Skipper ETNSLJB Specification sheet

SKIPPER ETNSLJB

100mm GATE VALVE FOR ECHO

SOUNDER TRANSDUCER

Operation And Installation Manual

Edition 20070522

Skipper Electronics A/S Telphone +47 23 30 22 70

Ryensvingen 5 Telefax +47 23 30 22 71

P.O.Box 151, Manglerud E-mail: skipper@skipper.no

0612 Oslo, Norway Co.reg.no: NO-965378847 -MVA

www.skipper.no

Weitergabe sowie Vervielfältigung dieser Unterlage, Verwertung und

Mitteilung ihres Inhaltes nicht gestattet, soweit nicht ausdrücklich

zugestanden. Zuwiderhandlungen verpichten zu Schadenersatz.

Toute communication ou reproduction de ce document, toute

Exploitation ou communication de ou son contenu sont interdites, sauf

Autorisation expresse. Tout manquement à cette règle est illicite et

Expose son auteur au versement de dommeges et intèrèts.

Copying of this document, and giving it to others and the use or

Communication of contents therof, are forbidden without express

Authority. Offenders are liable to the payment of damages.

Sin nuestra expresa autorización, queda terminantemente prohibida la

Reproducción total o parcial de este documento, asì como su uso

Indebido y/o su exhibición o comunicación a terceros. De los infractores Se

exigirá el correspondiente resarcimiento de daños y perjuicios.

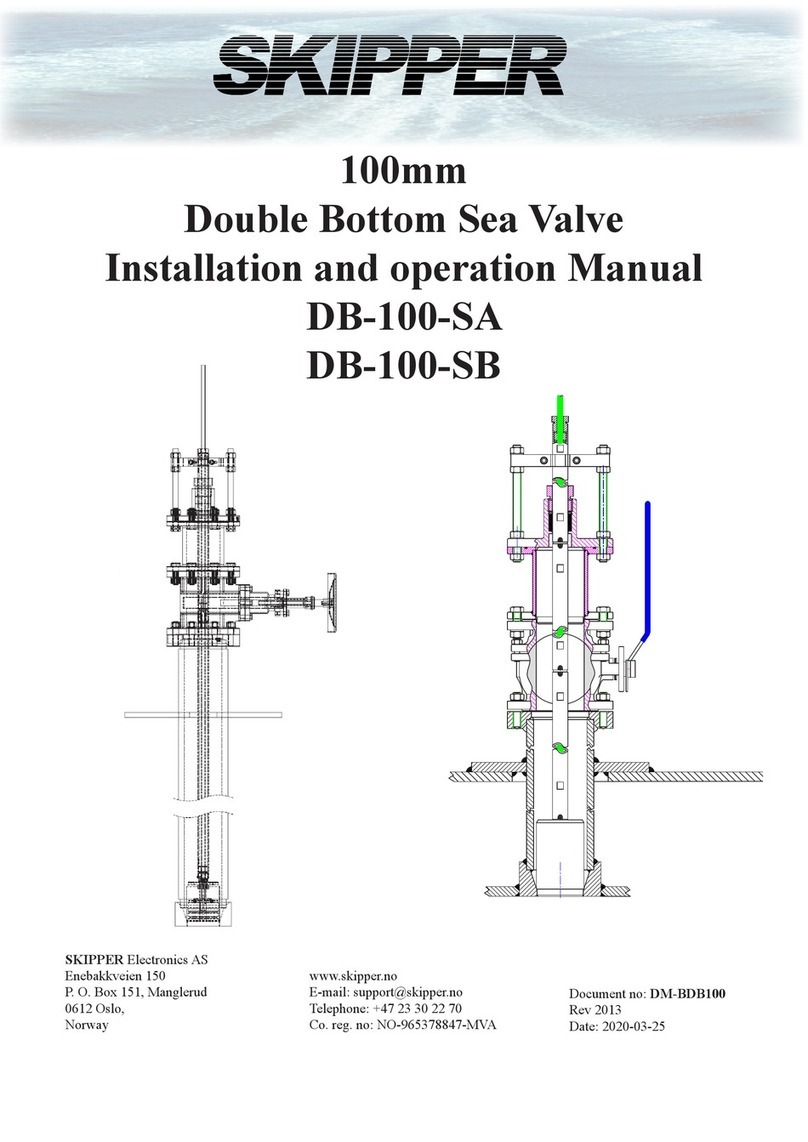

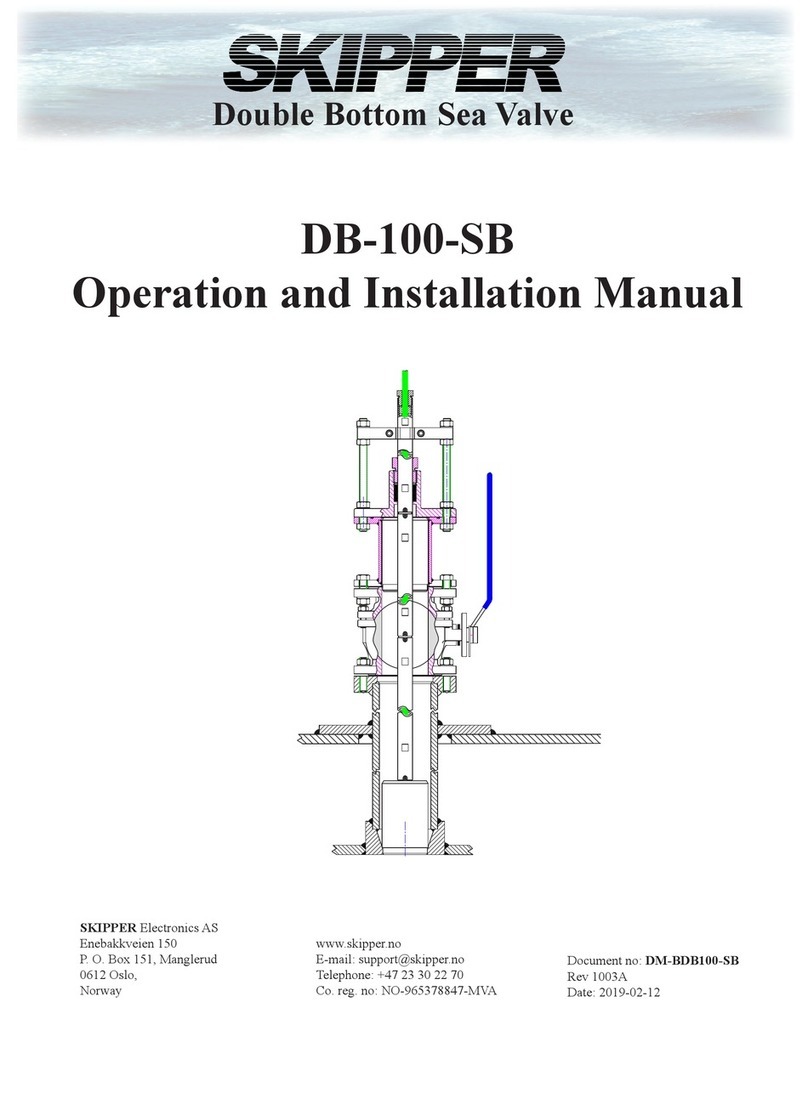

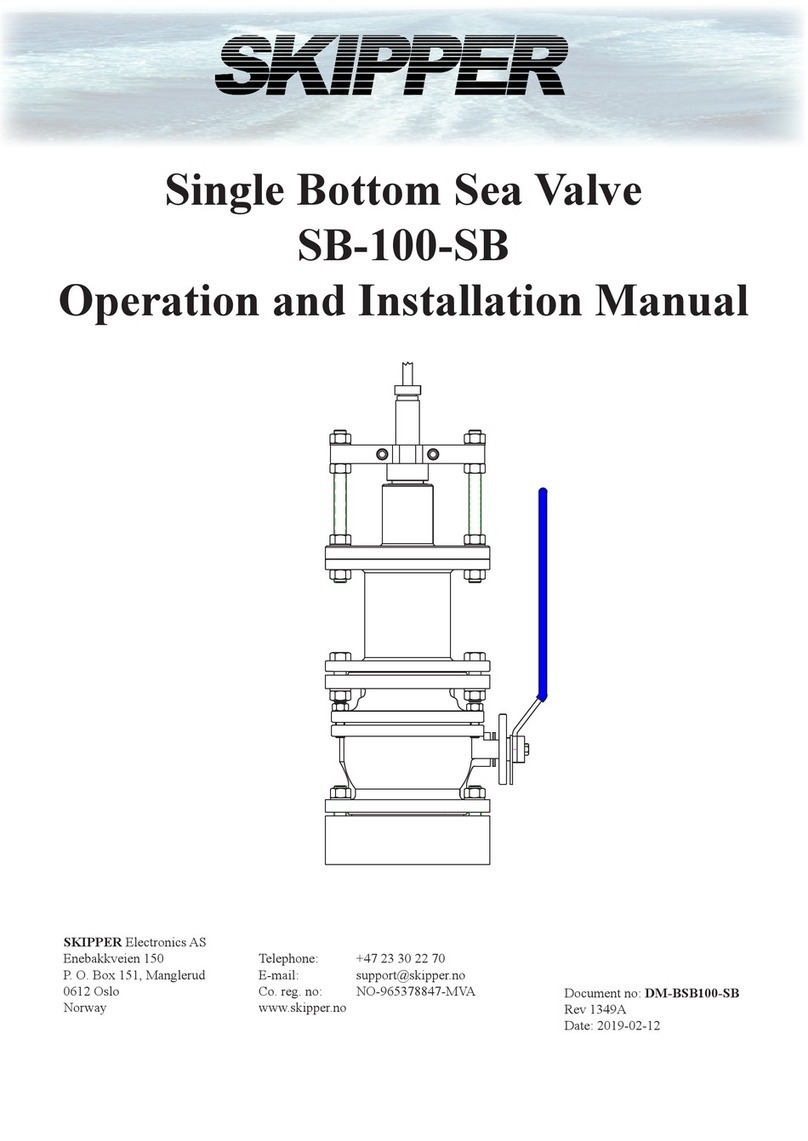

SKIPPER 100 MM GATE VALVE FOR

ECHO SOUNDER TRANSDUCER.

INSTALLATION.

The SKIPPER 100 mm Gate Valve Echo Sounder is used for installation of :

1: Echo Sounder Transducer type TGM 60-50-25L or TGM 50-200-25L.

The SKIPPER 100 mm Gate Valve Echo Sounder is delivered assembled for transport.

The parts necessary for nal assembly will be found on the gate valve itself, or packed in a box, delivered

with the gate valve.

First of all, it must be decided, where the gate valve should be installed. Normally, this will be in the fore

part of the ship, in the centerline, or as close to the centerline as possible. There must be no protruding

objects in front of the gate valve, or in the immediate area at both sides. Welding seams in this area should

be smoothened and rounded off, in order not to create turbulence or aeration at speed.

The gate valve should be placed in a dry space, large enough for installation and disassembly of the gate

valve and sensor unit. See drawing: “Minimum space for convenient access”.

When the position has been decided, the gate valve is disassembled, a suitable ( 220 mm.) hole is cut in the

hull, and the bottom ange, item # 1, is welded into the hull . Standard welding practice and procedures

should be observed.

The orientation of the bottom ange must be observed. The centerline or a parallel to the CL should run

between two bolts, as shown on the enclosed drawing.

The type of steel used in the gate valve bottom ange is: TP 316 / TP 316L.

When the bottom ange has cooled off,

place an O-ring item # 12 in the groove inside the bottom ange. Apply ample amounts of grease on O-ring.

And place 0.5 mm Klingersil gasket, item # 14 on top.

Then place the Gate Valve element, item # 2, on top of the bottom ange. The 16 mm nuts and washers

should be mounted but not tightened.

Place a 1.5 mm Klingersil gasket on top of the gate valve element.

Mount the intermediate element, item # 3, on top of the gate valve element.

The ange with only 6 pinbolts to be upwards.

Place an O-ring item # 12 in the groove inside the intermediate element. Apply ample amounts of grease on

O-ring.

All 8 nuts / washers should be mounted, but not tightened.

Open the gate valve fully and insert sensor housing into the gate valve,

moving it from side to side to align the different elements exactly.

With the sensor housing still in place, tighten the 16 nuts below and above the gate valve element.

After tightening, check that the sensor still moves freely, easy to pull all the way out and insert again.

Check that the transducer sensor housing, when fully inserted, is ush with the lower surface of the bottom

ange.

If the above point are not met exactly, it is possible to adjust the height of the gate valve by inserting

thicker or more than one “Klingersil” gaskets, alternatively changing the 1.5 mm gasket to a 0.5 mm gasket.

After the gate valve has been adjusted correctly, remove the sensor housing element.

Place the O-ring, item # 13, in the groove on top of the intermediate element. Apply grease to the O-ring.

Assemble sensor housing. Secure with 6 each washers / nuts.

Insert the 2 safety bolts item # 16 through the ange and secure with Nuts ( M16 counternuts )

NOTE !

The 2 safety bolts MUST be used during removal and installation of sensor elements when the ship is

aoat.

ASSEMBLY OF SENSOR HOUSING.

Place transducer element in the bottom of the sensor housing, item # 4.

Slide the pressure tube, item # 5, over the cable and place it on top of the transducer element.

Place the Nitril 3 mm gasket, item # 15, on top of the sensor housing.

Check that the top edge of the pressure tube is level with the top surface of the Nitril gasket.

If not, adjust with 1 mm shims plates between pressure tube and transducer element.

Place the top ange, item # 6, on top of the Nitril gasket and secure with 4 each 10 mm bolts and washers.

Install the washers, rubber gasket and bronze nut, items # 19, 20 and 21,

in the cable gland and tighten until the cable can not be moved in the cable gland.

Add washers if necessary.

The transducer housing is now ready to be installed in the gate valve.

To remove the transducer element, reverse the procedure.

REMOVAL OF ECHO SOUNDER TRANSDUCER UNIT

The sensor unit is secured with 6 each 16 mm pinbolts with nuts and washers, and two 16mm nuts on each

16 x 300 mm safety bolts.

There should be a split pin through the hole drilled near the top of the safety bolts.

WARNING !

ON VESSELS WITH DEEP DRAFT, THE SEA PRESSURE ON THE SENSOR UNIT

IS CONSIDERABLE, AND MAY PUSH THE UNIT UPWARDS, ONCE LOOSENED, WITH GREAT

FORCE.

WHEN REMOVING THE SENSOR UNIT ON SUCH VESSELS, AT LEAST ONE OF THE NUTS ON

THE SAFETY BOLTS SHOULD BE POSITIONED CLOSE TO THE SENSOR UNIT FLANGE PRIOR

TO LOOSENING THE 6 FIXING NUTS.

After the safety bolts have been correctly arranged, the 6 remaining nuts and washers may be unscrewed.

If the transducer unit sticks in its lowered position, insert the two 10 x 60 mm hexagon “lifting bolts” in the

threaded 10 mm holes in the top ange and use them to “break lock”.

Using the lifting bolts, it is possible to lift the unit approx. 40 mm,

enough to provide room for other lifting tools.

After “breaking lock” or lifting, unscrew the two 10 x 60 mm hexagon bolts and store them for future use.

If the sea pressure is high enough to lift the unit, release the nuts on the safety bolts gradually until the

sensor unit is clear of the gate valve piston.

Otherwise, lift the unit by hand or other tools until clear of the gate valve piston.

The unit is clear of the piston when it has been lifted Min. 220 - Max. 250mm.

Do not lift more than 250 mm, as the unit will clear the upper water sealing ring,

and there will be water leakage.

Close the gate valve.

Remove the Split pins and Nuts from the safety bolt and lift out the transducer unit.

It may be necessary to let the gate valve leak somewhat while lifting out the unit, as there will be vacuum

between the gate valve piston and the transducer unit.

In installations with too low headroom, after closing the gate valve, it is possible to split the gate valve

arrangement between the gate valve element and the intermediate element.

The transducer unit may then be removed sideways while still inside the intermediate element.

It should be noted, however, that this operation is very difcult,

as the xing bolts are not so easily accessible.

Such installations should therefore be avoided.

REINSTALLATION OF ECHO SOUNDER TRANSDUCER UNIT.

Before the sensor unit is reinstalled , please check that the O-ring on top of the intermediate element and

also the water blocking O-ring inside the intermediate element, are free of damage and well greased.

Grease the transducer unit with water resistant grease and insert it into the top of the intermediate element,

pushing it as far down as it will go. To avoid excessive leakage during the reinstallation, it should go past

the upper water blocking O-ring (Min. 220 - Max. 250mm) .

Secure the sensor unit unit by screwing the nuts on the safety bolts rmly down on the top ange.

To overcome the water pressure, open gate valve slightly to help transducer unit pass the o-ring.

Open the gate valve to full opening.

Push the sensor unit all the way down, and secure it with the 6 each 16 mm hexagon nuts and washers.

On vessels with deep draft, it may be necessary to use the two nuts on the safety bolts to force the trans-

ducer unit into position.

Securing with the 6 each 16 mm nuts and washers, and 2 each 16mm nuts and washers on the safety bolts.

Check for leakage, tighten or repair if necessary.

Table of contents

Other Skipper Control Unit manuals