALIC MANIFOLD,, SHORTC1200-47227

GAUGE STOP, 12"SDR11 & 15.5

C1600-25226FLAT WASHER 1" (2" O.D)99-141-00-0016225

HHCS, 1-8UNC X 4.5" LG

99-100-05-1636224

O'RING, BUNA #437

99-490-90-0437423

SHCS 3/8-16 X 1.5" LG

99-106-00-0624822Pin - Slotted Spring 5/16 X 2" LG99-163-00-2032221HOIST RINGC1600-21

120

SHOULDER BOLT 5/8 X 1.5" LG

99-114-00-0912119

HEAVY DUTY QUICK RELEASE PIN 5/8 X 3

C1600-19118WIPER SEAL 3.0 I.D X 3.5 O.DC1600-18217

PISTON SEAL TPO #437C1600-17216

BACK UP RING FOR O'RING #437

C1600-16415ROD T-SEAL 3.0 I.D X 3.375 O.DC1600-15214THREADED PLATE

C1600-14213

HANDLE

C1600-13

112PISTON ASMC1600-12211CYLINDER CAP, TOPC1600-11210LOCKING PLATEC1600-10

19

GAUGE STOP, 16"SDR11/15.5

C1600-0928

QUICK RELEASE PIN ASM 3/8 X 2.5

C200-1927LOCKDOWN BOLTC1600-0726ROD NUTC1600-0625

CYLINDER CAP, BOTTOMC1600-0524CYLINDER RODC1600-0423CYLINDER BODY (6.5 I.D)C1600-0322

UPPER BAR

C1600-02

11

LOWER BARC1600-01

1

32

33

REMOVE ALL SHARP CORNERS

UNLESS SPECIFIED OTHERWISE

C1600-A1 ASM DWG

16" HYD. SQUEEZE OFF TOOL

(261 Ton Force)

FOOTAGE TOOLS INC.

21

13

26

25

11

3

30

31

5

2

7

1

14

55

22

57

27

46

29

56

35

38

28

29

34

28

6

41

48

47

53 54

GROUNDING

LOCATION

REVISION HISTORY

REV DESCRIPTION ECN DATE BY

-ISSUED FOR PRODUCTION 1998 01AP19 NN

NOTE: ITEMS #9 & 27 ARE FOR REF ONLY.

STOPS TO BE MACHINED AS PER CUSTOMER REQUEST

36

45

40

39

DETAIL B (SEE PAGE 2 OF 2)

SECTION A-A

SCALE .25

DETAIL B

SCALE 0.40 : 1

1

1

2

2

3

3

4

4

A A

B B

C C

D D

SHEET 2 OF 2

DRAWN

CHECKED

QA

MFG

APPROVED

User

J. NGUYEN

N. NEAG

4/2/2019

4/3/2019

DWG NO

C1600-A1

TITLE

SIZE

C

SCALE

REV

-

A

A

46.30

57.25

13.44

5.62

5.66

5.75

8.00

REMOVE ALL SHARP CORNERS

UNLESS SPECIFIED OTHERWISE

C1600-A1 ASM DWG

16" HYD. SQUEEZE OFF TOOL

(261 Ton Force)

FOOTAGE TOOLS INC.

25

26

13

11

16

24

3

12

17

4

24

16

50

42

8

10

9

51 52

28

29

32

40

38

35

47

21

39

33

52

51

29

28

34

18

7

22

2

1

23

6

55

37

36

13 25

26

3

4

46

27

45

15

19

49

Table

PART NUMBER DESCRIPTION QTY ITEM

OPTIONAL GAUGE STOPS

C1600-26 GAUGE STOPS, 12" & 16"SDR 11 258

C1600-27 GAUGE STOPS, 12" & 16"SDR 9 259

C1600-28 GAUGE STOPS, 16"SDR 7 260

C1600-29 GAUGE STOPS, 12"SDR 7 261

56

27.00

58

59

60

61

OPTIONAL

GAUGE STOPS

FOOTAGE TOOLS WARRANTY

FOOTAGE TOOLS INC, hereinafter sometimes referred to as “Manufacturer” warrants

each new PE Pipe Squeeze Off Tool of its own manufacture to be free from defects in material

and workmanship, under normal use and service for the life of the tool after delivery to the end

user. Warranty is void unless warranty registration card is completed in full and returned

to FOOTAGE TOOLS INC within thirty days from the date of purchase. This warranty and

any possible liability of FOOTAGE TOOLS INC hereunder is in lieu of all other warranties,

expressed, implied, or statutory, including, but not limited to, any warranties of merchantability or

fitness for a particular purpose.

The parties agree that the Buyers SOLE AND EXCLUSIVE REMEDY against

Manufacturer, whether in contract or arising out of warranties, representations, instructions, or

defects shall be for the replacement or repair of defective parts as provided herein. In no event

shall Manufacturers liability exceed the purchase price of the product. The Buyer agrees that no

other remedy (including, but not limited to, incidental or consequential loss) shall be available to

him. If, during the warranty period, any product becomes defective by reason of material or

workmanship and Buyer immediately notifies Manufacturer of such defect, Manufacturer shall, at

its option, supply a replacement part or request return of the product to its plant in Toronto,

Canada. No parts shall be returned without prior written authorization and a return goods

authorization number from Manufacturer, and this Warranty does not obligate the Manufacturer

to bear any transportation charges in connection with the repair or replacement of defective

parts. The Manufacturer will not accept any charges for labor and/or parts incidental to the

removal or remounting of parts repaired or replaced under this Warranty.

This Warranty shall not apply to any part or product which shall have been installed or

operated in a manner not recommended by FOOTAGE TOOLS INC, nor to any part or product

which shall have been neglected, or used in any way which, in the manufacturers opinion,

adversely affects its performance; nor negligence of proper maintenance or other negligence,

fire, or other accident: nor if the unit has been altered or repaired outside of a FOOTAGE TOOLS

INC authorized dealership in a manner of which, in the sole judgement of FOOTAGE TOOLS

INC affects its performance, stability or reliability: nor to any product in which parts not

manufactured or approved by FOOTAGE TOOLS INC have been used, nor to normal

maintenance services or replacement of normal service items. Equipment and accessories not of

our manufacture are warranted only to the extent of the original Manufacturers Warranty and

subject to their allowance to us, if found to be defective by them.

The original purchaser, user is responsible for "downtime” expenses and all business

costs and losses resulting from a warrantable failure. FOOTAGE TOOLS INC specifically

disclaims any responsibility for any damages of any kind or description, whether to property or

person, in any way connected with or arising out of the use of FOOTAGE TOOLS INC products.

FOOTAGE TOOLS INC reserves the right to modify, alter, and improve any product or

parts without incurring any obligation to replace any product or parts previously sold with such

modified, altered, or improved product or part.

No person is authorized to give any other Warranty, or to assume any additional

obligation on the Manufacturers behalf unless made in writing, and signed by an officer of the

Manufacturer.

ECN1638A C1600 SQUEEZE OFF TOOL FOR PE PIPE Page 9 of 9

Tool Registration Card

Warranty registration

now available online.

Please visit

www.footagetools.com

and click on

‘warranty registration’.

Model:

S/N:

IMPORTANT NOTICE

IMPORTANT NOTICE

Vaughan, Ontario

54 Audia Crt. Unit #1

Toll Free: 1-888-737-3668

www.footagetools.com

Table of contents

Other FOOTAGE Tools manuals