Forever Green Indoors FGI Uniformity Pro User manual

1

Product Manual & Install Guide

FGI Uniformity Pro

The FGI Uniformity Pro is an indoor LED grow light fixture scientifically designed to replicate the light

of the sun with appropriate PAR (photosynthetically active radiation) levels for plant growth of all phases.

Brought to you by Forever Green Indoors, home of FGI brand LED grow lights

Forever Green Indoors 1314 S. Grand Blvd, Suite 2-127, Spokane, WA 99202

1-800-630-7345

FGI is a registered trademark of Forever Green Indoors

2

SAFETY PRECAUTIONS AND OPERATION

Before using your new FGI Grow Light, please read this manual thoroughly to ensure that you know how

to operate the features and functions that your new lamp offers safely and efficiently.

This light is not intended for use by persons (including children) with reduced physical, sensory, or

mental capabilities, or those who lack experience and knowledge, unless they have been given

supervision or instruction concerning the use of the lamp by a person responsible for their safety.

If you have any question, contact us at 1-800-630-7345 or find help and information online at

www.forevergreenindoors.com

Do not install light in a wet location or place where it may come in direct contact with running

water.

Deteriorated insulation on electrical parts may cause an electric shock or fire.

Do not place this light in direct heat from room heaters.

Do not plug several lights into the same multiple power strip. The light should always be plugged

into its own individual electrical outlet which has a voltage rating that matches the voltage listed

on the electrical rating. This provides the best performance and also prevents overloading of house

wiring circuits, which could cause a fire hazard from overheated wires.

Do not use a power cord that has cracks or abrasion damage along its length or at either end.

Do not bend the power cord excessively or place heavy objects on it.

Do not twist or tie the power cord.

Never unplug your light by pulling on the power cord.

The light must be safely grounded. Always make sure that you have grounded the light before

attempting to investigate or repair any part of the unit.

Power leakages can cause severe electric shock.

Never use gas pipes, telephone lines, or other potential lightning attractors as an electrical ground.

Improper use of the grounding plug can result in a risk of electric shock.

If it is necessary to use an extension cord, use only a 3-wire extension cord that has a 3-blade

grounding plug and

The marked rating of the extension cord should beAC 115-120 V, 10 A, or more.

If a grounding adapter is used, make sure the receptacle box is fully grounded.

Plug the power plug into the wall socket firmly. Do not use a damaged power plug, damaged power

cord, or loose wall socket. This may result in an electric shock or fire.

You need to remove all the protective plastic film before you initially plug the product in.

Do not spray the light with chemicals. Clean the light with a damp cloth using water only.

Before cleaning or performing maintenance, unplug the light from the wall socket, or turn off at

the breaker.

GENERAL CARE

The FGI Uniformity Pro product line is a passively cooled LED grow light. There are no moving parts.

3

They are sealed and designed for damp and wet environments and for maintenance-free performance.

Some basic care will keep your system operating at peak performance during the life of your FGI lamp.

In order for the system to properly cool itself, at least two inches of space is required between the power

supply/driver housing and the roof of your grow area. Failure to do so may shorten the fixture’s lifespan.

To achieve the optimal lifespan and performance of your fixtures, routinely check for and remove excess

dust, debris, and mineral build up from the glass diode surface and frame. Cleaning should always be

done with the fixture unplugged from its power source using a damp cloth. Use of compressed air can

help remove dust and plant material from the product housing.

BEST PRACTICES WITH LED FOR GROWING

Growing crops under artificial lighting requires experimentation based on the grow environment. FGI

LED lights are ideally suited to provide a full sunlike spectrum to aid in plant cultivation

Regularly check your plants growth and adjust for health as required.

Early in the plants growth phase, such as seedlings or nursery clones, light intensity should be low. Not

more than 100 umols/ms of PAR.

As the plants establish roots additional PAR can be applied. We recommend between 250-550 umols/ms

of energy during vegetative phases.

As the plants mature to a reproductive or flower stage light intensity can be increased to between 650-

1200 umols/ms. FGI grow lights deliver high levels of PAR, typically more than experienced in nature

when considering a full day of sunlight which waxes and wanes as the day progresses.

Adjustments to H2O, CO2, RH, nutrients, and temperature are typically required. These variables differ

based on grow medium and style.

Mount the fixture at least 12” from the top of your canopy to ensure optimal uniformity and consistent

PPFD.

Many plants prefer higher temperatures when exposed to high PPFD. Experiment with higher

temperatures to achieve higher yields. Canopy temperature and room ambient temperature often vary. For

accurate results, test at the canopy level to gauge leaf surface temperature.

We also recommend that growers keep a high quality PAR meter on hand designed for full spectrum LED

measurements.

ASSEMBLY INSTRUCTIONS

Unpacking the unit:

4

Your FGI Uniformity Pro ships partially constructed and folded (A) to reduce the expense of shipping

and protect the components in the light.

Illustration A

Take care when unpacking and handling the light fixture. Unpack gently and avoid pinching your fingers

when you fold the unit open.

Ensure the LED arrays do not come in contact with sharp objects or force that may damage the diodes.

The Uniformity Pro is ruggedly built but it can be damaged with rough handling.

Unbox and unfold module (B) and place on flush on a floor or a clear open table surface, cardboard or

plastic is recommended to be placed between the units lens and the surface you are working on to avoid

scratching the lens.

Illustration B

DO NOT POWER UP THE LIGHT UNTIL IT IS FULLY ASSEMBLED AND HUNG OVER THE

GROW AREA.

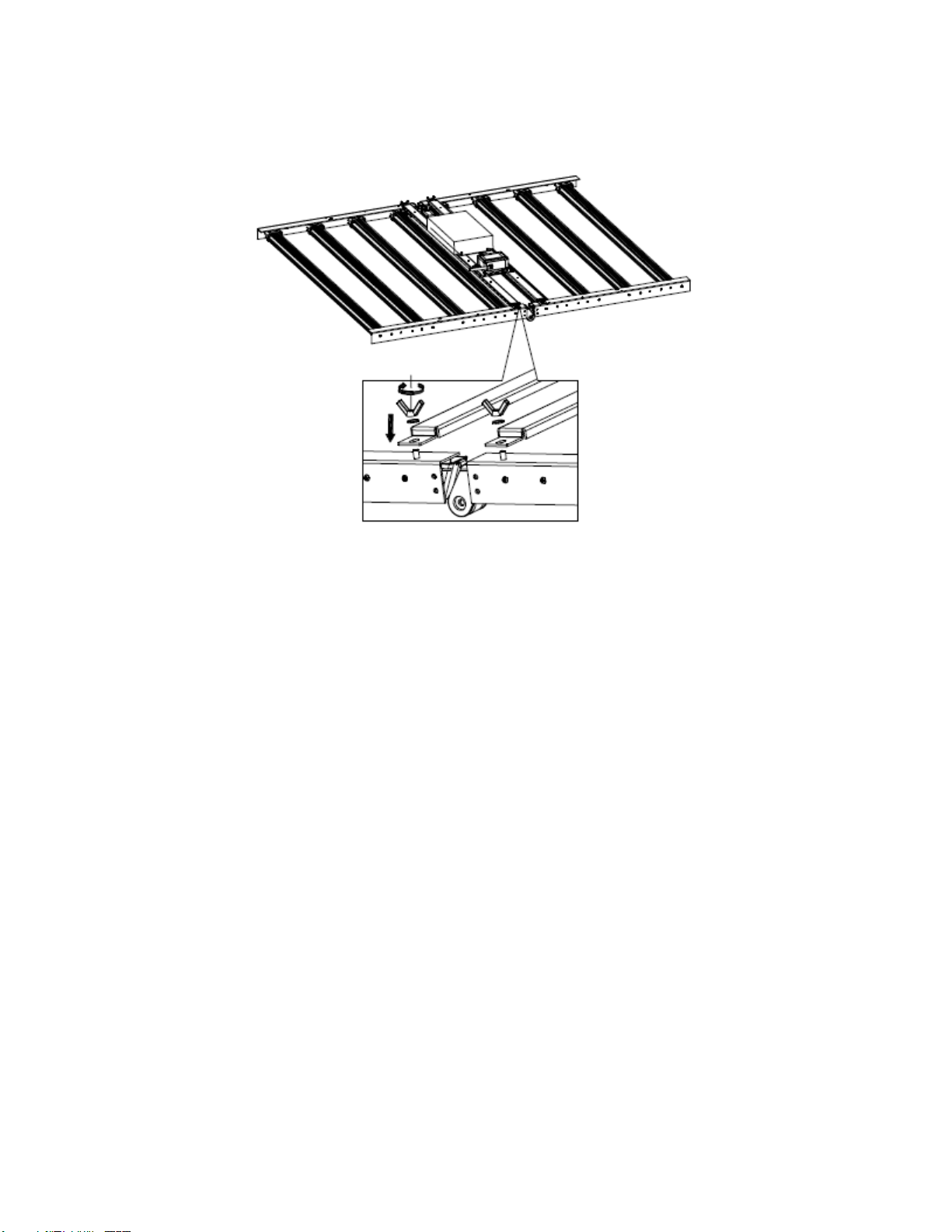

Mounting the Power Supply:

5

Mount the power supply by attaching the four wing nuts and washers to the screws protruding on the light

frame (C). Tighten securely but do not over tighten the nuts.

Illustration C

Place power supply enclosure on top of brackets, aligning the bracket mounts with the receivers. The snap

connector wiring connections are universal however they are slightly different lengths. Ensure the power

supply is aligned with the snap connector that easily connects to both ends without pulling or stretching

the cables.

Table of contents

Other Forever Green Indoors Lighting Equipment manuals