FORMTEK Lockformer LK-20 User manual

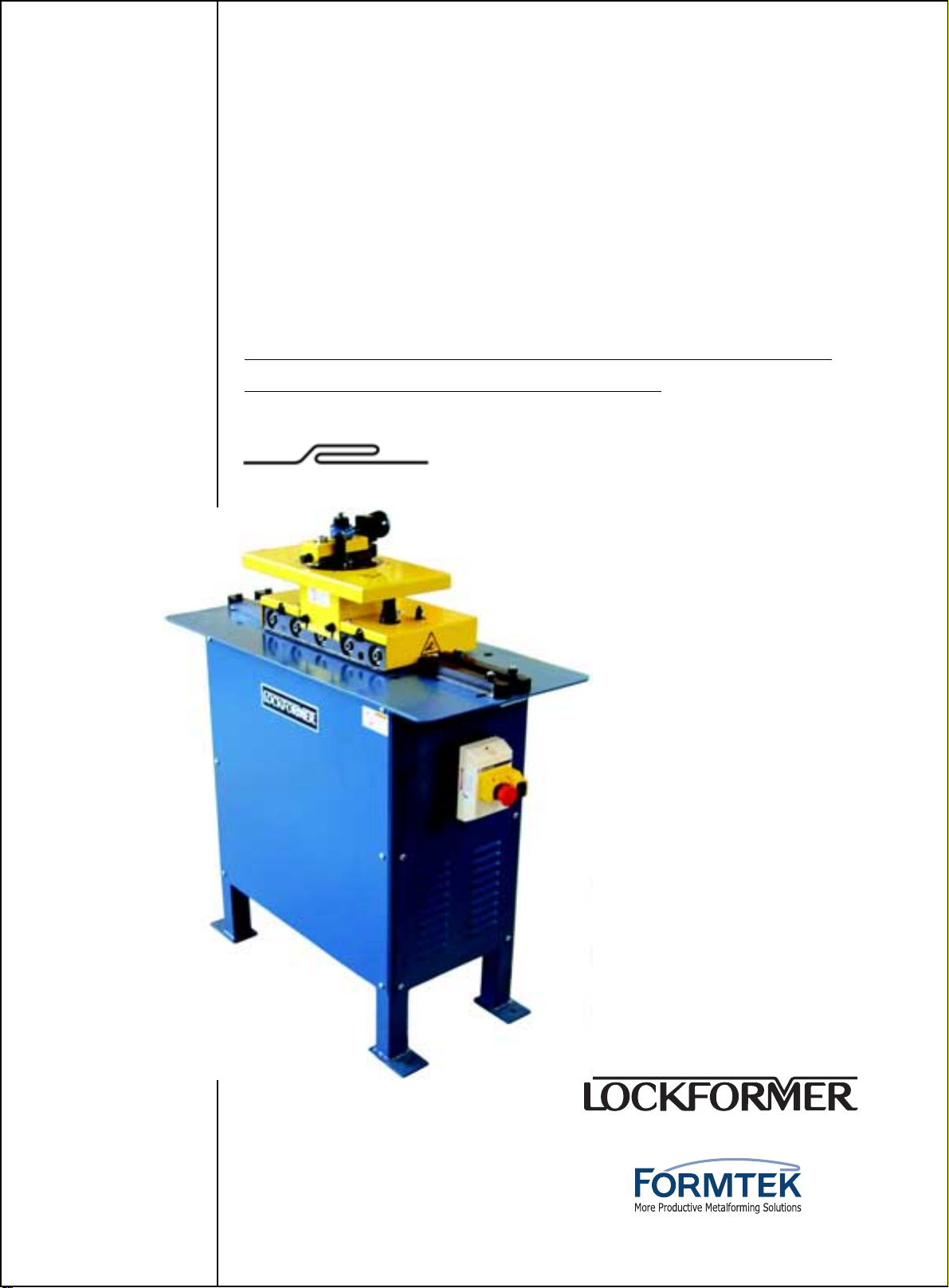

LK-20

PITTSBURGH LOCK MODEL 20

OPERATOR’S MANUAL

WITH AUTO-GUIDE POWER FLANGING ATTACHMENT

INSTRUCTIONS AND PARTS DIAGRAM

A PRODUCT OF

10-2009

VER. INT. LK20-02-CE

WARNING

THIS EQUIPMENT IS DESIGNED TO BE OPERATED WITH ALL

COVERS SECURED IN PLACE. OPERATION WITHOUT THESE

SAFEGUARDS MAY RESULT IN CONDITIONS WHICH ARE

HAZARDOUS TO THE OPERATOR AND OBSERVERS.

01

SAFETY GUIDELINES

B for op rating th machin , study and follow th saf ty pr cautions in this s ction.

Th s pr cautions ar int nd d to pr v nt injury to you and your f llow work rs. Th y

cannot, how v r, cov r all possibl situations. Th r for , EXERCISE EXTREME

CAUTION and us COMMON SENSE b for p rforming any proc dur or op ration.

Saf ty Pr cautions BEFORE Starting Th Machin (s)

Only one person should control the machine(s). Never allow anyone to operate the controls while

you are operating or working on this equipment. In addition to disconnecting power always us

lock outs and tagouts to prevent accidental start-up when performing maintenance procedures.

Keep your hands away from internal workings of the machinery when starting running or

stopping.

Keep your work area clean. Remove all scrap oil spills rags tools and other loose items that

could cause you to slip trip and fall.

When cleaning the machine or any of its components do not use toxic or flamable substances.

Do not perform any cleaning while the equipment is running.

Never override or disable any safety switch or safety interlock.

If so equipped make sure that hydraulic and pneumatic pressures are at specified levels before

operating this equipment.

Do not op rat th rollform r unl ss all cov rs and guards ar in plac .

Be sure that this Instruction Manual is kept near the machine so the operator can refer to it when

necessary.

Keep this equipment properly maintained.

Always turn off power to the machine(s) at the main disconnect before performing any

maintenance or adjustments so accidental start-up or electrocution cannot occur.

02

Saf ty Pr cautions WHILE

Op rating Th Machin (s)

Never leave the work area while the equipment is in operation.

Never leave the machine unattended while it is under power or in operation.

Always be alert while operating machinery.

Be alert for loose worn or broken parts. Do not attempt to operate any machinery with such parts

present or if the machinery is making unusual noises or actions.

Avoid skin contact prolonged breathing or eye exposure to any stock lubrication fluid being

used.

Be aware of the locations of the Pow r Off or Em rg ncy Stop button in case of an emergency.

B sur all guards and cov rs ar in plac .

Continually observe the rollforming process and related equipment. If any unusual condition

develops immediately stop and inspect the machine.

Protect yourself ! Wear safety glasses. Do not wear loose clothing neckties or jewelry. If long

sleeves must be worn avoid loose cuffs and buttons. Tie back and contain long hair.

Never adjust any roll feature or perform work near the rolls gears or power take off while they are

running. G n ral

If any pneumatic or hydraulic feature is used disconnect the main supply and exhaust pressure

and bleed the lines to prevent cycling on retained pressure.

Always shut off the power at the main disconnect switch before entering the electrical control

box.

Do not use compressed air to clean the machines. Air pressure may drive dirt and small chips

into the machine(s) bearing surfaces or cause bodily injury.

Th information contain d h r in is to b us as a g n ral guid only.

For furth r saf y information obtain and r ad th ANSI bull tin ntitl d:

ANSI B11.12-1996 Rollforming and Roll-B nding Machin s saf ty

R quir m nts for Construction, Car and Us .

CONTACT: Am rican National Standards Institut

11 W st 42nd Str t

N w York, N w York 10036

IMPORTANT

03

WARRANTY

Our warranty on th products w manufactur is limit d to r pair or r plac m nt without charg ,

of any part found to b d f ctiv in mat rials or workmanship. This warranty is for a p riod of

on y ar (unl ss oth rwis sp cifi d) from th dat of shipm nt from our factory, for all

m chanical f atur s of th machin xc pt purchas d compon nts that carry th warranty of

th original manufactur r.

This warranty is condition d on prop r installation, maint nanc and us of th quipm nt. Th

warranty will b void if th quipm nt is subj ct d to misus or abus d or if us d b yond th

standards in this manual, including mat rial dim nsions and gaug .

Warranty parts and compon nts will b shipp d fr ight coll ct from FORMTEK. If th d f ctiv

part has not b n r turn d to FORMTEK within 15 working days aft r r c iving th r plac m nt

part, your company will b r sponsibl for th cost of r plac m nt.

Th warranty provid d in this claus is in li u of all oth r warranti s, xpr ss or impli d, arising

by law or oth rwis , including th impli d warranti s of m rchantability and fitn ss for a particular

purpos which ar h r by disclaim d by FORMTEK and xclud d from this agr m nt. This

warranty shall not b modifi d for any r ason. In no v nt shall FORMTEK b liabl for

cons qu ntial or incid ntal damag s, including th cost of ass mbly or disass mbly, lost

production or p rsonal injury.

Th information in this docum nt has b n r vi w d and is b li v d to b compl t and accurat .

No r sponsibility is assum d for minor inaccuraci s or cont nt not addr ss d in this manual.

Furth rmor , FORMTEK r s rv s th right to mak chang s to any products h r in, at any tim , to

improv r liability, function, or d sign. FORMTEK do s not assum any liabiliti s arising out of any

us of any product d scrib d h r in, nor do s it conv y any lic ns und r its trad s cr ts or

pat nt rights nor th rights of oth rs.

To provide clarity to points in question

the illustrations and photos appearing

in this manual are shown with covers

and guards removed.

CAUTION

NEVE OPE ATE THIS EQUIPMENT

UNLESS ALL COVE S AND GUA DS

A E IN PLACE.

!!

!!

!

04

Common sense and xtr m care must be used at all times during the operation and maintenance of this equipment.

It is important that ALL personnel who will operate maintain or supervise the use of this equipment read and

understand the sections of this manual concerning SAFETY and the OPERATION of the equipment.

The equipment described in this manual was designed and manufactured for a specific function. It should not be

used for any other purpose or outside of the design specifications as this may result in damage to the equipment

and/or injury to the operator. Modifications or additions to this equipment should not be made. Any such modifications

or additions will void the warranty and may subject the operater to injury.

Replacement and maintenance parts must be purchased from FORMTEK or the component original equipment

manufacturer. Use of other parts may result in unsafe operation or failure of the machinery. If there is a question

to the suitability of a part proper personnel FORMTEK should be consulted.

In g n ral, v ry pi c of quipm nt must b tr at d with xtr m car . Whil op rating or maintaining

this quipm nt, ach individual must b awar of th ir own saf ty as w ll as th saf ty of all bystand rs.

SAFETY FI ST

SAFETY SIGN-OFF SHEET

I verify that I have read and understand the safety and operation sections

for this equipment:

It is the employer’s responsibility to instruct all persons who may come in contact with this equipment

on the safe operation and maintenance of this equipment. If a language barrier or other restriction

limits understanding this manual can be read to the individual with appropriate follow up questions

to verify understanding. Have each individual sign below only after demonstrating their understanding

of the safety practices described in this manual.

NAME DATE NAME DATE

05

SAFETY GUIDELINES

Do not wear loose clothing, neckties, improper gloves, or jewelry while operating this machine. If

long sleeves must be worn, avoid loose cuffs or buttons, Tie back or contain long hair.

Wear proper gloves to prevent lacerations caused by sharp edges of stock as it travels through the

forming operation.

Never operate this equipment unless all covers and guards are properly installed.

Be alert for loose, worn, or broken parts. Never operate this equipment unless it is in good working

condition.

As the stock enters the guides and feeds into the rolls, a pinch point is created as the stock advances.

Keep hands clear of area and all pinch points.

Always disconnect the main power supply power and install lock outs using a lockout / tagout procedure

when making adjustments or repairs.

When transporting, take into consideration that the machine is top heavy and may suddenly tip over.

The machine is designed for fixed installations and are not intended for portability.

You are NOT ready to operate this equipment if you have not read and

understood all of the safety information in this manual.

!!

!!

!

WARNING:

R m mb r that th information contain d in this manual is only a portion of an ad quat

training program. It must b coupl d with sp cific instructions for your application along

with full information of national and local saf ty r gulations that may apply.

Th Lockform r Rollform r d scrib d in this manual has b n t st d for nois DB l v ls.

At normal op rating distanc th machin should b no mor th n 75DB.

SOUND PRESSURE INFORMATION

YEAR OF MANUFACTURE

06

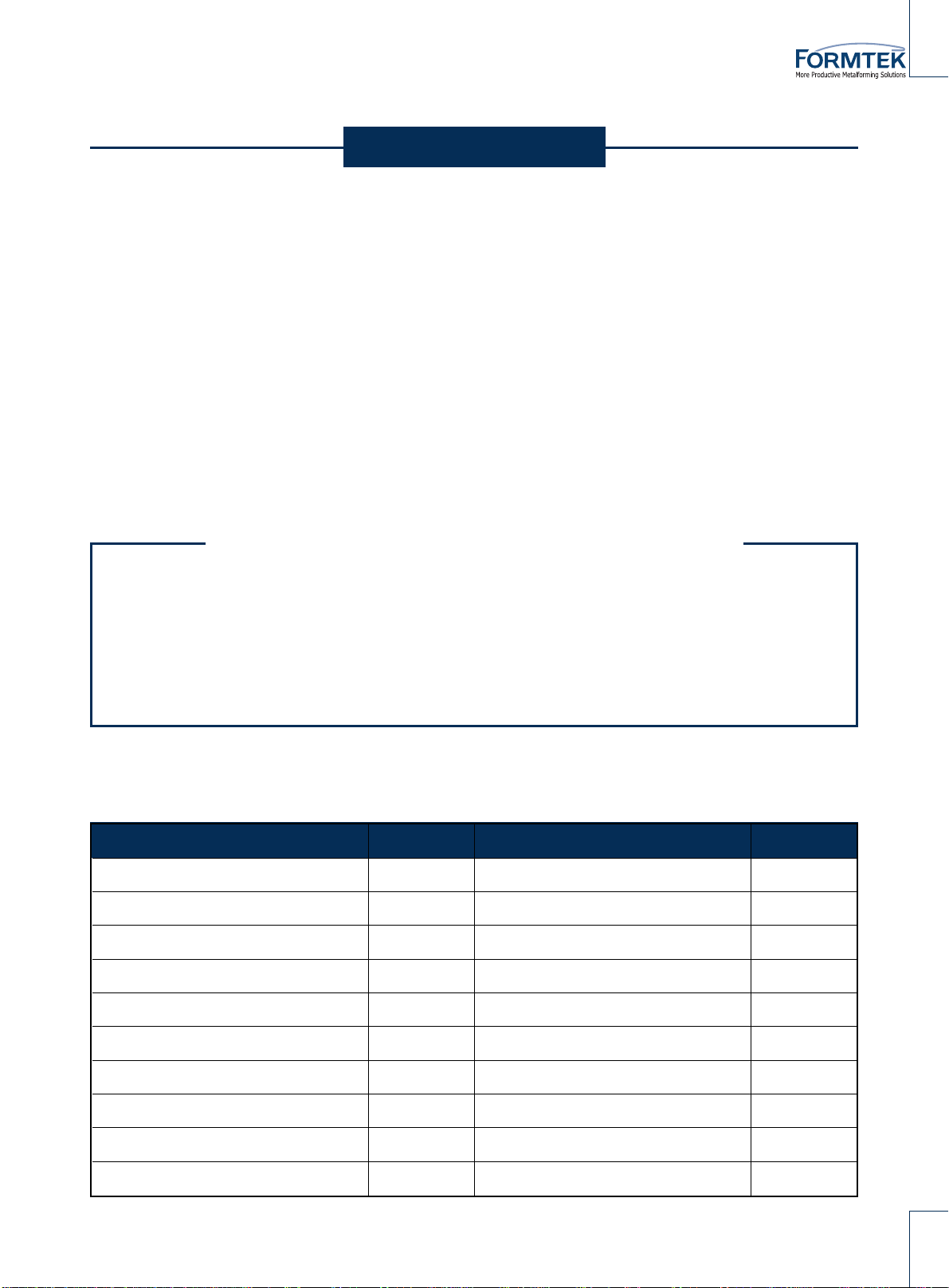

ELECT ICALS

INSTALLATION

Provide a clean flat well lighted installation site. Level the machine and anchor it to the floor.

Inspect the gears and drive assembly and remove any debris that may have accumulated during

shipping.

Standard Electrical: 2HP (1.5KW)

110 Volts 1 phase grounded power supply. Provide a sufficient 110V receptacle at the point of

operation. If a 3 phase motor is ordered install the power supply in compliance with national

electrical codes. For further information contact a certified electrician or Lockformer service dept.

(Contact information at www.Lockformer.com or tel# 1-630-964-8000)

CAPACITY

Maximum 1mm thickness (20 Gauge) black iron mild steel and Galvanized steel.

MATERIAL ALLOWANCE: = 25mm, 1”

(1) 25mm (1”) female PITTSBURGH

(2) 6mm (1/4”)90 degree (MALE)

Total amount of material (25mm Female PITTSBURGH + 6mm MALE)=31mm.

(1” Female PITTSBURGH + 1/4” MALE)= 1-1/4”

This allowance to be added for the seam formed sections for calculation of sheet sizes. The above

dimensions can be modified by moving the entrance gauge position to suit the requirements of a

specific project or material.

Not : The machine has been tested and adjusted at the factory on 0.6mm (26ga) through 1mm

(20 ga) thickness material and as delivered is ready for normal operation.

Female PITTSBURGH 90 degree (MALE)

07

BASIC OPE ATION

OPERATING

INSTRUCTIONS

PITTSBU GH FEMALE HOLD DOWN

ADJUSTMENT P OCEDU E

Hold the material against the entrance gauge and slide it into the forming rolls. Be sure that the

material remains against the gauge until the trail edge of material is engaged in the rolls.

Not : Minimum part length is 175mm(7”).

Make hold down adjustments as outlined below to accommodate slight variations in metal thickness

and hardness.

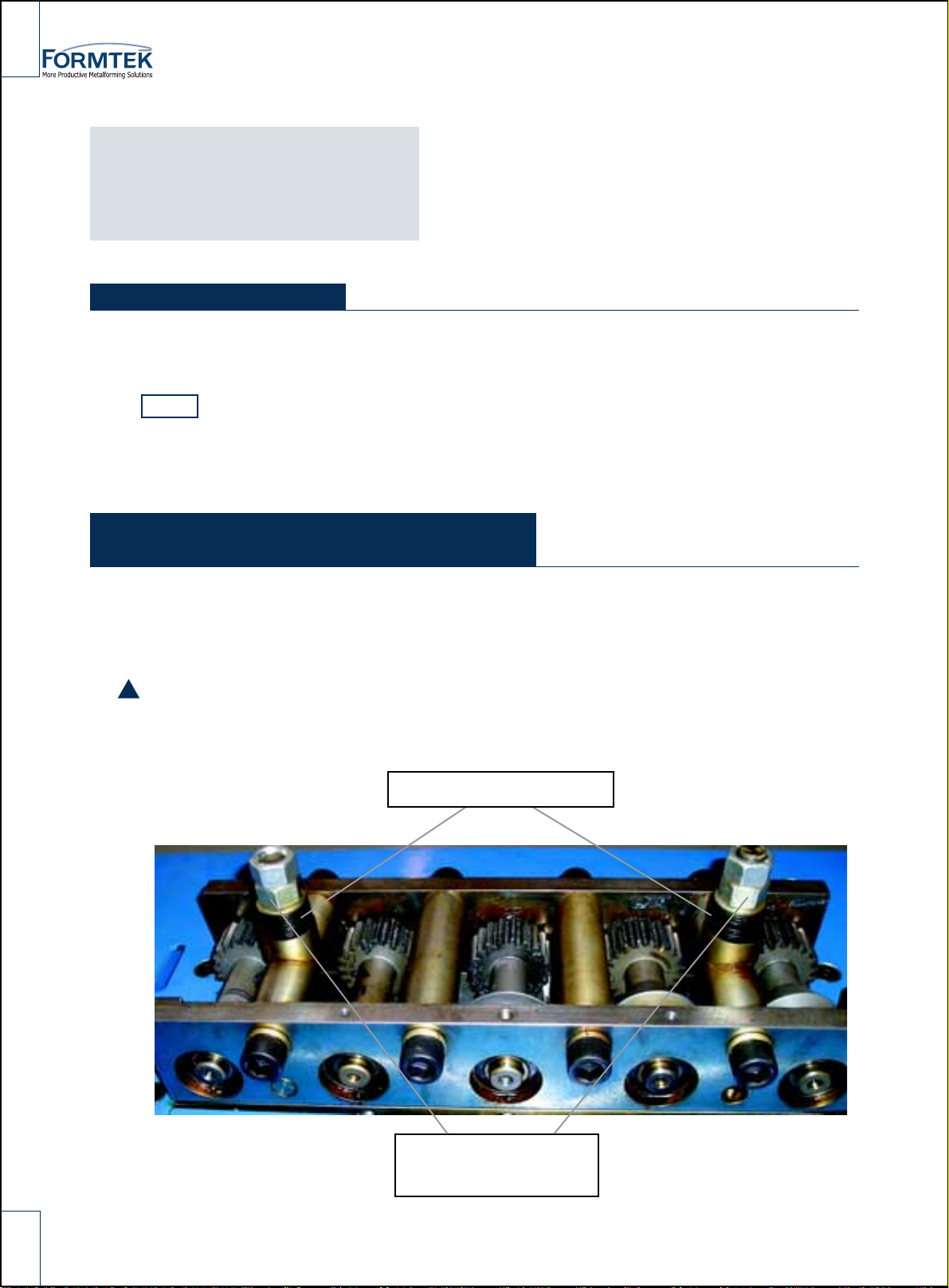

The HOLD DOWN ADJUSTMENTS NUTS are used to set the tension on the SPRING WASHERS.

These SPRING WASHERS are used to allow the top rollers to float upwards. This is necessary on

an LK-20 because of the various metal thicknesses that an LK-20 will form.

1. DISCONNECT POWER!

2. Install electrical lock outs to prevent accidental start up.

3. Remove top cover.

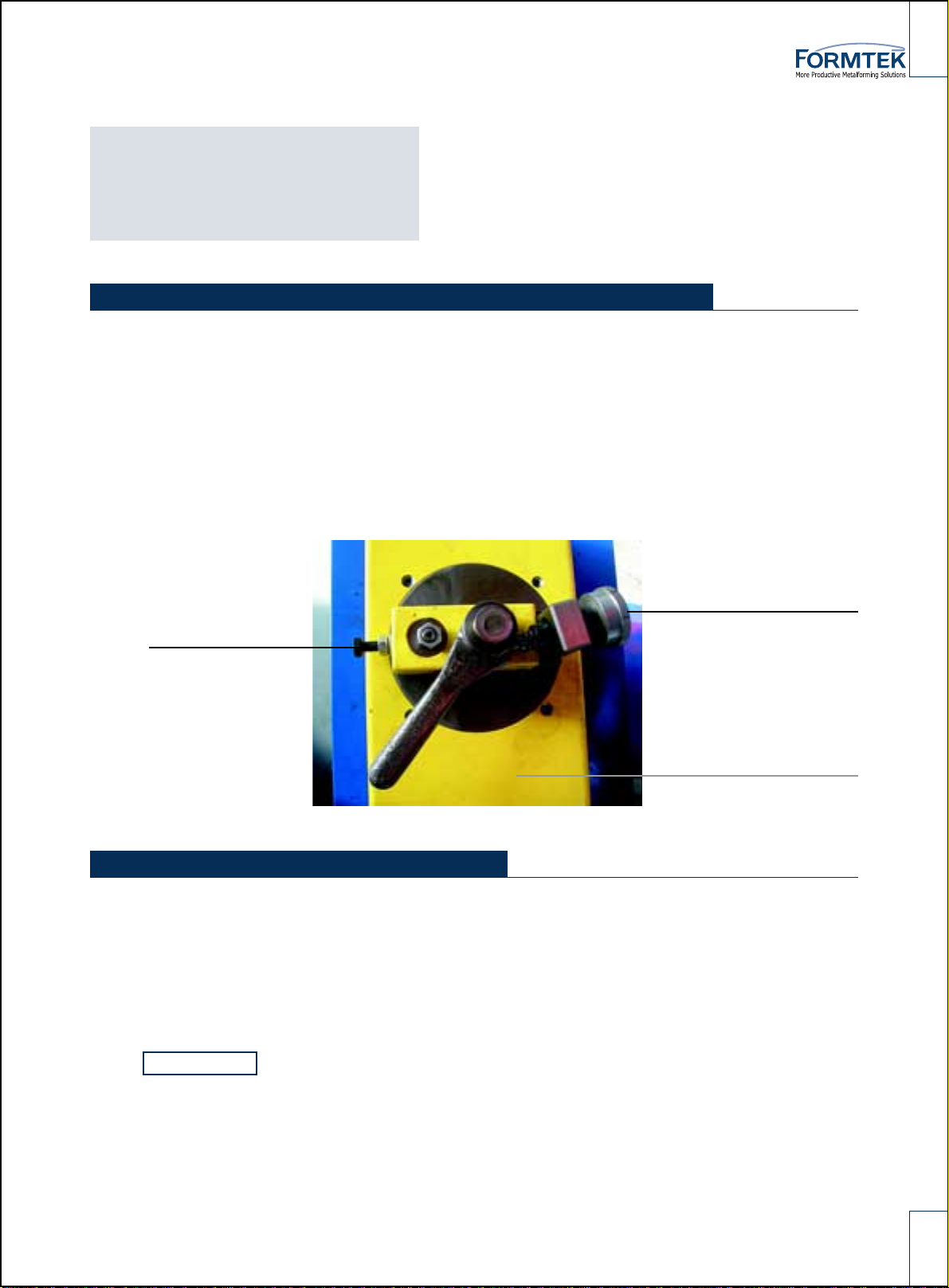

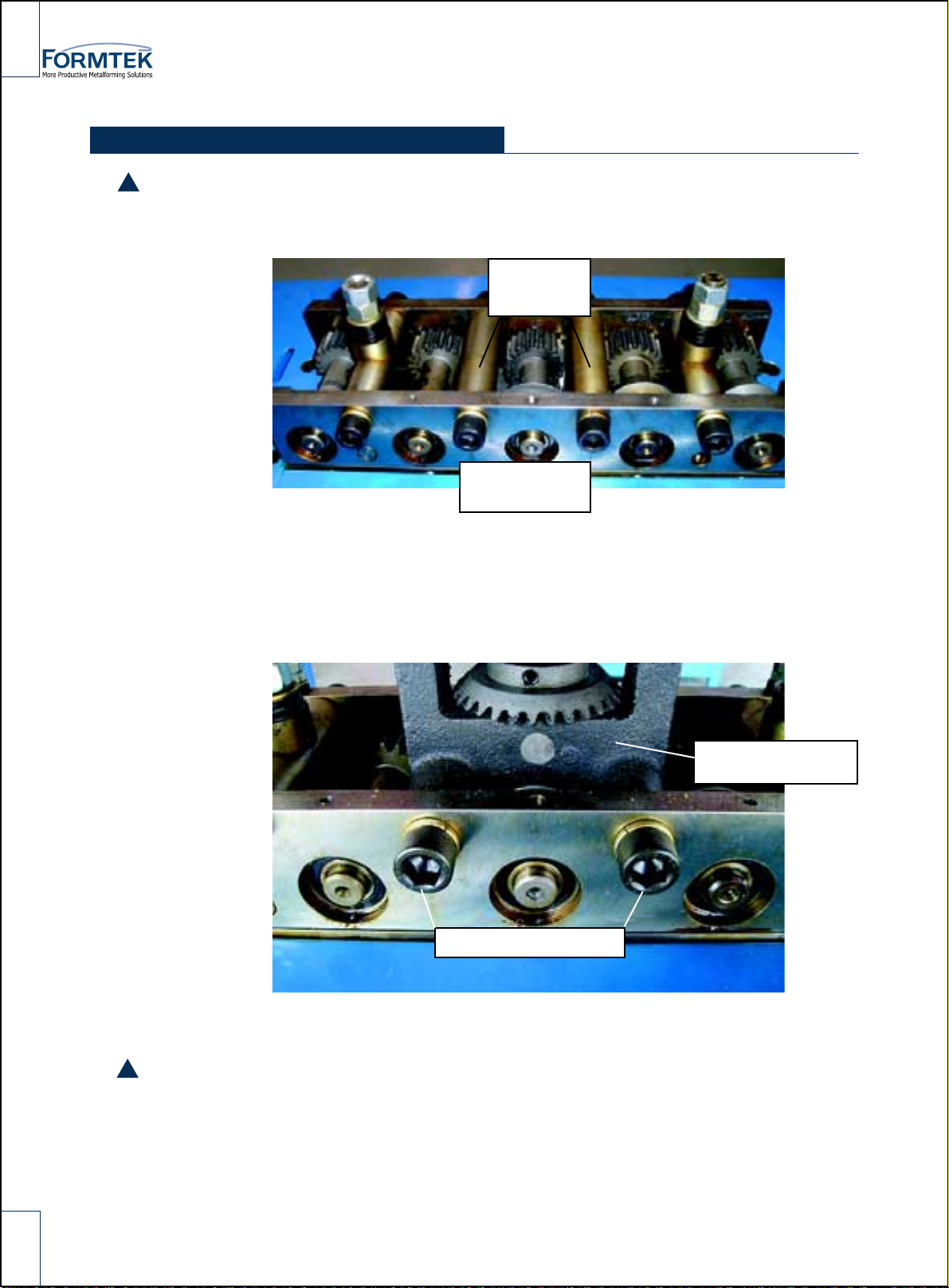

HOLD DOWN

ADJUSTMENTS

SPRING WASHERS

!

0

4. Loosen and remove the HOLDDOWN

lock nuts.

5. Tighten the hold down NUTS fully tight or set to

a torque value of 60MN (50 ft. lbs.)

6. After tightening loosen the NUT 1/4 turn

(90 degrees).

7. Retighten the lock NUT.

8. INSTALL THE COVER remove electrical power

lock outs restore power.

9. Run a test piece.

- If the stock slips in the rolls tighten the hold down nuts. It may be necessary to tighten the 1st

and 2nd HOLD DOWN nut unequally in order to obtain the desired result.

- If the stock curls up after forming or shows extremely pressure marks loosen the hold down

NUTS slightly.

*Do not adjust hold downs NUTS unless the stock slips in the rolls pulls away from the entrance

gauge or curls when exiting the rolls.

The Standard settings for the Auxiliary HOLD DOWN nuts are as follows:

1. Tighten the Auxiliary HOLD DOWN NUTS fully tight.

2. Loosen Auxilary HOLD DOWN NUTS 3/4 of a turn (270 degrees)

FORMTEK Machinery offers options for Auxiliary Rolls. Specific HOLD DOWN NUT adjustments

depend on which optional rolls are installed. The 3/4 turn specification may change depending on

the Auxiliary Rolls installed.

AUXILIA Y OLL HOLD DOWN NUTS

!

LOCK NUT

SPRING WASHERS

HOLD DOWN NUT

09

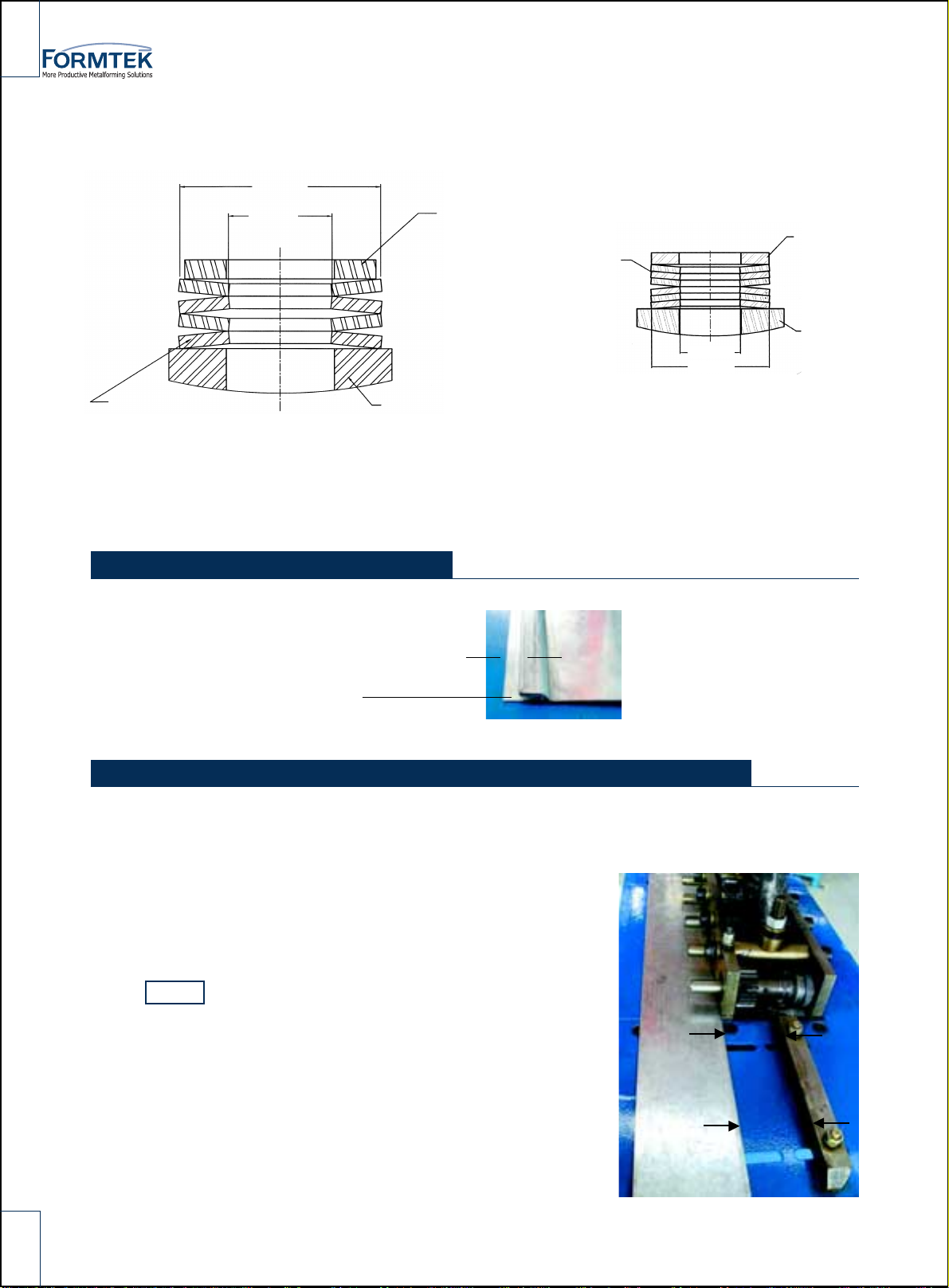

ø31.5(OD)

ø16.3(ID) 91166A310

SADDLE WASHER 7X635

96475K295

8 WASHERS

2 WASHERS PER GROUP

2 GROUPS PER STACK

STACK AS SHOWN

SCALE DOWN TO 256˚

HOLD DOWN SPRING WASHERS

HAMMER-OVER EDGE

¡ł

¡ł

FEMALE PITTSBU GH LOCK

HAMME -OVE EDGE ADJUSTMENT (ENTRANCE GAUGE)

The width of the FEMALE Pittsburgh lock hammer over edge is adjustable.

Move the FEMALE PITTSBURGH lock entrance gauge to produce a larger or smaller hammer

over edge.

NOTE: There should be a deep scribe or scratch mark in

the paint along the side of the entrance gauge and exit

gauge. This is the original line location of the gauge from

the factory. Slight adjustment from this line may be

required to increase or decrease the hammer over edge

width.

62mm

61mm

SCALE DOWN TO 306˚

5S355

96445K236

3 WASHERS PER GROUP

2 GROUPS PER STACK

91455A130

SMALL SPRING WASHERS

ø16(OD)

ø8.2(ID)

10

EXIT GAUGE

Never move the exit gauge bar for this roll set. This gauge is not intended to contact the material

under normal circumstances.

NOTE: There should be a deep scribe or scratch mark

along the side of the exit gauge this is the original line

location of the exit gauge from the factory. Slight

adjustment from this line may be required.

1. DISCONNECT POWER

2. Install lock outs to prevent accidental start up.

3. Remove the cover.

4. Unscrew and remove the right hand side table top section. This will expose the auxiliary

shafts on which the rolls will be mounted.

5. Select the first pair of rolls which are marked T1 (Top roll first station) and B1 (Bottom roll first

station). Slide them as a mated pair onto the shafts. All information stamped on the rolls must

face outward. Slide a key into each keyseat. Follow this procedure in sequence with each

remaining pair of rolls.

6. Fasten the rolls onto the shafts with the screws and washers provided.

7. Mount the entrance gauge and set it to the dimensions shown in the illustration.

8. Mount the exit gauge so the outside face of the vertical leg is parallel to the part as it passes

over the exit table. Set to allow approximately 1.5mm clearance between the part and the exit

gauge.

DOUBLE SEAM or ST AIGHT IGHT ANGLE FLANGE OLLS

!

CAUTION: The flat roll (called the opening roll) mounted horizontally after the last roll station

maintains the opening of the gap in the PITTSBURGH lock. Twisted or bent notches should be

flattened prior to feeding stock material into the machine. Failure to do this can result in breakage

of the opening roll.

OPENING OLL

NOTE: Standard auxiliary rolls are interchangeable between the standard LK 20 and the Super-

Speed models. Since different entrance gauges are required the model for which the rolls are

intended should be specified.

INSTALLATION AND OPE ATION OF AUXILIA Y OLLS

11

9. Replace the table top.

10. INSTALL THE COVER

11. Remove the lock outs.

12. Restore power to the machine.

!

1. DISCONNECT POWER.

2. Install lock outs to prevent accidental start up.

3. Remove the cover.

4. Unscrew and remove the right hand side table top section. This will expose the auxiliary shafts

on which the rolls will be mounted.

5. Select the first pair of rolls which are marked T1 (Top roll first station) and B1 (Bottom roll first

station). Slide them as a mated pair onto the shafts. All information stamped on the rolls must

face outward. Slide a key into each key seat. Follow this this procedure in sequence with each

remaining pair of rolls.

6. Fasten all rolls except the top number 2 onto the shafts with the screws and washers provided.

Do not insert a mounting screw into the top 2 rollshaft; this allows the roll to “float” laterally and

center itself to the bottom roll as the stock passes through.

7. Mount the entrance gauges so that the centerline of the stock aligns with the centerline of the

rolls.

8. Tighten the stud nuts so that the T5 and B5 rolls do not separate as the drive cleat passes

through.

9. Mount the exit gauge so the outside face of the vertical leg is parallel to the part as it passes

over the exit table. Set to allow approximately 1.5mm clearance between the part and the exit

gauge.

10. Replace the table top.

11. INSTALL THE COVER.

12. Remove the lock outs.

13. Restore power to the machine.

IMPORTANT: BE SURE TO CUT STOCK EXACTLY 54mm (21/8”) WIDE TO INSURE AN

ACCURATELY FORMED CLEAT.

D IVE CLEAT OLLS

!

!

12

G EASE D IVE GEA S

CLEANING THE OLLS

The recommended lubricant is Castrol Molub-Alloy 777-1 or equivalent. Apply grease to all drive

gears after every 40 hours of operation. If the machine is to be used in a damp environment apply

a film of oil or grease to all unpainted metal surfaces to prevent rust.

Keeping the forming rolls clean is an important step toward efficient operation of your machine.

Lockformer’s GALV-OFF aerosol spray cleaner will soften galvanized build up so that it flakes off

by itself. Daily use is recommended. GALV-OFF cleans and lubricates as well as protects the

forming rolls.

MAINTENANCE

13

IMPROPERLY FORMED/DEFORMED EDGES

-It may be necessary to add a slight lubricant to the surface of the sheet being formed to aid the

flow of material through the forming rolls. Lockformer’s GALV-OFF available from FORMTEK is

recomended.

-The operator may have to experiment with hold down settings for desired results. Run test pieces

to check different settings on the hold down nuts or bolts.

RUNNOUT

Some materials may have a tendency to drift away or runnout from the entrance gauge. The edge

dimensions will be uneven from beginning to end. Check the following points when runnout is a

problem.

-Be sure to hold the material firmly against the entrance gauge. Some materials will require significantly

more pressure then others.

- Hold down settings should be checked and reset. Some materials may require settings that are

tighter then this manual specifys. Use caution when setting the holdowns tighter then normal.

Prolonged use of the machine with tighter settings will reduce the life span on some of the machines

parts.

-Due to variations of the physical characteristics of material it may be necessary to reset the

entrance gauge bar if the material pushes away from the gauge bar or the lock is not formed

properly. There should be a scratched line along the side of the entrance gauge to locate the

original factory setting. Also it may be necessary to “Taper” the entrance gauge (set the gauge at

a slight angle) to eliminate runnout.

-The exit gauge bar can be used to push on the exiting material when the material is not flowing

straight or evenly throughout it’s length such as when the edge is running out. Difficult parts may

T OUBLE CHECKS

The CENTER SPACER is positioned between the top and

the bottom forming heads on the 2nd large hold down stud

(at the exit end of the machine near the opening roll). The

function of this spacer is to control the vertical clearances

between the top and bottom rolls at stations 4 and 5. The

vertical clearance between top and bottom rolls is set in the

factory with a feeler gauge to a clearance of 0.2-0.4mm

(0.008”-0.010”) at the outside edge of the rolls.

NOTE: It may be necessary to insert shim washers above

the spacer to obtain the proper clearance.

LK-20 CENTE SPACE

14

require exit gauge pressure along the materials edge such as long heavy pieces where an awkward

weight and size make it difficult for the operator to hold the piece straight during the forming

process. This technique must be used carefully. Other conditions may be causing the runnout

such as loose settings on the hold downs or improperly adjusted entrance gauges (those settings

should always be checked first).

Having the exit gauge bar push too hard against the material might make the situation worse. The

operator must run test pieces and inspect the formed product to determine the best adjustment

position of the exit gauge bar.

FOLLOW ALL SAFTEY PRECAUTIONS IN THE MANUAL WHEN MAKING ADJUSTMENTS

!

AUTO GUIDE FLANGING ATTACHMENT

LK-20-AGF

15

16

OPERATING

INSTRUCTIONS

To adjust clearance between flanging rolls tighten the adjusting screw on the front of the block of

the machine all the way then loosen the screw approximately one eighth of a turn. (This setting is

usually correct for 26 gauge material). Do not set front gauge adjusting screw too tight. It should

be set just tight enough to draw the metal through the rolls. Too tight a setting will stretch and

wrinkle the material.

To adjust the spring tension on the compensator arm tighten the adjusting dial on the back side of

the flanger to the stop and then turn back to the proper gauge setting shown on the adjusting dial.

ADJUST UNIT FO GAUGE MATE IAL TO BE USED

Before inserting material into the rolls turn up a “starting flange” This is done by inserting the

leading edge of the work to be flanged in the slot cut into the table and bending the piece away

from the operator approximately 45°. Start the leading edge of the material into the rolls. As the

material passes through the rolls the compensator arm will make contact with the material and

guide it through the rolls. If the material pulls out of the rolls it is an indication that either the front

adjusting screw is loose or the back adjusting dial is not tight enough.

IMPORTANT: When starting a partially formed part that has a radius:

1. Push the compensator arm back

2. Feed the part into the rolls

3. As the unformed part enters the rolls move the compensator arm forward against the part

4. Push firmly on the part while watching the flange height guide the part threw the rolls and as

the flange is forming the compensator arm should hold the part.

5. The operator should only need to hold the piece gently as the compensator arm controls the

part as it flows threw the machine.

TU N UP A “STA TING FLANGE”

BACK ADJUSTING DIAL

FRONT ADJUSTING SCREW

COMPENSATING ARM

17

¡ł

1. DISCONNECT POWER – INSTALL ELECTRICAL LOCKOUTS

2. Remove the top cover from the2. Loosen the front mounting screws on spacers # 1 and # 4

3. Remove spacers #2 and # 3 by removing their mounting screws. Install Auto Guide power

Flanger (AGF)

Loosen #1 #2

spacer screw

¡ł

Remove

spacer #2

Tigjten screw completely

INSTALLATION AND OPERATION

Installed Auto Guide

power Flanger(AGF)

*Be sure to allighn and mesh the gears !

4. Replace the top cover.

5. Remove electrical lockouts

6. Restore Power

!

!

1

7T459 9104KDDG

815U6 OPENING ROLL

5V675 OPENING ROLL

1H345 SPRING 91595A712 PIN

BEARINGS

HOLDER

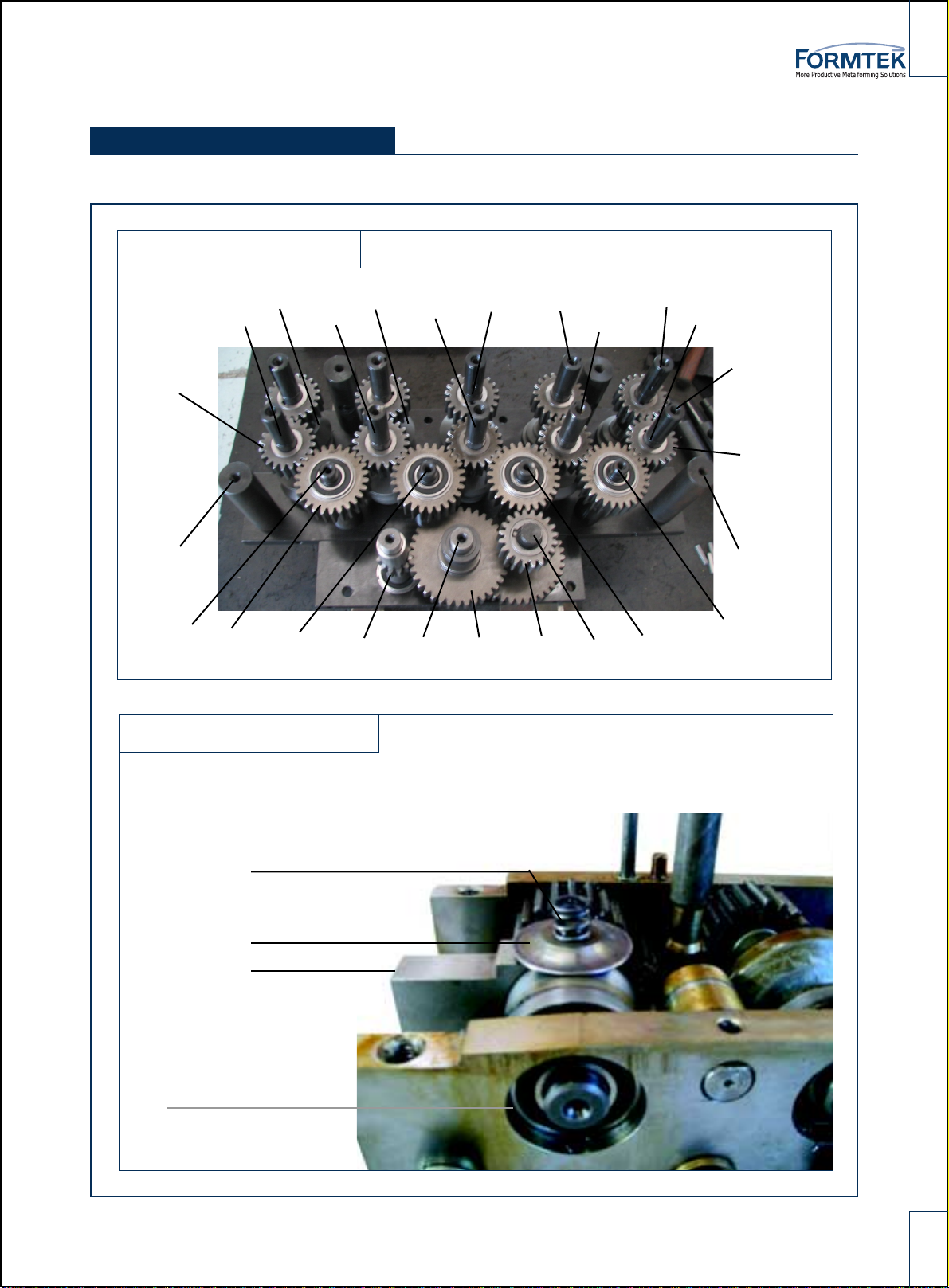

FIG.1 Chassis

FIG.2 Opening Roll

M0B748(T1)

M0B391 (2) M0B390

248M2 (4)

M0B759 (10)

8Q536

LK-20 PARTS DIAGRAM

M0B388 M0B389 M0B392 M0B684

M0B758 (10)

M0B749(B1)

M0B752(T3)

M0B753(B3)

M0B750(T2)

M0B751(B2) M0B755(B4)

M0B752(T4)

M0B757(B5)

M0B754(T5)

248M2 (4)

3X667 (4)

8G598 8G598

M0B759 (10)

19

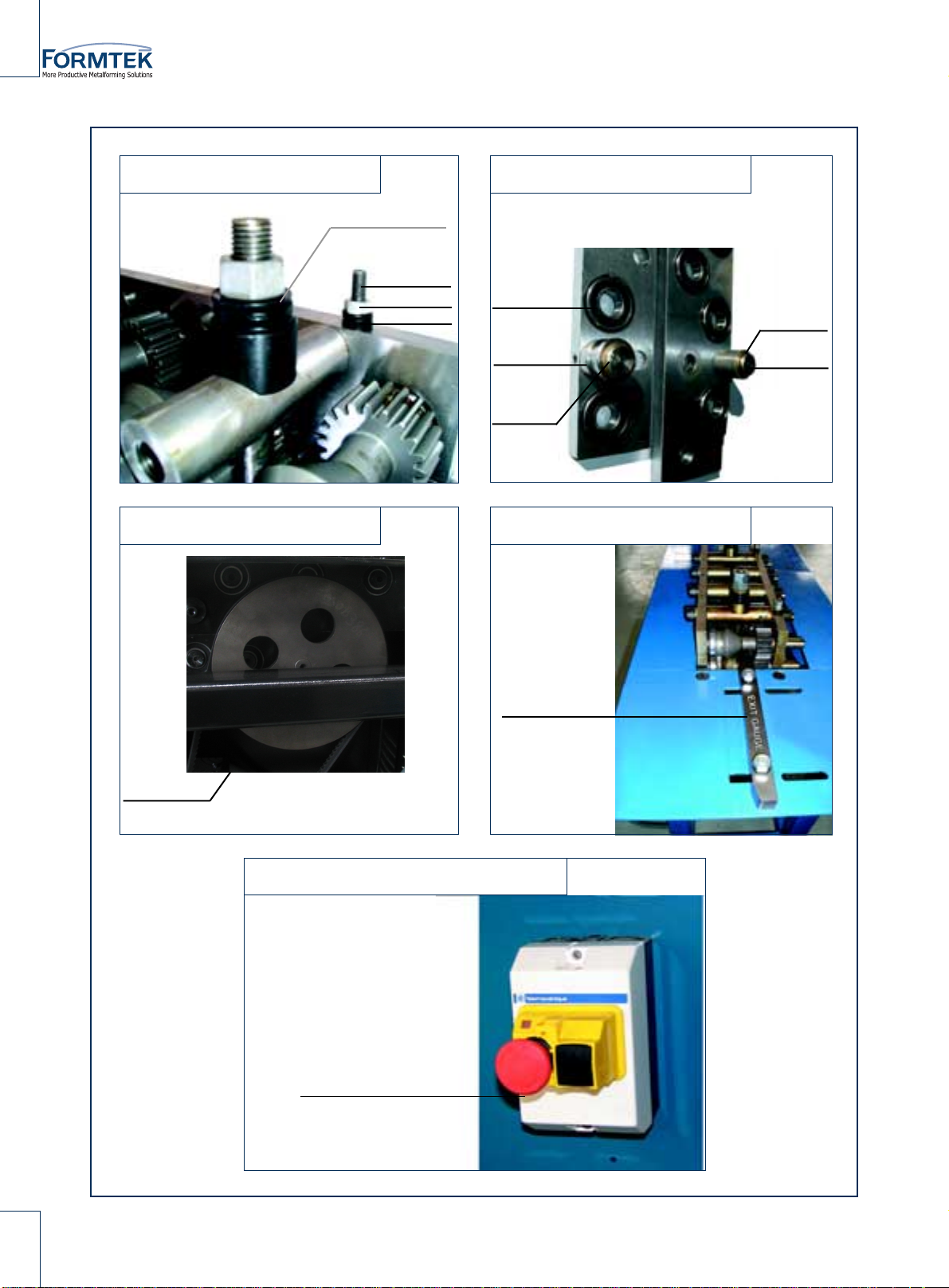

STARTER ASSMBLY

AD-0A9802

5D228 (2)

3G 380

PIN (2) 5Y067

BEARING 87R78

5N 261

THRUST

WASHER (3)

7814K21

SPRING WASHER(8) 96475K92

STUP (2) 96445K236

NUT (4) 90685A045

FIG.3 Hold Down FIG.4 Straightener Roll

FIG.7 Motor Control

FIG.5 Top PULLEY FIG.6 Exit Gauge

SPRING WASHER(12)

96445K236

PULLEY

M0B386

PULLEY

Table of contents

Other FORMTEK Industrial Equipment manuals