Forematic F300 Series User manual

F300 series doc. F05v1.2

P1

▪Description 2

▪Preparation

▪Contents 3

▪Rail assembly 3

▪Installation

▪Header bracket 5

▪Door bracket 6

▪Lifting the rail 6

▪Rail brackets 7

▪Electrical 7

▪Programming

▪Initial settings 8

▪Remotes 11

▪Commissioning

▪Trouble shooting 12

▪Accessories 13

▪User notices

▪Manual disconnect 14

▪Safe operation 14

▪Warranty 15

F350 Classic F360 Duro F370 Primo

F390 Agro

doc. F05

iss V1.2

F300 series Installation manual

Specifications

Supply 180-240Vac 50Hz

Speed 12-14cm/sec opening, 8-12cm/s closing

Duty cycle 25% 20 times/hr

Temp’ -20°C to 40°C

Door height 220cm for 3m rails, 280cm for 3.6m rails

F350 F360 F370 F390

Standby power <4.5W <6.5W <6.5W <6.5W

Door max size <8m² <11m² <11m² <16m²

Door max weight <114kg <157kg <157kg <180kg

Motor power 100W 150W 150W 170W

Force 700N 1100N 1100N 1300N

Motor torque 3.2Nm 4.8Nm 4.8Nm 8.0Nm

F300 series doc. F05v1.2

P2

Description

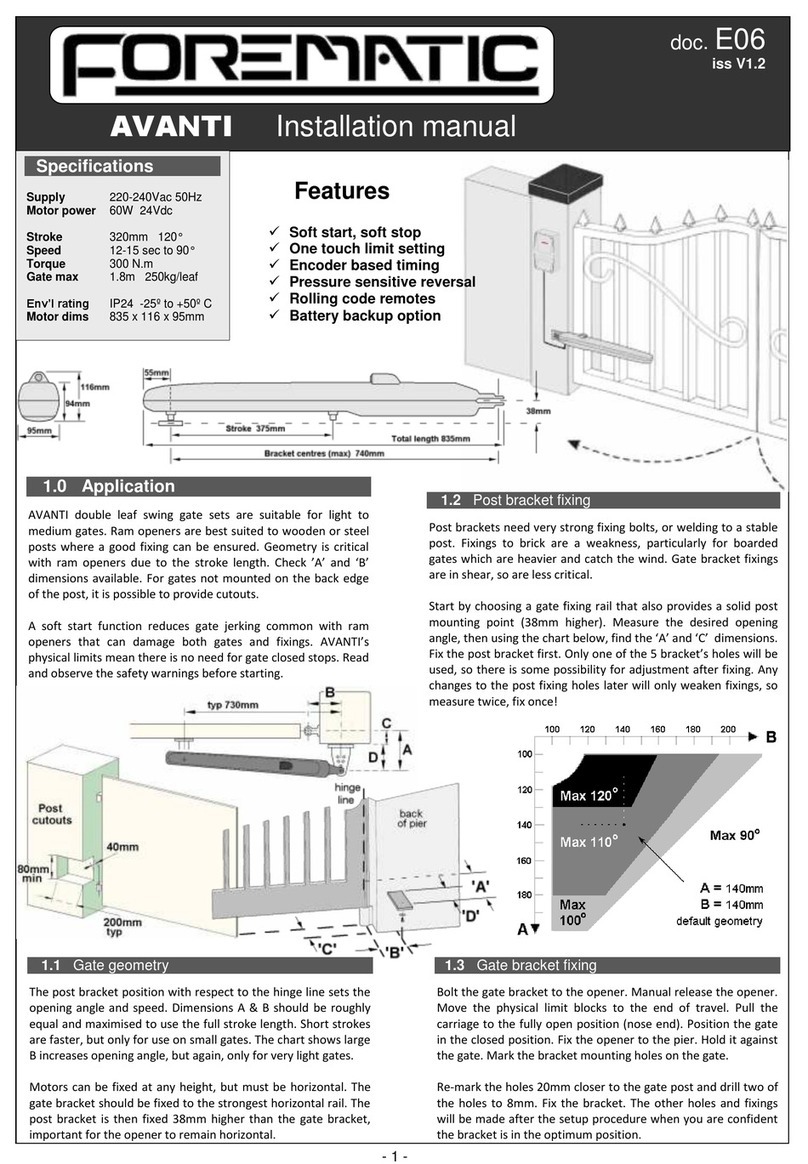

F300 series garage door openers are designed for horizontally

tracked domestic garage doors. Fitting to other door types or in

public areas is at the installer’s discretion.

All openers meet European norms for safety as required by EU

law. Refer to the certificate of conformity in this manual for list of

standards in compliance.

All models use the same 1 part or 2 part belt drive rails at a

standard length of 3m. 2 part rails are delivered with the belt

assembled inside and a connector sleeve to join.

Openers have a 24Vdc motor. An incremental encoder monitors

door position. On commissioning the opener runs a door test to

record minimum forces required. Doors cannot be moved while

the opener is engaged. An override cord on the rail disengages

the motor. Used in exceptional circumstances, e.g. power failure.

Remote controls vary between models. All Foresee remotes,

wireless buttons, wireless keypads are compatible with any

Foresee control panel. The opener can be set to respond to 1 of 4

channels. A home can have 4 automated doors and/or gates. Up

to 15 remotes can be registered to an opener. A safety input is

provided for optional safety photo beams or edges.

Auto-close option is up to 4 minutes. The opener beeps for 20

seconds before closing. You need to be confident a car can

pull in clear of the door every time. We recommend fitting a

photobeam to prevent the door closing until doorway is clear.

User Safety warnings

Automatic doors can be hazardous. It is the responsibility

of the home owner to be aware of the risks and provide,

adequatewarning of hazards. Users should be given instruction on

the safe use of the automatic door. Do not let children or untrained

people use remotes.Donotletunsupervised children near the door.

Thismanualiswrittenforengineersawareof construction criteria for

automatic doors and accident prevention criteria in force in the

automation industry.Only qualifiedpersons may do installation work

on a door that could affect the door’s risk assessment.

Turn off the power before working on the gate. We recommended

signage towarn usersand members of the public of risk of injury to

pedestrians.Donotpermitpublicaccesstothedoorarea. Donot use

remotes when out of sight of the door.

DESCRIPTION

Door condition

Automated doors must be sound, well balanced, and in good

working order. Guide rollers and tracks must be free running

and well maintained. A door should be able to be lifted with one

hand, and stay in the half way position un-supported. The door

frame and ceiling mounting points must be sound to take the

opener’s weight and horizontal forces required to pull the door.

The rail length determines the door height. Max height for a 3m

rail is 2.24m. Longer rails can be specified for up to 2.8m doors.

Openers may be used on canopy doors with a convertor arm,

but at the installers risk.

Doors without an alternative access door may need an external

emergency door release in case of power failure. Remove all

bolts from the door to prevent jamming while automated.

Openers are delivered in sets;

FK351 / FK352 “Classic” - 700N motor, 1 or 2 piece belt drive

FK361 / FK362 “Classic” - 1100N motor, 1 or 2 piece belt drive

FK371 / FK372 “Classic” - 1100N motor, 1 or 2 piece belt drive

FK391 / FK392 “Classic” - 1300N motor, 1 or 2 piece belt drive

F300 series doc. F05v1.2

P3

Contents

The opener carton contains a motor head,

the fixing pack above, two hangers, and a

curved arm. Remotes and accessories

depend on the set so check the carton label.

Assembling a 2 piece rail

A two piece rail pack may be ordered. to be assembled on site. Rails can be made up to

3m or 3.6m lengths. Follow the instructions below. One piece rails need no assembly.

2

Take out any cardboard packing. Snip any

packing ties that hold the chain.

Turn over the centre rail section and

turn up the four locking tabs.

Lay it down and align the rail sections

letting the chain lay flat inside the rail.

4

Slide the locking sleeves across the rail

ends. This is not easy. It best done on a

flat surface. If continues to resist, check

the ends of the rails for damage.

5

PREPARATION

Clear an area 3m long. Lay down some

cloth or carboard to keep the chain clean.

Cut off all the packaging.

1

There are two sections. The chain is

laid out through the sections. Stretch

the sections out in a line to take out

any tangles in the chain

3

F300 series doc. F05v1.2

P4

The roof hangers may also be fitted

to the rail and motor head if you

know the roof joist positions. Apply

a finger of grease to the chain.

Turn the rail over (chain down) and fit the

rail over the motor shaft and olive. It will

need a bit of patience to align it. Fit two

saddle clamps with the four self tappers.

11

10

9

Place the motor head in its

polystyrene box for protection while

assembling.

Find the olive in the accessories bag.

Fit it to the motor shaft first.

Check that the chain engages properly with

both cog wheels. The chain should be long

enough. Slacken off the spring if necessary

6

8

When the sections are joined

together, turn the rail over, then turn

up all the remaining locking tabs.

Be careful not to let the chain fall out

when it is upside down.

Tighten the chain checking for tension.

The chain should move sideways, but

not touch the top or bottom of the rail

7

PREPARATION

F300 series doc. F05v1.2

P5

The header bracket is fixed to the door frame in the centre

of the opening. It must be set high enough for the door

not to interfere with the rail throughout the door’s travel.

Bracket height depends on the door thickness and door

roller design. Open the door to see the highest point the

door edge reaches.

Mark hole centres,

then mount the

bracket with four

suitable fixings.

The header bracket’s lower slotted mounting holes must

be at least 10mm above the highest point the door

reaches. The slotted holes can be set 200mm higher if you

prefer, but over 50mm from the ceiling.

Header bracket

INSTALLATION

F300 series doc. F05v1.2

P6

You will need a step ladder. Lean

the opener against the door

frame with the motor resting on

poly-styrene packaging for

protection.

Fix the rail end to the header

bracket with the long bolt. Insert

the bolt thru the bracket’s square

hole first. Fix the roof hangers to

the opener head.

Lift the head onto the steps until the

rail is horizontal. Ensure the

opener’s rail is parallel with the

door guides.

Run the door up & down. Check it

clears the opener. Bend the two

roof hangers ready to fix to the

ceiling.

Lifting the rail

Fit the ‘J’ bar to the door

bracket with the cotter pin.

Insert the split pin. Open

one leg to secure it.

Height is not critical,

but should be within

150mm of the top of

the door.

The full force of the opener will be pulling on this

bracket. Bolting through the door is best, with the nuts

on the inside. Coach bolts have plain heads that cannot

be tampered with from outside.

Find the 8mm cotter pin, its

split pin, and the ‘J’ bar.

The door bracket fixes to the centre of the

door below the header bracket. It

required a strong fixing, so choose a

structural member of the door.

Door bracket

INSTALLATION

F300 series doc. F05v1.2

P7

Run the door up and down to

make sure it clears the rail and

brackets. Then connect the ‘J’

bracket to the rail carriage.

Lift the opener to the horizontal. Measure the

height Hfrom the top of the rail to some

useful fixing points, such as a roof joist. Bend

up two ‘U’ brackets from the perforated strip

supplied.

Open the garage door and align the motor

head laterally. Mark the ceiling. Lower the

opener, then fix the bracket to your ceiling

marks. Fix the third saddle clamp to the rail

near to the motor head, then bolt it to the

hanging ‘U’ bracket, or a piece of angle.

Fix the second ‘U’ bracket half way along the

rail. This time you must use the two plastic rail

clamps because the J bracket passes this

point

Rail brackets

U bracket made from

roof hanger strip

Third saddle clamp

holding the rail near

the motor head

Check the rail is perfectly

level and secure. Brackets

may need slight bending.

The chain may scrape

inside the rail if it is not

true.

Two plastic rail

clamps holding the

rail at a mid

position.

H

Electrical

The opener is pre-wired

with a UK plug. On power

up, the courtesy light will

come on and the motor will

beep. The display will then

show a circulating pattern

of LEDs.

INSTALLATION

F300 series doc. F05v1.2

P8

PROGRAMMING

Programmed via the 4 buttons “S”, “P”, “+”

and “-“. Key “S” stores remotes. Key “P” is an

enter button. The display shows the

programme step number. The “+” and “-“keys

are used to set the parameter. On power up the

lamp comes on, there’s a beep, then display

shows a circulating pattern.

A flashing display means the parameter is waiting to be

set, or the motor is still running. Programming must be

finalised in correctly, or settings will not be saved.

Use + and –to select

step “1” then press “P”.

The “1” begins to flash.

Use + and –buttons to set the

door open position. The door

closes with the –button and

opens with the + button

Press “P” to save

the open setting.

Step 1 –set open position

The first step sets the door open

position. Take care, it is the first

time a motor has lifted the door.

The open position is not critical.

It is not necessary to set the door

to the very furthest position.

Programming teaches the opener about a

door. The opener will not function until the

first three programming steps are complete.

The next five steps have default settings that

are typical of most installations. Remotes are

supplied pre-programmed to the opener.

To start, press

and hold “P”

for 5 seconds.

The display

shows step 1.

Use + and –to select

step “2” then press “P”.

The “2” begins to flash.

Do not to set the door closed position

too tight or the door frame will be

seen as an obstacle. Set closed point

10mm before the door touches the

frame.

You can switch between the open and

close settings but press “P” each time.

Step 2 –set close position

Use + and –to set the door

closed position. The door

closes with the –button and

opens with the + button

Press “P” to save

the close setting.

1. Set open position

2. Set closed position

3. Force learning

4. Opening speed Default = 1 (fast)

5. Alarm setting Default = OFF

6. Auto-closing Default = OFF

7. Service alarm Default = OFF

8. Condominium Default = OFF

A

F300 series doc. F05v1.2

P9

The opener runs a cycle measuring the

force required at each stage. Close the

door. Use + –keys to select step 3.

Press “P” to start the test. The 3 flashes

as the door opens. When it has stopped,

press “P” to save the force settings.

Press “P” to run a closing test. When

the door is closed fully, press “P” to

save.

Step 3 –force learning

PROGRAMMING

If a door stays open for 10 mins the alarm

sounds. The options are ‘0’for disabled,

“1”to enable. Default is off.

Select step “5”then press “P”

Press “+” (beeps once). or “-“(beeps

twice) to choose, then ….

Press “P” to save the new setting

Step 5 –alarm setting

The options are ‘0’for fast opening, or

‘1’for same opening speed as closing

speed. Default setting is fast opening.

Select step “4”the press “P”

Press “+” (beeps once). or “-“(beeps

twice) to choose, then ….

Press “P” to save the new setting

Step 4 –opening speed

Sets a service alarm to sound after 2000

cycles. The default setting “0”is off.

Select step “7”then press “P”

Select step “7” then press “P”

Press “+” (beeps once). or “-“(beeps twice)

to choose, then ….

Press “P” to save the new setting

Step 7 –service alarm

Step 6 –auto close time

The opener can be programmed to

close after a time delay. 0 is disabled.

0 = disabled 1 = 30 s 2 = 60 s

3 = 90 s 4 = 120 s 5 = 150 s

6 = 180 s 7 = 210 s 8 = 240 s

Select step “7”then press “P”

Displays shows auto-close setting 0-9.

Press “+” (beeps once). or “-“(beeps

twice) to choose, then ….

Press “P” to save the new setting

This mode remotes have no effect

during opening. Remotes can only

close the door when fully open.

Select step “8”the press “P”

Press “+” (beeps once). or “-“(beeps

twice) to choose, then ….

Press “P” to save the new setting

Step 8 –condominium

F300 series doc. F05v1.2

P10

For two garage doors, set left door to

channel 2, set right to channel 1.

Whichever channel is pressed, both

courtesy lights will light.

The se

Channel setting

USER SETTINGS

Add remotes Delete remotes

Remotes supplied with openers are

already set in memory. Openers can store

up to 15 remotes. To add a new remote,

press “S” for 1 sec. The point LED will

light.

Choose the button you wish to

open the door. Press that button

twice to add it. Add more remotes

while the point is still on.

Remotes cannot be deleted individually.

The whole memory must be cleared, then

re-enter good remotes.

Press ‘S’ for 8 secs. The ‘0’will

appear on the left. Holding ‘S’

for 5 secs more until the 0

disappears. Memory is clear.

Programming must be finalised

correctly to save the changes you

have made. You can finalise any

time after completing step 3.

Optional, return to step “1”.

Hold down “P” key for 5 secs,

or until display shows “0”.

The opener is now ready to use.

Finalise programming

Re-calibrate force

With the door open, press ‘S’twice. The display

flashes ‘3’showing step 3. Press ‘-‘to begin the

force learning cycle. The door will close, pause,

then re-open. It leave step 3 automatically.

PRESS

TWICE

Do not use the remote during the sequence.

Cycle counter viewing

Press both ‘P’and ‘S’at the same

time. A single digit will show.

1 = 1000 2 = 3000 3 = 6000

4 = 9000 5 = 12000 6 = 15000

7 = 18000 8 = 21000 9 = 24000

After 5 secs the display will return

to normal.

F300 series doc. F05v1.2

P11

The trouble shooting table is a summary of the most common issues encountered.

Troubleshooting

DISPLAY CODES

LLimit reached (this is normal)

Fmotion interrupted (force exceeded)

His an encoder failure

Aindicates a safety input is open

ON POWER UP check that

•The courtesy light comes on

•The motor beeps once

•Display shows the circular pattern

If any of these fail, check all the fuses.

FIRST CHECK

Check the power is on and the disconnect

is engaged. Try another remote. Check the

rail is correctly tensioned and that the door

is properly balanced and free running.

1

Remote will not programme in.

Is remote LED on? Is it the right remote type? Is

the memory full? Is the program light on?

Theremotemightbefaulty.Openerproblem likely.

Did you complete the “finalise programming” step?

2

Scraping noise from the rail.

Chain or belt is rubbing or jamming.

The motor can be heard straining.

Rail not flat along its length, or chain too slack. Is

the chain worn or broken? Check the chain is

wrapped around the middle of the end cog wheel.

Adjustrailcentresupport.Re-tensionchain or belt.

Remove the motor head. Re-seat the chain on its

pulley. Check the offset ring is fitted properly.

3

Courtesy light comes on but door doesn’t

move.

If you can hear the motor running, perhaps the

release cord has been pulled. Is the chain in the

middle of the cog at the motor end.

You may be pressing the wrong button.

The disconnect is not engaged.

The chain is broken.

4

The door opens as soon as the power is

turned on.

Has the client lost a remote? Could it be under a

book or object resting on the button?

If there is a an exit button, disconnect it. Is the

FR11’s LED on all the time?

5

Thedoordoesnotopen afteranycommand

Checkpower toopener.Door bolts not released?

Dooris blocked from outside? Check the remote.

Checkthe supplysocketwithalamporpower tool.

Clearany obstructions.Use anotherremote. Motor

shouldbeepeachtime itgetsaremote command.

6

The door almost fully closes, then

immediately opens again

Check the floor beneath the door is clear. Try

helping the door down from inside the garage.

Opener interprets the door frame as an obstacle.

Run through the close limit programming again.

7

The door gets half way down, then stops

and re-opens.

Pull the release cord. Run the door manually. Is it

well balanced? Check the door springs & cables.

Inspect the door rollers. They must not be loose.

Balance the door properly, then run through the

programminglimitsand force mapping. Doors will

skew if the springs are uneven orrollers are loose.

8

An ‘L’ appears on the display

This is normal. The door has reached its limit.

9

Themotorrunsand thechainorbeltmoves,

but the door doesn’t move.

Try moving thedoormanually.If itis jammed, then

clear the jam first. See fault reference 7.

If the doormoves,the releasehasnotre-engaged.

The door running gear mayneedagood servicing.

10

The door does not stop where it is set.

Check fault reference 6.

Re-do limit programming. Make sure you follow

‘finalise programming’ or settings won’t be saved.

11

Poor remote range.

Check remote batteries. Try remote. Check the

antenna cable end is not touching metal

Metal doors and foil backed plasterboard reduce

range. You may need to extend the antenna.

Symptom Points to check Remedies to try

COMMISSIONING

F300 series doc. F05v1.2

P12

COMMISSIONING

The FA31 optional photo beam prevents

the door closing if the beam is blocked

by a car or any other object. If an object

moves into the beam while the door is

closing, it will stop and re-open. Used

when the automatic closing is enabled.

Mount 250mm above floor level. Door

parts must cross the beam in normal

travel. Photobeam function must now be

enabled in Step 4 of the programming.

Photo beam fitting

Run a cable to each side

of the door frame. Keep

the cable clear of moving

door gear. Any damage

will stop the door closing.

The PCB includes a 15 code radio receiver,

24V battery charger, output for an external

24V lamp, and lock interface. Programming

is all external, with 4 buttons, display, and

an internal alarm beeper for feedback.

There are no user serviceable parts inside.

FR11 wireless button and FA62 wireless

keypad require only external programming.

PCBs have terminal blocks to wire in access

controls and sensors. Safety inputs shown

with yellow wires are for N/C contacts.

IR1 Photobeam for re-open

IR2Photobeam for re-close

WICKET DOOR Stop in either direction

We support standard wiring colours shown

on the diagram.

GREEN Button or access control inp’

BLUE Common for power & inputs

YELLOW Safety beam or edge input

RED +24Vdc aux power

PCB & accessories

F300 series doc. F05v1.2

P13

Declaration of Conformity

We hereby declare, that Remote Controlled Garage Door Openers F-350, F-380, f-390 240V have been

manufactured in accordance with the following standards or normative documents ;

EN 60335-1 :2012/A15: 2021 EN 60335-2-95: 2015/A2: 2019 EN 62471: 2008

EN 62223: 2008 EN 13241: 2003/A2: 2016 EN 12635: 2002/A1: 2008

EN 12453: 2017/A1 2021 EN 300 220-1 V3.1.1: 2017 EN 300 220-2 V3.1.1: 2017

EN 62479: 2010 EN IEC 55014-1: 2021 EN IEC 55014-2: 2021

EN 55015: 2019 EN 55015: 2019/A11 2020 EN 61547: 2009

EN 61000-3-2: 2019/A1: 2021 EN 61000-3-3: 2013/A1: 2019 EN 301 489-1 V2.2.3: 2019

EN 301 489-3 V2.1.1: 2019 EN ISO 12100:2010 AfPS GS 2019: 01 PAK

In accordance with the essential requirements of the following directives when used as intended according to the

manufacturer’s instructions

2006/42/EG The machinery Directive with amending directives

2011/65/EU RoHS directive

2014/53/EU RED Directive

13.03.2021–FOREMATIC

9 Vanalloys Estate, Stoke Row, Mr H WYNN JONES

Henley RG9 5QW, United Kingdom Director

Maintenance & repair

An opener fitted and maintained to these

instructions will give long reliable

service. The door’s running gear must be

kept in good working order. We

recommend the door is operated

manually at least once per month to

check for wear. Openers will hide

problems developing within the door

tracks and springs. Faults not attended to

early may develop.

Damage resulting from low maintenance

is not covered by the warranty. Spares

are available from your dealer. Only

competent persons should be allowed to

fit spare parts.

Repeat program steps 1 to 3 if a motor

part is replaced. Re-programming all

steps if the PCB is replaced.

Garage doors & openers can be dangerous. These safety

warnings are to protect users of automated doors. Cut

this label out and stick it to the door, or download a copy.

Safe operation

Warning –AUTOMATIC DOOR

•Do not let children operate or play with remotes.

•Never go under the door when partially open.

•Operate the door only when in eye contact.

•Keep the door regularly maintained.

•Make sure there are no people or objects

in the path of the moving door.

Only authorised and responsible

persons should be allowed to

use the door controls.

Manual operation

A disconnect pull cord is fitted to the rail

to allow the door to open in the unlikely

event of a power failure. Pull once, then

lift the door manually.

The door will re-

engage the drive

automatically on the

next cycle.

A door mounted

release is available for

releasing the door from

outside.

USER NOTICES

F300 series doc. F05v1.2

P14

Forematic

9 Vanalloys Estate

Stoke Row

Henley RG9 5QW www.forematic.com QPF05v2

Period

The purchaser is granted a warranty covering the safe and reliable

function of the Foresee Garage Door Operator (Mechanics, Motor and

Motor Control Systems) for a period of 3 years from the date of purchase.

The warranty period for replacement parts is 6 months or to the end of the

current warranty period, which ever is longer.

Requirements

Warranty claims are only applicable in the country where the Operator

was purchased. The product must have been purchased through our

authorised distribution channels. The warranty only covers damage to the

contract object. The fully completed warranty card together with the

receipt of purchase correspondingly dated substantiates your right to

claim under the warranty.

Performance

During the warranty period we undertake to rectify any and all defects to

the Foresee product which can be proved to be attributed to a material or

manufacturing fault. We will, at our discretion, either exchange a

defective product for a fault free product, repair it or make a refund. We

do not accept costs for dismantling and installation , or for carriage. Parts

replaced under warranty are the property of the warrantor.

Warranty exceptions

The warranty does not cover damage caused through:

•Wear & Tear

•Improper Installation

•Negligent Care and/or Maintenance

•Improper Initial and/or Subsequent Use

•Negligent or Wanton Destruction

•External substances such as water, salt, alkaline or acid

solution

•Abnormal Environmental Influences

•Mechanical damage through improper Transport and/or

Installation

•Additional Priming or other Surface Protection treatments

•Repair by Non-qualified or Incompetent Persons

•Using non-Foresee parts without the Approval of the

Manufacturer

•Removal of product Identification, or otherwise making it

unidentifiable

A separate 2 Year warranty is granted on Radio Equipment, accessories

and system controls. There is no warranty on Consumables (eg fuses,

batteries, bulbs)

Warranty

USER NOTICES

This manual suits for next models

4

Table of contents

Other Forematic Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

Chamberlain

Chamberlain PowerLIft CS110MYQ Installation and operating instructions

Chamberlain

Chamberlain 1280R 1/2 HP owner's manual

Chamberlain

Chamberlain 8557W user guide

SAMT

SAMT RGD350 Installation instructions and user guide

Chamberlain

Chamberlain POWER DRIVE PD420 owner's manual

Automatismos Pujol

Automatismos Pujol Marathon Pro III manual

Chamberlain

Chamberlain Whisper Drive Security+ 182671D owner's manual

Schellenberg

Schellenberg 60990 manual

D-force

D-force DF800N Owner's instructions

Craftsman

Craftsman 41A638-1 instructions

Wayne-Dalton

Wayne-Dalton Optimal Installation, user operation & maintenance manual

DITEC

DITEC ION4 Technical manual