TABLE OF CONTENTS

i

Table of Contents

TABLE OF CONTENTS ..............................................................................................................................I

SECTION 1 – GETTING ACQUAINTED ................................................................................................ 1

SAFETY PRECAUTIONS......................................................................................................................... 1

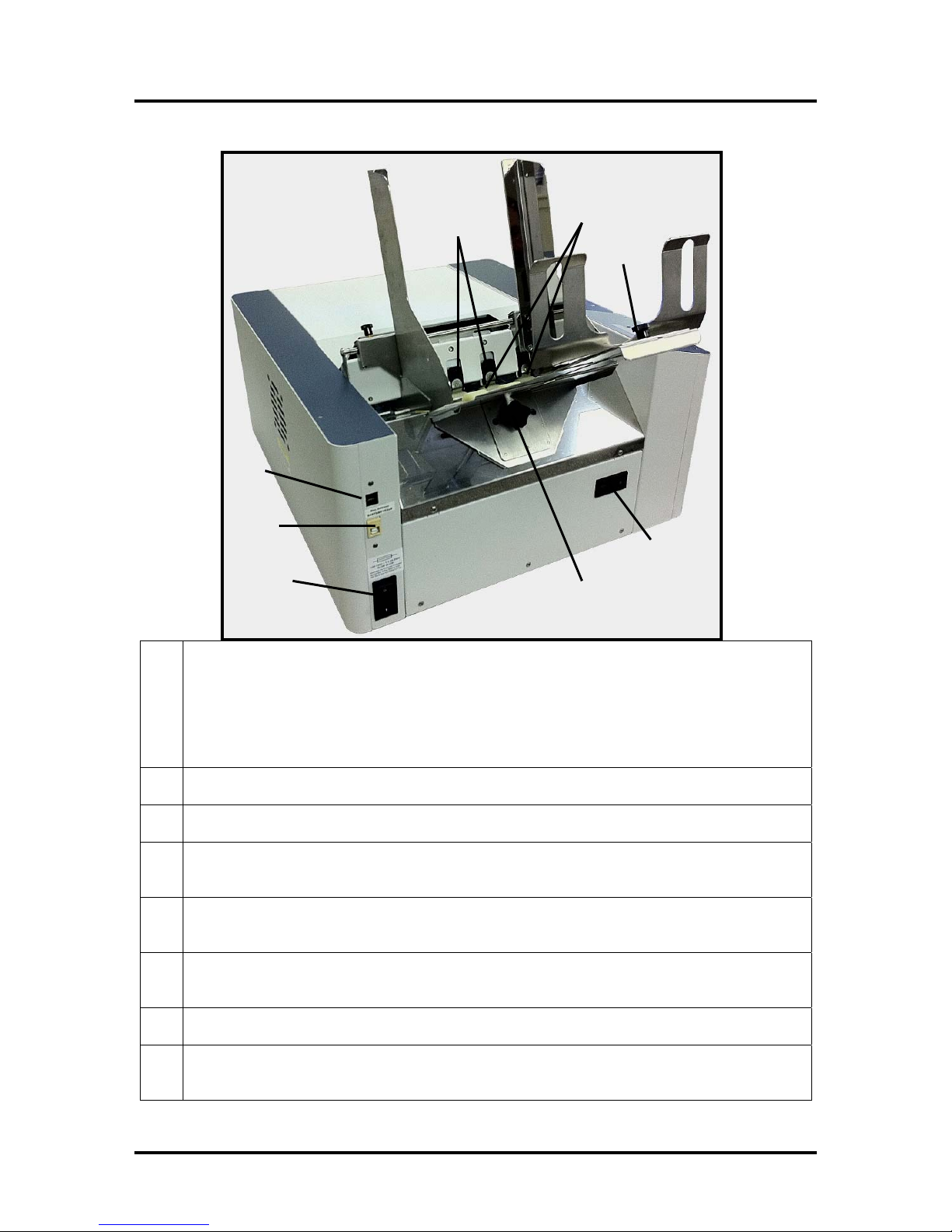

FRONT VIEW ............................................................................................................................................... 2

REAR VIEW ................................................................................................................................................. 3

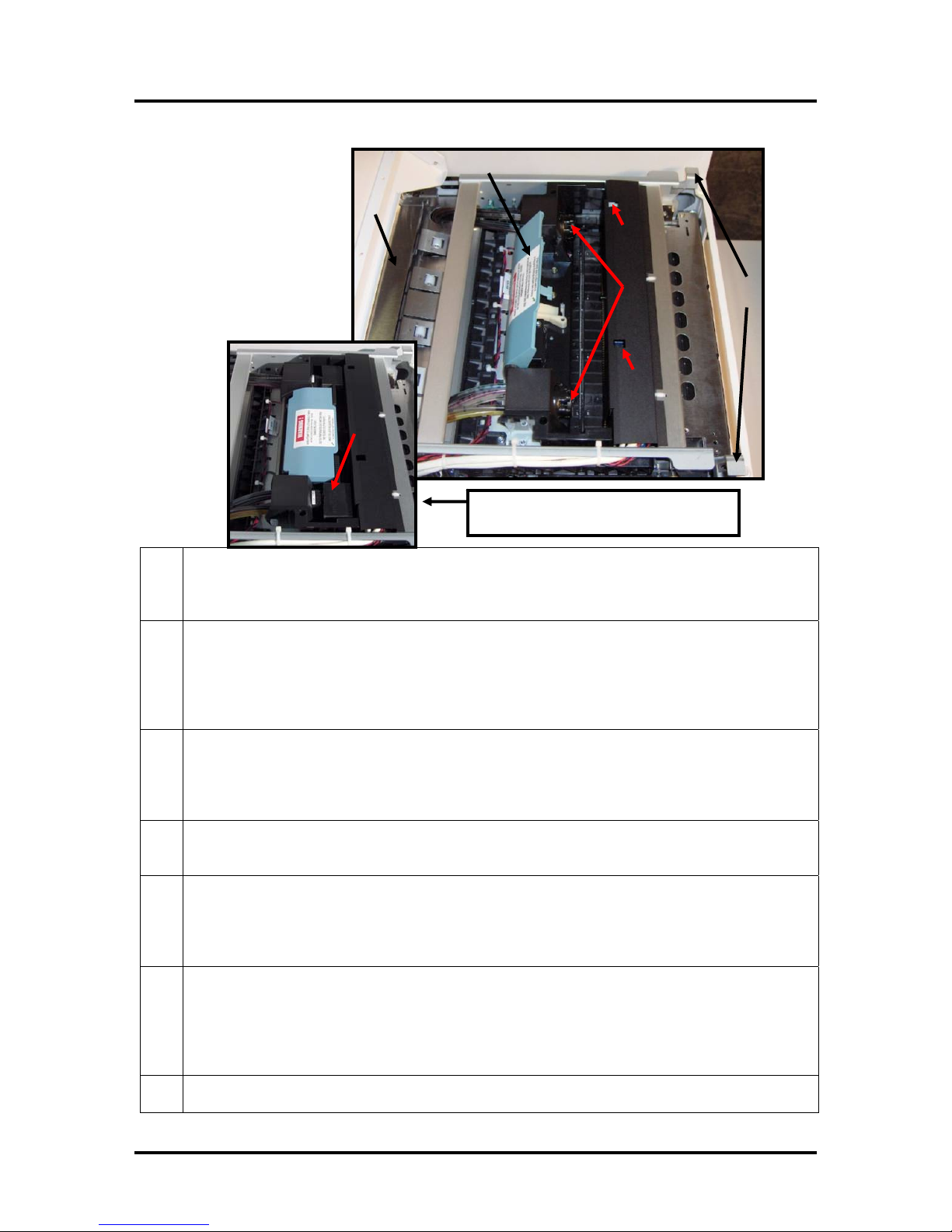

PRINT ENGINE AREA ................................................................................................................................... 4

BEHIND THE INK TANK DOOR ..................................................................................................................... 5

SECTION 2 – INSTALLING THE PRINTER.......................................................................................... 6

TRANSPORT INSPECTION ............................................................................................................................. 6

TOOLS NEEDED ........................................................................................................................................... 6

CHOOSING THE LOCATION .......................................................................................................................... 6

Work-Table Surface Must be Level......................................................................................................... 6

UNPACKING................................................................................................................................................. 7

Accessory Box Contents.......................................................................................................................... 8

INSTALLING MEDIA GUIDES........................................................................................................................ 9

CONNECTING THE PRINTER ....................................................................................................................... 11

Connecting Power ................................................................................................................................11

Connecting to the Computer................................................................................................................. 11

Minimum Computer System Requirements........................................................................................... 11

INSTALLING THE SERVICE STATION .......................................................................................................... 12

INSTALLING THE PRINTER SOFTWARE ....................................................................................................... 16

INSTALL THE INK TANKS........................................................................................................................... 19

Ink Tank Anatomy................................................................................................................................. 19

PROCEDURE (Installing the Ink Tanks): ............................................................................................ 20

INSTALLING THE PRINTHEAD CARTRIDGE ................................................................................................. 22

Printhead Cartridge Protective Packaging .......................................................................................... 22

Procedure (Installing the Printhead): .................................................................................................. 23

SECTION 3 – OPERATING THE PRINTER......................................................................................... 27

CONTROL PANEL FUNCTIONS .................................................................................................................... 27

Printer Status Light Indicators ............................................................................................................. 28

SETTING UP THE FEED ............................................................................................................................... 31

PRINTER DRIVER AND TOOLBOX FEATURES.............................................................................................. 34

Printer Driver Properties ..................................................................................................................... 34

Using the M Series Toolbox Utility ...................................................................................................... 38

PRINTING................................................................................................................................................... 41

Printhead Cartridge Conditioning ....................................................................................................... 41

General Software Setup Info: ............................................................................................................... 41

Setting Up a Job in MS Word® (2003)................................................................................................. 42

SECTION 4 – OPERATOR MAINTENANCE ....................................................................................... 52

INK TANK STORAGE AND HANDLING ........................................................................................................ 52

REPLACING THE INK TANKS ...................................................................................................................... 52

PRINTHEAD CARTRIDGE STORAGE AND HANDLING .................................................................................. 54

CLEANING THE PRINTHEAD CARTRIDGE ................................................................................................... 54

From the M Series Driver: ................................................................................................................... 54